Inductance coil end bending and cutting device and application method thereof

A technology of inductance coil and cutting, which is applied in the direction of coil manufacturing, etc., can solve the problems of low pass rate of inductance coil, complex structure, and low production efficiency of inductance coil, so as to improve the production efficiency and pass rate, reasonable structure design and fast folding The effect of curved cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

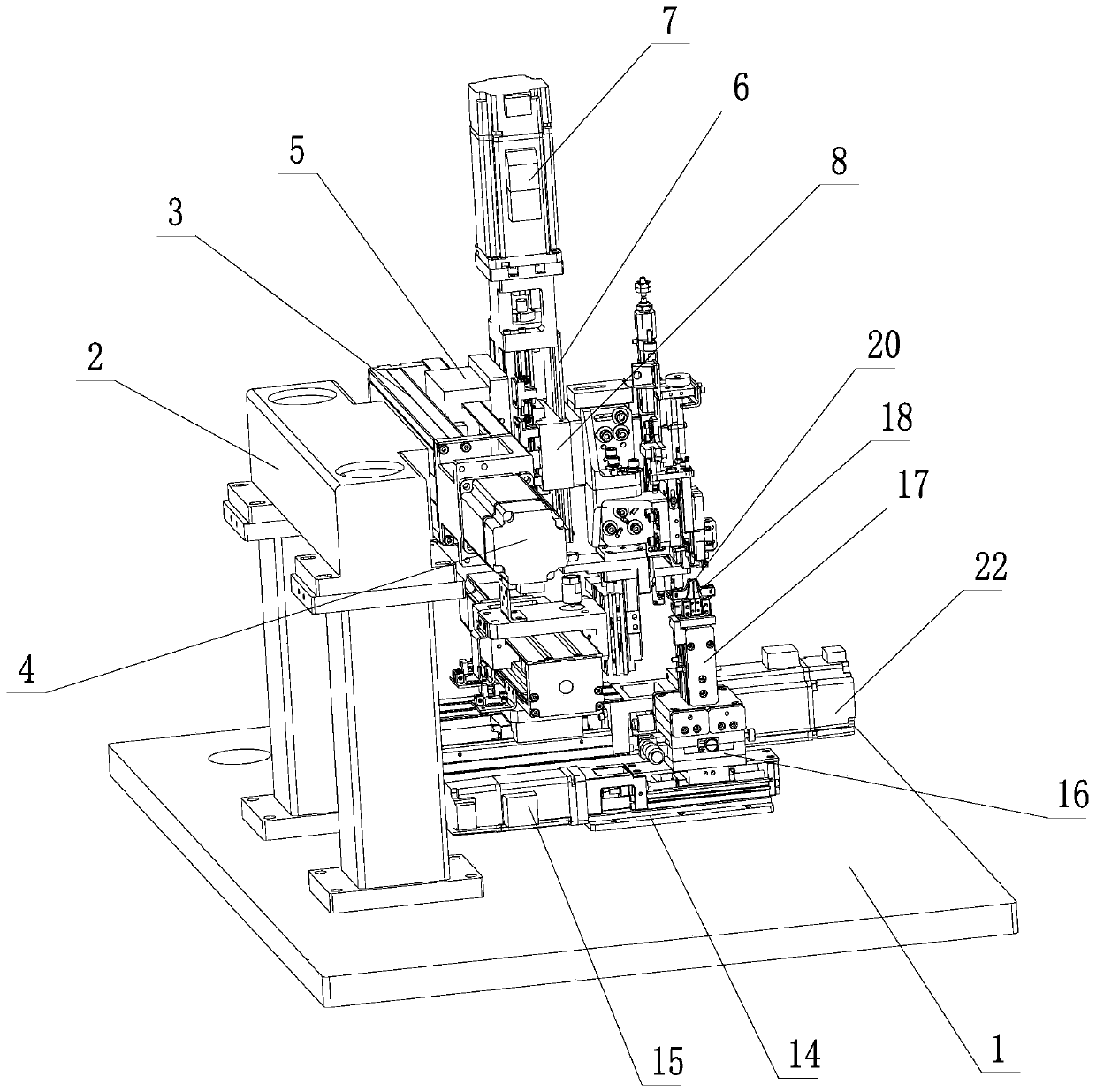

