Stamp hole bonding pad surface mounting type image visual processing module

A surface mount, image vision technology, applied in the field of image processing, to achieve the effect of improving stability, good portability, and improving signal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

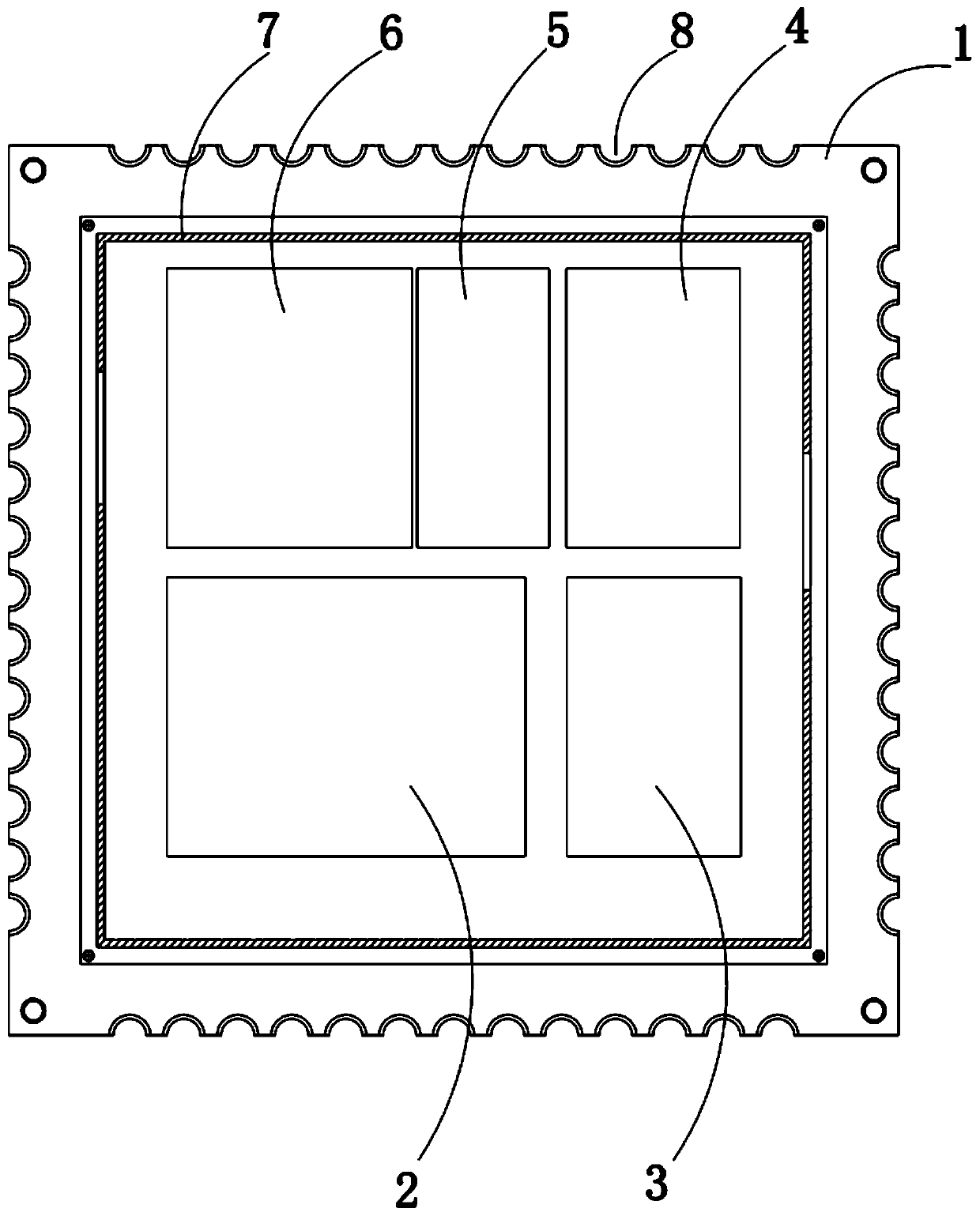

[0045] Please refer to Figure 1-Figure 4 , in the first embodiment of the invention:

[0046] Stamp hole pad surface mount type image vision processing module includes:

[0047] PCB substrate 1;

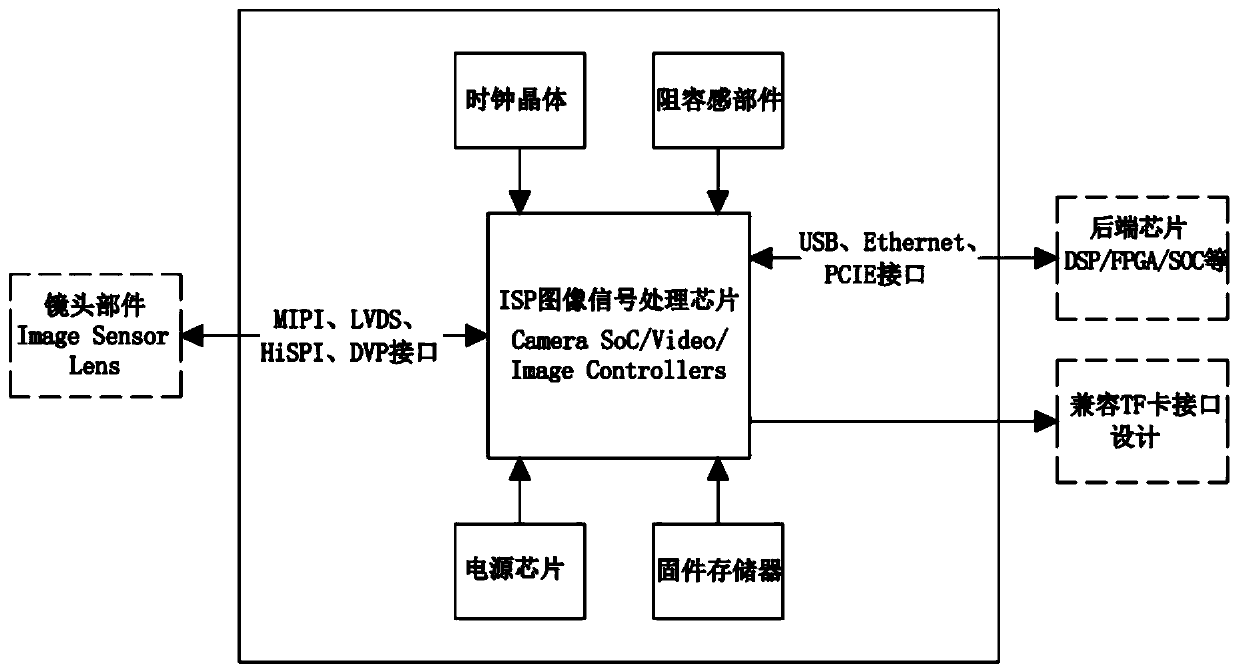

[0048] ISP image processing chip 2, the ISP image processing chip 2 is installed on the top of the PCB substrate 1;

[0049] A resistance-capacitance sensing component 3, the resistance-capacitance sensing component 3 is installed on the top of the PCB substrate 1;

[0050] A power chip 4, the power chip 4 is mounted on the top of the PCB substrate 1;

[0051] A clock crystal 5, the clock crystal 5 is mounted on the top of the PCB substrate 1;

[0052] A firmware memory 6, the firmware memory 6 is mounted on the top of the PCB substrate 1 .

[0053] The ISP image processing chip 2 includes Camera SoC, Video, Image Controllers chips with image signal and media services.

