Wire-cut electrical discharge machining (WEDM) nanosecond pulse power supply system and control method

A technology of electric spark wire and pulse power supply, which is applied in the direction of electric pulse generator circuit, energy storage element to generate pulse, circuit, etc., can solve the problem of cutting surface finish limit and other problems, and achieve the goal of improving surface finish, reducing loss and avoiding energy loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

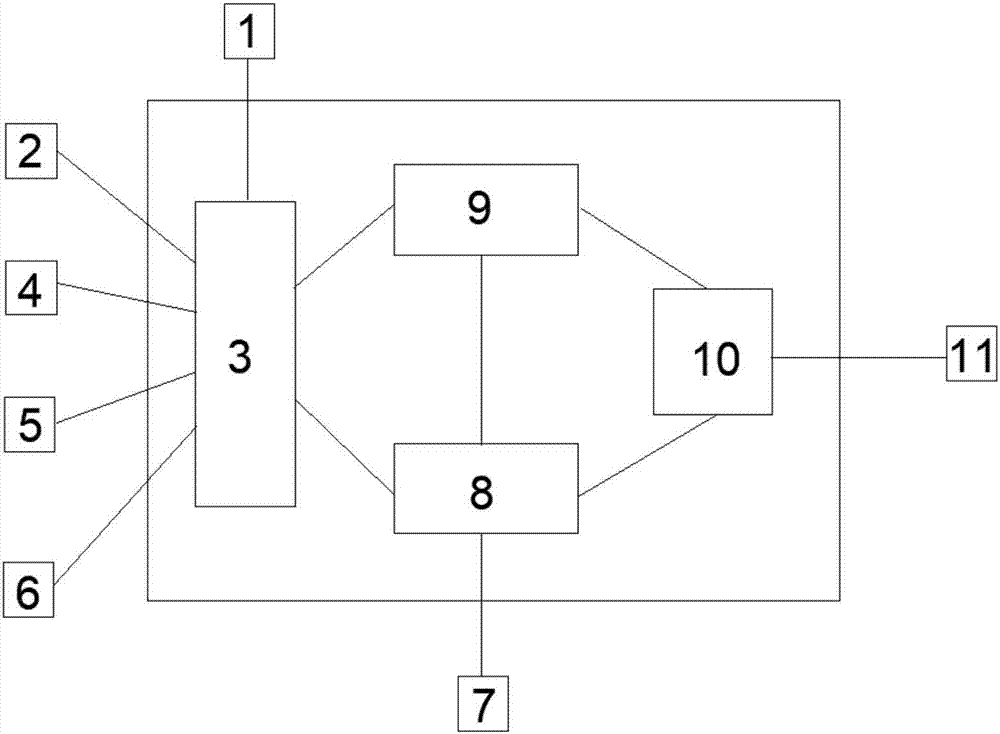

[0031] Such as figure 1 As shown, a nanosecond-level pulse power supply system for wire electric discharge cutting includes a power supply body, and the power supply body includes a microcontroller system module 3, a rectification module 10, a power conversion module 9 and a high-frequency pulse module 8, and the The microcontroller system module 3 adopts an ARM architecture micro-control chip, and one end of the microcontroller system module 3 is externally connected with an auxiliary power supply input interface 1 and several input and output interfaces, and the input and output interfaces include a pulse output enabling input interface 2, Silk speed control interface 4, configuration number interface 5 and communication interface 6, the other end of the microcontroller system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com