Patents

Literature

33results about How to "Compliant with circular economy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A method for producing anhydrous hydrogen fluoride and silicon tetrafluoride by utilizing fluosilicic acid

InactiveCN102275877AImprove conversion rateLow costFluorine/hydrogen-fluorideHalogenated silanesSlagHexafluorosilicic acid

The invention discloses a method for producing anhydrous hydrogen fluoride and silicon tetrafluoride by utilizing fluosilicic acid. The method of the invention is specifically to firstly react fluosilicic acid solution with sodium sulfate at normal temperature to obtain sodium fluosilicate and dilute sulfuric acid. Filtration, dilute sulfuric acid is concentrated to make concentrated sulfuric acid, then mixed with filter cake sodium fluorosilicate ointment, added to the pre-reactor, reacted at 50-200 ° C to generate silicon tetrafluoride gas, and the silicon tetrafluoride gas passes through the degassing tower Silicon tetrafluoride products are obtained after treatment; the remaining materials in the pre-reactor are transported to the rotary furnace, and then hydrogen fluoride gas is released in the rotary furnace at 150-350 °C, and the hydrogen fluoride gas is purified to produce anhydrous hydrogen fluoride products. The remaining slag in the rotary kiln is discharged through the furnace tail. The fluosilicic acid solution used in the present invention is derived from the by-products of phosphate fertilizer or anhydrous hydrogen fluoride, the cost of raw materials is low, a new source of fluorine is opened up, and the obtained anhydrous hydrogen fluoride and silicon tetrafluoride products have wide application fields and outstanding economic benefits , high value-added products.

Owner:DO FLUORIDE CHEM CO LTD

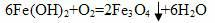

Method for preparing ammonium sulfate and Fe3O4 from titanium dioxide production waste acid solution

InactiveCN102086039AMature technologySimple processFerroso-ferric oxidesAmmonium sulfatesIron BlackFilter press

The invention relates to a method for preparing ammonium sulfate and Fe3O4 from titanium dioxide production waste acid solution. The method is characterized by comprising the following steps: (1) concentrating the titanium dioxide production waste acid solution to 25-35wt%, sending the concentrated solution to a storage tank for standby; (2) sending the solution concentrated in the step (1) to an oxidation pond, introducing ammonia water, stirring with a stirrer to perform neutralization reaction; (3) introducing steam in the oxidation pond after the reaction to ensure that the temperature of the solution is increased to 90-95 DEG C, introducing compressed air at 60 DEG C while heating continuously to ensure that the oxidation reaction of Fe(OH)2 is performed continuously and Fe3O4 precipitate is obtained; and (4) sending the precipitated Fe3O4 to a filter press to perform solid-liquid separation, wherein the solid is iron black and the liquid is ammonium sulfate solution. In the method of the invention, the titanium dioxide production waste acid is used to react with ammonia water to prepare ammonium sulfate; and the technology is mature and the process is simple and is convenient to operate.

Owner:LUOHE XINGMAO TITANIUM IND

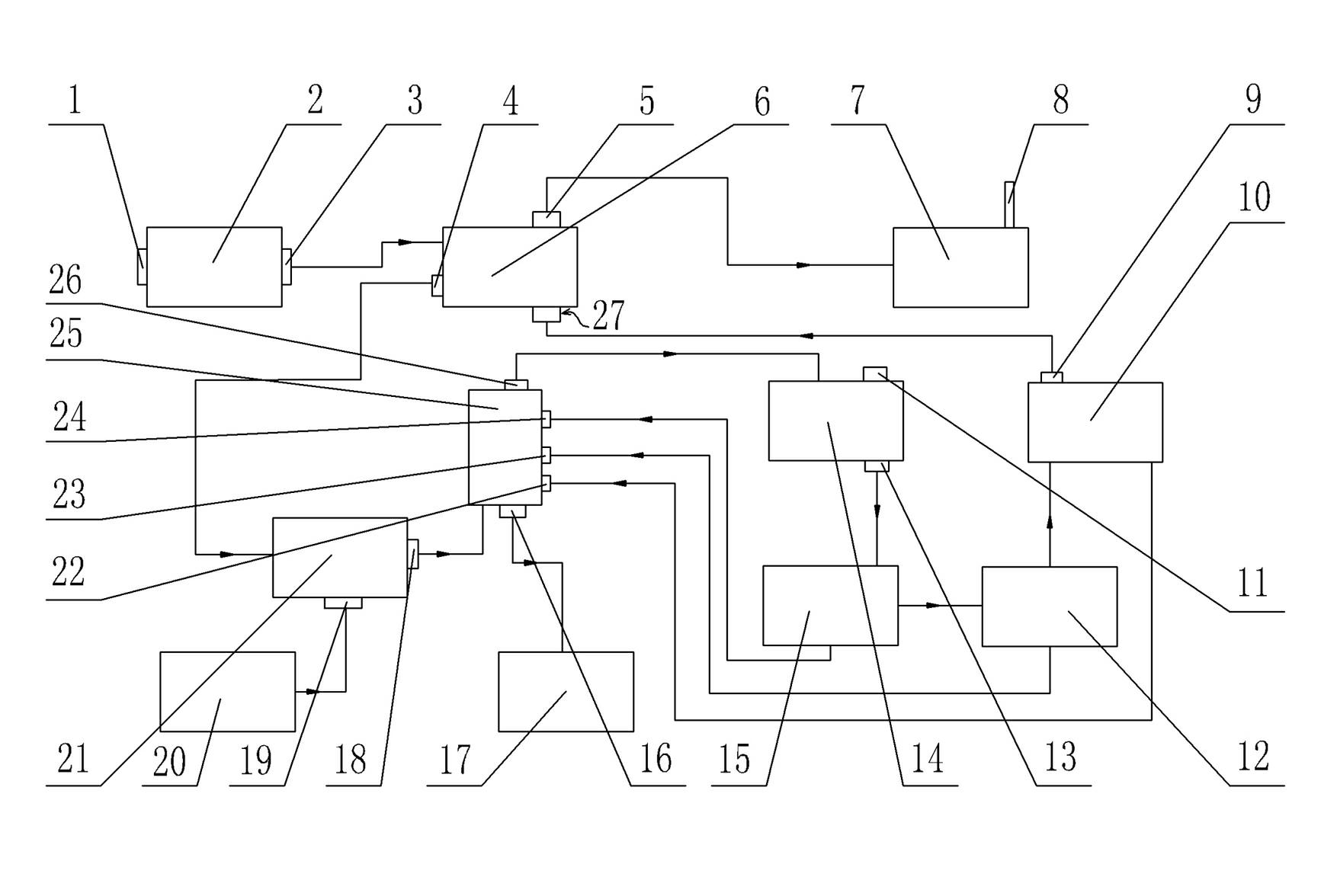

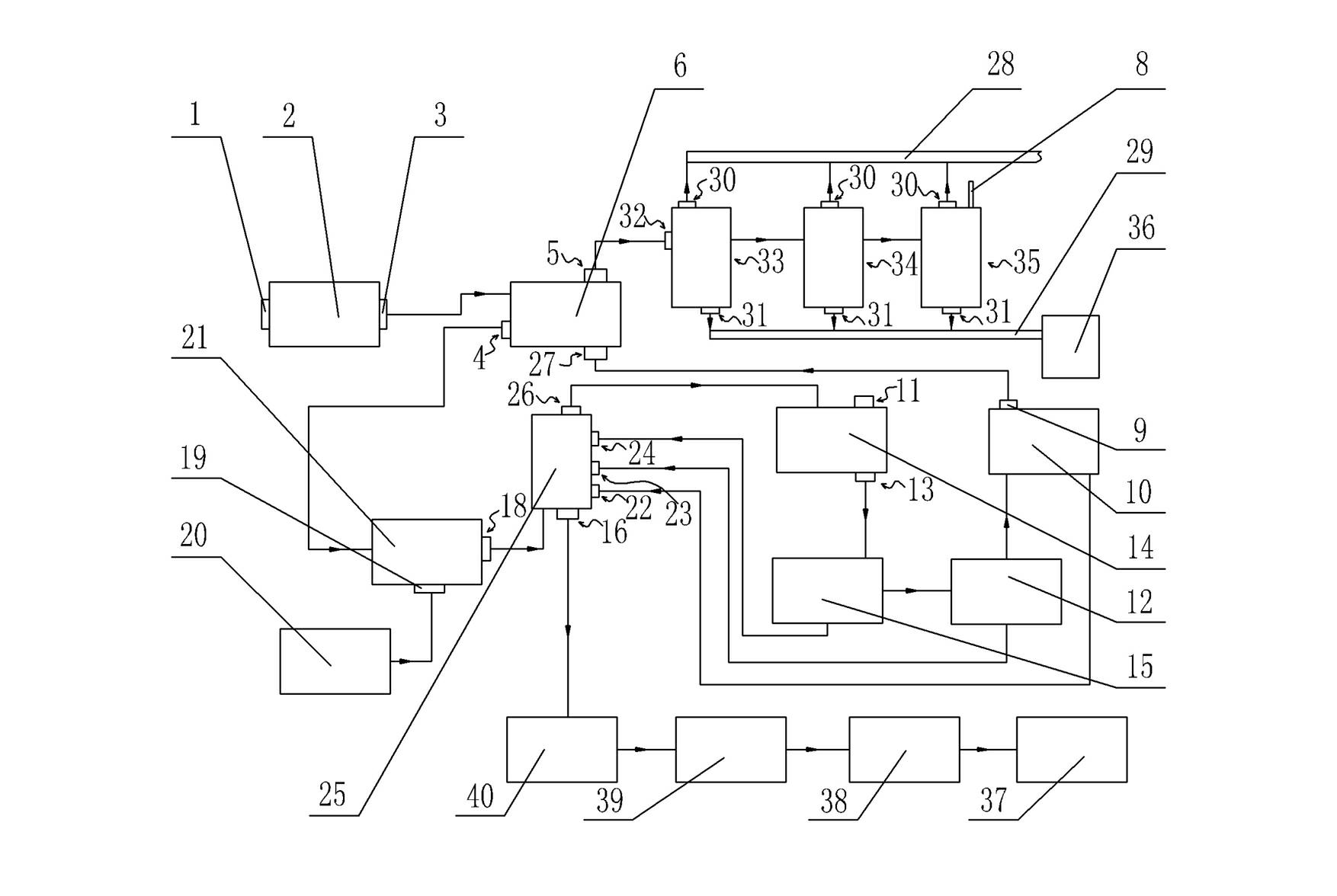

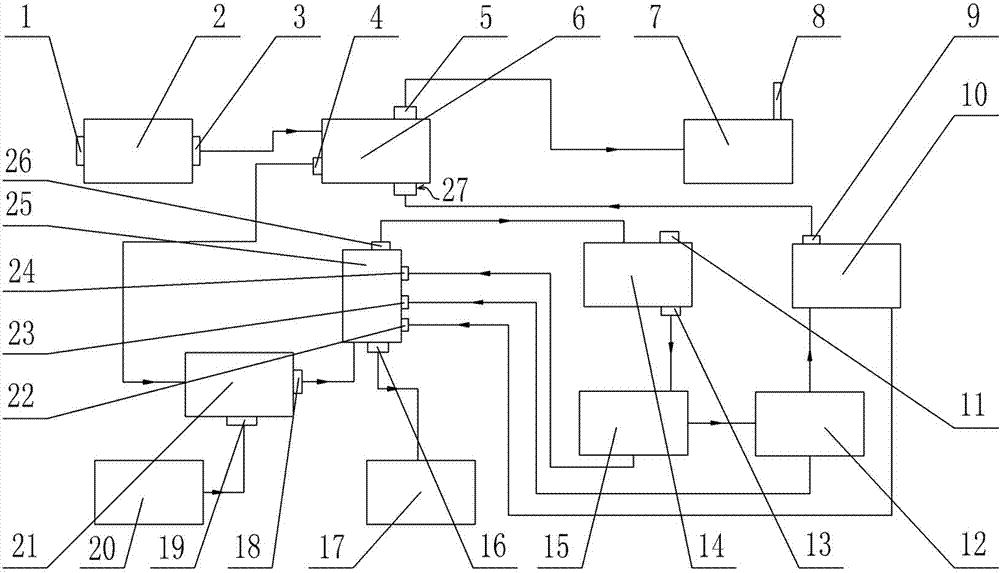

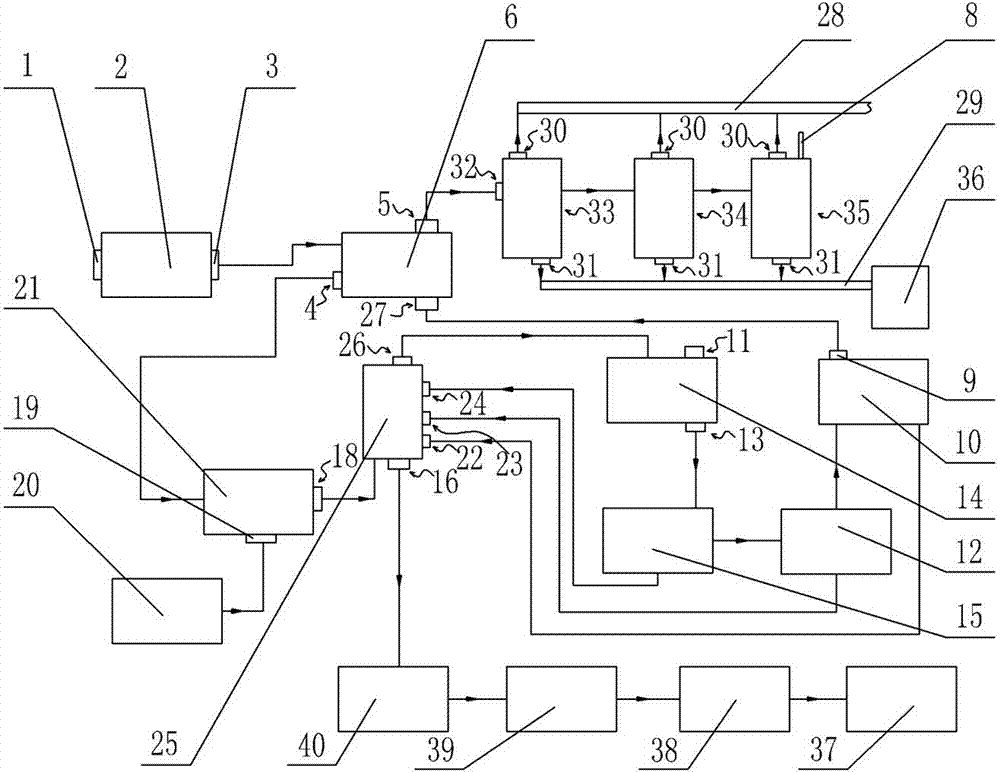

Production system and production method for anhydrous aluminum fluoride

ActiveCN102320639AImprove conversion rateIncrease profitAluminium fluoridesHydrogen fluorideAluminum fluoride

The invention belongs to the technical field of aluminum fluoride production, concretely discloses a production system and a production method for anhydrous aluminum fluoride. The anhydrous aluminum fluoride production system comprises a hydrofluoric acid evaporator, wherein the hydrofluoric acid evaporator is connected in series to a tail gas heat exchanger, a tail gas outlet and a hydrogen fluoride gas outlet are provided with the tail gas heat exchanger, a tail gas washing apparatus is provided with the tail gas outlet, a gas mixing chamber is provided with the hydrogen fluoride gas outlet, a double-layer fluidized bed reactor is provided with a gas mixture outlet of the gas mixing chamber, the bottom of the double-layer fluidized bed reactor is provided with an aluminum fluoride product outlet, a high temperature tail gas outlet of the double-layer fluidized bed reactor is provided on the top, a reaction material inlet is provided on the double-layer fluidized bed reactor, a firstorder gas flow reactor is provided at the high temperature tail gas outlet of the double-layer fluidized bed reactor, the first order gas flow reactor is connected in series to a second order gas flow reactor, a third order gas flow reactor and a fourth order gas flow reactor, the second order gas flow reactor, the third order gas flow reactor and the fourth order gas flow reactor are communicated with the double-layer fluidized bed reactor, the fourth order gas flow reactor is communicated with the tail gas heat exchanger.