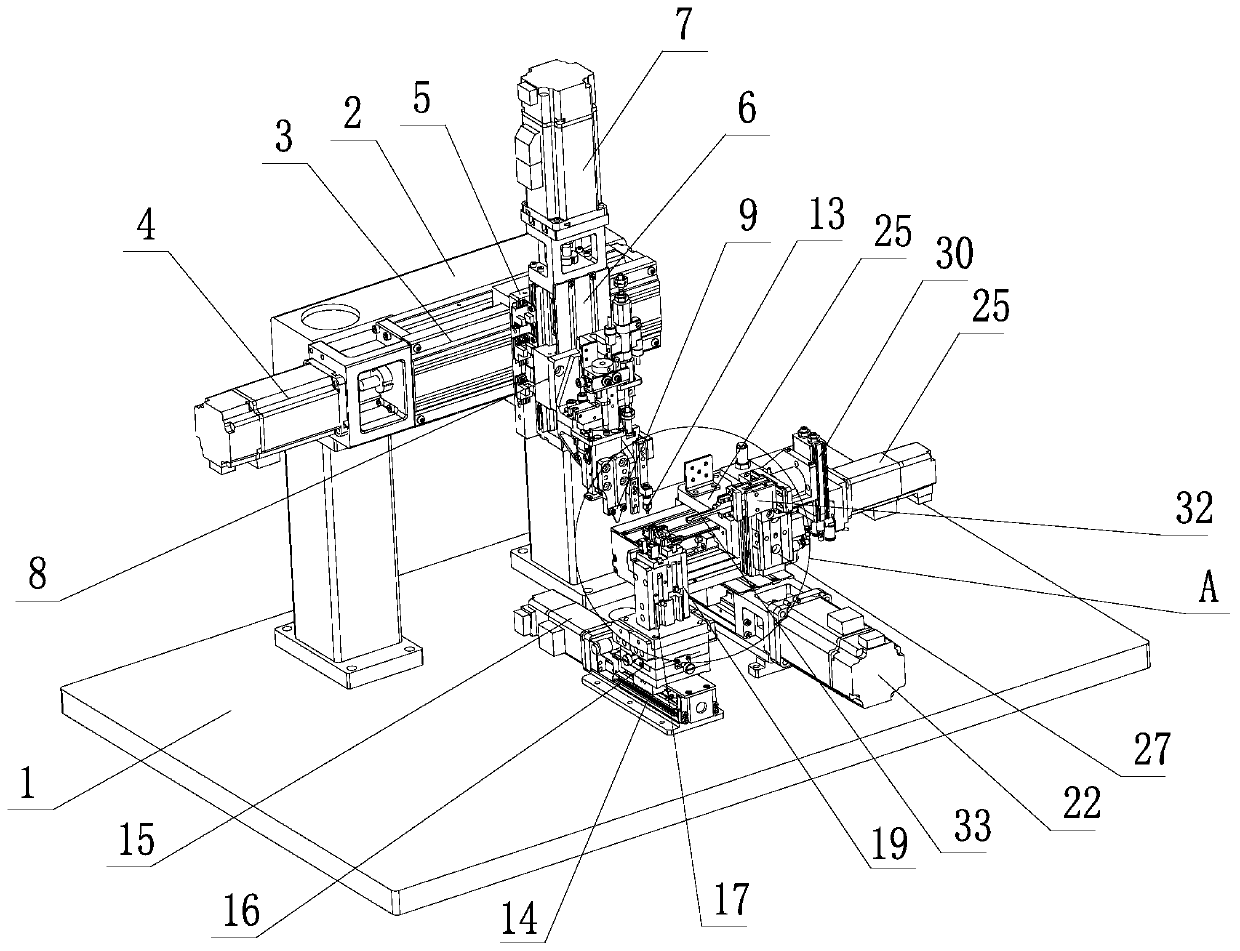

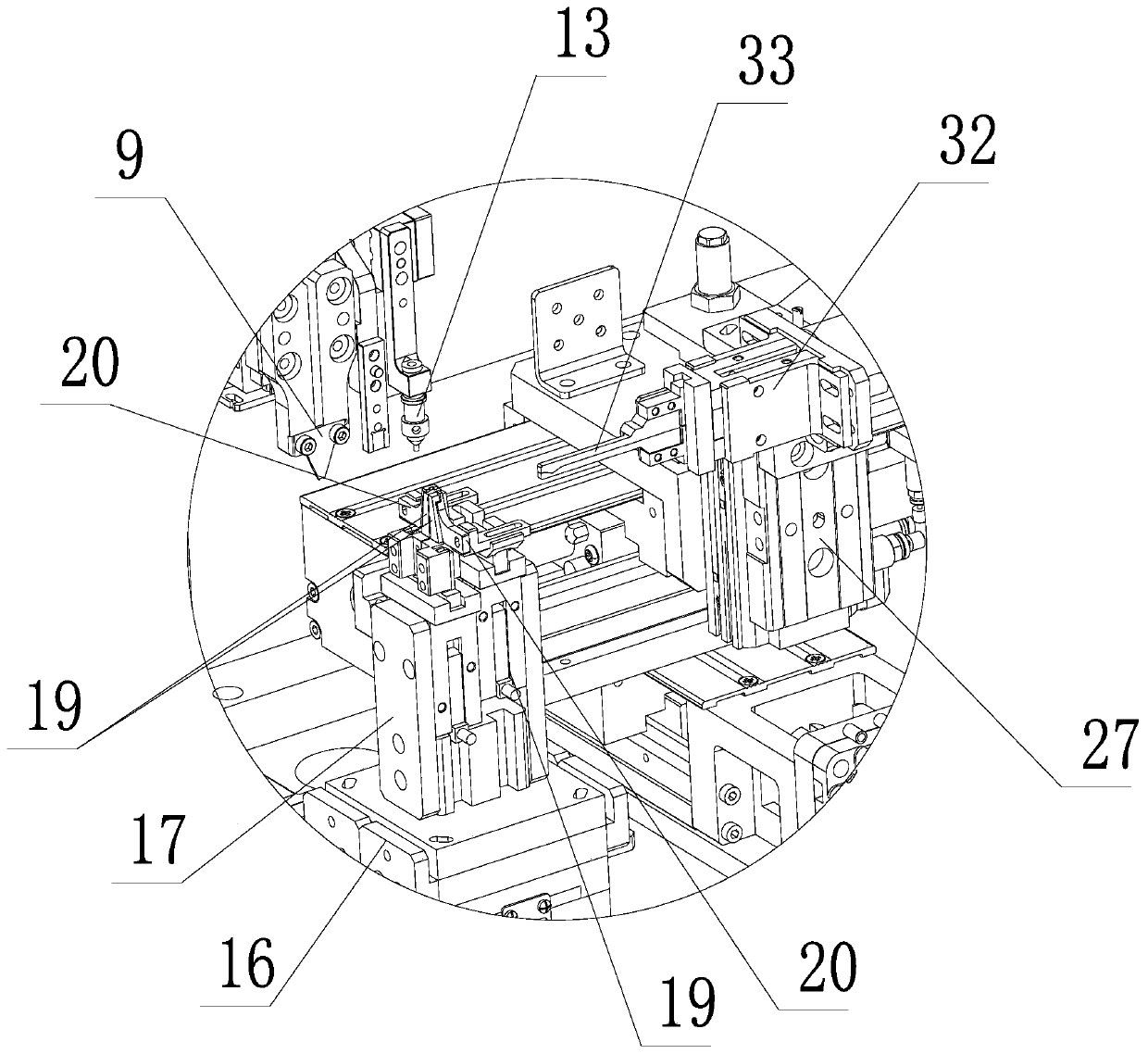

[0021] Specific embodiment one, please refer to Figure 1-7 , a bending and cutting device for an induction coil wire end, including an operating table 1, a crossbeam 2, a cutting lateral movement guide rail 3, a workpiece longitudinal movement guide rail 14 and a thread turning jaw longitudinal movement guide rail 21, characterized in that: the crossbeam 2 Fixed on the console 1, the side of the beam 2 is fixed with a cutting lateral movement guide rail 3, the cutting lateral movement guide rail 3 is provided with a cutting lateral movement slider 5, and the cutting lateral movement slider 5 can slide along the cutting lateral movement guide rail 3 driven by the cutting lateral movement servo motor 4, and the cutting vertical movement guide rail 6 is fixed on the cutting lateral movement slider 5, and the cutting vertical movement guide rail 6 is provided with a cutting vertically moving slider 8, which can slide along the cutting vertically moving guide rail 6 driven by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com