Dry treatment process and dry treatment equipment for waste gas containing viscous dust

A dry treatment and treatment process technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problem that the treatment rate cannot meet the requirements of VOCs treatment, reduce the efficiency and life of conventional dust collectors, and affect the treatment effect of VOCs equipment. and other problems, to achieve the effect of improving the efficiency of dust removal treatment, not producing secondary pollution, and increasing treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] This embodiment relates to a dry treatment process, which is used for efficient dust removal treatment of waste gas containing viscous dust.

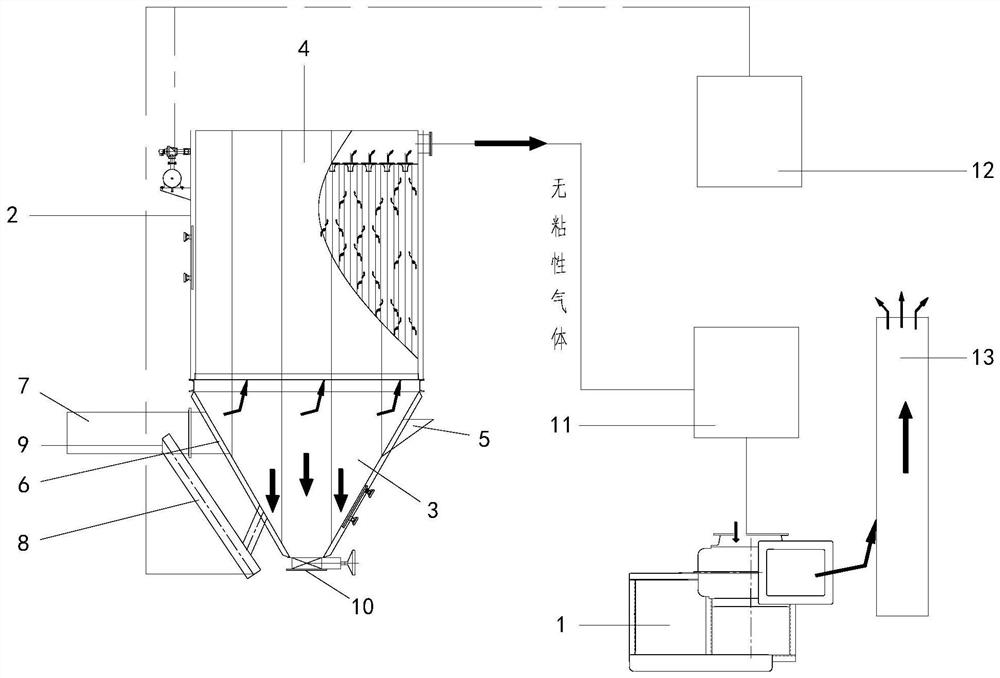

[0028] A dry processing equipment such as figure 1 As shown, it includes a dust removal processing unit, and the dust removal processing unit includes a dust remover 2 connected with a fan 1, and the dust remover 2 is provided with an ash hopper 3, and a filter assembly 4 placed above the ash hopper 3 and communicated with the ash hopper ; On one side wall of the ash hopper 3, an anti-sticking agent dosing port 5 is penetrated, and an exhaust gas input port 6 is penetrated on the other side wall, and the exhaust gas input port 6 is arranged on the outside of the ash hopper. The waste gas conveying pipeline 7 is connected; the waste gas conveying pipeline 7 communicates with the bottom of the ash hopper 3 through a frequency conversion or multi-stage speed regulating screw conveyor 8, and in the waste gas conveying pipeline 7, it ...

Embodiment 2

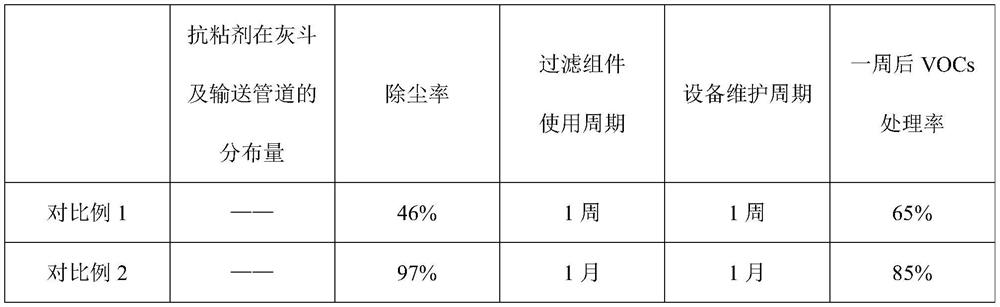

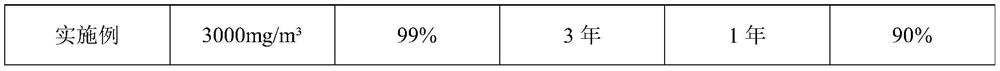

[0042] The present embodiment relates to the comparison of the dedusting effect of the embodiment and the comparative example, with the waste gas from spraying paint (its initial pollution concentration is: particulate matter 800mg / m 3 , total non-methane hydrocarbons 260mg / m 3 ) as an example.

[0043]

[0044]

[0045] It can be seen from the results in the above table that the dry treatment process of the present invention not only eliminates the stickiness of the dust by wrapping the sticky dust with the anti-sticking agent, but also enables the filter assembly to be used repeatedly, and the maintenance frequency of the equipment is extended from the usual one week to It lasted for a year, and increased the particle size of the dust, so that the dust removal rate increased from about 80% to more than 99%, and it can produce synergistic increase with the VOCs treatment step and deodorization treatment step after the dust removal treatment step. It has obvious advanta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com