Liquefied natural gas vaporization system and automobile

A technology of liquefied natural gas and natural gas, which is applied in the direction of charging system, oil supply device, internal combustion piston engine, etc., which can solve the problems of rising vaporization temperature of vaporized gas, inability to vaporize, and affecting the combustion efficiency of natural gas engine 17, so as to ensure stability , to avoid the effect of too high or too low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

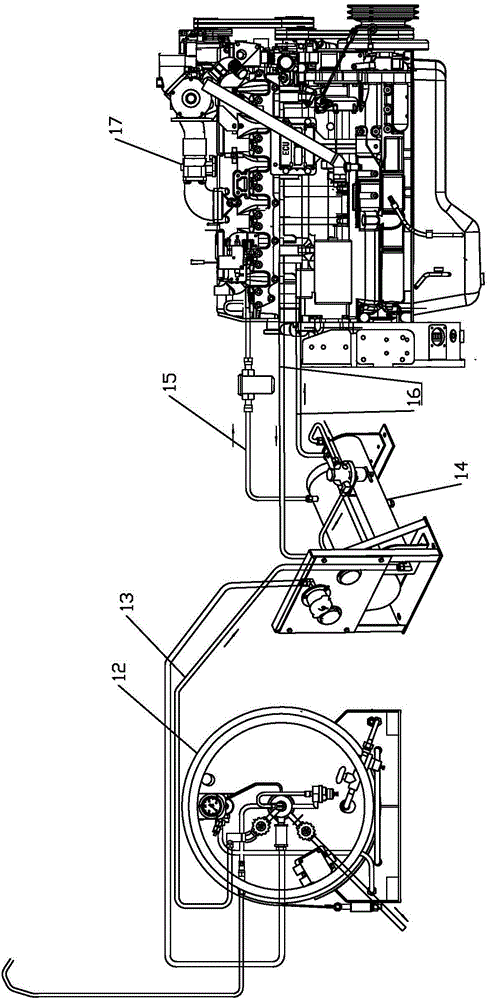

[0019] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

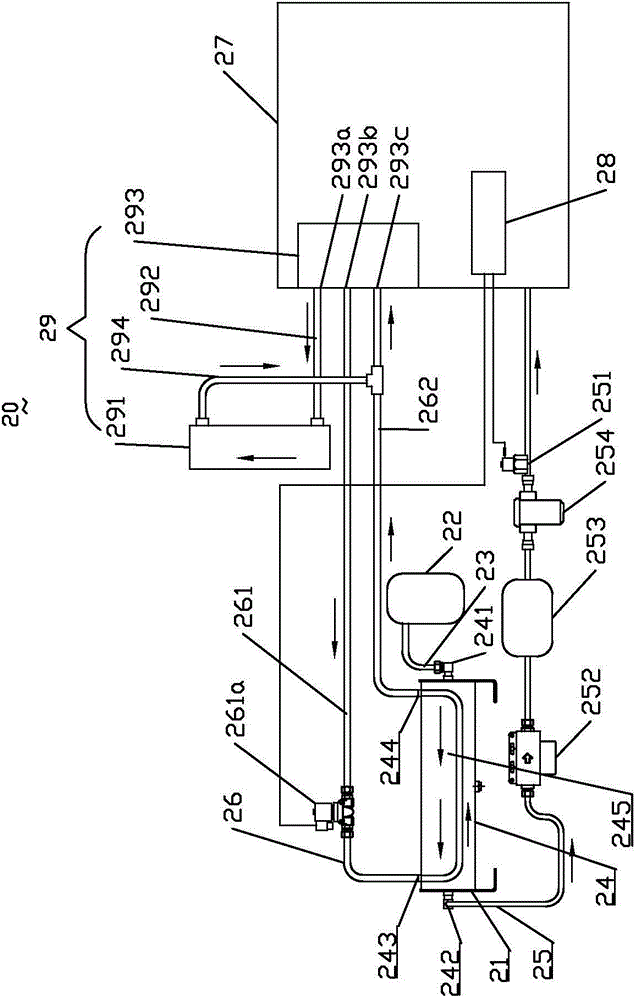

[0020] figure 2 The structure schematic diagram of the liquefied natural gas vaporization system of the present invention is shown. See figure 2 , the liquefied natural gas vaporization system 20 of the present embodiment is used for vaporizing liquefied natural gas to supply the liquefied natural gas engine, which includes a liquefied gas bottle 22, a liquid pipe 23, a vaporizer 24, a gas pipe 25, a heat medium pipe 26, gas equipment 27, electronic control Unit 28 and cooling device 29. The liquefied gas cylinder 22 communicates with the vaporizer 24 through the liquid pipe 23, and the vaporizer 24 communicates with the gas equipment 27. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com