Blade for centrifugal fan impeller, centrifugal fan impeller and extractor hood

A centrifugal fan and impeller technology, which is applied to the components of the pumping device for elastic fluid, the removal of oil fume, the machine/engine, etc., can solve the problem of increasing the viscous resistance near the impeller wall, aggravating the airflow collision loss, and easily causing end face separation. vortex and other problems, to achieve the effect of not weakening the working ability, suppressing disturbance, and increasing the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

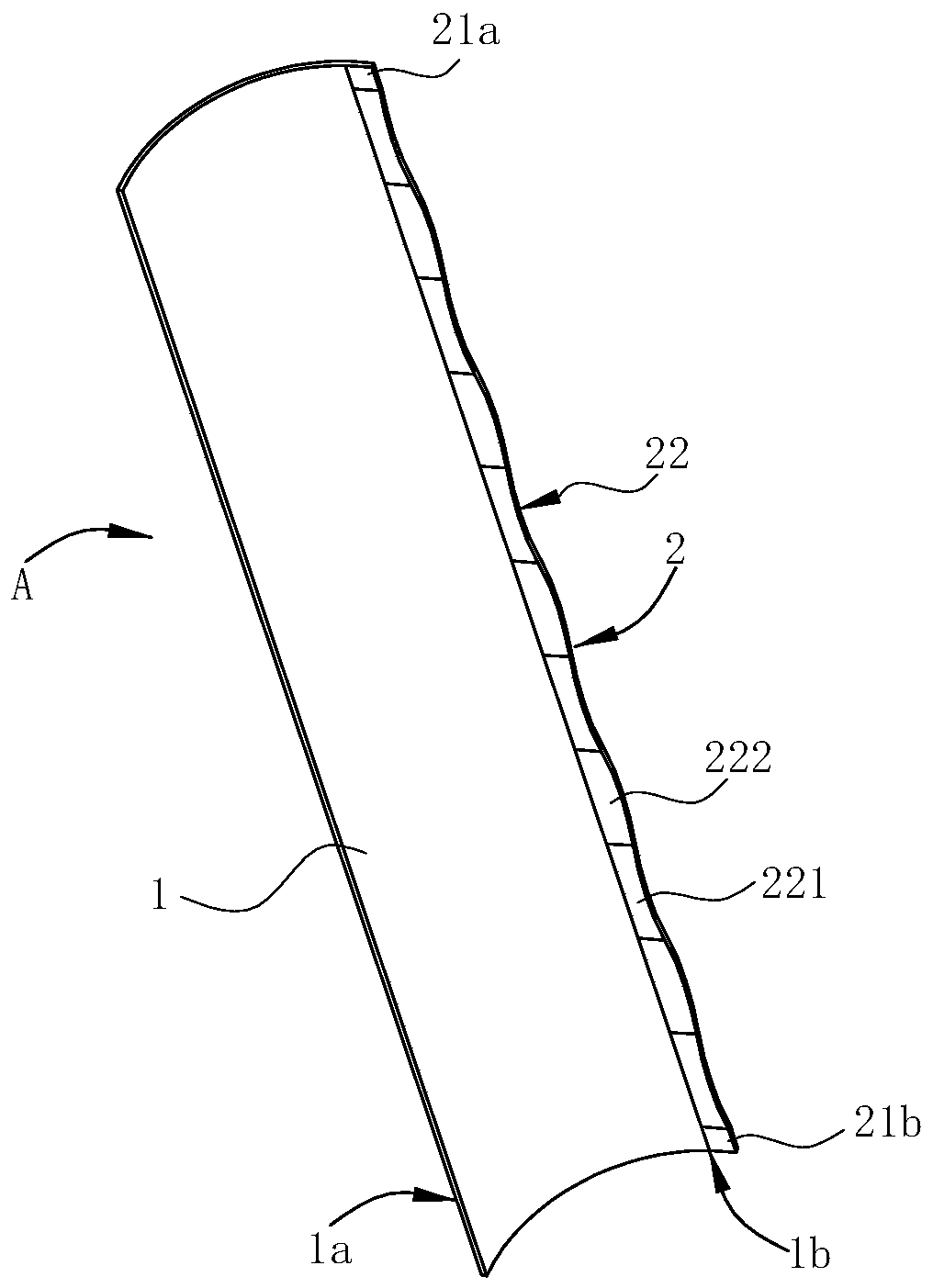

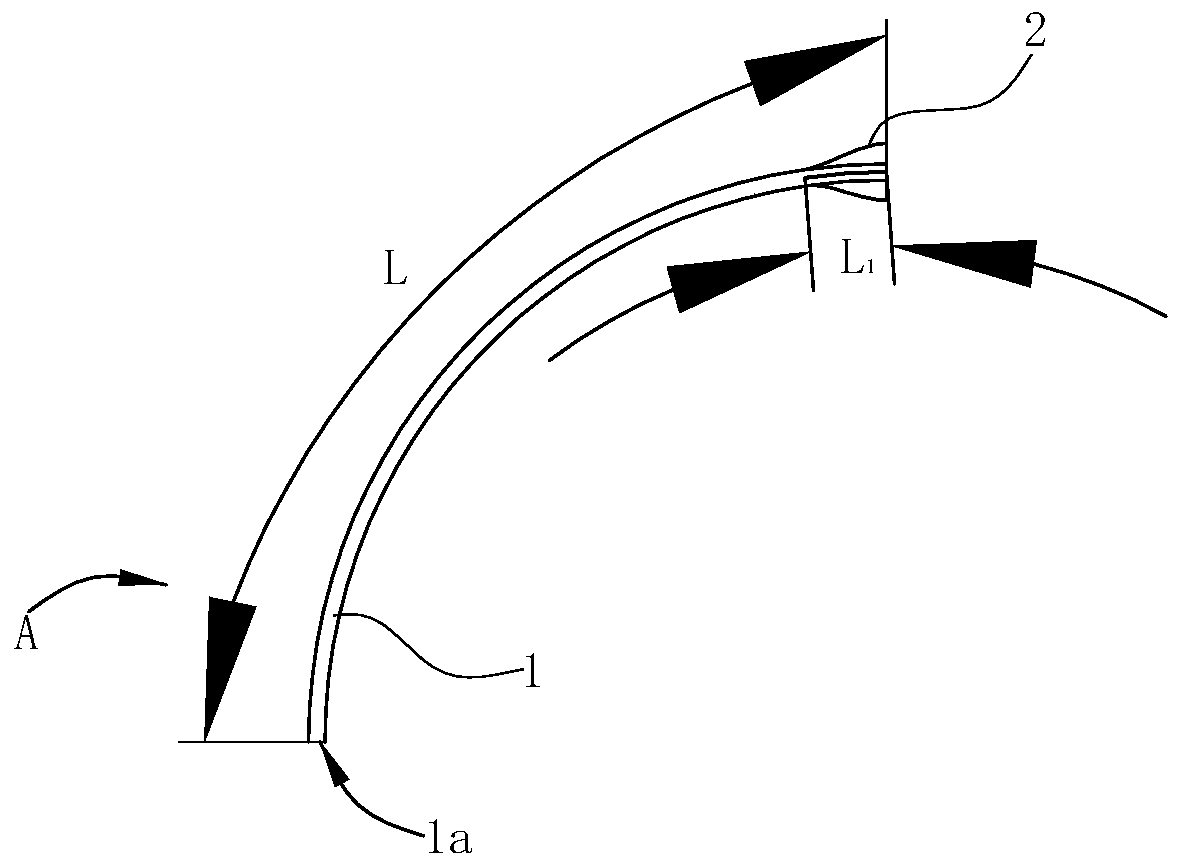

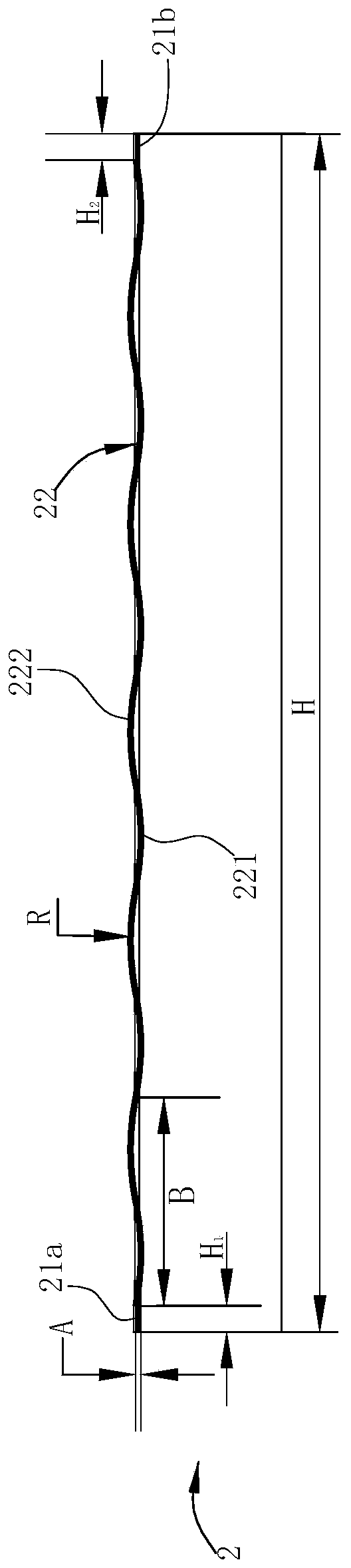

[0030] Such as Figure 1~4 As shown, the range hood of this preferred embodiment includes a casing and a centrifugal fan arranged in the casing, and the centrifugal fan includes a motor and a centrifugal fan impeller connected to the output shaft of the motor. In this embodiment, the centrifugal fan impeller includes A front ring 3 , a rear ring 4 opposite to the front ring 3 , a wheel disc 5 and at least two blades A.

[0031] Such as Figure 4 As shown, the wheel disc 5 is located between the front ring 3 and the rear ring 4, and the edge of the wheel disc 5 is connected with the rear ring 4 through at least two strip-like webs 51. Fixed perforation 52 .

[0032] A plurality of blades A are arranged at intervals along the circumferential direction of the front ring 3, and the two ends of each blade A are respectively fixed on the front ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com