A high-efficiency pyrolysis recovery method for silicone rubber waste

A technology of silicone rubber waste and recycling method, applied in the field of materials, can solve the problems of increased process difficulty, large acid dosage, high process temperature, etc., and achieves the effects of improving cracking efficiency, less basic catalyst, and lowering process temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) pulverization: the dimethyl silicone rubber waste is washed, cut into pieces, and dried, and after the surface impurities are cleaned by ultrasonic or mechanical vibration, the silicone rubber waste is pulverized into particles by a rubber crusher, and the particle size is 1-2mm;

[0043] (2) double cracking: put the crushed silicone rubber particles into the cracking reactor, then add phenyl ether solvent and the copper complex of 0.3% of sodium hydroxide by weight of silicone rubber and 0.3% by weight of sodium hydroxide by adding phenyl ether solvent Depolymerization was carried out at a high temperature of 150 °C under a nitrogen atmosphere for 3 h to obtain crude DMC with a content of 79% cracked products;

[0044] (3) polymerization rearrangement: the crude DMC is added to the rearrangement reactor, then the potassium hydroxide-methanol solution that the concentration is 1% is added, and the consumption is 15% of the crude DMC quality, and 1% of the crude DMC q...

Embodiment 2

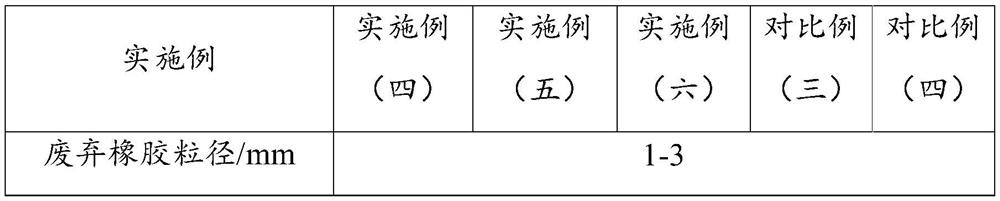

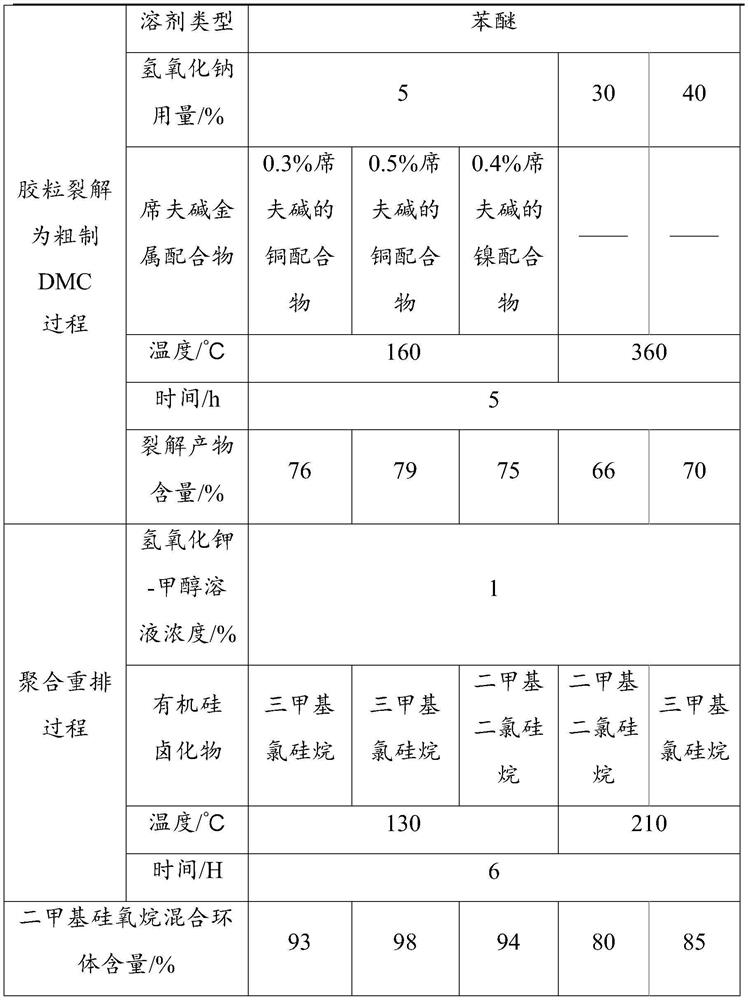

[0047] (1) pulverization: the dimethyl silicone rubber waste is washed, cut into pieces, and dried, and after ultrasonic or mechanical vibration cleaning the surface impurities, the silicone rubber waste is pulverized into particles by a rubber crusher, and the particle size is 1-3mm;

[0048] (2) Double cracking: put the crushed silicone rubber particles into the cracking reactor, then add tetraethylene glycol dimethyl ether solvent and sodium hydroxide with an amount of 5% by weight of silicone rubber and 0.5% by weight of sodium hydroxide Depolymerization of the copper complex of fern base was carried out at a high temperature of 170 °C under nitrogen atmosphere for 3.5 h, to obtain crude DMC with a content of cracked products of 82%;

[0049] (3) polymerization rearrangement: the crude DMC is added to the rearrangement reactor, then the potassium hydroxide-methanol solution that the concentration is 1% is added, and the consumption is 15% of the crude DMC quality, and 1.5% ...

Embodiment 3

[0052] (1) pulverization: the dimethyl silicone rubber waste is washed, cut into pieces, and dried, and after ultrasonic or mechanical vibration cleaning the surface impurities, the silicone rubber waste is pulverized into particles by a rubber crusher, and the particle size is 2-3mm;

[0053] (2) double cracking: put the crushed silicone rubber particles into the cracking reactor, then add phenyl ether solvent and the amount of sodium hydroxide that is 5% of the weight of the silicone rubber, 0.4% of the weight of the sodium hydroxide, the nickel coordination of the Schiff base Depolymerization was carried out at a high temperature of 190 °C under nitrogen atmosphere for 5 h to obtain crude DMC with a content of 79% cracked products;

[0054] (3) polymerization rearrangement: the crude DMC is added to the rearrangement reactor, then the potassium hydroxide-methanol solution that the concentration is 1% is added, and the consumption is 15% of the crude DMC quality, and 1.5% of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com