Bypass flow valve and gas water heater comprising same

A flow valve, hot water pipeline technology, applied in fluid heaters, multi-way valves, valve devices, etc., can solve the problems of water temperature fluctuating cold and hot, gas water heater outlet water temperature rising, heat exchangers not being able to heat up quickly, etc. , to achieve the effect of preventing sudden rise or sudden drop, and avoiding excessively high or low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described by means of embodiments below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the following embodiments.

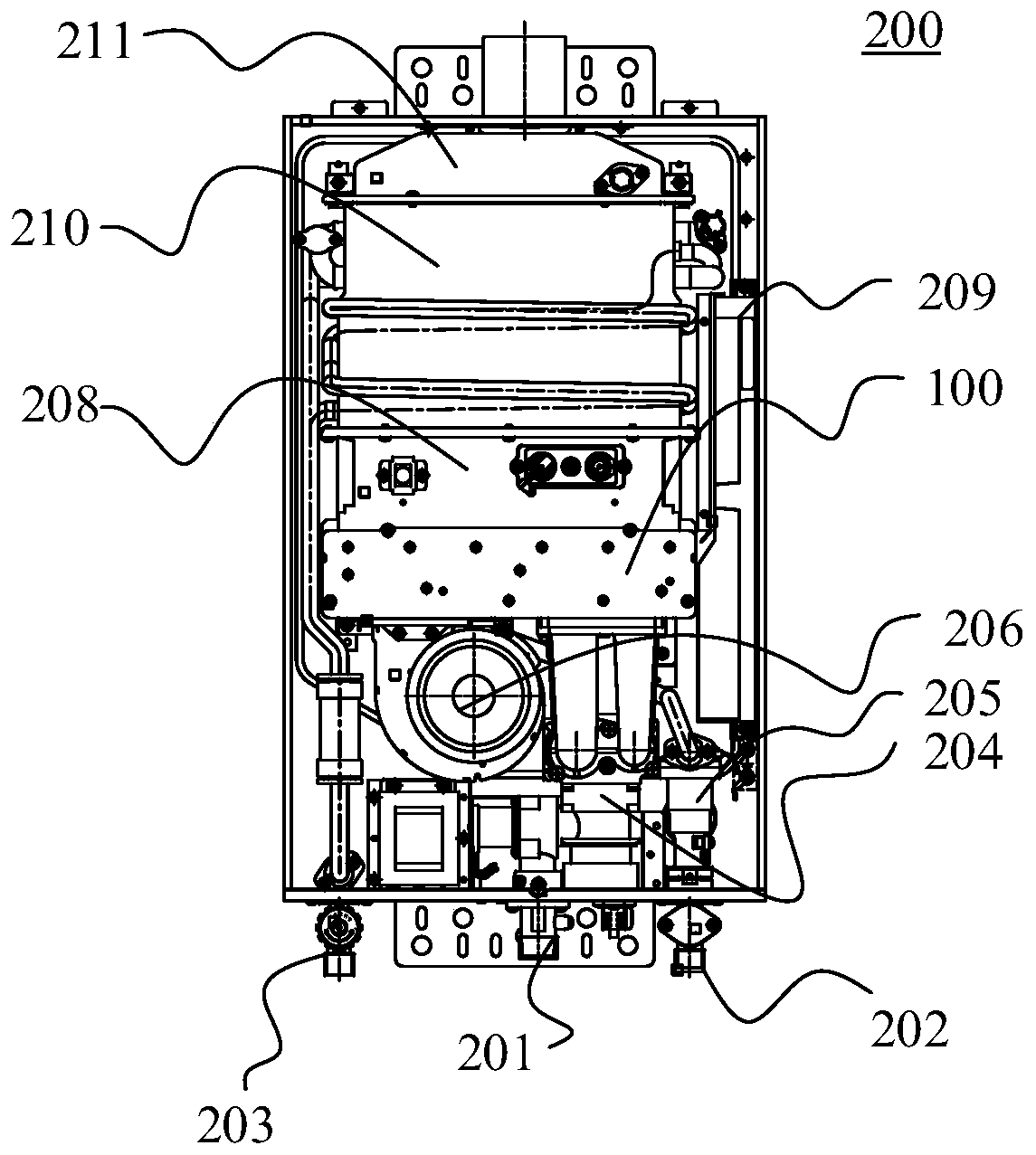

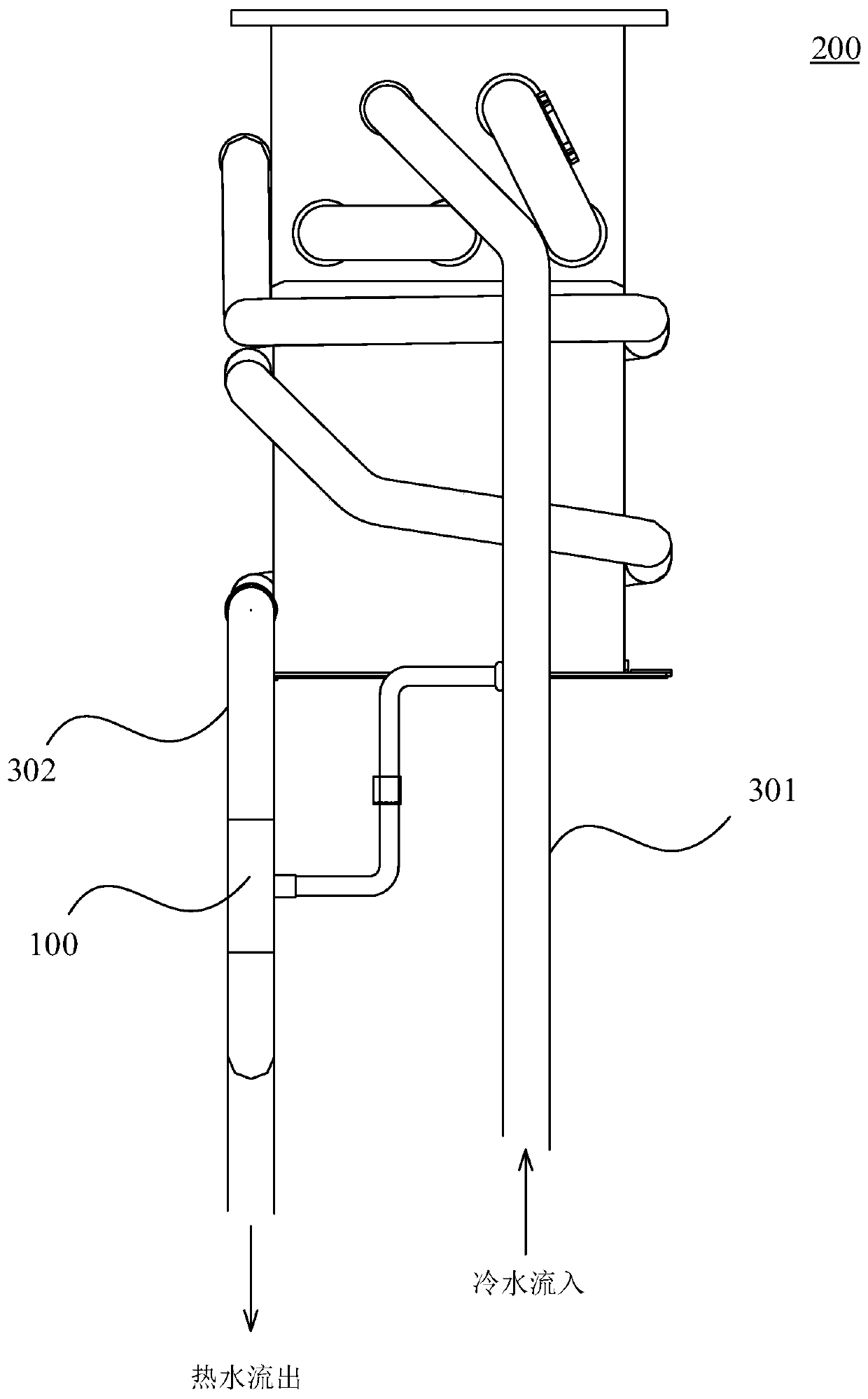

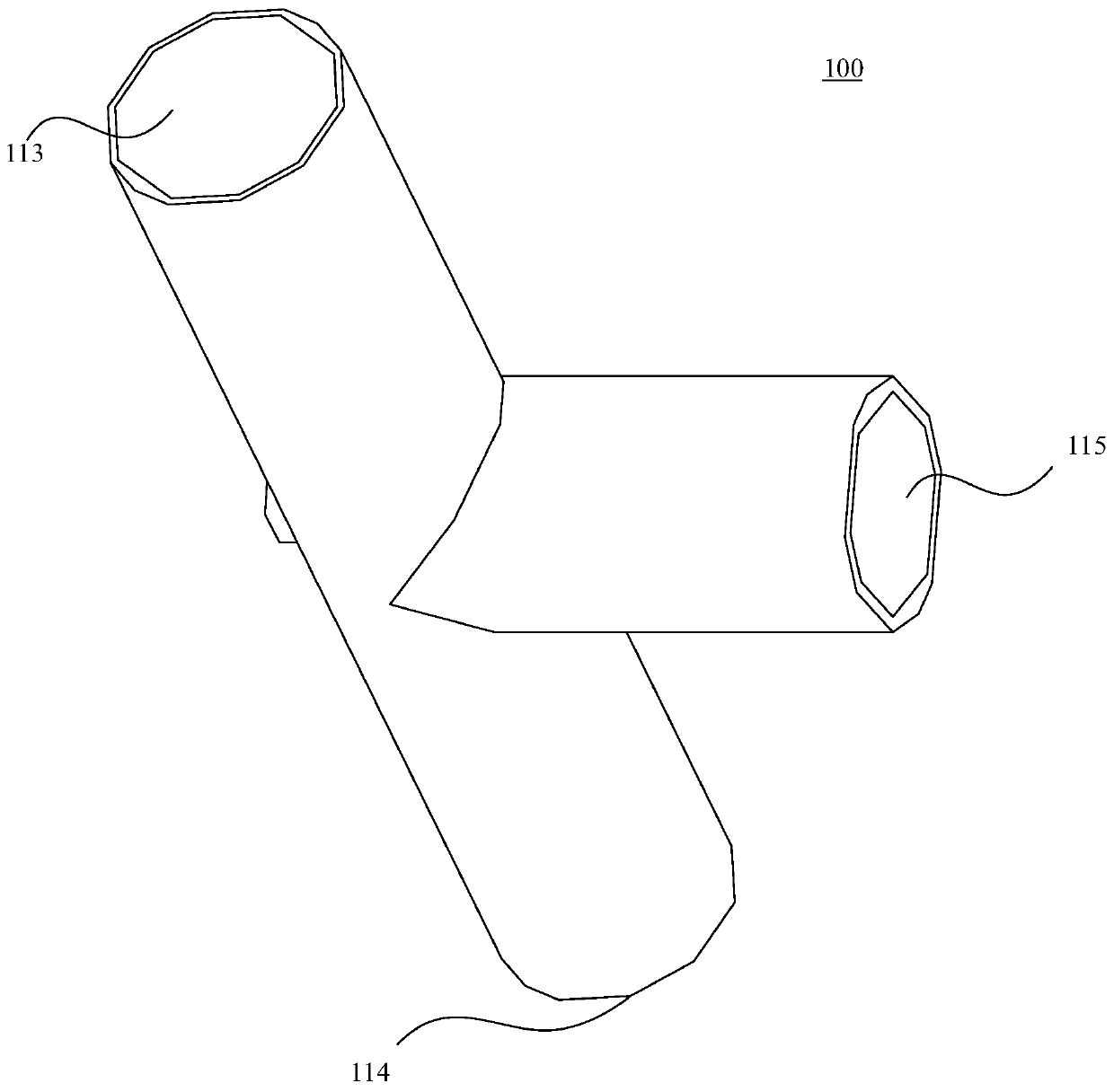

[0060] Such as Figure 1-2 As shown, the gas water heater 200 includes: an air inlet connector 201, a water inlet connector 202, a water outlet connector 203, a proportional valve assembly 204, a water volume valve assembly 205, a fan assembly 206, a gas distributor 100, a combustion chamber box 208, and an electric controller Assembly 209 , heat exchanger assembly 210 , and hood assembly 211 .

[0061] Proportional valve assembly 204 is used to control gas on-off and gas flow, water valve assembly 205 is used to detect water flow signal and transmit it to electric controller assembly 209, fan assembly 206 is used to control air intake, gas distributor 100 is used to distribute and adjust the gas flow, the electric controller assembly 209 is used to detect signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com