A preparation method for high-purity manganese source applied to lithium battery cathode material

A positive electrode material and manganese source technology, which is applied in the field of high-purity manganese source preparation, can solve the problems of limited raw material sources, unsatisfactory economic and social benefits, and the inability to obtain high value-added utilization of manganese-containing waste liquid. The effect of high product purity and high product added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

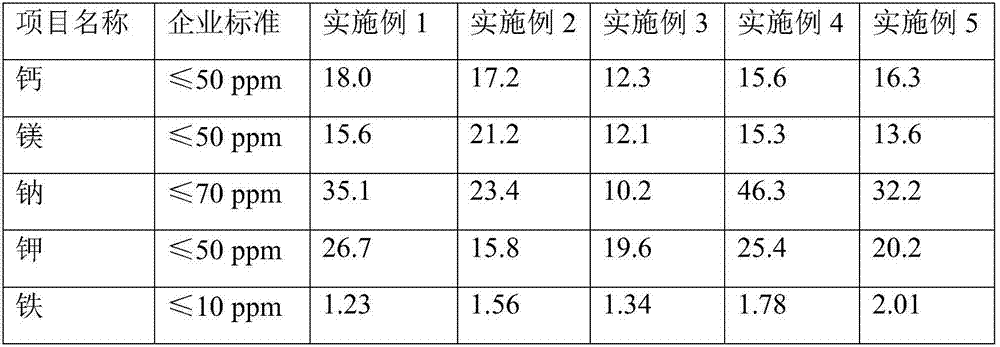

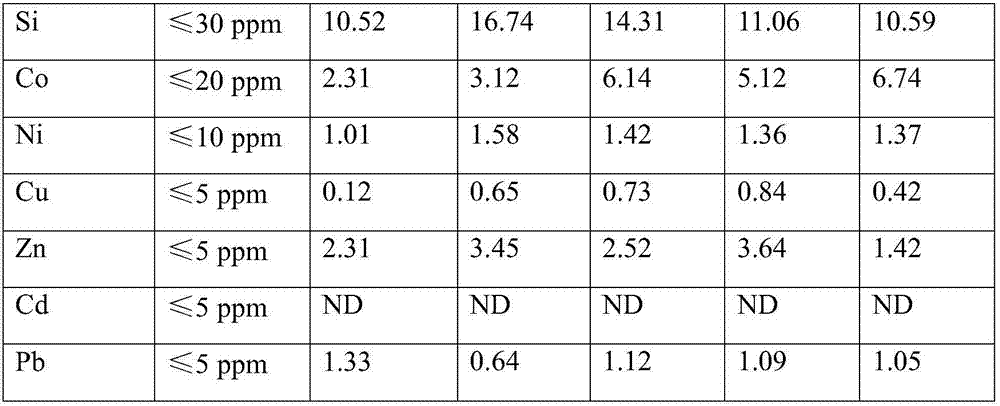

Examples

Embodiment 1

[0030] A preparation method for high-purity manganese source applied to lithium battery cathode material

[0031] 1) Manganese source preparation: adjust the concentration of manganese sulfate solution to 30 ° Be';

[0032] 2) Manganese source impurity removal: In the manganese sulfate solution of step 1), add hydrogen peroxide to remove iron impurities in the solution, react for 50 minutes, filter to obtain filtrate 1, add sulfide salt to remove heavy metal ions in the filtrate 1, and adjust the pH value 4.5, the filtered filtrate 2 is for standby; this step is in the high temperature stage, pay attention to the position of the liquid level, and keep it not lower than the original liquid level when pressing the filter;

[0033] 3) prepare the mass fraction of 15% ammonia water, measure the manganese ion concentration of the filtrate, pass nitrogen protection in the reaction kettle, inject the filtrate 2 obtained in step 2) into the reaction kettle, drip the ammonia water into...

Embodiment 2

[0046] A preparation method for high-purity manganese source applied to lithium battery cathode material

[0047] 1) Manganese source preparation: adjust the concentration of manganese sulfate solution to 32°Be';

[0048] 2) Manganese source impurity removal: In the manganese sulfate solution of step 1), add hydrogen peroxide to remove iron impurities in the solution, react for 30 minutes, filter to obtain filtrate 1, add sulfide to the filtrate 1 to remove heavy metal ions, and adjust the pH value 5.0, the filtered filtrate 2 is set aside; this step is in the high temperature stage, pay attention to the position of the liquid level. When pressing the filter, it must be kept not lower than the original liquid level;

[0049] 3) prepare the mass fraction of 15% ammonia water, measure the manganese ion concentration of the filtrate, pass nitrogen protection in the reaction kettle, inject the filtrate 2 obtained in step 2) into the reaction kettle, drip the ammonia water into th...

Embodiment 3

[0062] A preparation method for high-purity manganese source applied to lithium battery cathode material

[0063] 1) Manganese source preparation: adjust the concentration of manganese sulfate solution to 35 ° Be';

[0064] 2) Manganese source impurity removal: In the manganese sulfate solution of step 1), add hydrogen peroxide to remove iron impurities in the solution, react for 40 minutes, filter to obtain filtrate 1, add sulfide salt to remove heavy metal ions in the filtrate 1, and adjust the pH value It is 4.8, and the filtered filtrate 2 is set aside; this step is at a high temperature stage, pay attention to the position of the liquid level. When pressing the filter, it must be kept not lower than the original liquid level;

[0065] 3) prepare the mass fraction of 15% ammonia water, measure the manganese ion concentration of the filtrate, pass nitrogen protection in the reaction kettle, inject the filtrate 2 obtained in step 2) into the reaction kettle, drip the ammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com