Wet method desulfurizing white smoke trailing treatment device and method

A technology of wet desulfurization and white smoke, applied in the direction of chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems affecting corporate image, hot air pollution, poor visual effects, etc., to improve visual effects and reduce emissions The effect of volume and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention are described below through specific embodiments. On the premise that there is no conflict with the purpose of the present invention, the embodiments mentioned below and the technical features in the embodiments can be combined with each other.

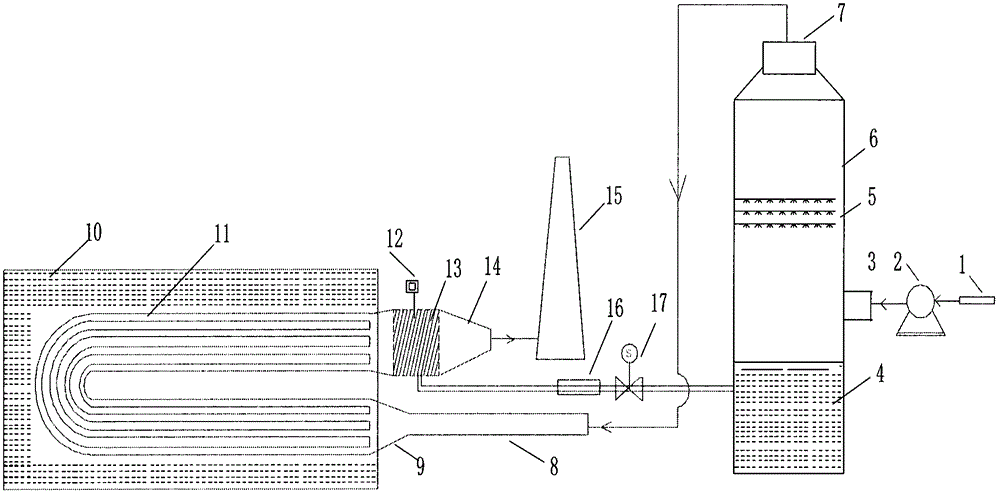

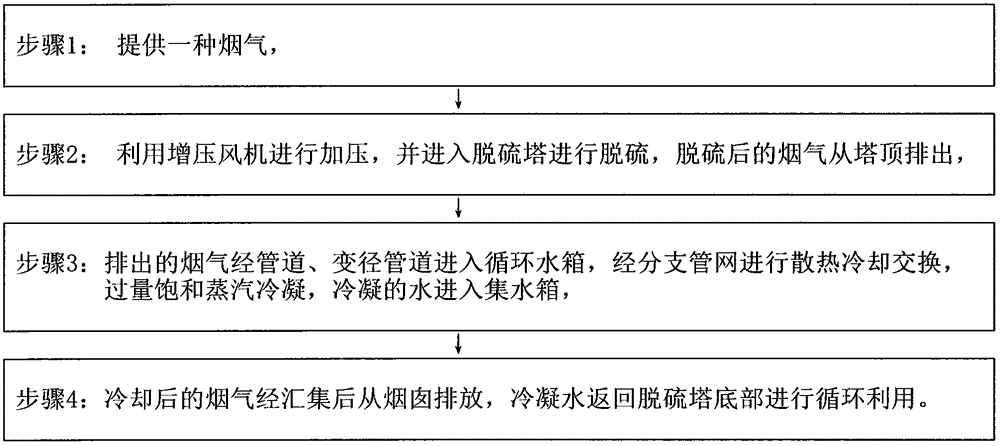

[0029] Such as figure 1 As shown, the marks in the figure are: 1-flue gas pipe, 2-boosting fan, 3-flue gas inlet, 4-lime slurry, 5-spray layer, 6-desulfurization absorption tower, 7-desulfurization tower outlet, 8-Pipeline, 9-Inlet reducing pipe, 10-Cooling water tank, 11-Branch pipe network, 12-Liquid level gauge, 13-Collecting tank, 14-Exit reducing pipe, 15-Chimney, 16-Water pump, 17- valve.

[0030] The technical scheme adopted in the present invention is: after the flue gas is desulfurized in the desulfurization absorption tower by the booster fan, the flue gas enters the water tank after being changed in diameter and branched through the pipeline, and then cools and radiat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com