Owner:DO FLUORIDE CHEM CO LTD

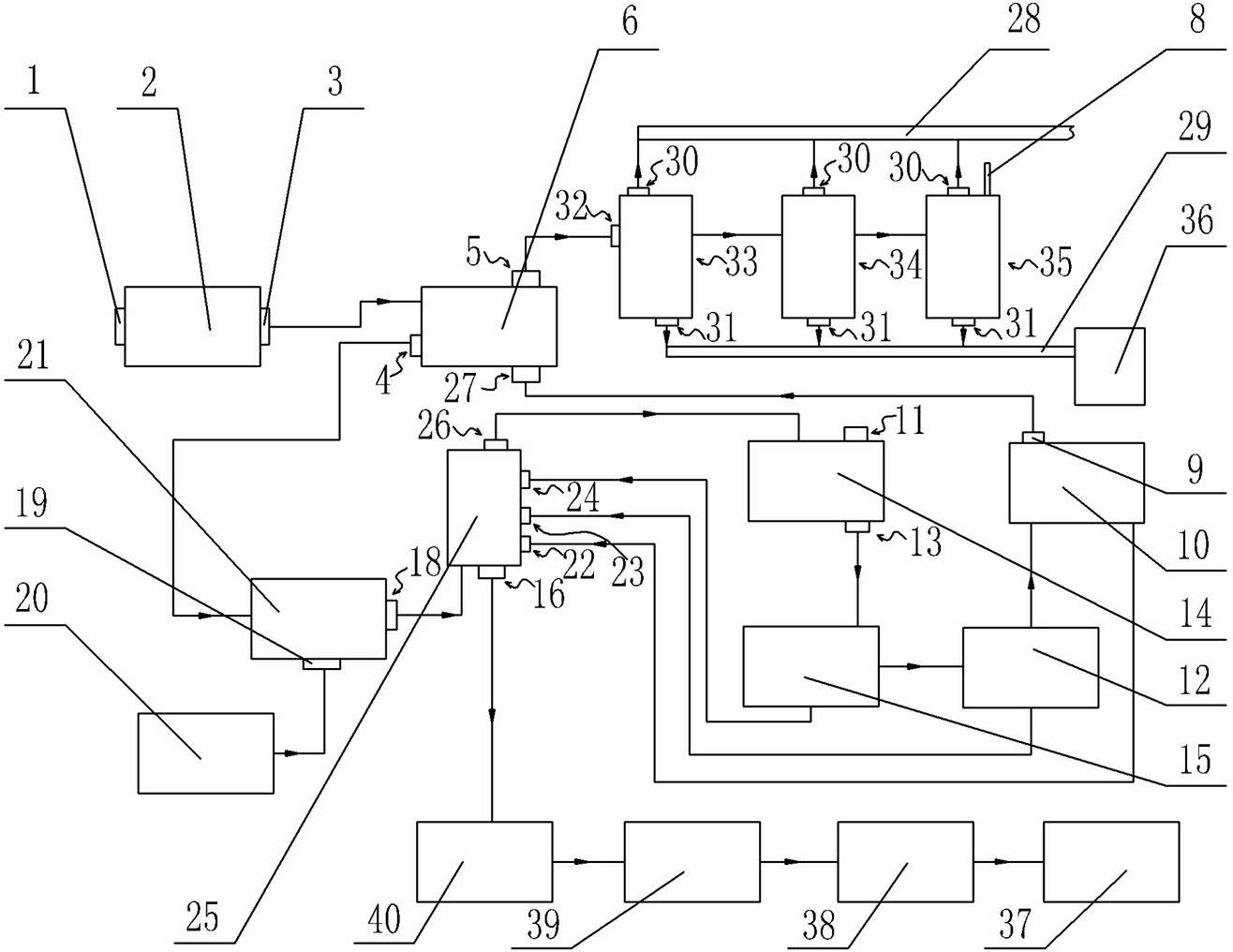

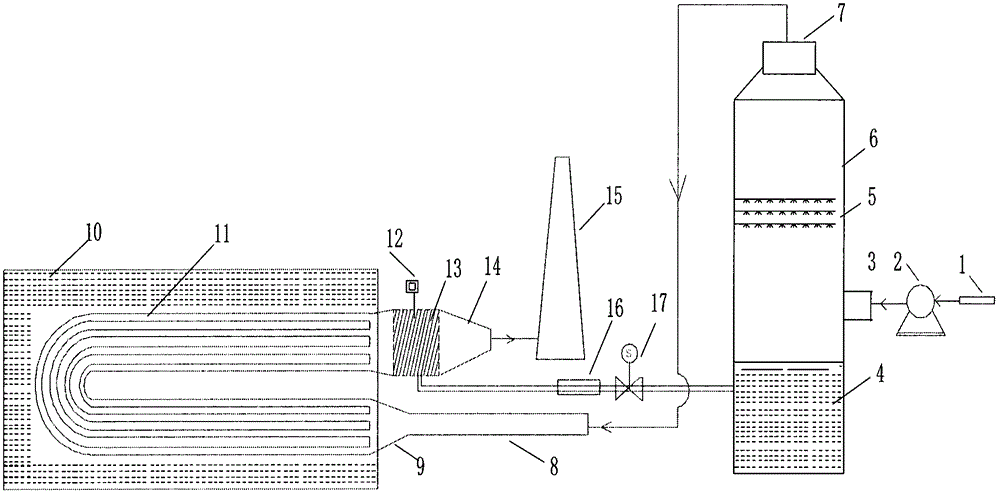

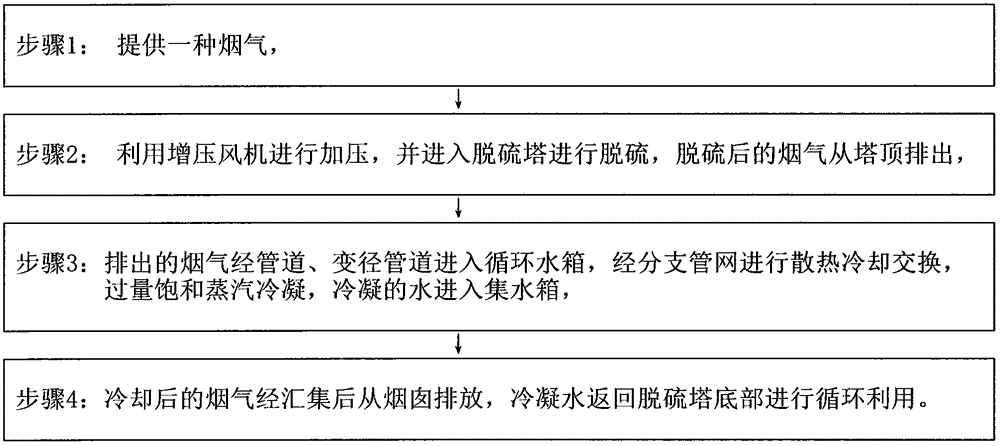

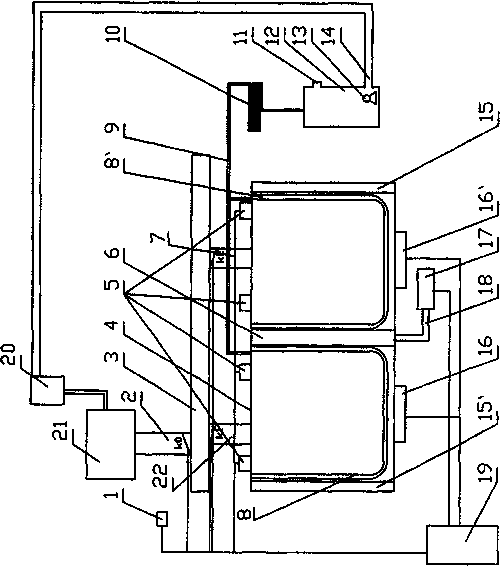

Wet method desulfurizing white smoke trailing treatment device and method

InactiveCN105268301AEliminate smearingImprove visual effectsDispersed particle separationWater sourceWater content

The invention relates to a wet method desulfurizing white smoke trailing treatment device and method. The treatment device comprises a booster fan, a desulfurizing tower, a reducing pipeline, a branch pipe network, a cooling water tank, a water collection tank, a draining pump, a valve, a chimney and a pipe. Flue gas is subjected to desulphurization in the desulfurizing absorbing tower through the booster fan, reducing is carried out through the pipe, then the flue gas goes into the water tank, heat radiation cooling exchange is carried out in the water tank through the branch pipe network, the temperature of the wet flue gas is lowered to about 40 DEG C from original about 55 DEG C, thus excess saturated vapor in the flue gas is condensed, the condensed water goes into the water collection tank and returns to the bottom of the desulfurizing tower for reuse, and the cooled flue gas is collected through the reducing pipe, goes into the chimney and is discharged. The excess water content in flue gas can be lowered, saturated vapor waste water is recovered, the desulfurizing tower white smoke trailing problem is solved effectively, the situation that residues in flue gas cannot pollute water resources is ensured, and secondary water treatment is avoided.

Owner:李正福

Method for extracting cellulose, lignose and compound fertilizer from cotton-seed hull

InactiveCN101476252AIncrease profitSolve the disadvantages that only a single product can be extractedLignin derivativesPaper material treatmentFiberCellulose

The invention provides a method for extracting cellulose, lignin and composite fertilizer from cottonseed shell, which comprises the following steps: adding lignin dissolving agent and water into a container according to the proportion of 1-5:1000; adding 10-20 liquid amount of cottonseed shells; heating to 70-90 degrees centigrade and keeping for 6-10 hours; separating out crude fibers, rinsing, refining and drying to obtain the finished fiber product; sending the rinsed solution into the socking container for reuse; acidifying the solution in the first boiling pool, and press filtering to precipitate solid that is lignin; adjusting the pH value of the solution after lignin extraction to neutral, concentrating, drying, granulating to obtain composite fertilizer. Besides the cellulose, the invention can co-produce lignin and composite fertilizer, changes improves the abuses of single product, water resource waste and serious environment pollution existing in the current technologies in our country.

Owner:JIAHE BIOTECH

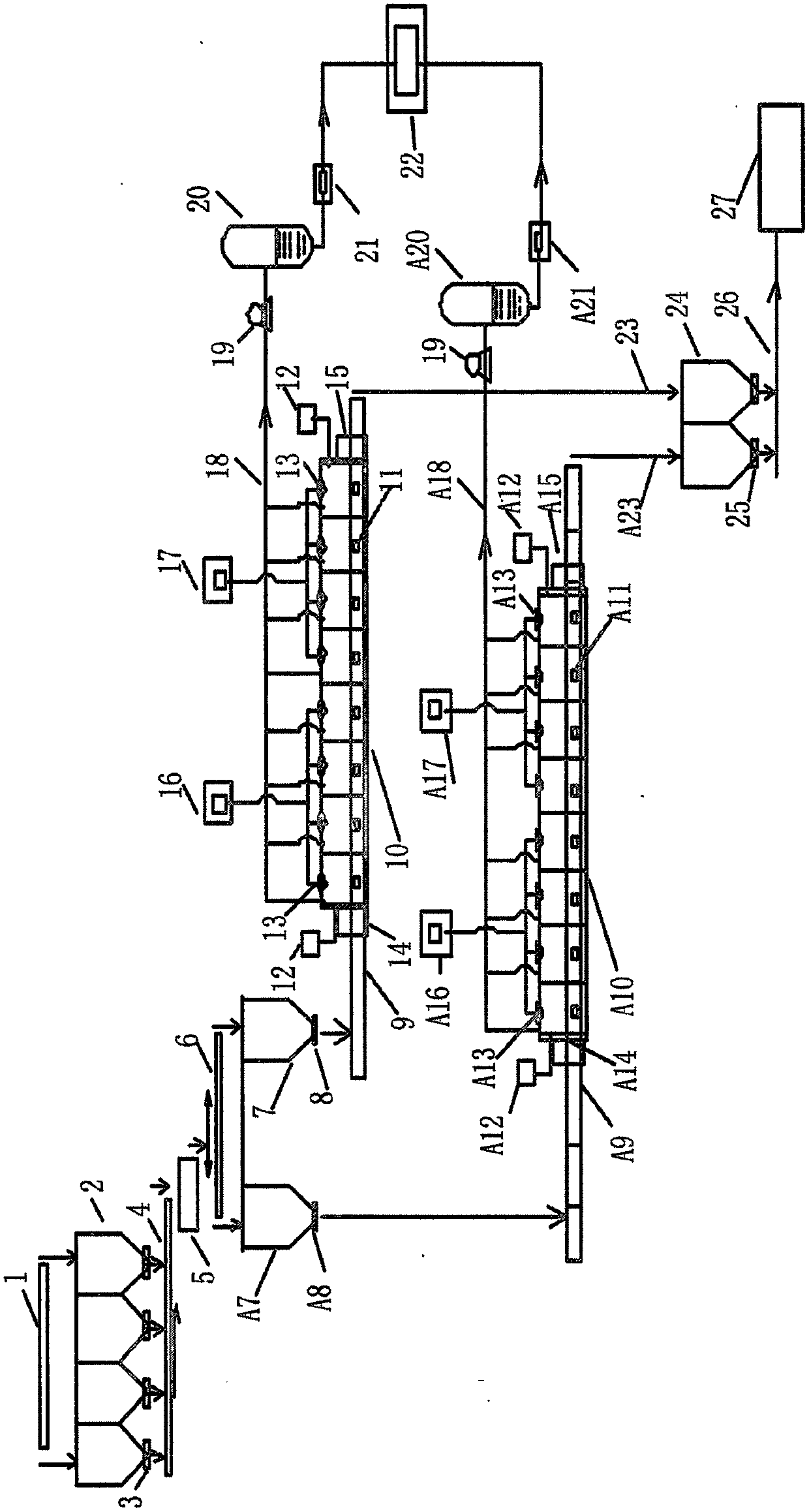

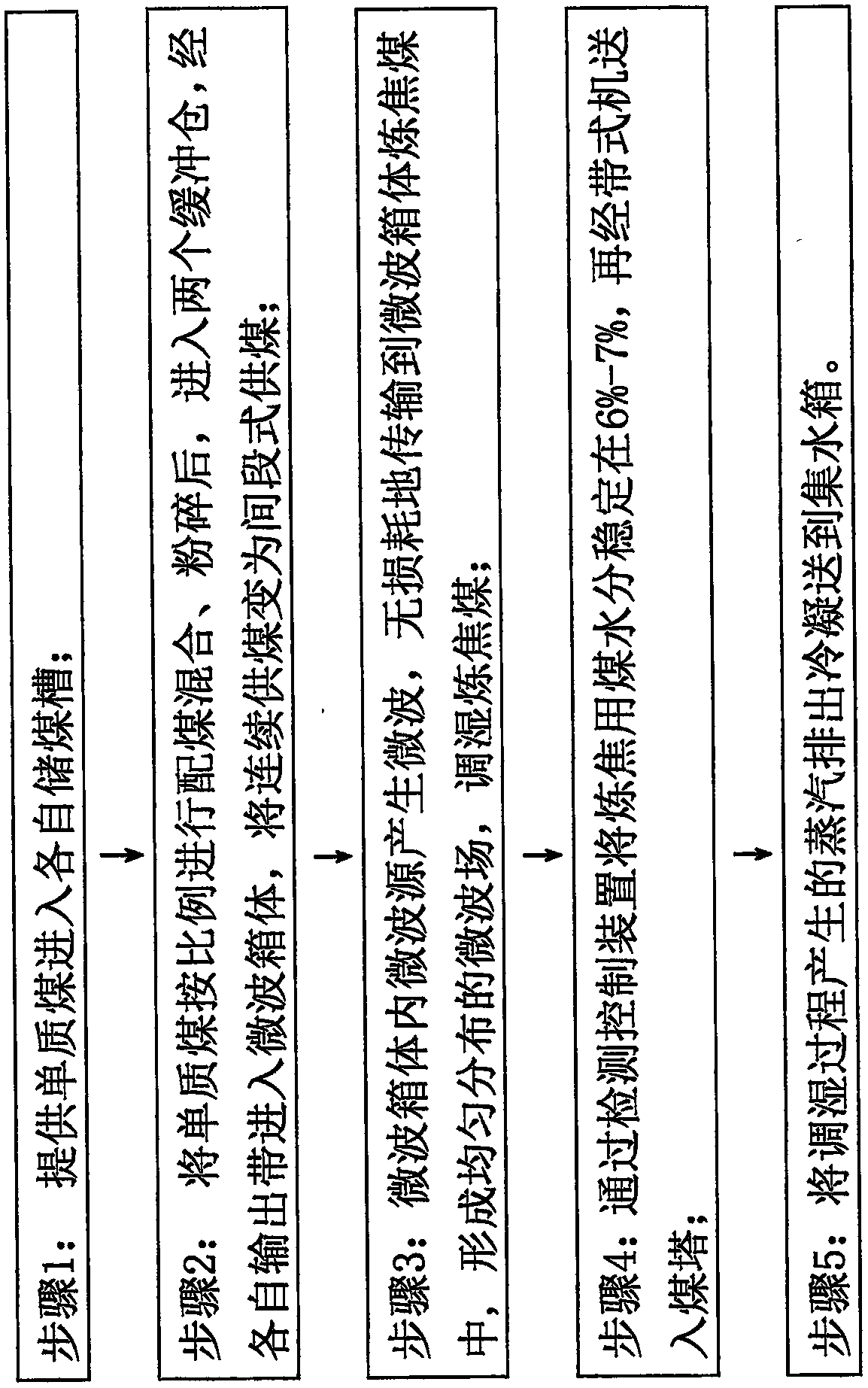

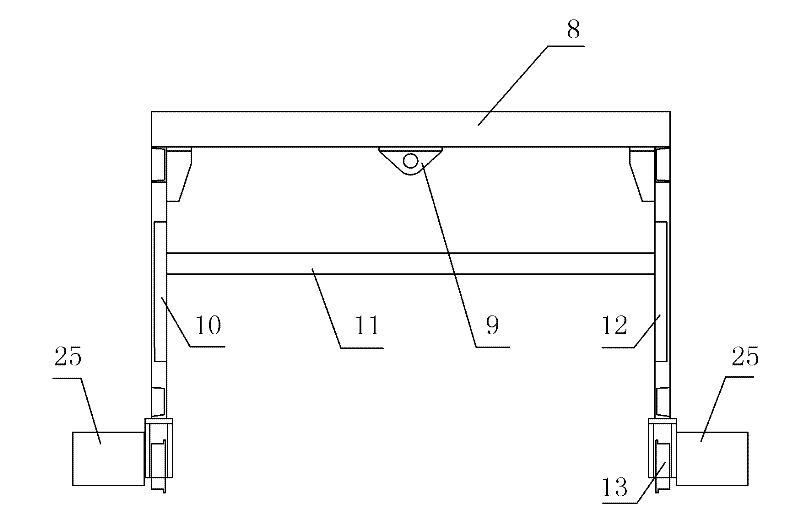

Device and method for regulating humidity of coal powder by utilizing microwave preheating

