Production system and production method for anhydrous aluminum fluoride

A water fluoride, production system technology, applied in the direction of aluminum fluoride, aluminum halide, etc., can solve the problems of high impurity content in products, high raw material cost of aluminum fluoride products, etc., and achieve stable product quality, significant social and environmental benefits , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 and Embodiment 2 are two specific embodiments of the anhydrous aluminum fluoride production system provided by the present application. Embodiment 3 and Embodiment 4 are two specific embodiments of the production method of anhydrous aluminum fluoride provided by the present application.

[0022] Example 1

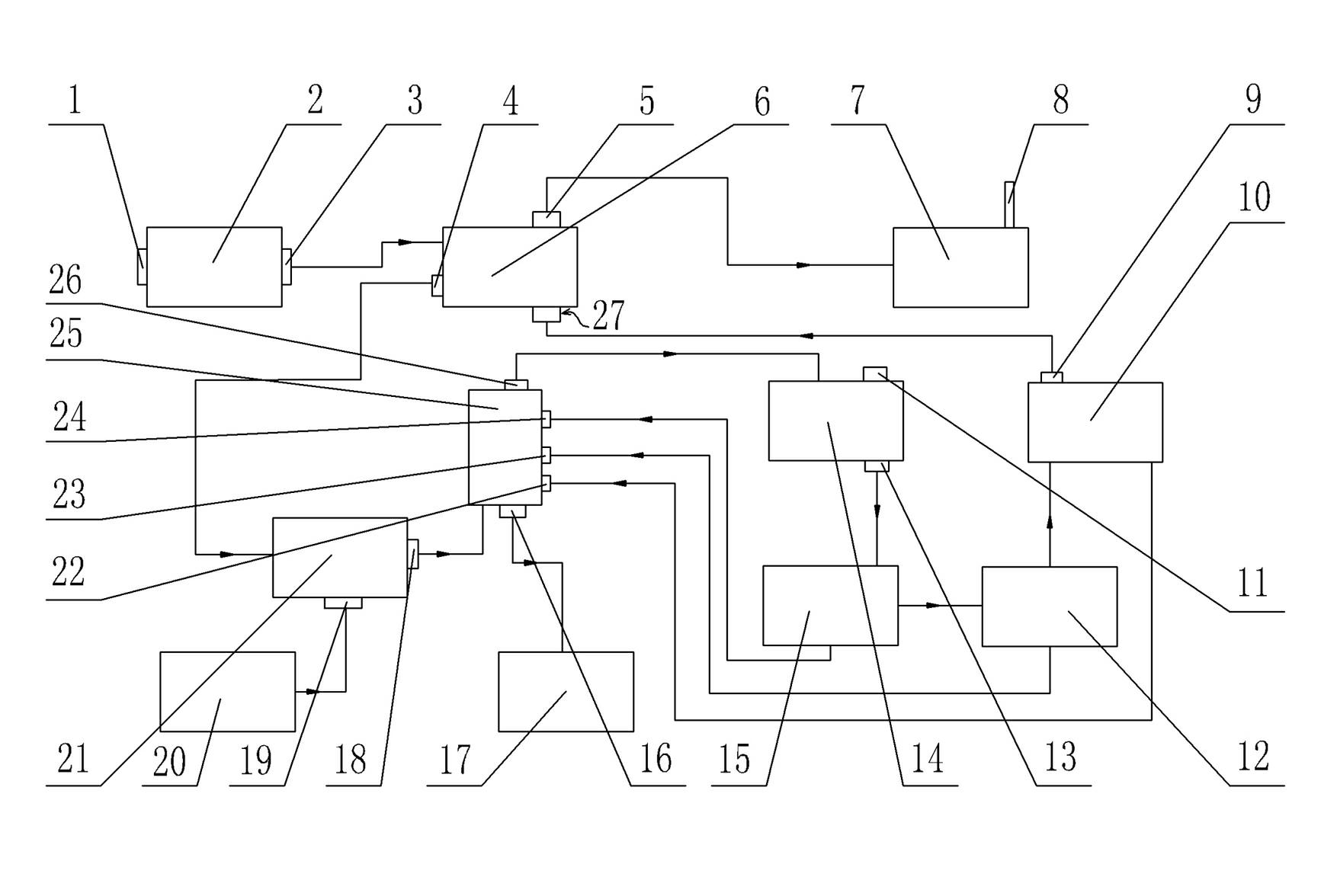

[0023] Such as figure 1As shown, a production system of anhydrous aluminum fluoride includes a hydrofluoric acid evaporator 2, and the hydrofluoric acid evaporator 2 is provided with a hydrofluoric acid inlet 1 and a first outlet 3 of hydrogen fluoride gas, and a first outlet 3 of hydrogen fluoride gas Tail gas heat exchanger 6 is arranged in series, and tail gas heat exchanger 6 is provided with tail gas inlet 27, tail gas outlet 5 and hydrogen fluoride gas second outlet 4, and tail gas outlet 5 string is provided with tail gas washing device 7, and tail gas washing device 7 is provided with Tail gas evacuation pipeline 8, hydrogen fluoride gas second...

