Technological method for preparation of sodium carbonate from sodium sulfate

A process method, sodium sulfate technology, applied in the direction of carbonate preparations, etc., can solve the problems of high production cost, pollution, salt loss environment, etc., and achieve the effect of realizing resource recycling, reducing steam consumption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

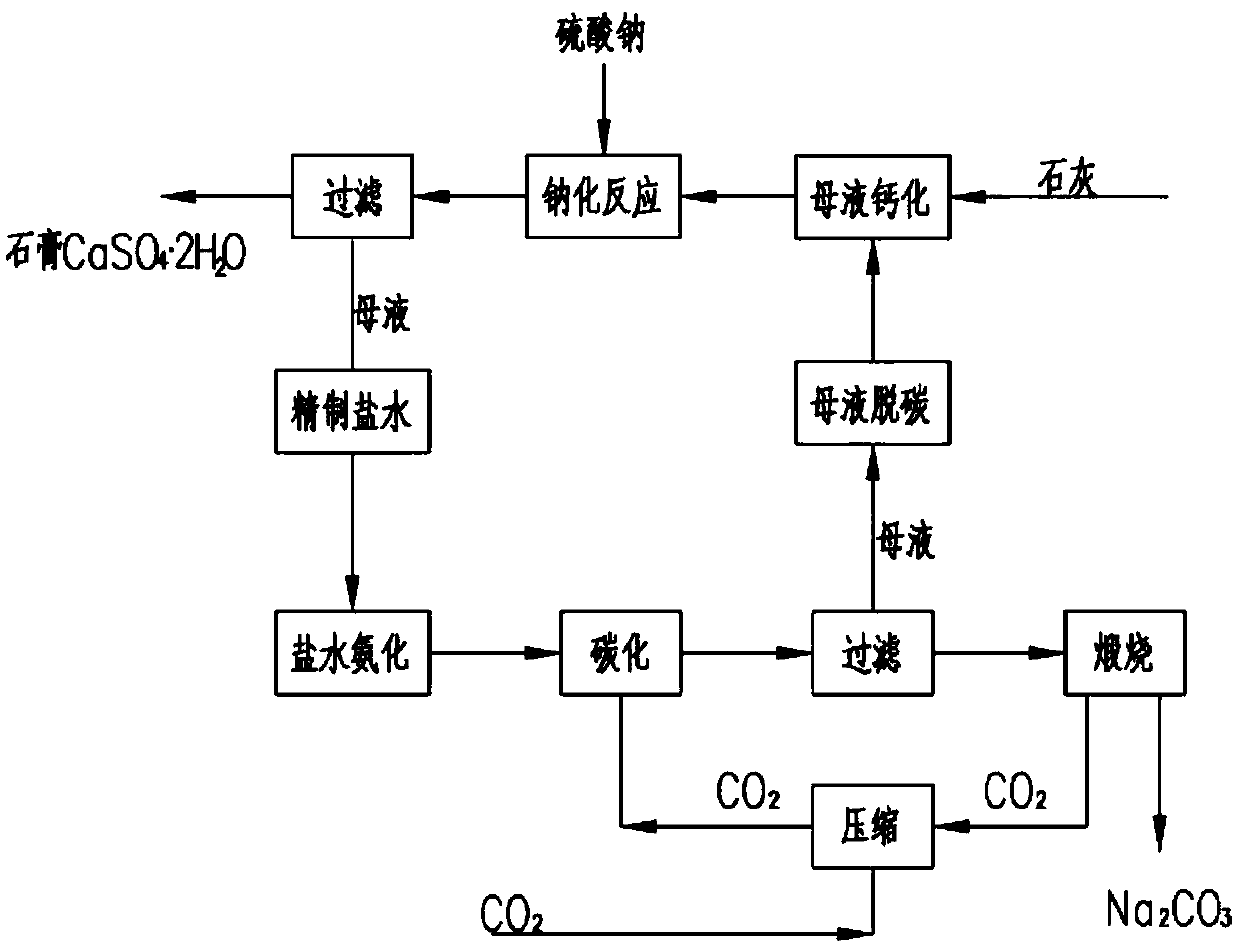

[0033] Basic technological process of the present invention is implemented as follows:

[0034] The specific process is as follows: sodium sulfate and limestone are used as the main raw materials, chloride ions and ammonia are used as intermediates in the process, and the main products are sodium carbonate and gypsum.

[0035] The main by-products are gypsum (CaSO 4 2H 2 O).

[0036] The main reaction process is as follows

[0037] 1. The main reaction equation of carbonation:

[0038] 2NaCl+2NH 3 +H 2 O+CO 2 =2NaHCO 3 ↓+2NH 4 Cl

[0039] 2. The main equation of thermal decomposition reaction:

[0040] NH 4 HCO 3 (heating) = NH 3 +H 2 O+CO 2 ↑

[0041] 2NaHCO 3 (heating) = Na 2 CO 3 +H 2 O+CO 2 ↑

[0042] Na 2 CO 3 +2NH 4 Cl (heating) = 2NH 3 +H 2 O+CO 2 ↑+2NaCl

[0043] 3. The main equation of calcification reaction (dissolving calcium hydroxide):

[0044] 2NH 4 Cl+Ca(OH) 2 =2NH 4 OH+CaCl 2

[0045] 4. Sodiumization reaction equation:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com