InactiveCN105505424AImprove coke qualityImprove coke oven operation stabilityCoke ovensWater contentPulverizer

The invention provides a device and method for regulating humidity of coal powder by utilizing microwave preheating. The device comprises coal storage tanks, a pulverizer, two buffer bins, a microwave box, a microwave device, an exhaust fan, a condenser, conveyer belts, a detection device and the like. Single coals enter the respective coal storage tanks via belt-type machines; an automatic coal blending device is arranged below each coal storage tank; the feed amount is controlled according to the given value, the coal is sequentially spread on a coal blending belt, enters the pulverizer to be pulverized, and enters the two buffer bins; and the coals enter the microwave box through the respective conveyer belts, so that the continuous coal feed is converted into intermittent coal feed. Microwaves generated by a microwave source in the microwave box are transmitted to the coking coal in the microwave box without any loss so as to form a uniformly-distributed microwave field and humidify the coking coal. A detection control device is utilized to keep the water content of the coking coal to be 6-7%, the coking coal is continuously sent into the coal tower by the belt-type machine, and the vapor generated in the humidifying process is discharged, condensed and sent to a water collection tank. The device has the advantages of high humidifying efficiency, favorable uniformity and energy saving, and can enhance the coke quality.

Owner:李阳春

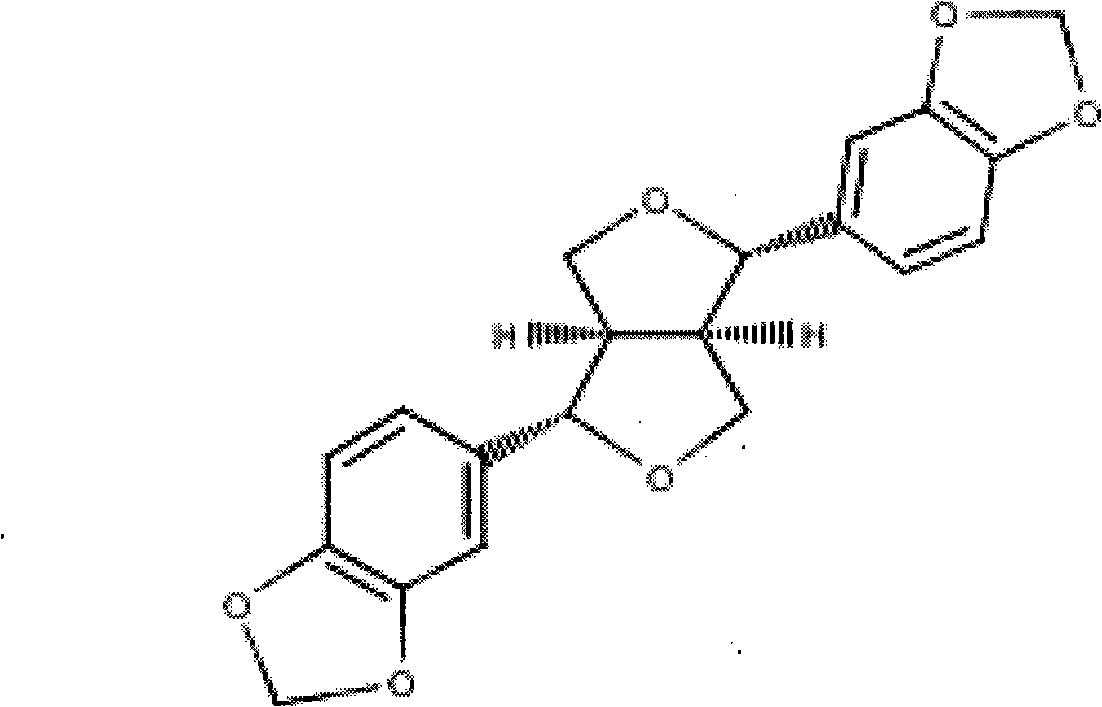

Preparation method of sesamin

InactiveCN102432619AGood effectReduce energy consumptionOrganic chemistryGradient elutionDissolution

The invention relates to a preparation method of sesamin. With sesame as a raw material, the method comprises the steps of: adding ethanol for twice refluxing extraction, conducting pressure reduction and solvent recovery, carrying out mixing to obtain a sample which is then applied on macroporous resin for adsorption, performing gradient elution with a mixed solution of ethyl acetate and methanol, collecting sesamin fractions, recovering the reagent to a small volume, disposing the fractions for crystallization, then implementing refluxing in absolute ethyl alcohol for saturated dissolution, and conducting crystallization so as to obtain a product. Adoption of the method provided in the invention for production has the advantages of low cost, high yield as well as high purity, and is in accord with the principles of circular economy and also characterized by low carbon and environmental protection.

Owner:苏州北商智业管理咨询有限公司

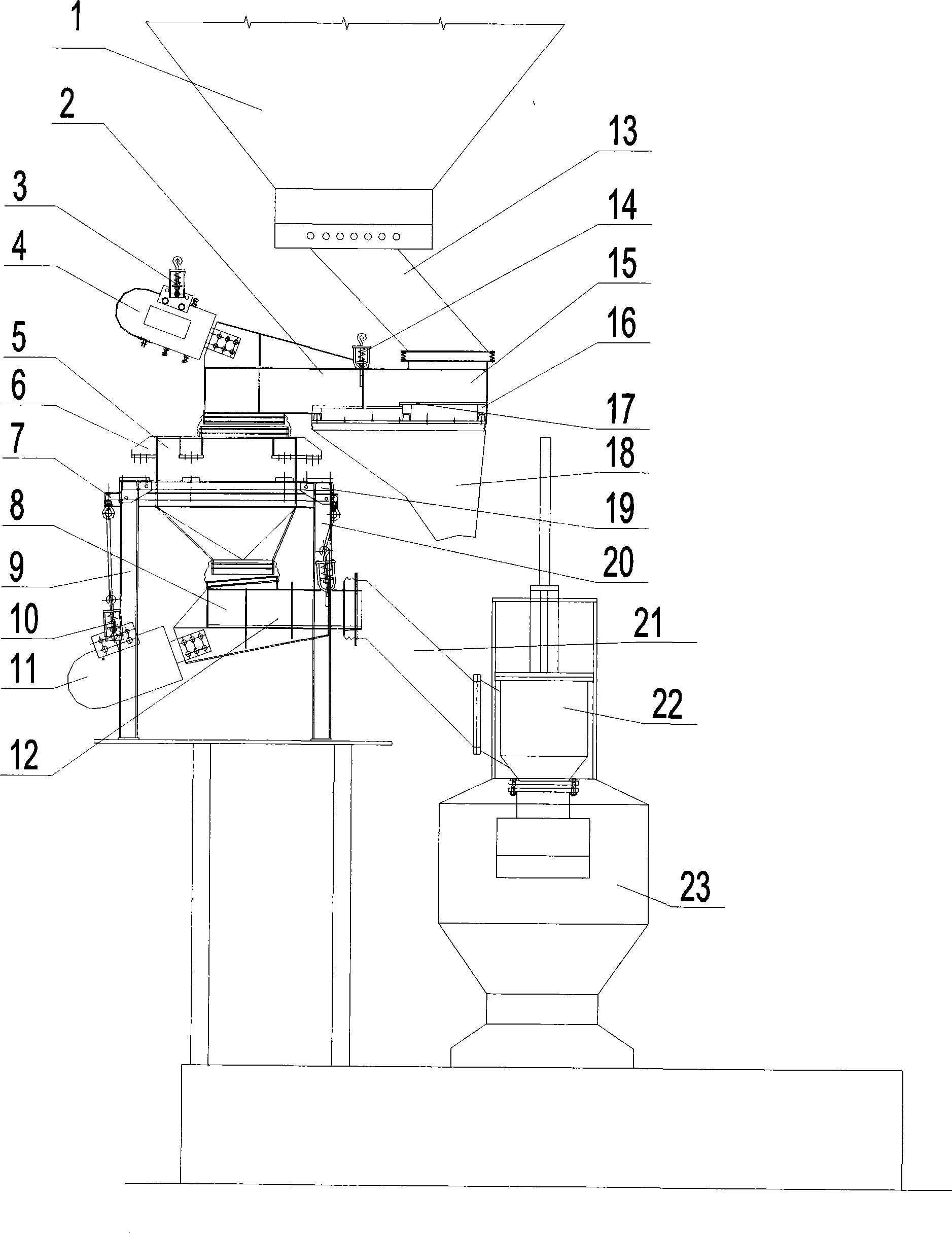

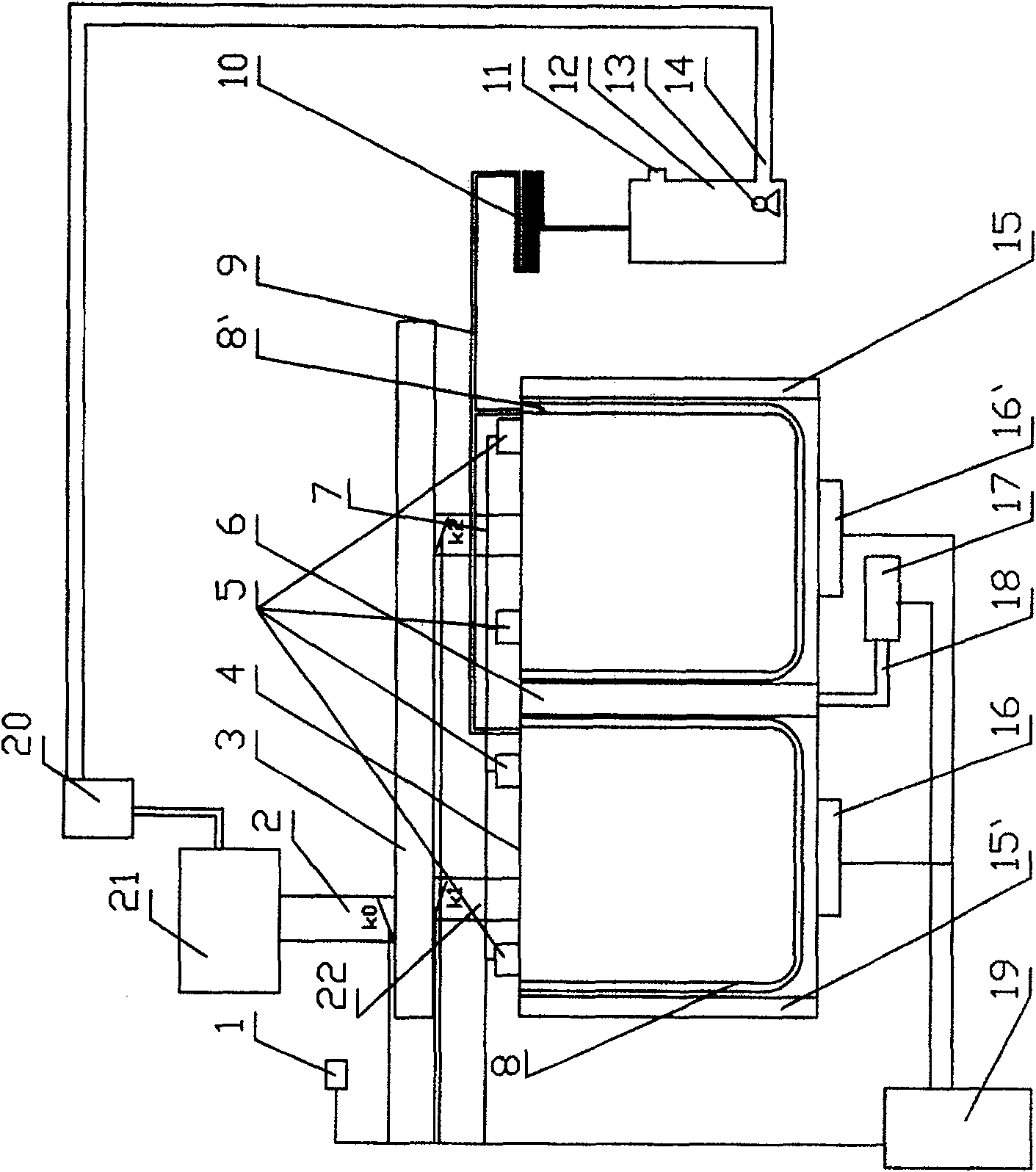

Molded coal continuous gasification fixed bed coke charging powder exhaust metering control system

InactiveCN101475841AAvoid enteringIncrease productivityCombined combustion mitigationFixed-bed gasificationControl systemFixed bed

The invention relates to a coke-charging powder-discharging metering control system for a fixed bed for continuous briquette gasification, which consists of a large bunker, a pressure-reducing chute, a powder discharge chute and a feeding chute, wherein an upper feeding machine, a weighing bunker, a lower feeding machine and a weighing supporting frame are also arranged below the large bunker; the large bunker is positioned above the upper feeding machine, the pressure-reducing chute is connected below the large bunker, the upper feeding machine and the pressure-reducing chute are connected in a flexible connection mode, and the weighing bunker is arranged at a discharge outlet below the upper feeding machine; a powder screening device is arranged in a silo, and is connected with the lower feeding machine below the weighing bunker in a flexible connection mode; and the weighing bunker is supported on the weighing supporting frame. The system is provided with the powder screening device, a powder discharge device and a weighing device, and can basically prevent powder coal from entering a gas-making furnace, thereby improving the production efficiency and the yield of coal gas; on the other hand, the recollected powder coal can also be recycled, which satisfies the national industrial policy of recycling economy, energy conservation and emission reduction, and greatly improves the benefit of enterprises.

Owner:李志宇

Biological integrated control method for diseases of garden stuff and economic crop

InactiveCN101438665ASimple operation processImprove qualityBiocideFertilising methodsDiseasePlant disease

The invention relates to a biological integrated disease control method of fruits, vegetables and economic crops, in particular to a complex application method of a biological anti-bacterial agent containing Bacillus subtilis BS2-5, BS6 and BS8-2 bacteria and a bacterial manure containing biochemical fulvic acid. The method comprises the following steps: mixing the diluted biological anti-bacterial agent and a prepared biochemical fulvic acid foliage fertilizer and then spraying the mixture to leaf surfaces of the fruits and the vegetables every 10-20 days after plants start budding according to the growth requirement of branches and leaves of the fruits, the vegetables and the economic crops; and simultaneously flushing or irrigating roots of the fruits and the vegetables with a water flush fertilizer containing the biochemical fulvic acid. The method can cause the biological anti-bacterial agent and the bacterial manure containing biochemical fulvic acid to give full play by the complex application thereof, inhibit and kill pathogenic bacteria on the leaf surfaces and around the roots of the plant by beneficial microbial colonies, play a role of reducing the fertilizer consumption by replacing a chemical pesticide control on the plant diseases with a biological integrated control on the plant diseases, thus realizing green production of the economic crops and achieving a purpose of safe consumption, realizing a process of pollution-free and green production.

Owner:陈五岭

Recyclable artificial turf

ActiveCN108824128AMeet the requirementsImprove water resistanceGround pavingsCoatingsBreaking strengthFiber

The invention relates to a recyclable artificial turf. The recyclable artificial turf comprises grass fibers, bottom cloth and an adhesive layer; the bottom cloth is arranged under the grass fibers; the adhesive layer is arranged under the bottom cloth; during preparation, firstly, components of glue water in weight parts are 95-100 parts of aqueous polyolefin dispersion, 0.5-1 parts of thickeningagents, 1-5 parts of deionized water and 2-3 parts of pigment fillers; secondly, the turf is correspondingly coated for two times, coated and dried; and thirdly, the turf is perforated and cut to obtain the recyclable artificial turf. According to the recyclable artificial turf, the preparation method is simple, the steps are easy to operate, the wire drawing performances, such as breaking strength, elongation, wire drawing section and appearance, of the prepared recyclable artificial turf satisfy requirements of manufacturing the artificial turf through wire redrawing, and better water resistance is realized.