Embodiment 2

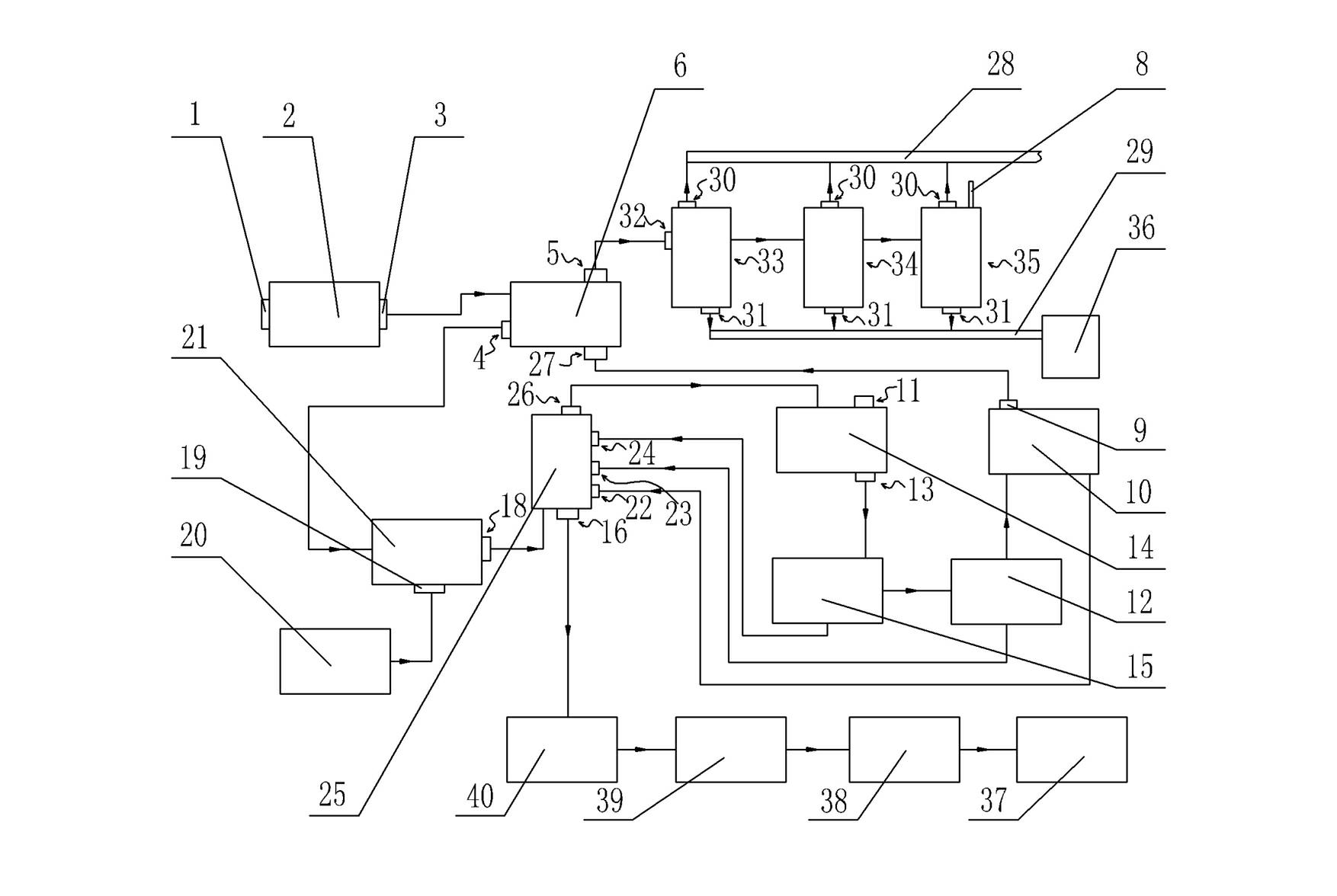

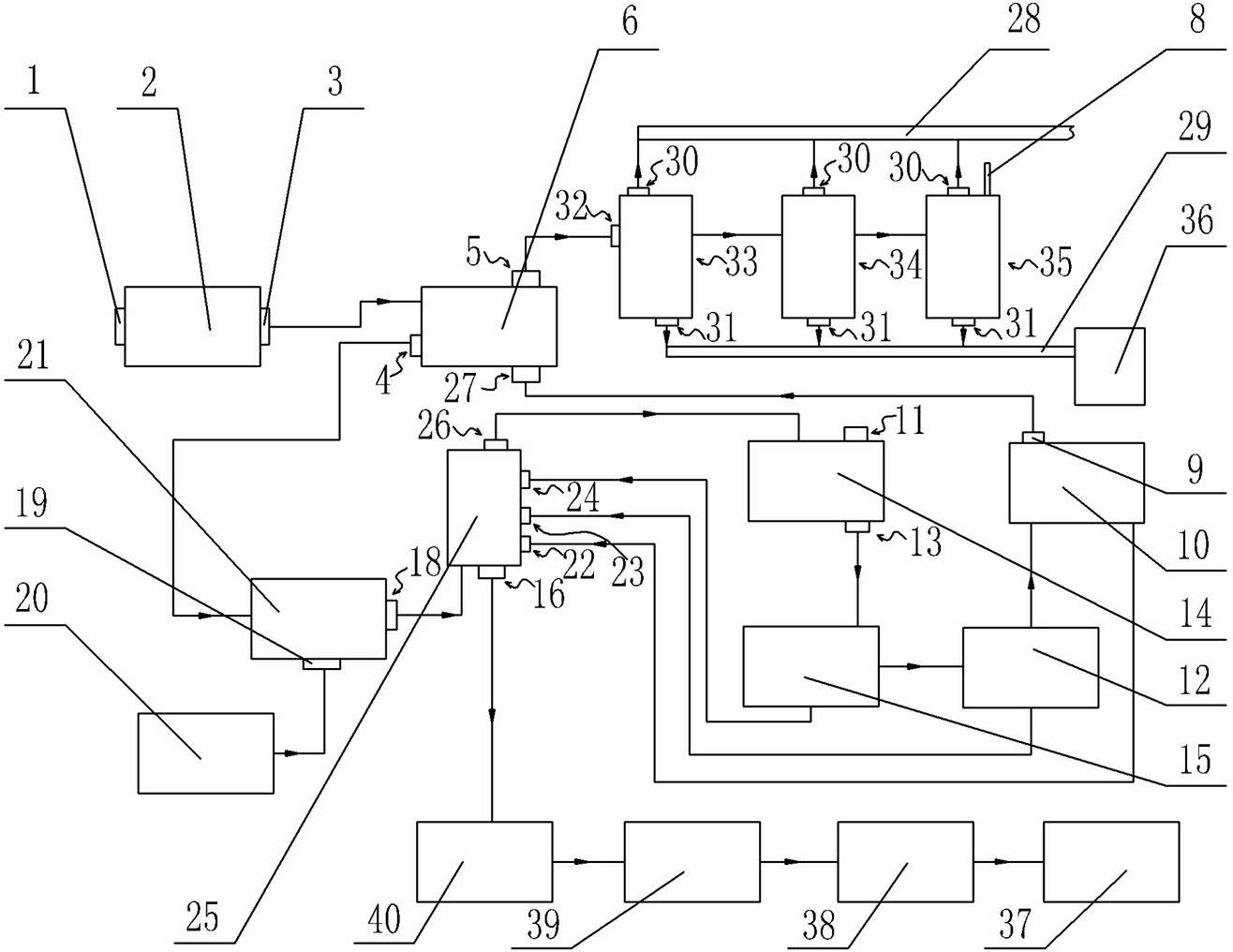

[0026] Such as figure 2 As shown, a production system of anhydrous aluminum fluoride includes a hydrofluoric acid evaporator 2, and the hydrofluoric acid evaporator 2 is provided with a hydrofluoric acid inlet 1 and a first outlet 3 of hydrogen fluoride gas, and a first outlet 3 of hydrogen fluoride gas A tail gas heat exchanger 6 is arranged in series, and the tail gas heat exchanger 6 is provided with a tail gas inlet 27, a tail gas outlet 5, and a second hydrogen fluoride gas outlet 4, and the tail gas outlet 5 is sequentially provided with a first Venturi scrubber 33, a second Venturi scrubber Li scrubber 34 and the 3rd Venturi scrubber 35, the first Venturi scrubber 33 is provided with the first Venturi scrubber tail gas inlet 32, the first Venturi scrubber tail gas inlet 32 is arranged on the tail gas heat exchanger 6 The tail gas outlet 5 on the top is connected, the third Venturi scrubber 35 is provided with a tail gas emptying pipeline 8, and the first Venturi scru...

Embodiment 3

[0029] A kind of production method of anhydrous aluminum fluoride, concrete steps are:

[0030] (1) Anhydrous hydrofluoric acid feed

[0031] The anhydrous hydrofluoric acid pump sends 1000kg of anhydrous hydrofluoric acid to the hydrofluoric acid evaporator 2 after being metered by the flow meter and the control valve, and the anhydrous hydrofluoric acid is vaporized by steam heating in the hydrofluoric acid evaporator 2 Become hydrogen fluoride gas, then hydrogen fluoride gas flows out from hydrogen fluoride gas first outlet 3, enters tail gas heat exchanger 6 through control valve, carries out heat exchange with the tail gas from four-stage airflow reactor 10 in tail gas heat exchanger 6, then from hydrogen fluoride The gas second outlet 4 comes out and enters the gas mixing chamber 21, mixes with the hot air provided by the hot blast stove 20 in the gas mixing chamber 21, and is sent to the bottom of the double-layer fluidized bed reactor 25 through the mixed gas outlet 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com