Reinforced beam system

一种加强梁、加强元件的技术,应用在模块化加强梁连接件系统领域,能够解决部件大、成本高等问题,达到优化抗弯强度和抗剪强度、减少侧向不稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

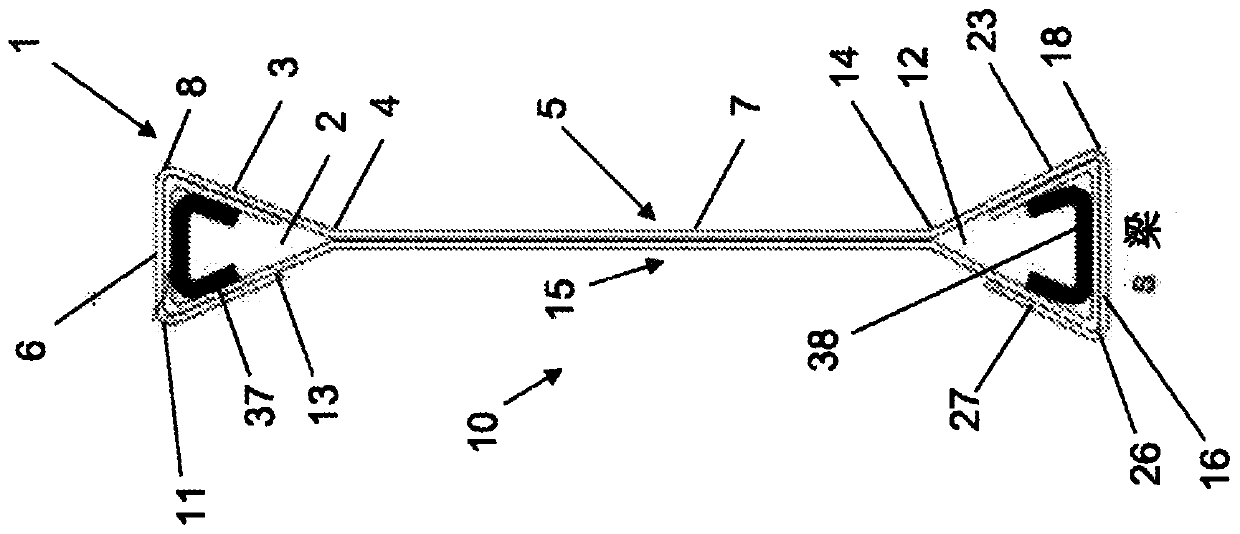

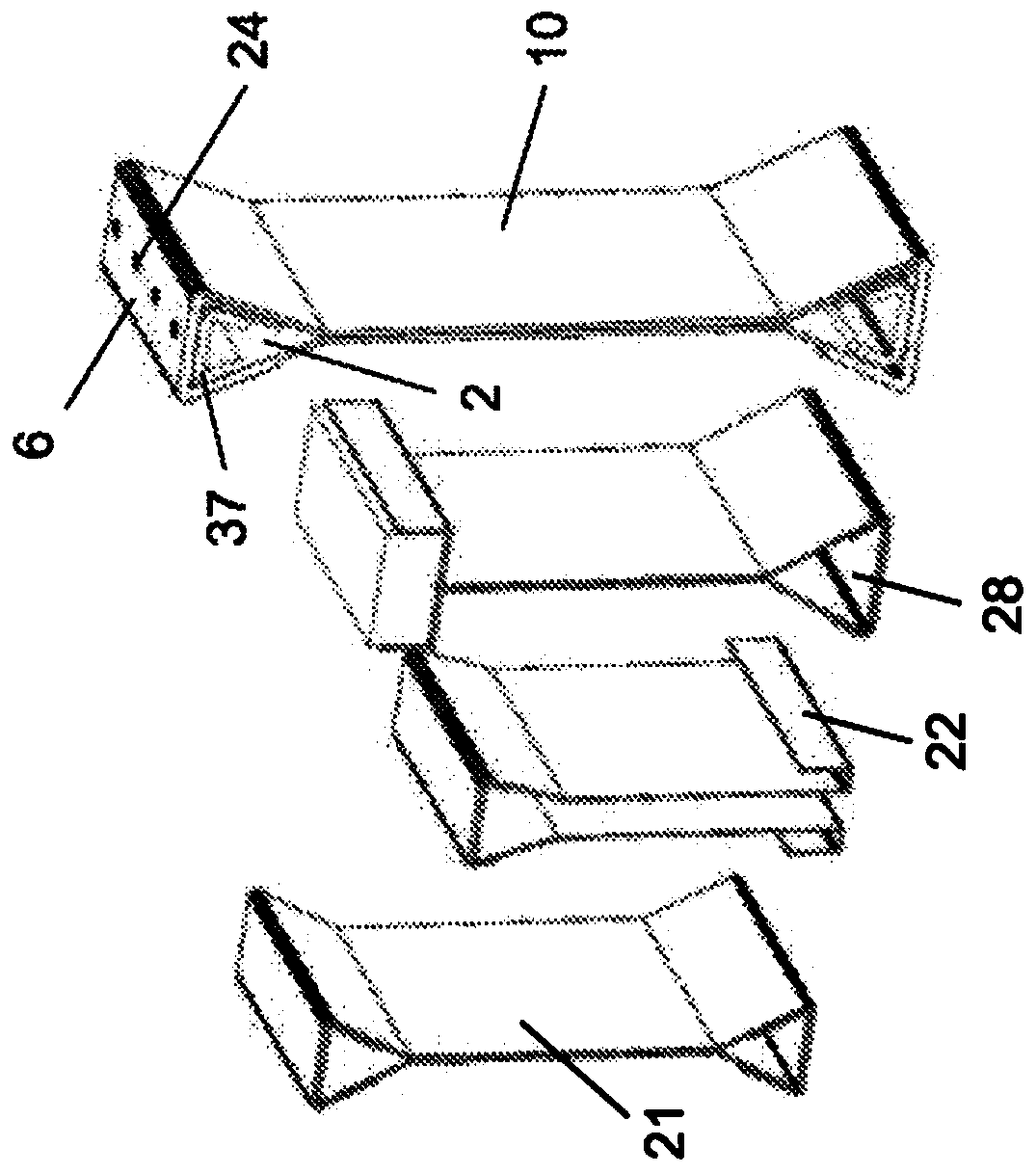

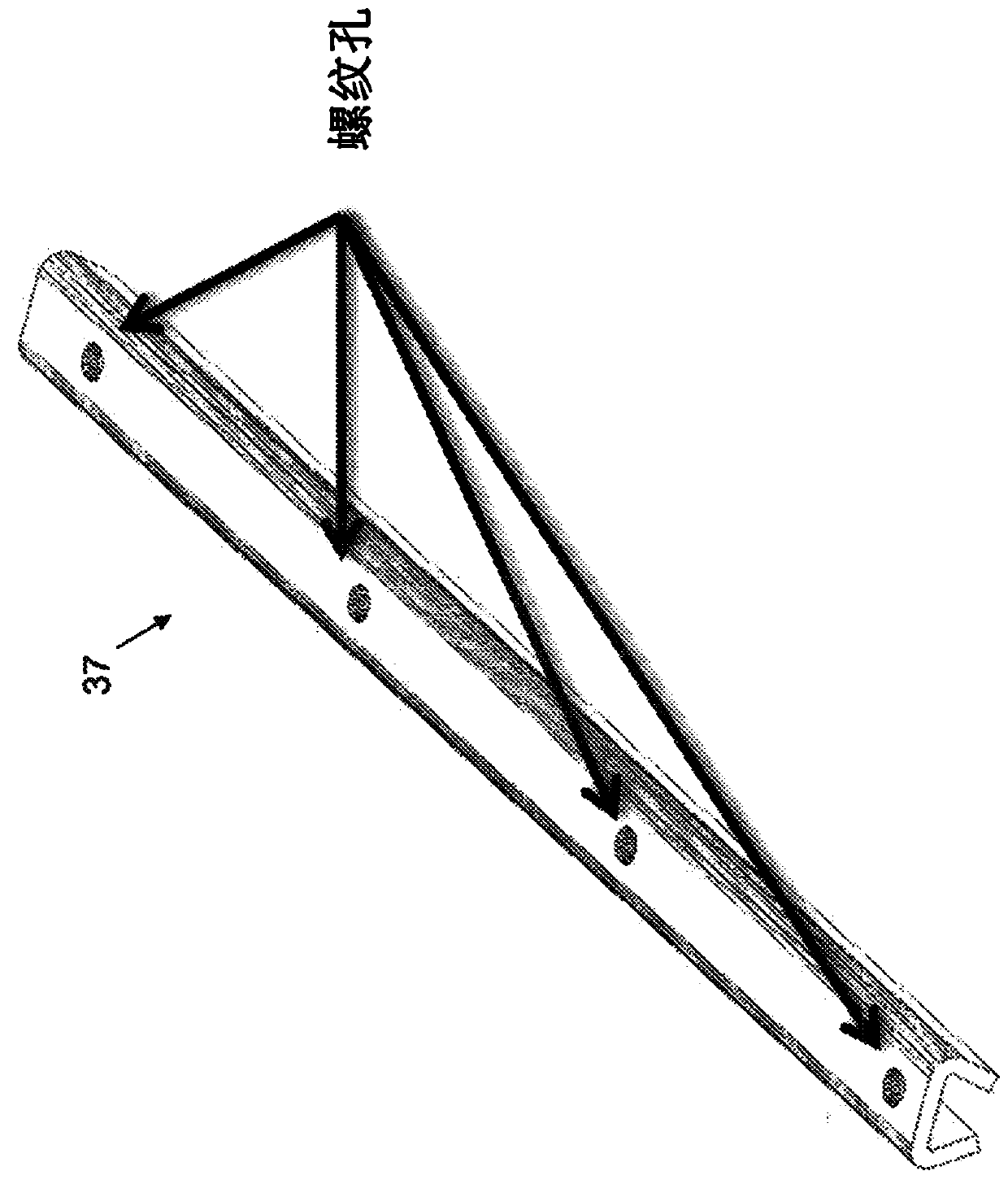

[0068] The present invention is a novel stiffening beam system comprising one or more lightweight structural beams having two triangular shaped head sections which provide increased lateral stability and strength-to-weight ratio, and at least one reinforcing element inserted inside and connected to the head portion of the beam.

[0069] Although some prior art beams have been constructed with triangular shaped head sections made by the cold rolling process, these head sections are closed triangles and their third side cannot be formed quickly and automatically due to the The inaccessibility of three sides and the inability of the roller to support the fed sheet metal because it bends to form a closed triangle. In contrast, the beam of the present invention is a composite beam made of two separate and oppositely oriented members arranged such that the corresponding head portions of the two members nest within each other. Each head portion is an incomplete triangle so the lip (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com