Owner:无锡市桑丽人造草坪地毯有限公司

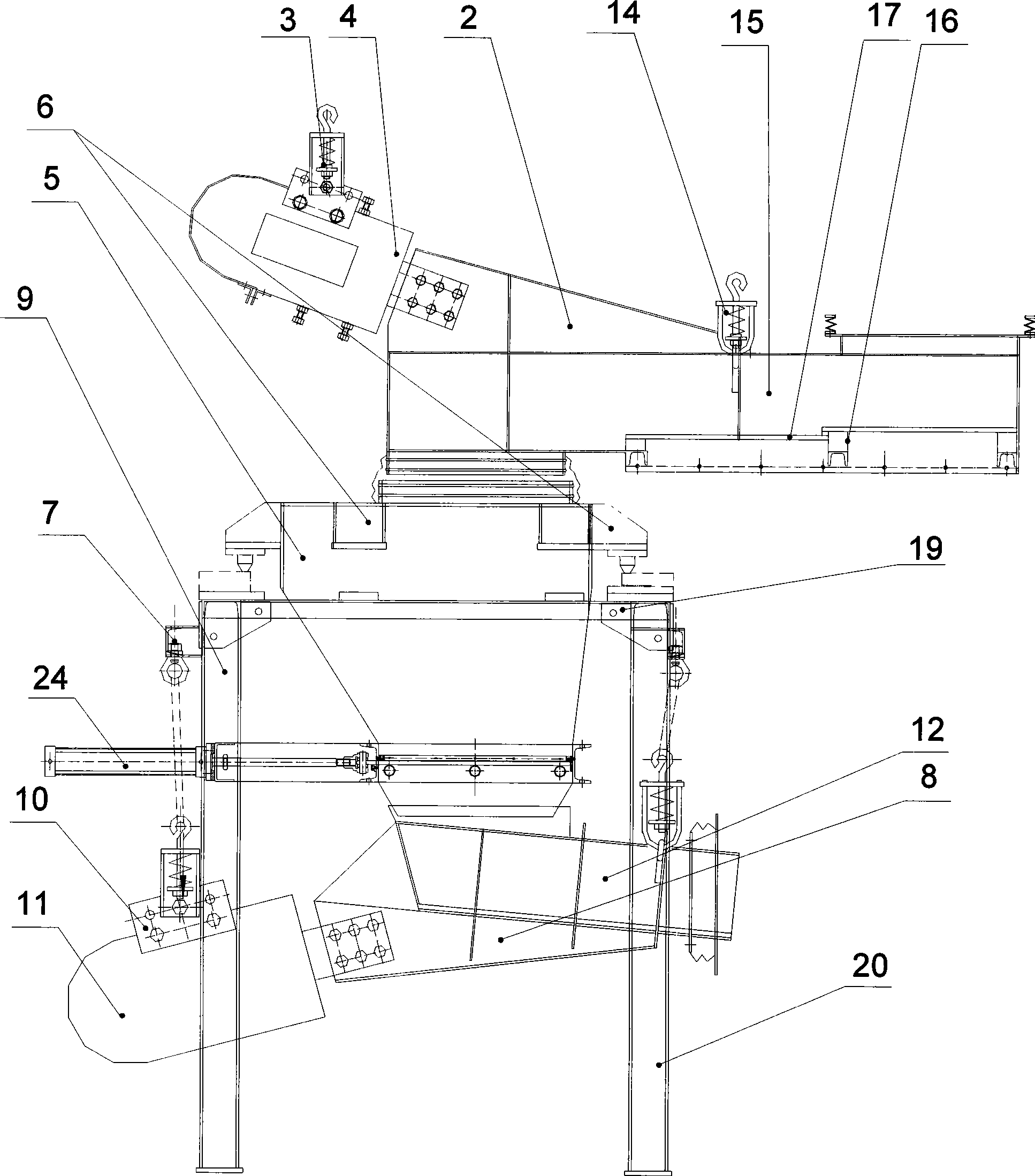

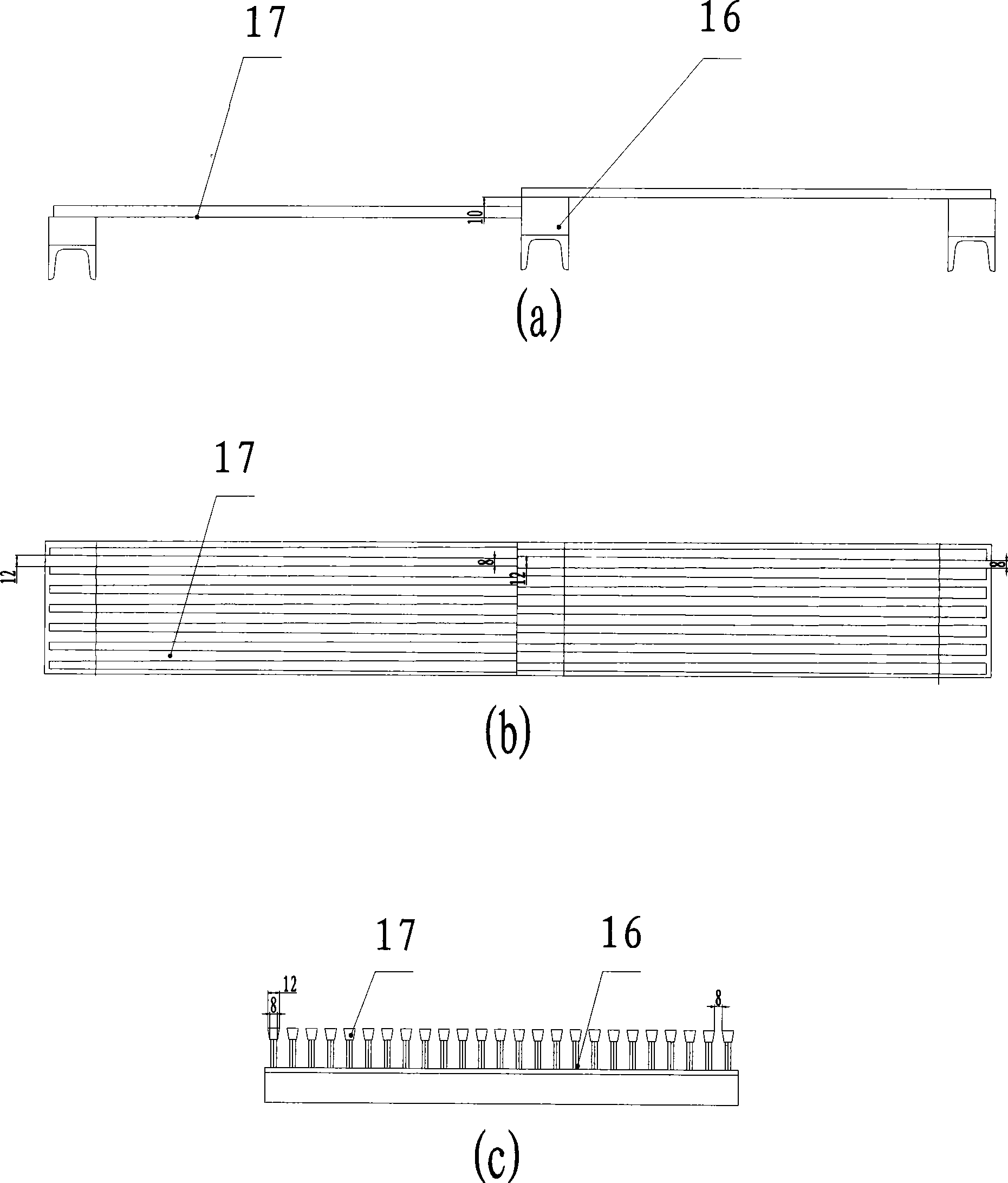

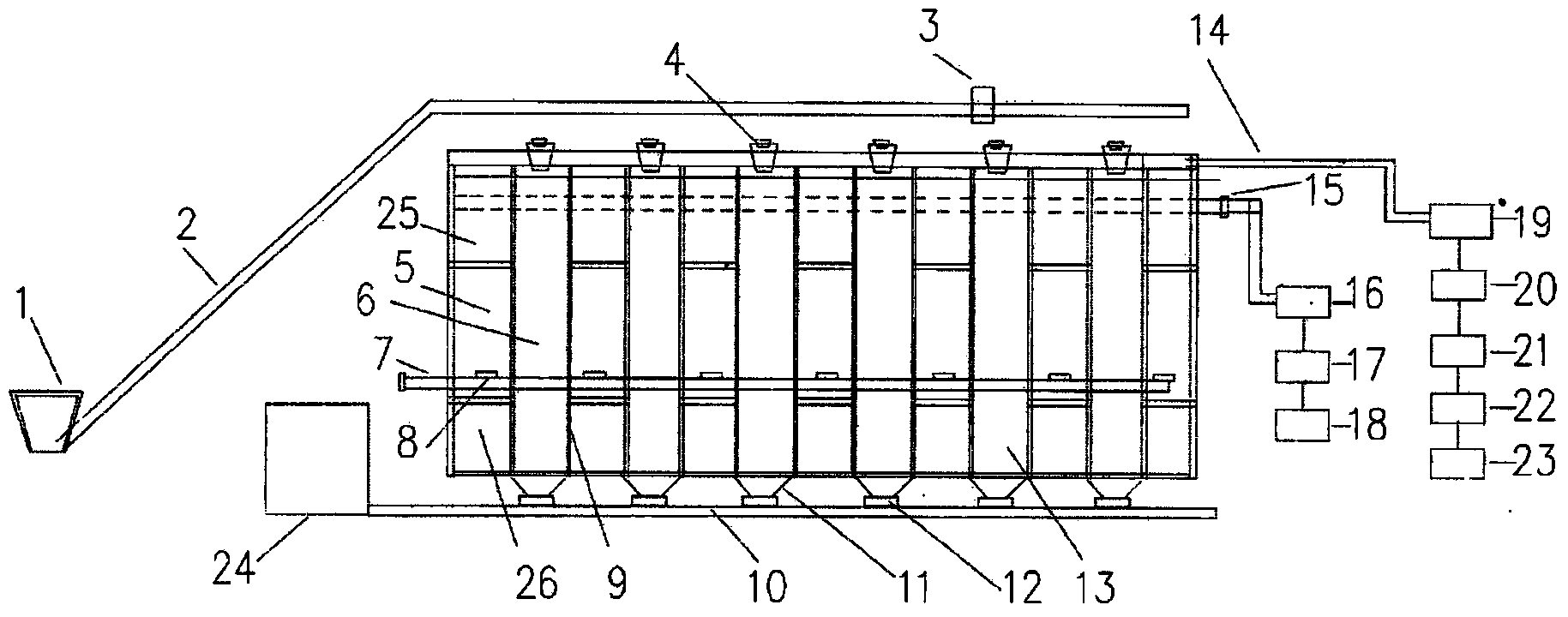

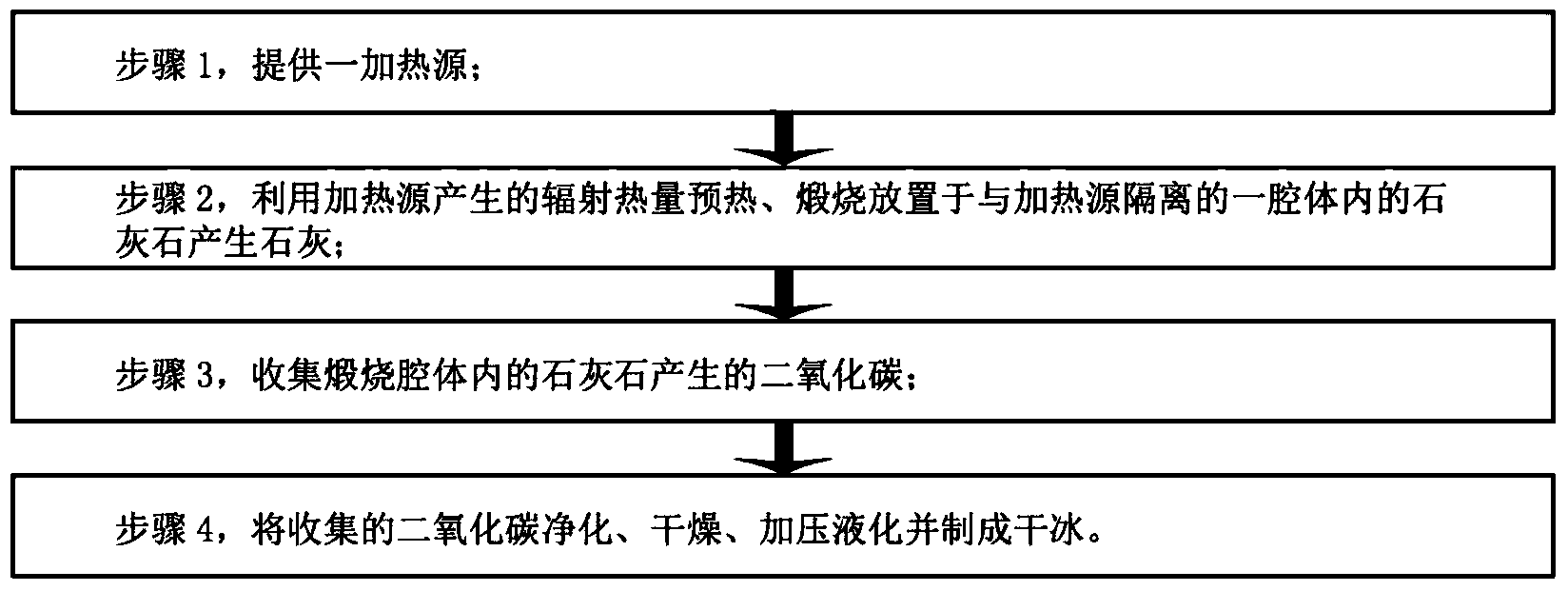

Device and method for manufacturing dry ice by utilizing radiant heat to produce active lime

InactiveCN104261700AImprove product qualityHigh purityCarbon compoundsEnergy inputCombustion chamberRadiant heat

The invention provides a device and a method for manufacturing dry ice by utilizing radiant heat to produce dry ice. The device and the method are applied to lime stones with small particle size of 20-40 mm in mine production. Roasting is carried out through heat transferred through radiation by a combustion chamber in a roasting chamber, the roasted lime stones are decomposed into calcium oxide and carbon dioxide, the calcium oxide is cooled, discharged out through an ash discharging device and fed into an ash bin for storage, the carbon dioxide passes through a drying device, a pressure device, a carbon dioxide liquefying plant and a dry ice device through connected waste gas pipelines to generate dry ice, after coal gas or powdered coal in the combustion chamber is combusted, the coal gas or powdered coal is discharged out through a fan for waste heat recovery and are discharged through a chimney. Active lime with higher quality can be obtained, pure carbon dioxide can be effectively recycled and is processed and manufactured into food grade dry ice, and meanwhile waste heat can be recycled for secondary use, so that a new way with larger market prospect is developed for the production of active lime and comprehensive application of resources in our country.

