Method for preparing ammonium sulfate and Fe3O4 from titanium dioxide production waste acid solution

A technology of waste acid solution and ammonium sulfate, which is applied in the direction of chemical instruments and methods, ammonium sulfate, ferrous oxide, etc., can solve the problem of unsolvable titanium white waste acid treatment, and operation can not solve the problem of titanium white Problems such as waste acid treatment, low production consumption, etc., to achieve the effect of increasing added value, reducing treatment costs, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) The waste acid solution (mainly containing sulfuric acid and ferrous sulfate) with a mass percentage concentration of 20% in the production of titanium dioxide first passes through the waste heat generated at the kiln tail during the production of titanium dioxide in the previous section, and the waste acid is discharged by using the Venturi tube principle. The concentration is concentrated from the original mass percentage concentration of 20% to 30%, and sent to waste acid and ferrous sulfate storage tanks for temporary storage.

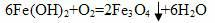

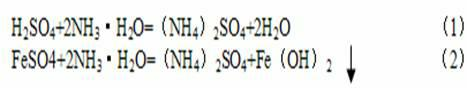

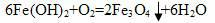

[0026] (2) Put the above (40M 3 ) The concentrated waste acid and ferrous sulfate solution are sent to the oxidation pool made of concrete and anti-corrosion materials, and then added (30 M 3 ) of waste ammonia water with a mass percentage of 20% (the amount added accounts for about 20% of the volume of the oxidation tank), and the neutralization reaction is carried out under the agitation of the agitator. The reaction equation is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com