Terminal wire production system and production process using the equipment

A production system and terminal wire technology, applied to lines/collector parts, connected connections through deformation, electrical components, etc., can solve problems such as danger, time-consuming and labor-intensive problems, reduce defective rate, ensure system operation, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

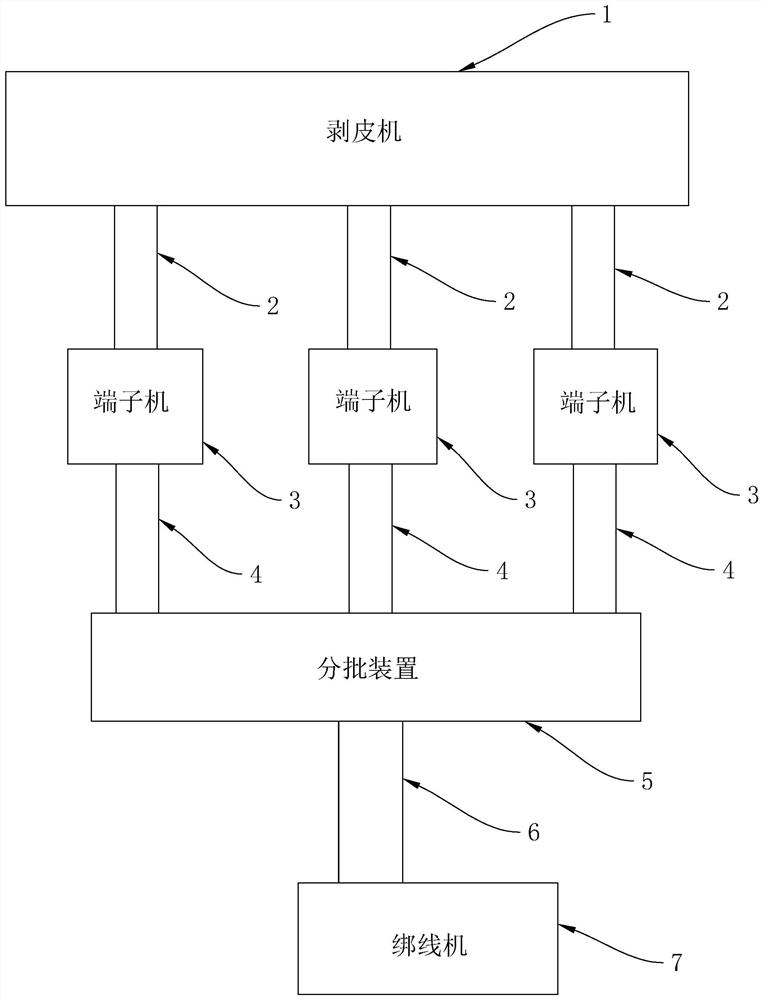

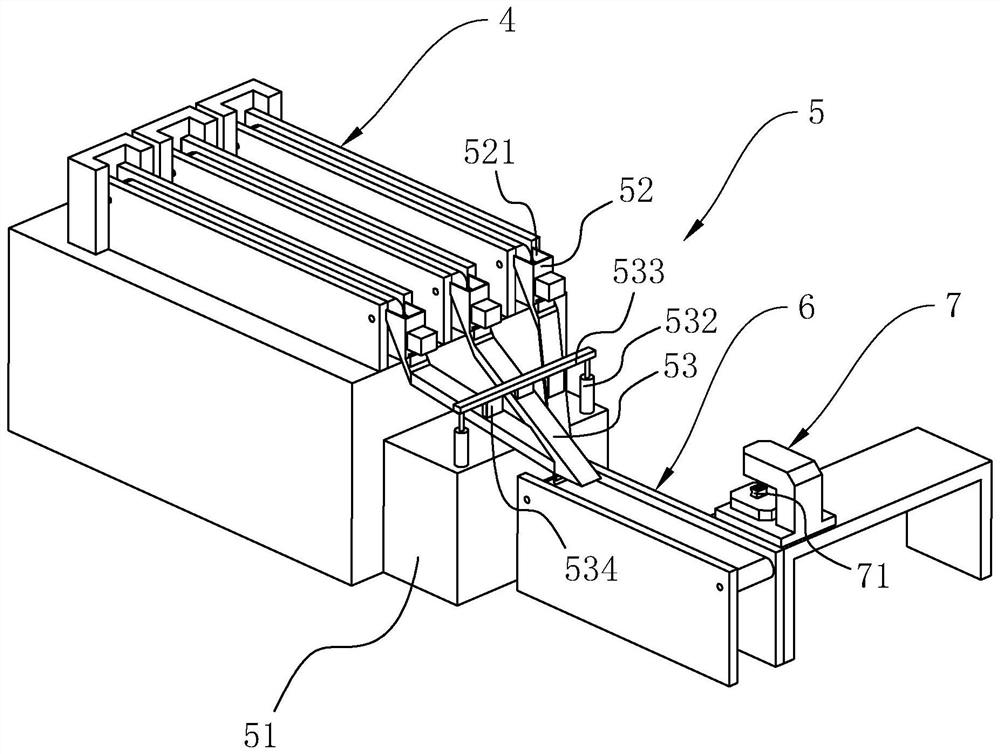

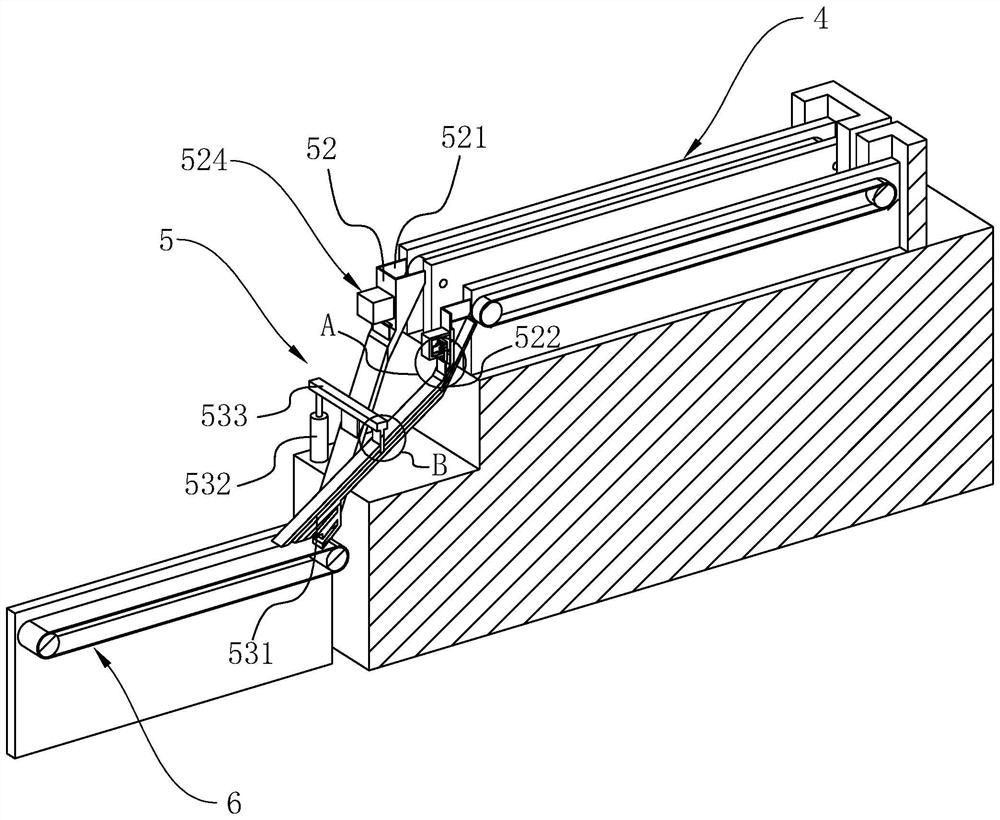

[0052]Example 1: A terminal line production system, such asfigure 1 As shown, it includes: a peeling machine 1, a plurality of terminal machines 3, and a wire binding machine 7. The peeling machine 1 is connected with a plurality of first transmission belts 2, and the other end of each first transmission belt 2 is arranged close to the corresponding terminal machine 3. Each terminal machine 3 is connected with a second transmission belt 4, and the other end of all the second transmission belts 4 is connected with a batching device 5 together. The batching device 5 is connected with a third conveyor belt 6, and the other end of the third conveyor belt 6 is arranged close to the wire binding machine 7. The worker puts the wires on the stripping machine 1 for processing. After the stripping machine 1 strips and cuts the wires, the fallen wires will be automatically transported to the terminal machine 3 by the first conveyor belt 2, and the operator of the terminal machine 3 The wires a...

Embodiment 2

[0062]Embodiment 2: A production process using a terminal line production system, the specific steps are as follows:

[0063]1. Put the long wires into the wire stripping machine, the wire stripping machine strips and cuts the long wires, and the control system 8 counts the number of stripping times of the wire stripping machine.

[0064]2. The wires processed by the wire stripping machine fall onto the first transmission belt 2 and are transported by the first transmission belt 2 to the vicinity of the terminal machine 3.

[0065]3. The wire is transferred from the first conveyor belt 2 to the terminal machine 3. The terminal machine 3 presses the hardware head to the wire end, and the control system 8 counts the number of pressing of the terminal machine 3 at the same time.

[0066]4. The terminal machine 3 drops the processed wires onto the second conveyor belt 4, and the second conveyor belt 4 transmits the wires to the lower hopper 52, and multiple wires processed by the terminal machine 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com