Owner:李正福

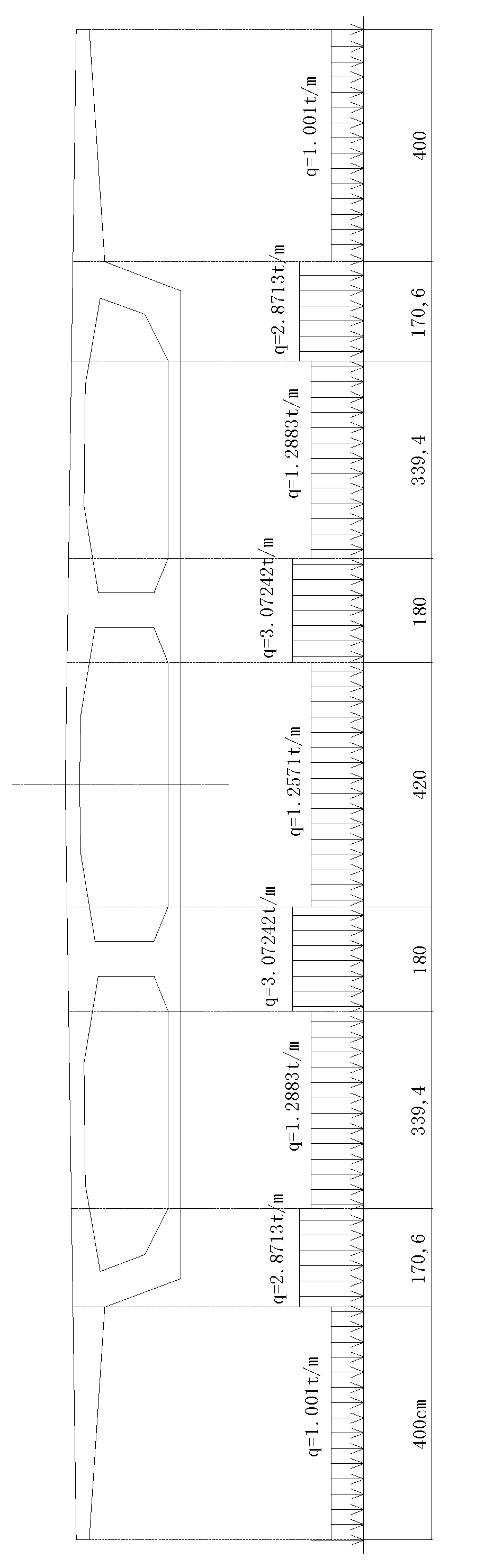

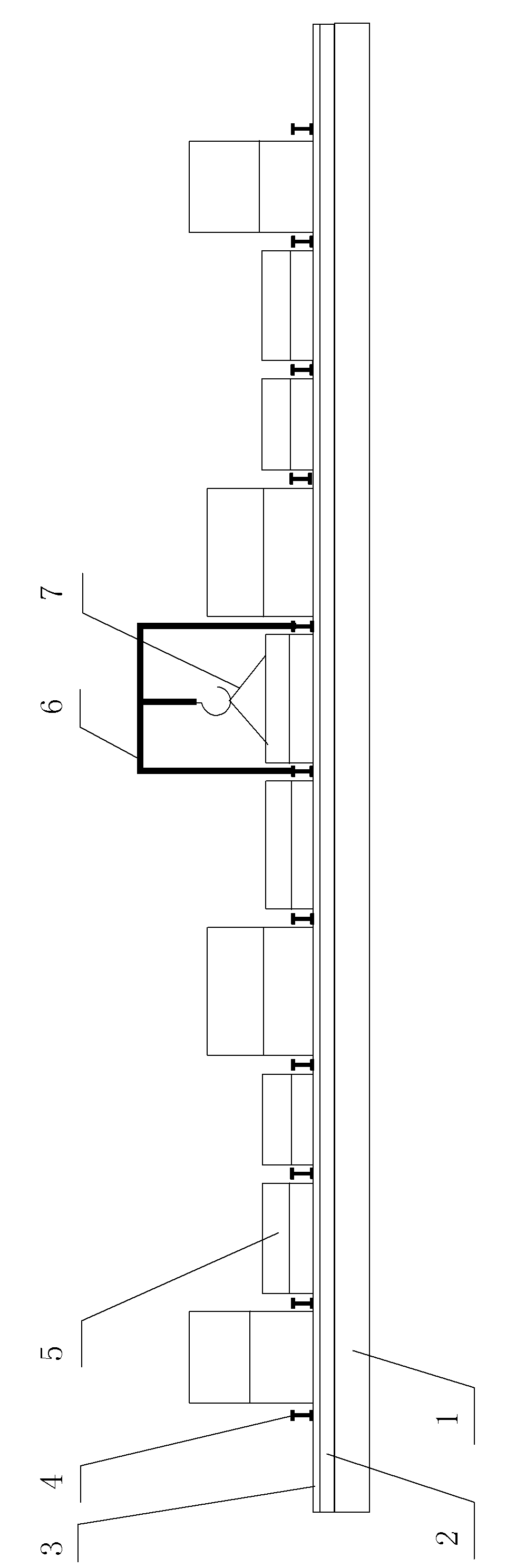

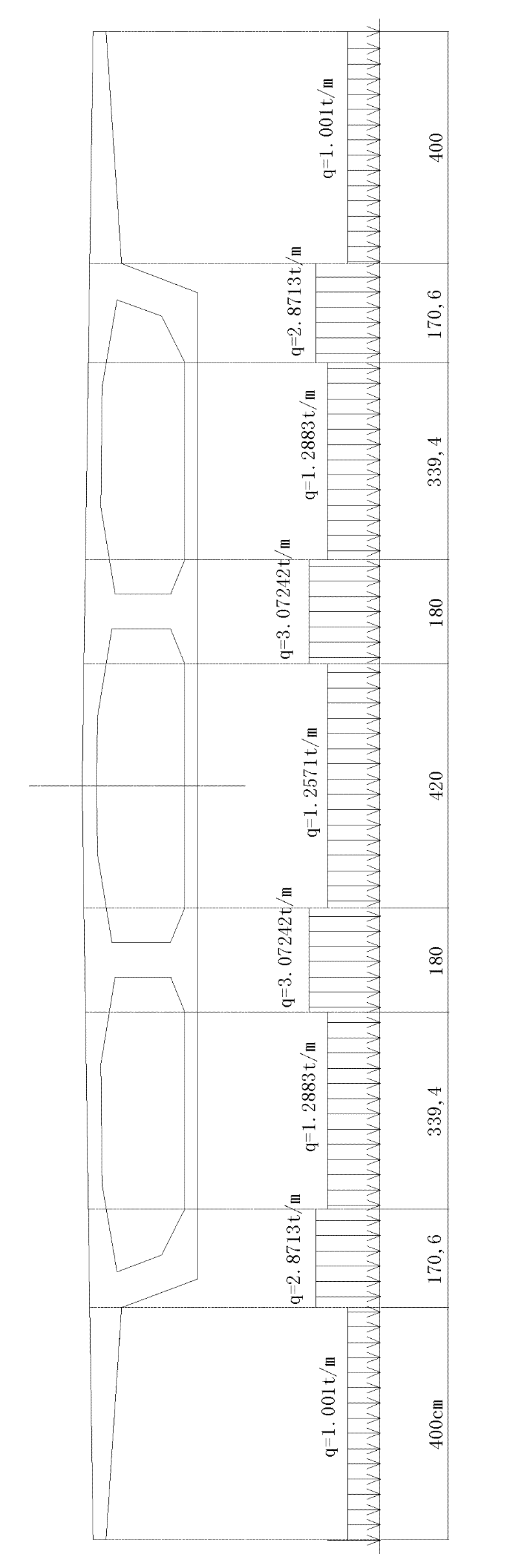

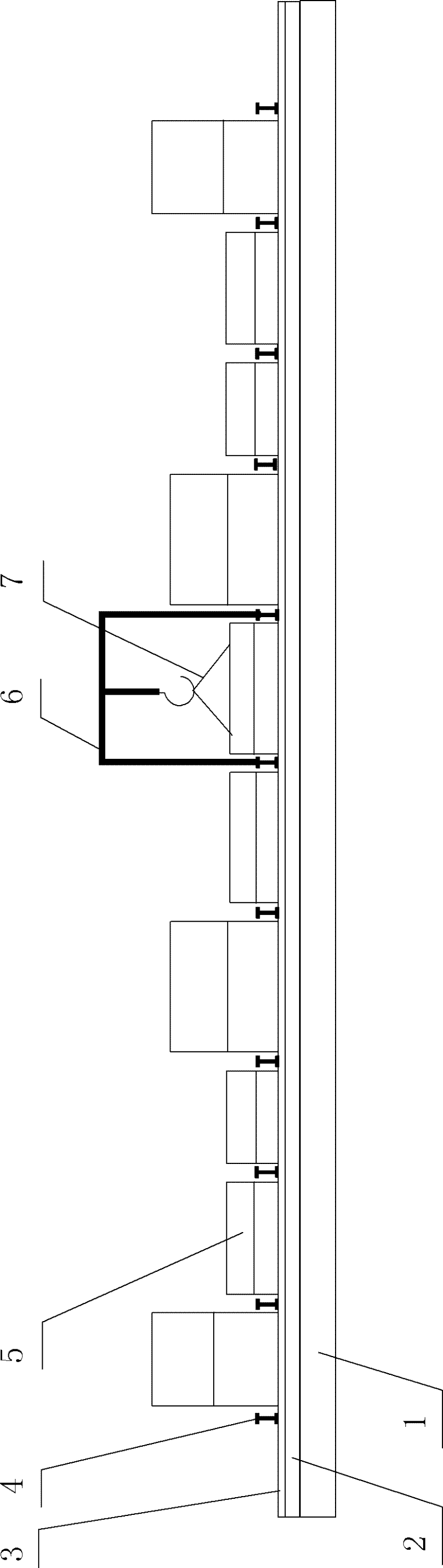

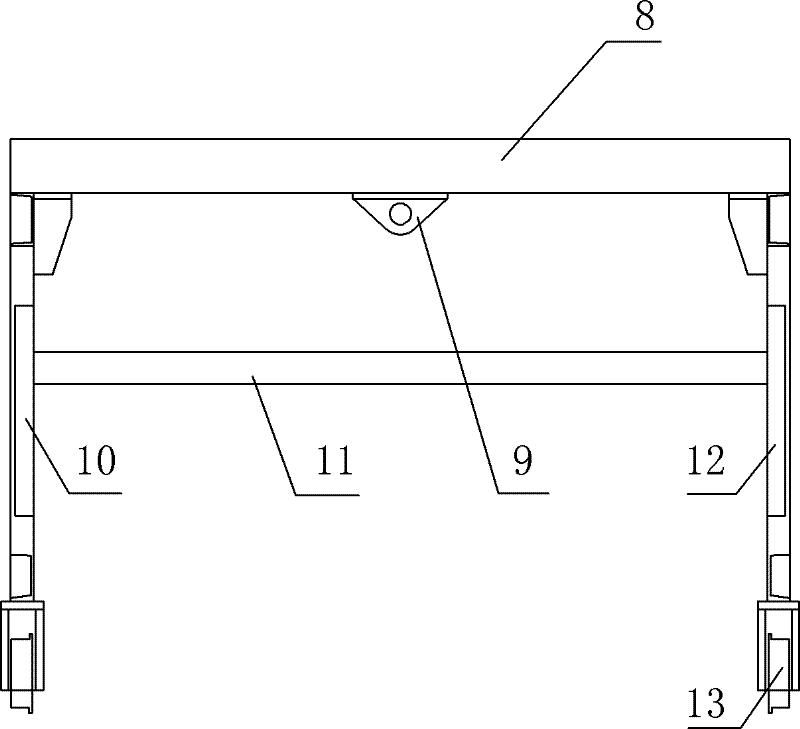

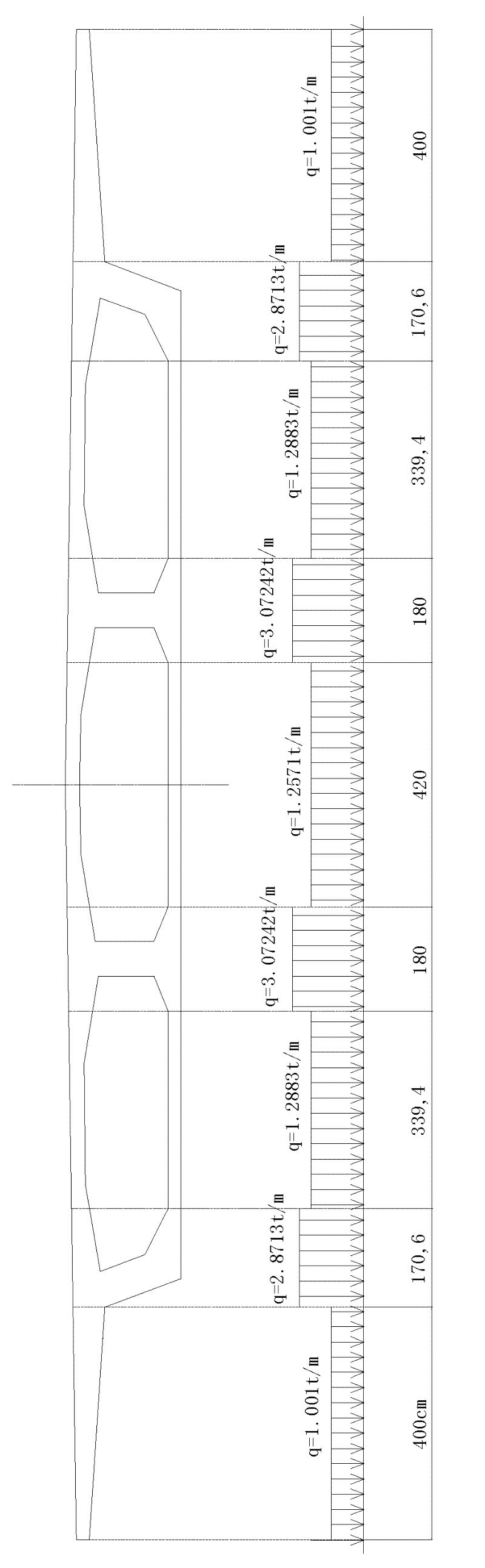

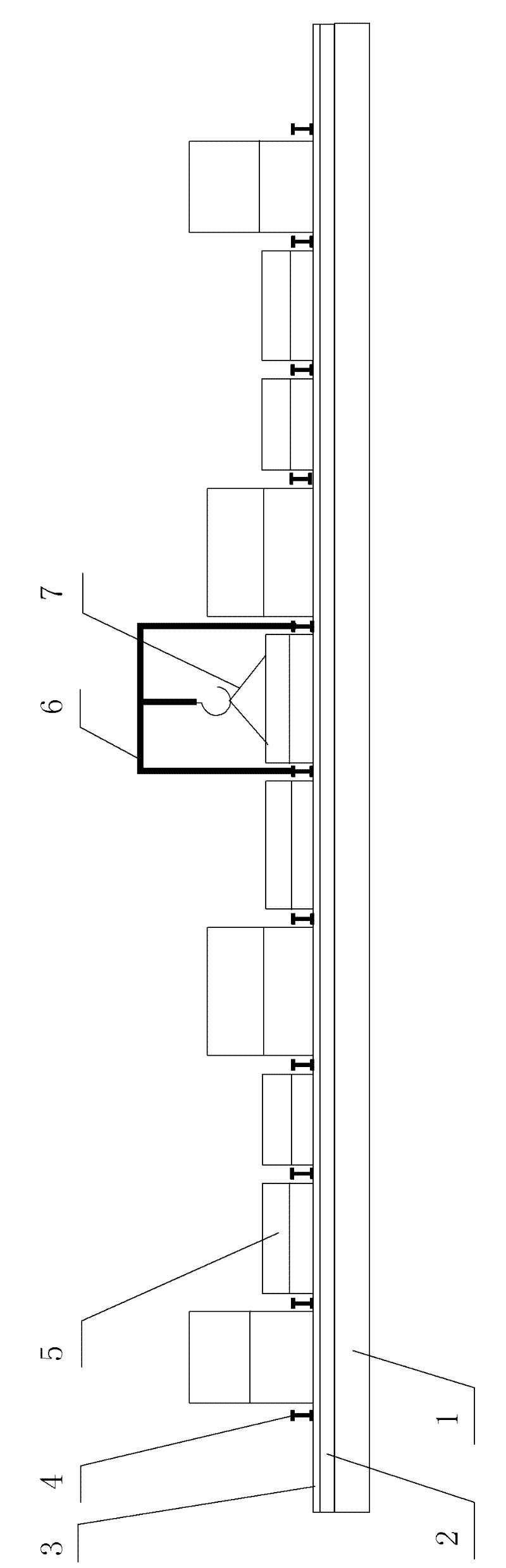

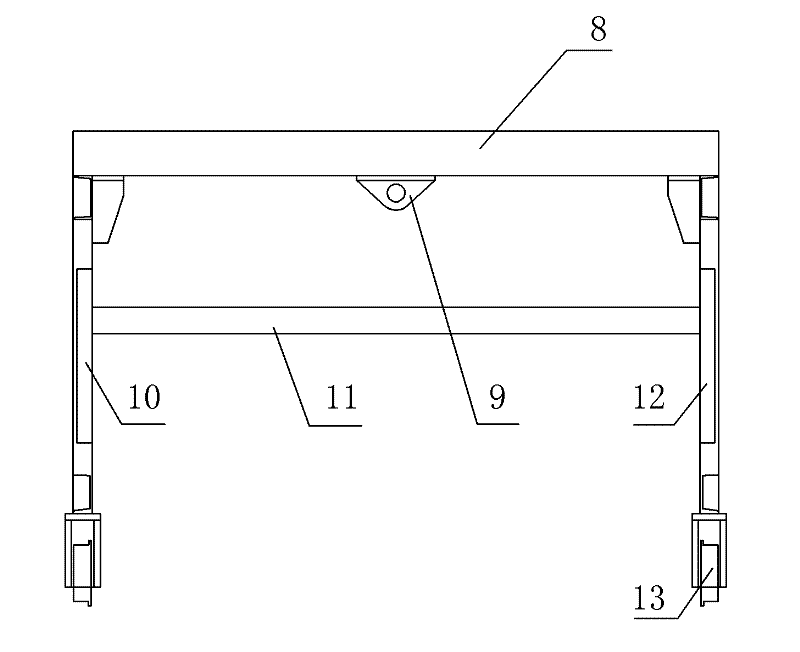

Method for carrying out load test on bridge support frame by prefabricated parts moved through tractive walking

InactiveCN102012313AReduce collapse accidentsReduce casualtiesMachine part testingTest efficiencyGallows

The invention relates to a method for carrying out load test on a bridge support frame. The method for carrying out load test on the bridge support frame by prefabricated parts moved through tractive walking is characterized by comprising the following steps: firstly placing a template special for loading on a box-beam template on the bridge support frame; installing a plurality of rails on the template special for loading along the longitudinal direction of the bridge support frame; placing gallows frames on the rails, using a tractor to tow the gallows frames to walk to transport the prefabricated parts horizontally to lift and lower the prefabricated parts on the first layer, carrying out load test detection on the bridge support frame and then lifting and lowering the prefabricated parts on the second layer after meeting the requirement; carrying out detection again after completing loading; after test detection meets the requirement, firstly unloading the prefabricated parts on the second layer and then unloading the prefabricated parts on the first layer after all the prefabricated parts on the second layer are unloaded. The method has good reliability and safety, high test efficiency, standard test measurement and high precision of load simulation.

