A feeder automation system using can bus communication

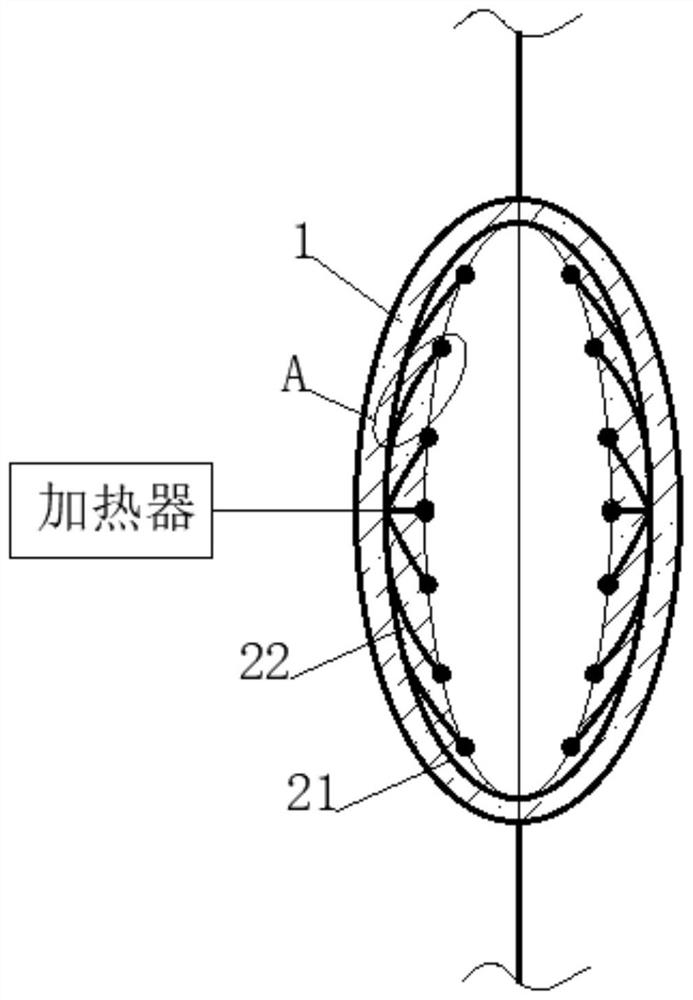

A CAN bus and feeder automation technology, applied in the field of communication, can solve problems such as complexity, fault expansion, and loss, and achieve the effects of increasing surface area, improving safety, and accelerating heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

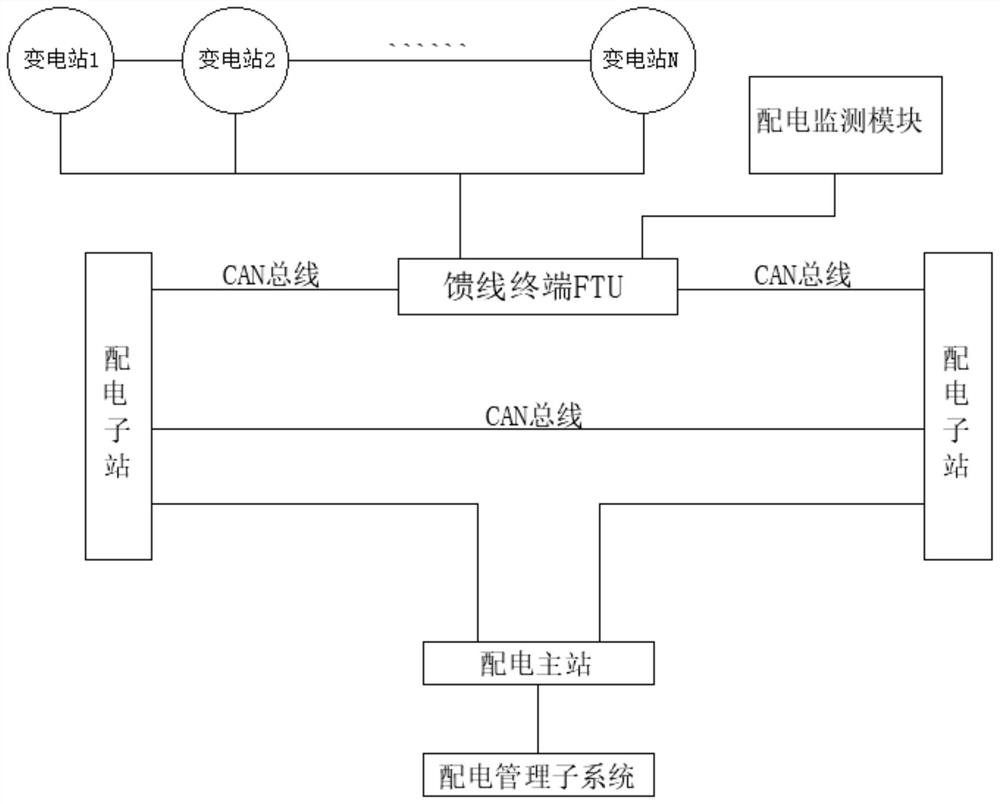

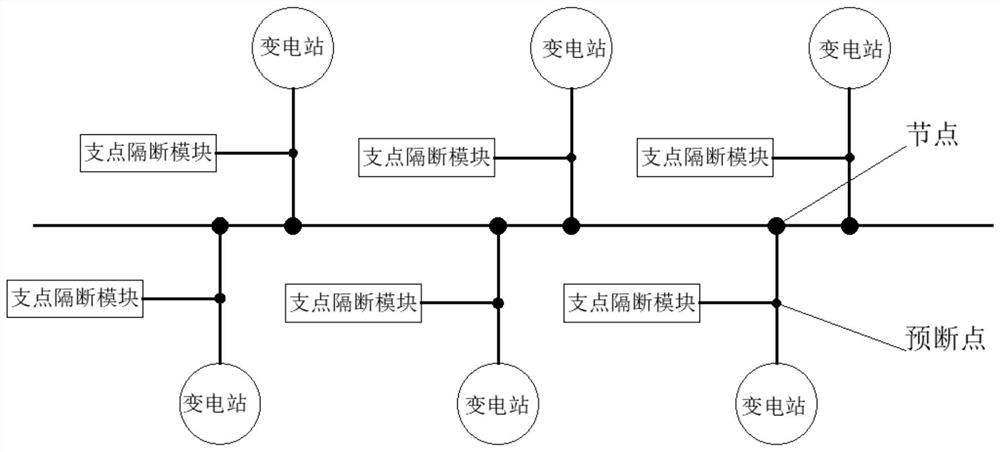

[0047] see figure 1 , a feeder automation system using CAN bus communication, including a power distribution management subsystem and two distribution substations, a power distribution master station is connected between the power distribution management subsystem and the two distribution substations, and two distribution substations The feeder terminal FTU is connected between them, and the feeder terminal FTU is connected with multiple substations. The connection points between multiple substations and the feeder form nodes. The feeder terminal FTU is also connected with a power distribution monitoring module. The communication between the substation and the feeder terminal FTU is through the CAN bus, and the CAN bus communication adopts shielded twisted-pair wires. There are fulcrum isolation modules between multiple substations and nodes. FTU signal connection, two adjacent fulcrum partition modules are connected with each other, so that the two fulcrum partition modules c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com