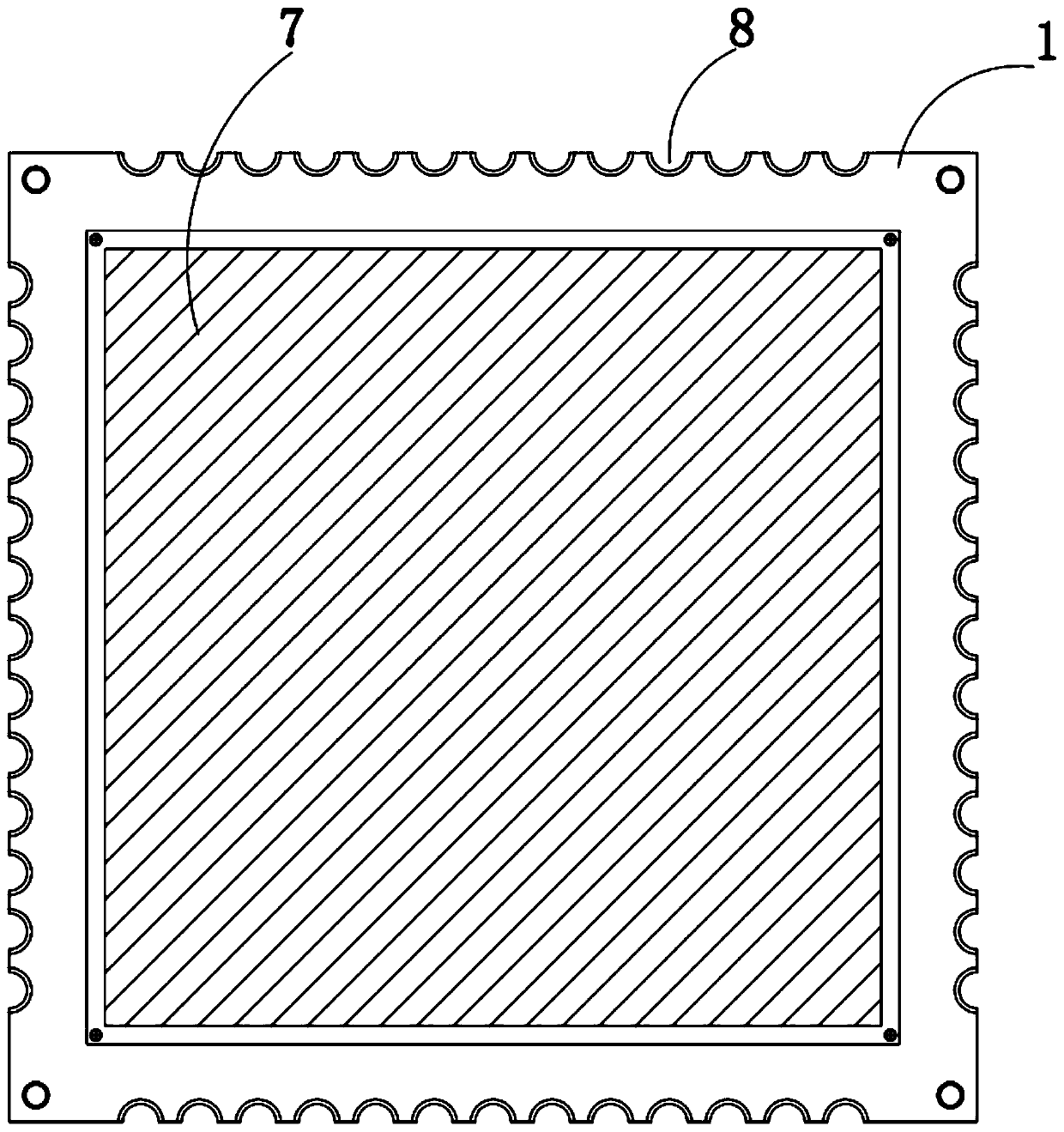

[0054] A shielding case 7 is fixedly mounted on the top of the PCB substrate 1 .

[0055] The four sides of ...

no. 2 example

[0071] Please refer to Figure 5-6 The difference between this embodiment and the first embodiment is that a camera connector 9 is installed on the PCB substrate 1, the camera connector 9 is located in the shield 7, and the shield 7 is provided with an avoidance hole 11 , and the avoidance hole 11 is adapted to the camera connector 9, and the camera connector 9 is used for connecting external lens components.

no. 3 example

[0073] Please refer to Figure 7 The only difference between this embodiment and the first embodiment is that the PCB design of the PCB substrate 1 adopts a large copper pad 11 exposed at the bottom of the substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com