Owner:CHINA FIRST METALLURGICAL GROUP

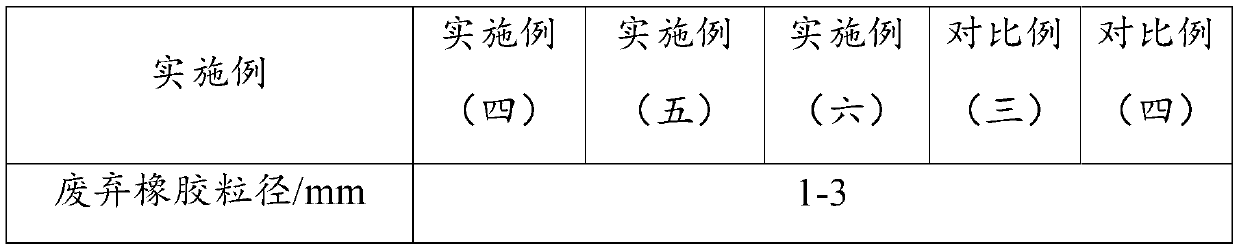

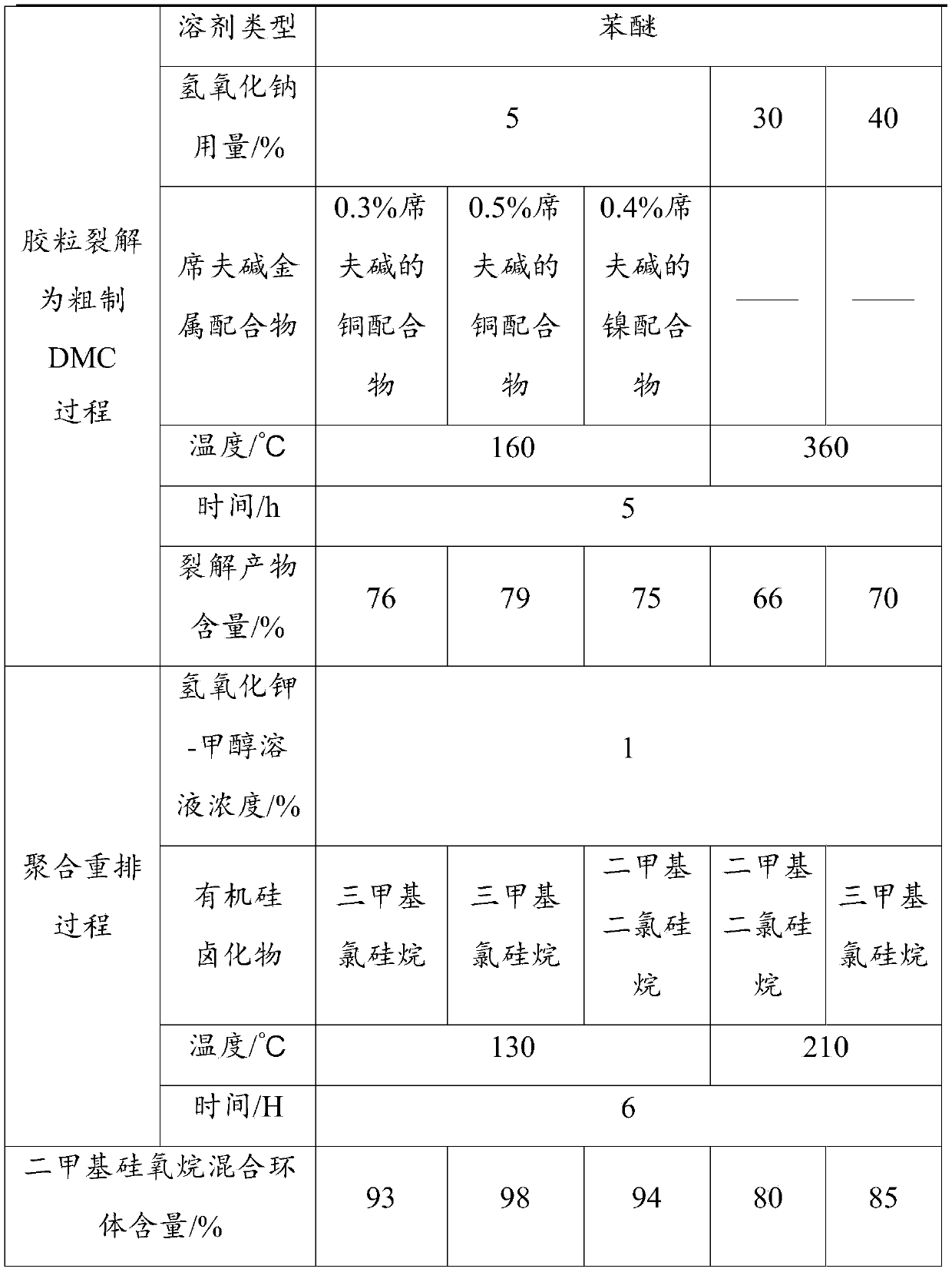

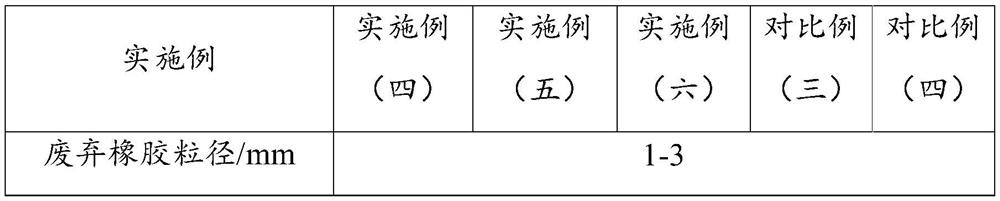

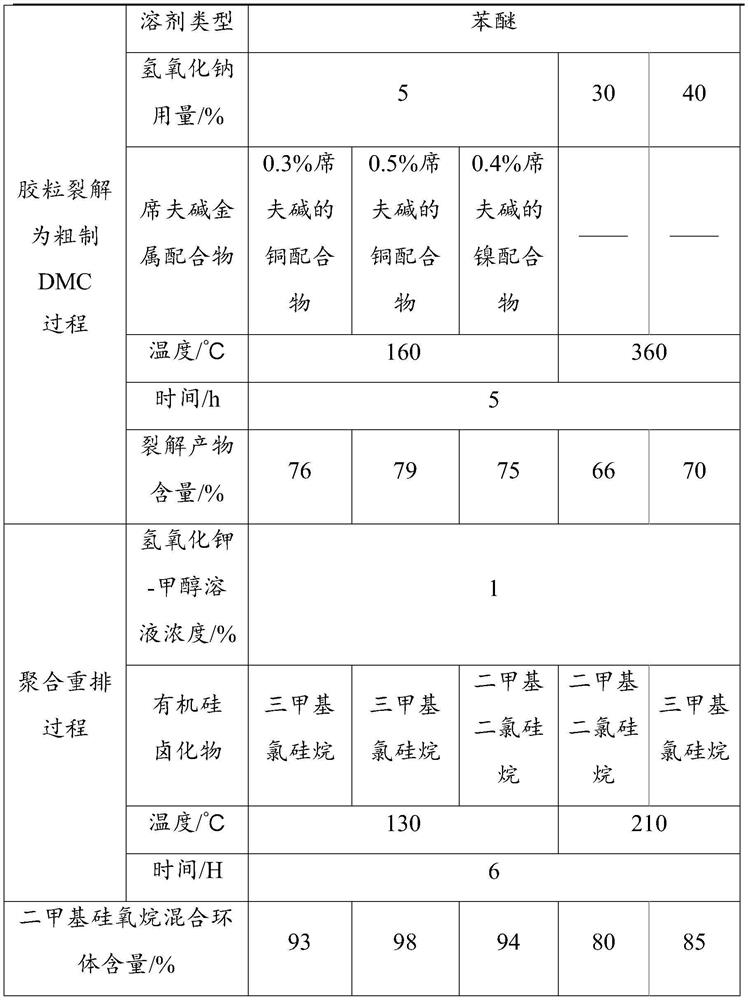

High-efficiency cracking recovery method for silicone rubber waste

ActiveCN111040243AReduce dosageImprove stabilitySilicon organic compoundsPlastic recyclingPolymer scienceDepolymerization

The invention relates to a cracking recovery method of silicone rubber waste. The method comprises the following steps: crushing of the silicone rubber waste; double cracking: putting crushed siliconerubber particles into a cracking reaction kettle, then adding a high-temperature-resistant inert solvent, alkali metal hydroxide and a Schiff base metal complex, and carrying out depolymerization ata high temperature of 140-200 DEG C in a nitrogen atmosphere to obtain crude DMC, wherein the usage amount of the alkali metal hydroxide is 5-8% of the weight of the silicone rubber waste; polymerizing and rearranging; and decolorizing and deodorizing, thereby obtaining the refined cyclosiloxane DMC. According to the cracking recovery method of the silicone rubber waste, double cracking and polymerizing and rearranging are organically combined and reasonably arranged, so the method has the advantages of low use of basic catalyst in recovery, high waste silicone rubber recovery efficiency, litter generated waste and accordance with circular economy.

Owner:GUANGZHOU BAIYUN CHEM IND

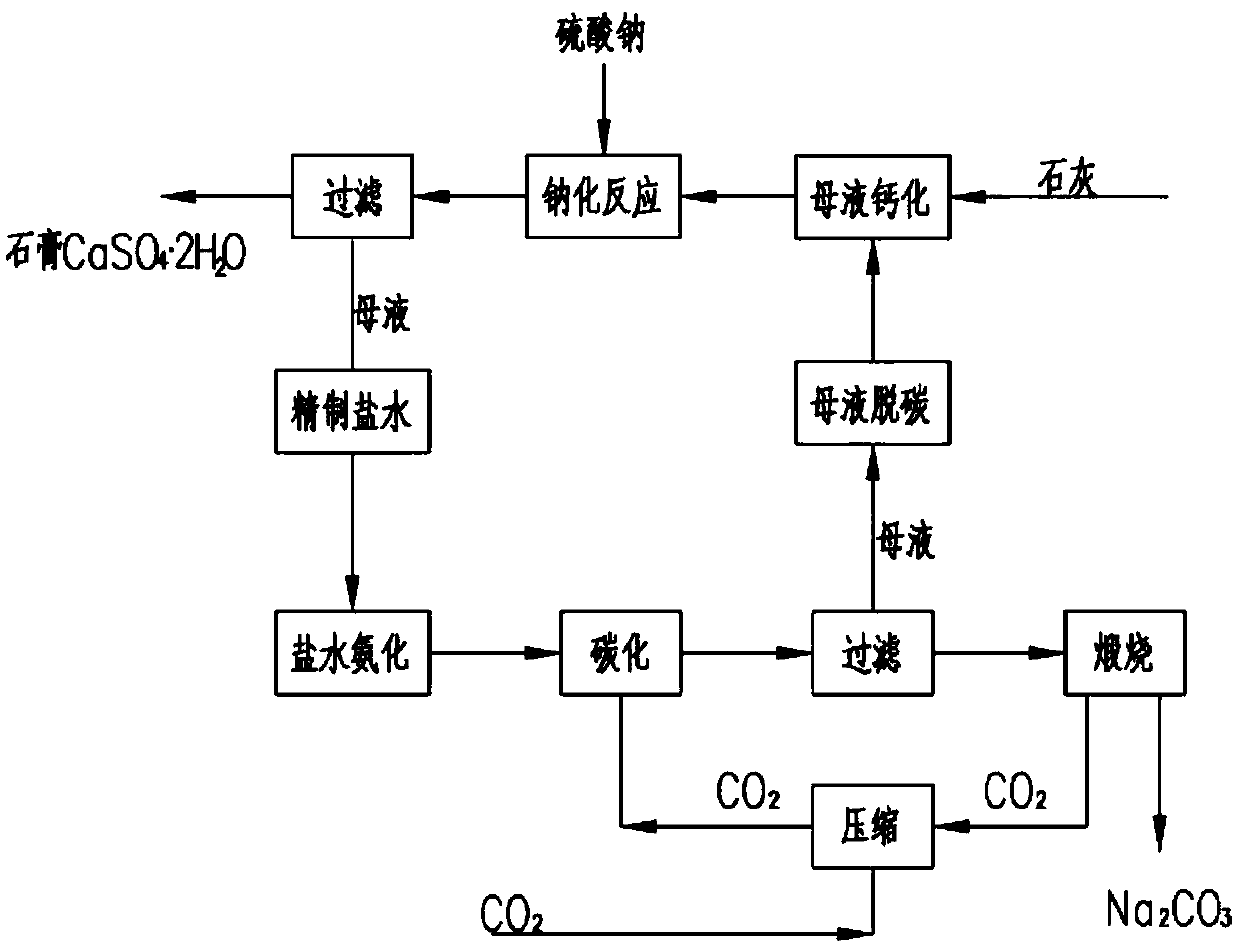

Technological method for preparation of sodium carbonate from sodium sulfate

The invention relates to a technological method for preparation of sodium carbonate from sodium sulfate. Sodium sulfate and limestone are adopted as the main raw materials, chlorine ions and ammonia are adopted as the intermedia of the process, and the main products are sodium carbonate and gypsum. The method provided by the invention uses sodium sulfate as the main raw material to produce sodiumcarbonate, the process does not involve ammonia distillation procedure, the system does not discharge wastewater, and the consumption of steam and new water is reduced, great changes occur to the technological process and basic principles, and the raw material utilization rate reaches 98% or above. The method provided by the invention reduces energy consumption, realizes recycling of resources, does not produce wastewater, and can change the existing sodium carbonate production, and at the same time provides a new way for deepening utilization of sodium sulfate and enterprises producing sodiumsulfate waste salt.

Owner:SHAANXI KEYUAN ENVIRONMENTAL PROTECTION & ENERGY SAVING TECH +1

Production system and production method for anhydrous aluminum fluoride

ActiveCN102320639BImprove conversion rateIncrease profitAluminium fluoridesAluminum fluorideHydrogen fluoride

The invention belongs to the technical field of aluminum fluoride production, concretely discloses a production system and a production method for anhydrous aluminum fluoride. The anhydrous aluminum fluoride production system comprises a hydrofluoric acid evaporator, wherein the hydrofluoric acid evaporator is connected in series to a tail gas heat exchanger, a tail gas outlet and a hydrogen fluoride gas outlet are provided with the tail gas heat exchanger, a tail gas washing apparatus is provided with the tail gas outlet, a gas mixing chamber is provided with the hydrogen fluoride gas outlet, a double-layer fluidized bed reactor is provided with a gas mixture outlet of the gas mixing chamber, the bottom of the double-layer fluidized bed reactor is provided with an aluminum fluoride product outlet, a high temperature tail gas outlet of the double-layer fluidized bed reactor is provided on the top, a reaction material inlet is provided on the double-layer fluidized bed reactor, a first order gas flow reactor is provided at the high temperature tail gas outlet of the double-layer fluidized bed reactor, the first order gas flow reactor is connected in series to a second order gas flow reactor, a third order gas flow reactor and a fourth order gas flow reactor, the second order gas flow reactor, the third order gas flow reactor and the fourth order gas flow reactor are communicated with the double-layer fluidized bed reactor, the fourth order gas flow reactor is communicated with the tail gas heat exchanger.

Owner:DO FLUORIDE CHEM CO LTD

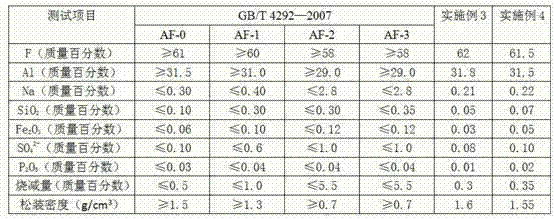

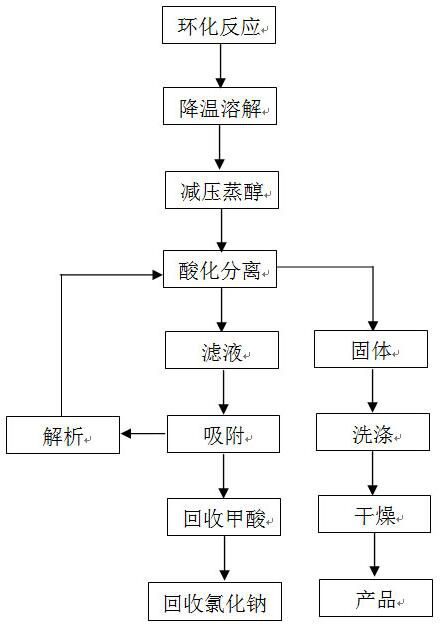

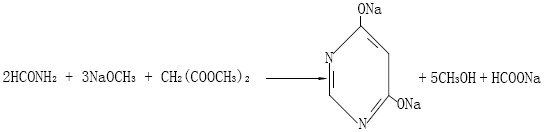

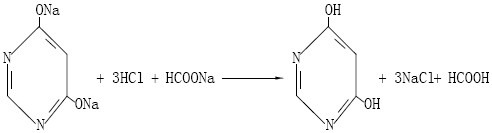

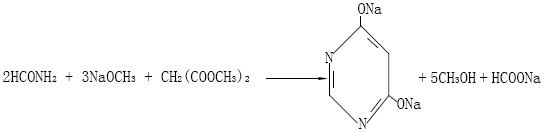

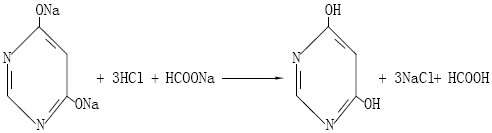

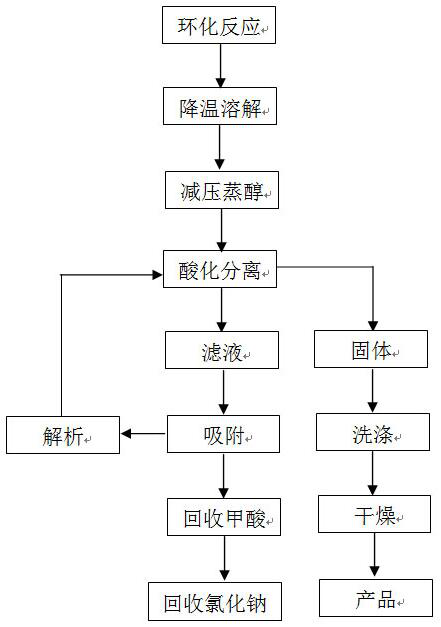

Method for preparing 4,6-dihydroxypyrimidine

The invention belongs to the technical field of synthesis of 4, 6-dihydroxypyrimidine, and particularly relates to a method for preparing 4,6-dihydroxypyrimidine. The method comprises the following steps: (1) cyclization reaction; (2) cooling and dissolving; (3) alcohol distilling under reduced pressure; (4) acidification and separation; (5) washing; (6) adsorption; (7) formic acid recycling; (8) sodium chloride recycling; and (9) analyzing. According to the method provided by the invention, the 4,6-dihydroxypyrimidine in the acidified wastewater is adsorbed by the adsorbent resin, so that the product yield is improved, the content of organic matters in the wastewater is reduced, the defect that the wastewater is difficult to treat is overcome, the quality of a byproduct sodium chloride is improved, the content of organic matters in a byproduct salt is reduced, and good economic benefits and social benefits are achieved.

Owner:潍坊滨海石油化工有限公司

Environmental protection toilets for trains

InactiveCN100579842CReduce volumeImprove efficiencyBathroom accessoriesSanitationMicrowavePressure system

The invention discloses an environment protection toilet for a train, which includes a toilet, a touching switch, a flushing tank, a temporary storage tank, a storage tank and a controller, wherein, the toilet is connected with the inferior temporary storage tank via a pipeline. A switch is arranged on the joint between the temporary storage tank and the pipeline, and a storage tank is positioned under the temporary storage tank, wherein, the storage tank is connected with the temporary storage tank via the pipeline, and a switch is arranged on the joint of the temporary storage tank and the pipeline; a storage bag and an air bag are arranged inside the storage tank, one end of the air bag is connected with pressure system of the train. The storage tank is also provided with a microwave generator. The microwave generator heats and evaporates the moisture in the feces and the moisture enters a condenser via a condensing tube arranged on the storage tank to be cooled. The cooled moisture is collected in a header tank. The cooled water in the header tank is sent to the flushing tank via a pump arranged in the header tank. The bottom of the storage tank is further provided a weighing device. Therefore, the environment protection toilet has the advantages of integrating feces collection and treatment, thus reducing secondary pollution of the feces.

Owner:珠海国青酒店管理有限公司

Method for carrying out load test on bridge support frame by prefabricated parts moved by electrically operated gallows frames

InactiveCN102012314BReduce collapse accidentsReduce casualtiesMachine part testingGallowsStandard test

Owner:CHINA FIRST METALLURGICAL GROUP

A method for preparing 4,6-dihydroxypyrimidine

The invention belongs to the technical field of 4,6-dihydroxypyrimidine synthesis, and specifically relates to a method for preparing 4,6-dihydroxypyrimidine, comprising the following steps: (1) cyclization reaction; (2) cooling and dissolution; (3) ) Alcohol distillation under reduced pressure; (4) Acidification and separation; (5) Washing; (6) Adsorption; (7) Recovery of formic acid; (8) Recovery of sodium chloride; (9) Analysis. The method provided by the invention absorbs 4,6-dihydroxypyrimidine in the acidified wastewater through the adsorption resin, which not only improves the product yield, reduces the content of organic matter in the wastewater, solves the disadvantage of difficult wastewater treatment, but also improves the by-product The quality of sodium chloride reduces the content of organic matter in the by-product salt, which has good economic and social benefits.

Owner:潍坊滨海石油化工有限公司

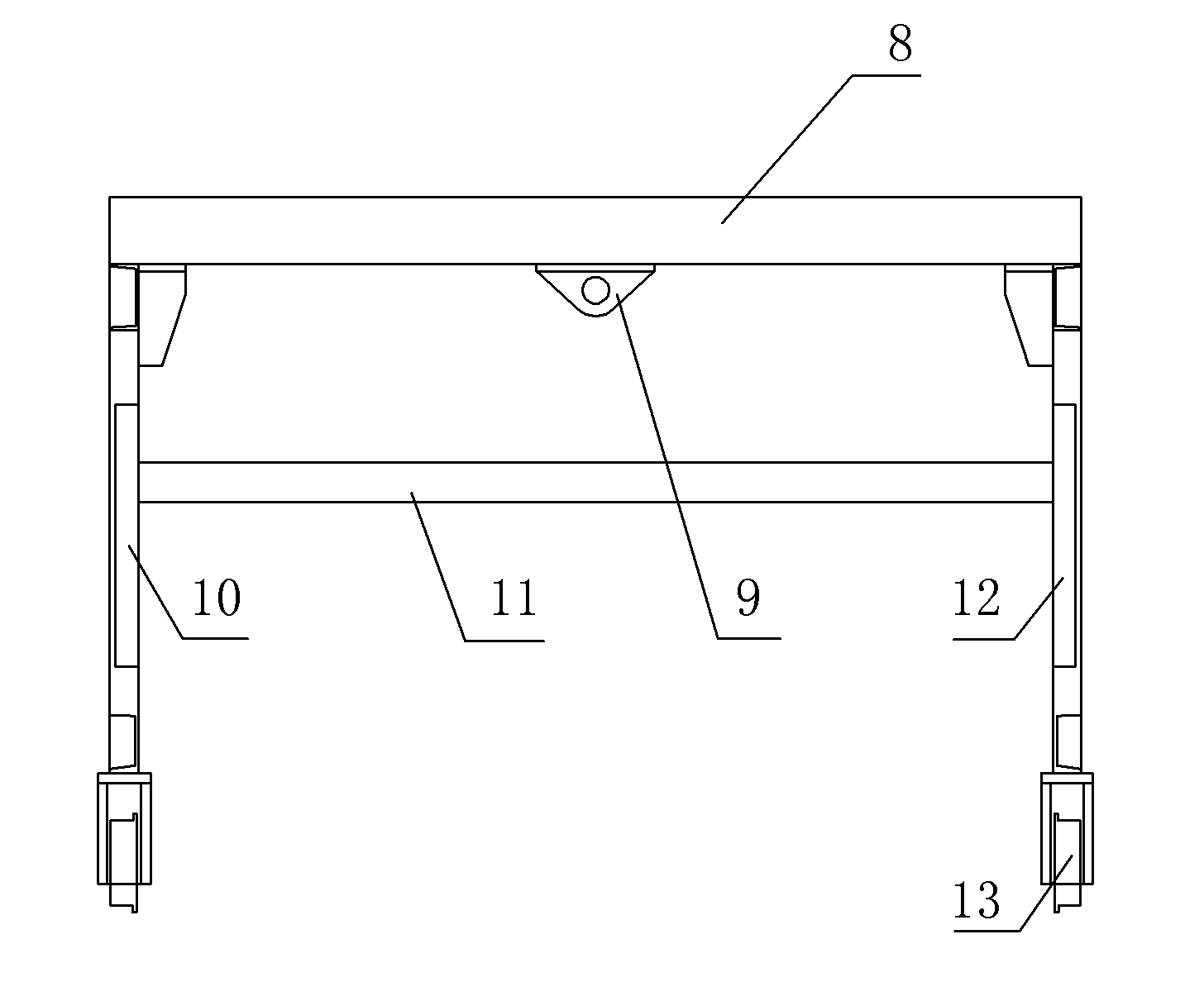

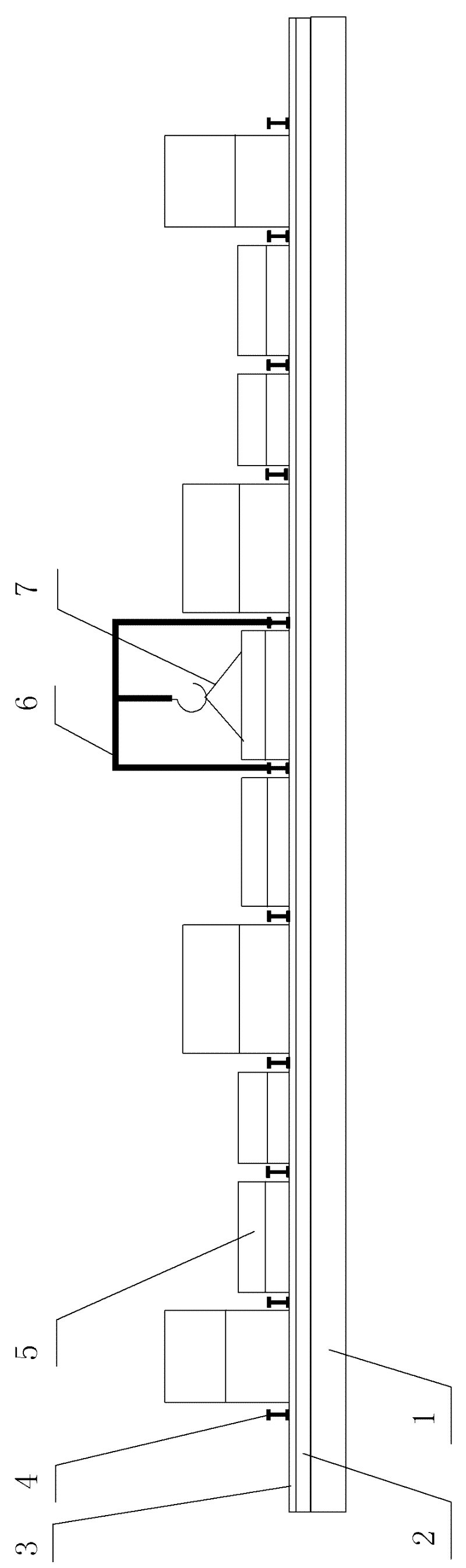

Method for performing load test for bridge support frame with hand-propelled movable prefabricated part

InactiveCN102023092BReduce collapse accidentsReduce casualtiesMachine part testingEngineeringStandardization

The invention relates to a method for performing a load test for a bridge support frame. The method for performing the load test for the bridge support frame with a hand-propelled movable prefabricated part is characterized in that the method comprises the following steps of: firstly installing a load special mould on a box girder mould arranged on the bridge support frame; installing a pluralityof tracks on the load special mould along the vertical direction of the bridge support frame; installing door-shaped hangs on the tracks; pushing the door-shaped hangs with hands to realize the horizontal transportation of the prefabricated part for carrying out the hanging and release of a first layer of prefabricated part, performing load test detection for the bridge support frame, and then carrying out the hanging and release of a second layer of prefabricated part after the requirement of load test detection is reached; and carrying out the detection again after finishing loading; unloading after requirements of testing and detecting are reached, wherein the second layer of prefabricated part is unloaded firstly, and the first layer of prefabricated part is unloaded after the second layer of prefabricated part is completely unloaded. The method has good reliability and safety, and also has high accuracy for test measure standardization and load simulation.

Owner:CHINA FIRST METALLURGICAL GROUP

Method for carrying out load test on bridge support frame by prefabricated parts moved through tractive walking

InactiveCN102012313BReduce collapse accidentsReduce casualtiesMachine part testingTest efficiencyGallows

Owner:CHINA FIRST METALLURGICAL GROUP

Modified phosphogypsum powder and product thereof

The invention relates to a modified phosphorus gypsum powder and a product thereof and belongs to the technical field of phosphorus chemical engineering or building material. The invention aims to provide a modified phosphorus gypsum powder which needs no calcination, improves quality, saves energy, increases benefit and protects environment and a product thereof. The invention comprises the following main technical point: 70 to 75 portions of phosphorus gypsum, 1 to 5 portions of a crystal transformation agent and 20 to 25 portions of an activating agent; the crystal transformation agent is one or more than two of aluminium sulfate, ferric sulfate and sodium sulfate; the activating agent is one or more than two of slag, cement, quicklime, alum slag and high bauxite; the material compositions of the crystal transformation agent are prepared to form an aqueous solution; the raw materials of the activating agent are mixed and grinded to form a powder body; the agglomerated phosphorus gypsum is shattered, is thrown into a wheel grinding and mixing machine, is subjected to roller compaction and mixing and is cured for 24 hours around; when free water is detected not more than 3 percent, the phosphorus gypsum is thrown into a pulverizer; the fineness is controlled to be 0.08 mm; and the modified phosphorus gypsum powder is obtained. The modified phosphorus gypsum powder has remarkable economic, social and environmental benefits.

Owner:ANHUI DEJIA NEW BUILDING MATERIALS

A kind of preparation method of recyclable artificial turf

The invention relates to a recyclable artificial turf. The recyclable artificial turf comprises grass fibers, bottom cloth and an adhesive layer; the bottom cloth is arranged under the grass fibers; the adhesive layer is arranged under the bottom cloth; during preparation, firstly, components of glue water in weight parts are 95-100 parts of aqueous polyolefin dispersion, 0.5-1 parts of thickeningagents, 1-5 parts of deionized water and 2-3 parts of pigment fillers; secondly, the turf is correspondingly coated for two times, coated and dried; and thirdly, the turf is perforated and cut to obtain the recyclable artificial turf. According to the recyclable artificial turf, the preparation method is simple, the steps are easy to operate, the wire drawing performances, such as breaking strength, elongation, wire drawing section and appearance, of the prepared recyclable artificial turf satisfy requirements of manufacturing the artificial turf through wire redrawing, and better water resistance is realized.

Owner:无锡市桑丽人造草坪地毯有限公司

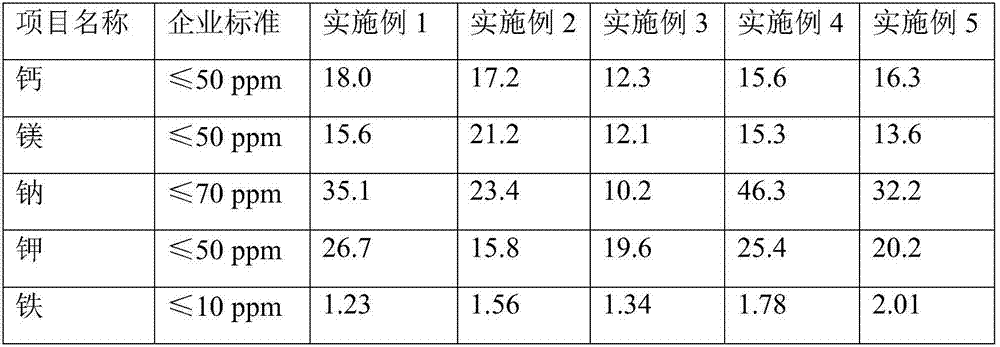

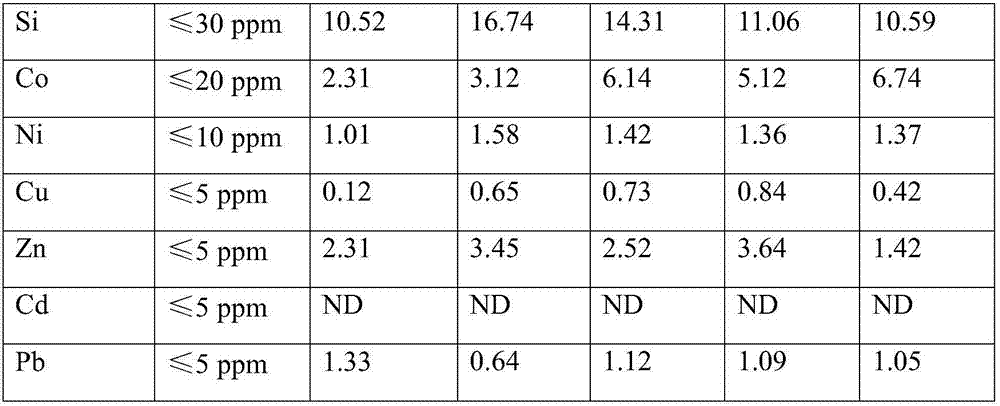

A preparation method for high-purity manganese source applied to lithium battery cathode material

ActiveCN105645475BMeet the requirementsHigh purityCell electrodesManganates/permanganatesManganateManganese

The invention relates to the technical field applied to lithium battery anode materials (lithium manganate, nickel, cobalt and lithium manganate tri-element material and manganese, iron and lithium phosphate), in particular to a preparation method of a high-purity manganese source (manganese hydroxide) applied to lithium battery anode materials. The preparation method includes: adjusting concentration of a manganese sulfate solution to 30-35 Be';adding hydrogen peroxide into the manganese sulfate solution to remove iron impurity in the solution, adding sulfurizing salt to remove heavy metal ions, and adjusting pH value to 4.5-5.0 to obtain filtered filtrate; feeding nitrogen into a reaction kettle for protection, injecting the obtained filtrate into the reaction kettle, dropping ammonia into the reaction kettle at constant speed, holding temperature for reaction after dropping of ammonia is completed, washing precipitate, and drying to obtain a finished product. By using the preparation method, the defect that an existing process utilizing high-purity manganese carbonate or high-purity metal manganese and adding acid for dissolving at home and abroad is limited by high-purity raw materials is overcome, and the product is shallow peach hexagonal crystals, is high in purity and little in impurity and meets using requirements on the lithium battery anode materials.

Owner:HUBEI HAOYUAN MATERIAL TECH

A high-efficiency pyrolysis recovery method for silicone rubber waste

ActiveCN111040243BReduce dosageImprove stabilitySilicon organic compoundsPlastic recyclingPolymer scienceDepolymerization

The invention relates to a method for cracking and recovering silicon rubber waste, which comprises the following steps: crushing the silicon rubber waste; double cracking: putting the crushed silicon rubber particles into a cracking reaction kettle, and then adding a high-temperature-resistant inert solvent and an alkali metal hydroxide , Schiff alkali metal complexes, depolymerization at a high temperature of 140-200°C under a nitrogen atmosphere to obtain crude DMC; the amount of the alkali metal hydroxide is 5%-8% of the weight of the silicone rubber waste; polymerization rearrangement ; Decolorization and deodorization to obtain refined cyclosiloxane DMC. The cracking recovery method of silicone rubber waste organically connects double cracking and polymerization rearrangement, and rationally arranges, so that less alkaline catalysts are used in recovery, waste silicone rubber recovery efficiency is higher, and waste generated is less, which meets the requirements of The advantages of a circular economy.

Owner:GUANGZHOU BAIYUN CHEM IND

Environment-friendly train toilet

The invention discloses an environment-friendly train toilet, comprising a toilet bowl, a touch switch, a flushing tank, a pending tank, a storage tank and a controller; the toilet bowl is connected with the pending tank below the toilet bowl through a pipeline; the connection of the pipeline with the pending tank is provided with a switch; the storage tank is arranged below the pending tank; thestorage tank is connected with the pending tank through a pipeline, and the connection of the pending tank with the pipeline is provided with a switch; a storage bag and an inflatable bag are arrangedin the storage tank; one end of the inflatable bag is connected with a pressure system of a train; the storage tank is also provided with a microwave generator; the microwave generator heats and evaporates water in excrement; vapor enters a condenser and cools through a condensing pipe mounted on the storage tank; the cooled water is collected in a water collection tank; a water pump arranged inthe collection tank conveys condensate in the water collection tank into the flushing tank; a weigher is also mounted at the bottom of the storage tank. Therefore, the environment-friendly train toilet integrates excrement collection and treatment so that secondary contamination by excrement is lessened.

Owner:SUZHOU BOHAN ENVIRONMENTAL PROTECTION TECH

Method for extracting cellulose, lignose and compound fertilizer from cotton-seed hull

InactiveCN101476252BIncrease profitSolve the disadvantages that only a single product can be extractedLignin derivativesPaper material treatmentCelluloseFiber

The invention provides a method for combined producing cellulose, lignin and composite fertilizer from cottonseed shell, which comprises the following steps: adding lignin dissolving agent and water into a container according to the proportion of 1-5:1000; adding 10-20 liquid amount of cottonseed shells; heating to 70-90 degrees centigrade and keeping for 6-10 hours; separating out crude fibers, rinsing, refining and drying to obtain the finished fiber product; sending the rinsed solution into the socking container for reuse; acidifying the solution in the first boiling pool, and press filtering to precipitate solid that is lignin; adjusting the pH value of the solution after lignin extraction to neutral, concentrating, drying, granulating to obtain composite fertilizer. Besides the cellulose, the invention can co-produce lignin and composite fertilizer, changes improves the abuses of single product, water resource waste and serious environment pollution existing in the current technologies in our country.

Owner:JIAHE BIOTECH

Resource utilization and harmless treatment method for gold tailings

PendingCN114308375ARealize "Zero Emissions"No pollution in the processSolid separationOre concentrateMining engineering

The invention discloses a resource utilization and harmless treatment method for gold tailings. Underflow obtained after ore dressing plant tailing slurry desliming enters a settling machine to be graded, the graded underflow of the settling machine is sieved and subjected to coarse sand removal to obtain a coarse sand product, and undersize tailing slurry is subjected to magnetic separation to obtain a non-magnetic product and a magnetic product; wherein non-magnetic products are graded by adopting a cyclone, graded overflow enters a thickener to be concentrated, underflow of the cyclone and underflow of the thickener are mixed and then dehydrated, and feldspar concentrate is obtained; wherein magnetic products are classified through a cyclone and then conveyed to a high-frequency vibrating screen for dehydration, and magnetic separation minerals are obtained; mixing tailing slurry under the high-frequency vibrating screen with the desliming overflow and the graded overflow, concentrating, and performing filter pressing to obtain a fine silt tailing filter cake, and enabling return water to enter a sedimentation tank for recycling. A gold tailing disposal mode is provided for the gold mine, the problem of unbalanced mining and filling of the gold mine is solved, and economic benefits and environmental benefits are remarkable.

Owner:SHANDONG GOLD MINING LINGLONG +1

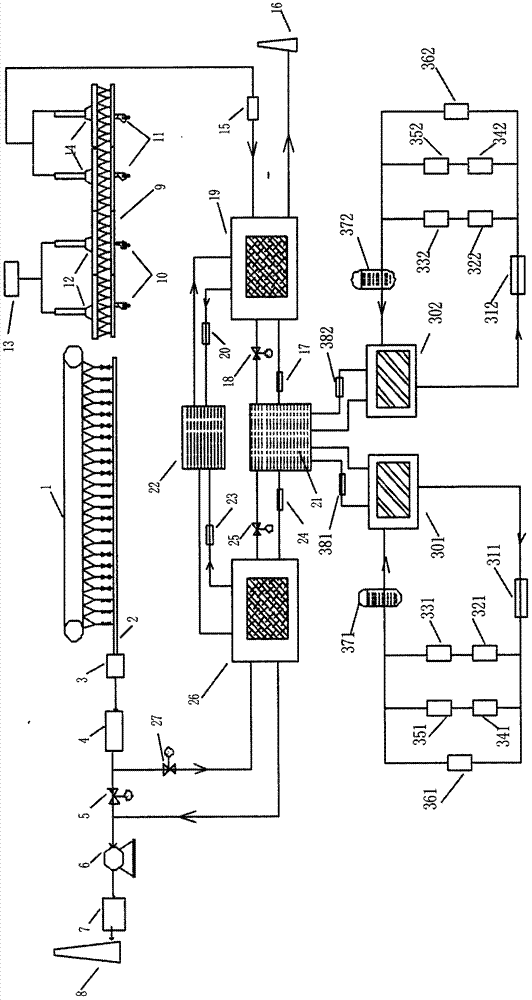

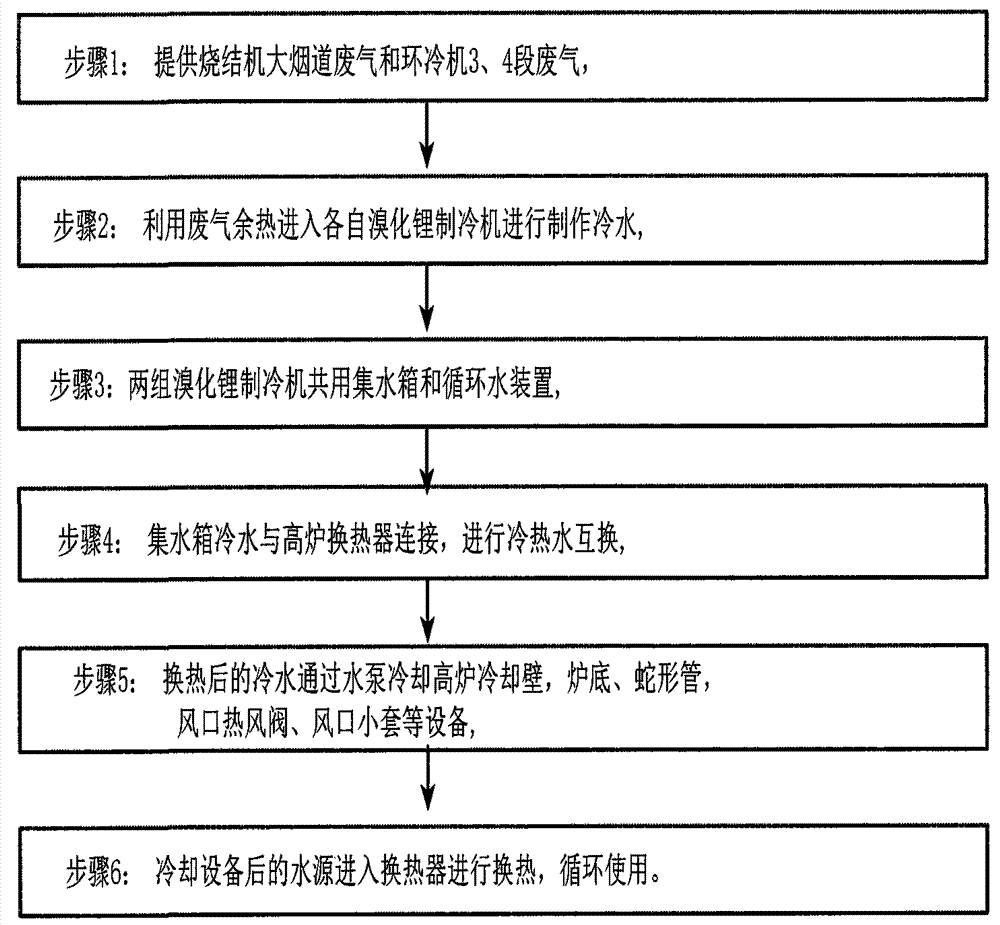

A device for cooling circulating water of blast furnace by using low-temperature residual heat of sintering

ActiveCN105318735BReduce wasteImprove cooling effectClimate change adaptationEnergy efficient heating/coolingLithium bromideHot blast

Owner:浙江源程冶金科技发展有限公司

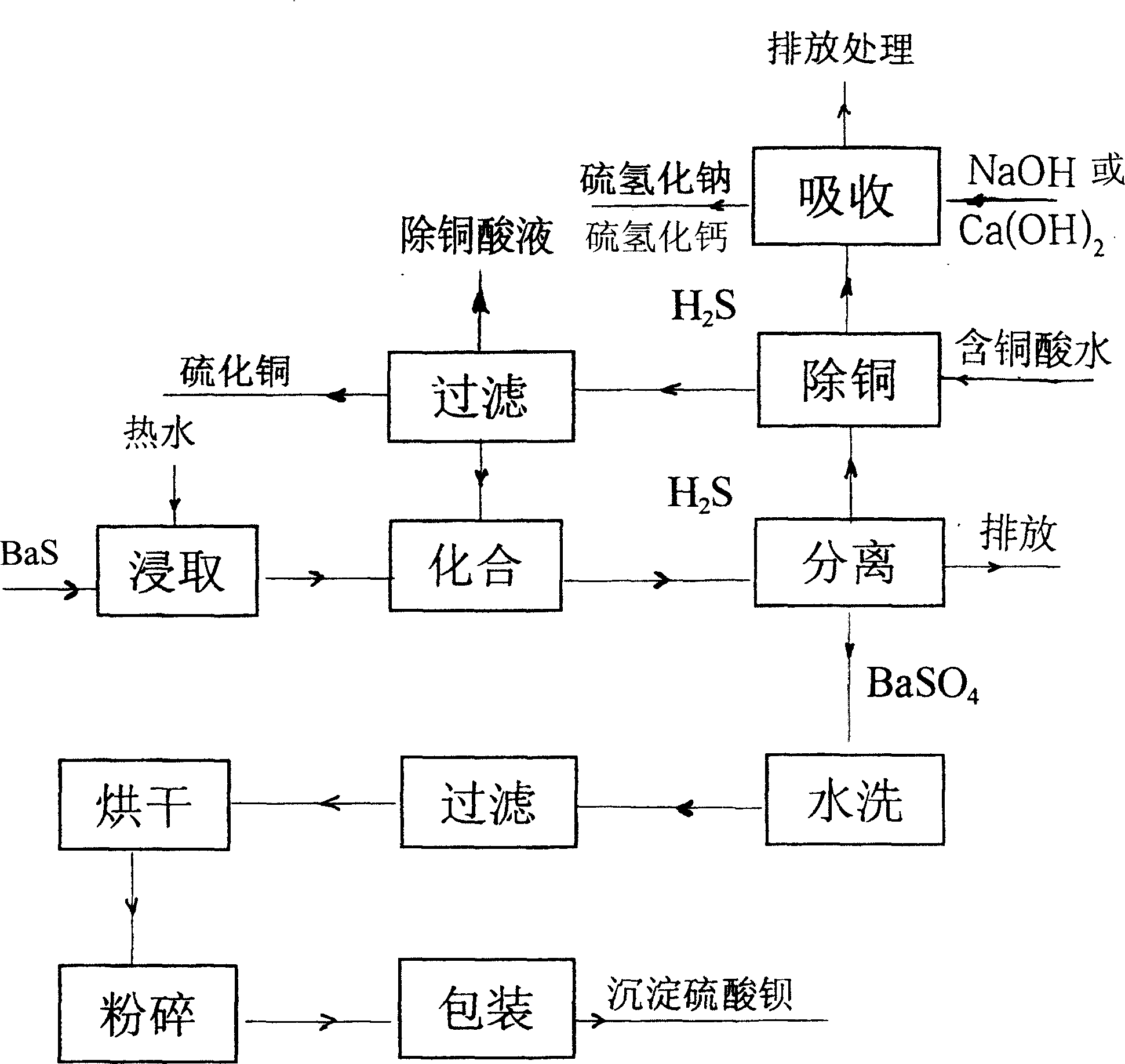

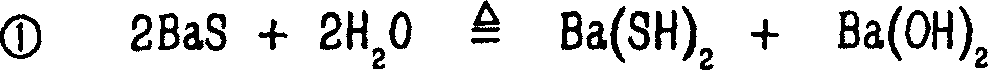

Method for treating copper-containing waste acid water

ActiveCN1321910CTake advantage ofWide range of usesWater/sewage treatmentSodium hydrosulfideChemical products

The treatment method for copper-containing acid sewage comprises: treating the sewage with barium sulphide or sodium sulfide to prepare a plurality of chemical products, such as barium sulfate, and can recycle acid liquid with H+ content more than 16% as iron rust remover. This invention has no pollution and well social and economic benefits.

Owner:CHINA PINGMEI SHENMA GRP KAIFENG XINGHUA FINE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com