Hinge and cutting and grinding device for machining hinge

A cutting, grinding and hinge technology, used in metal processing equipment, grinding/polishing equipment, shearing machine equipment, etc., can solve problems such as sliding and large force on blades, reduce manufacturing costs, improve work efficiency, and facilitate processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

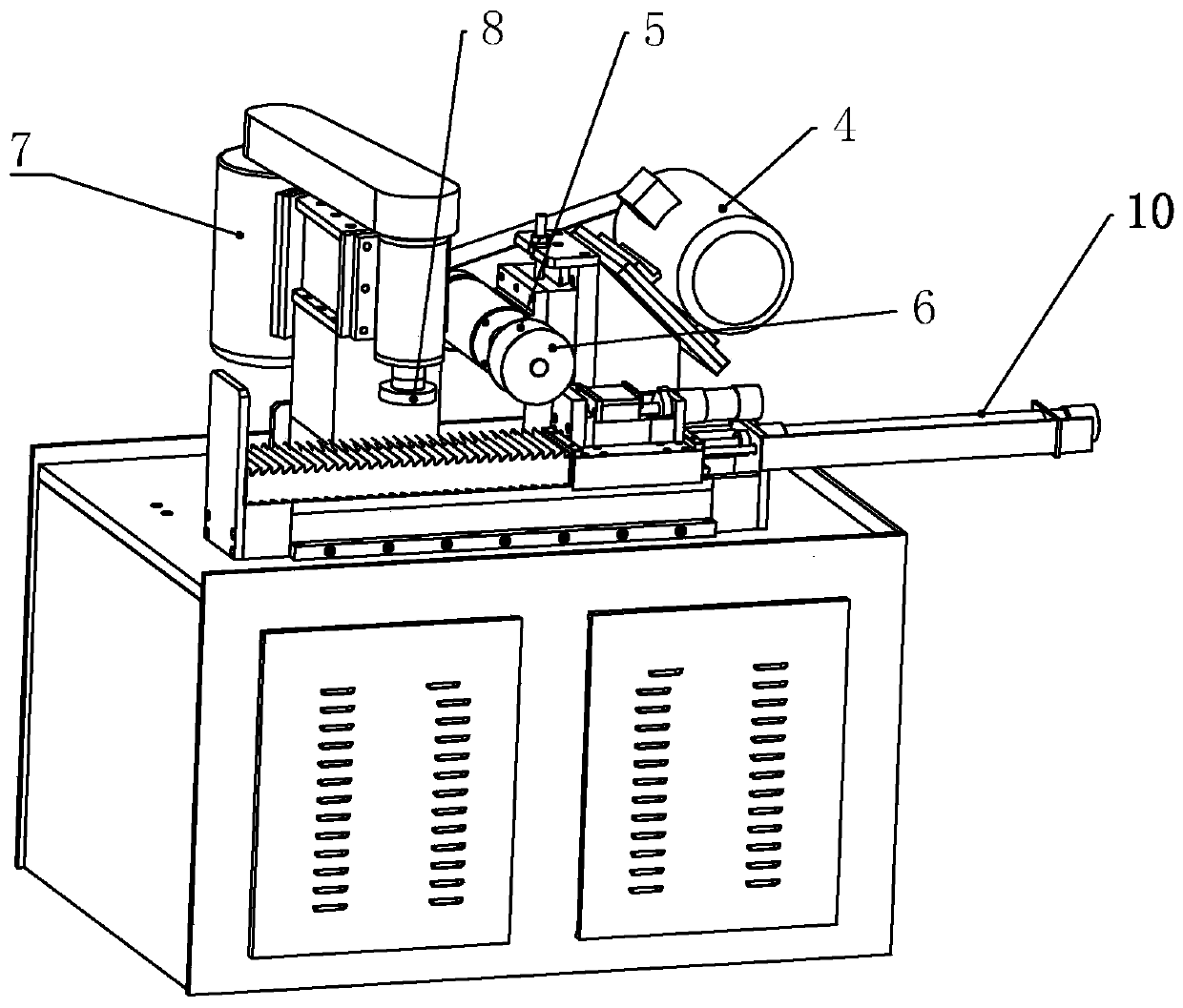

[0032] The hinge of the present invention and the embodiment of cutting and grinding equipment for the hinge will be further described with reference to the accompanying drawings.

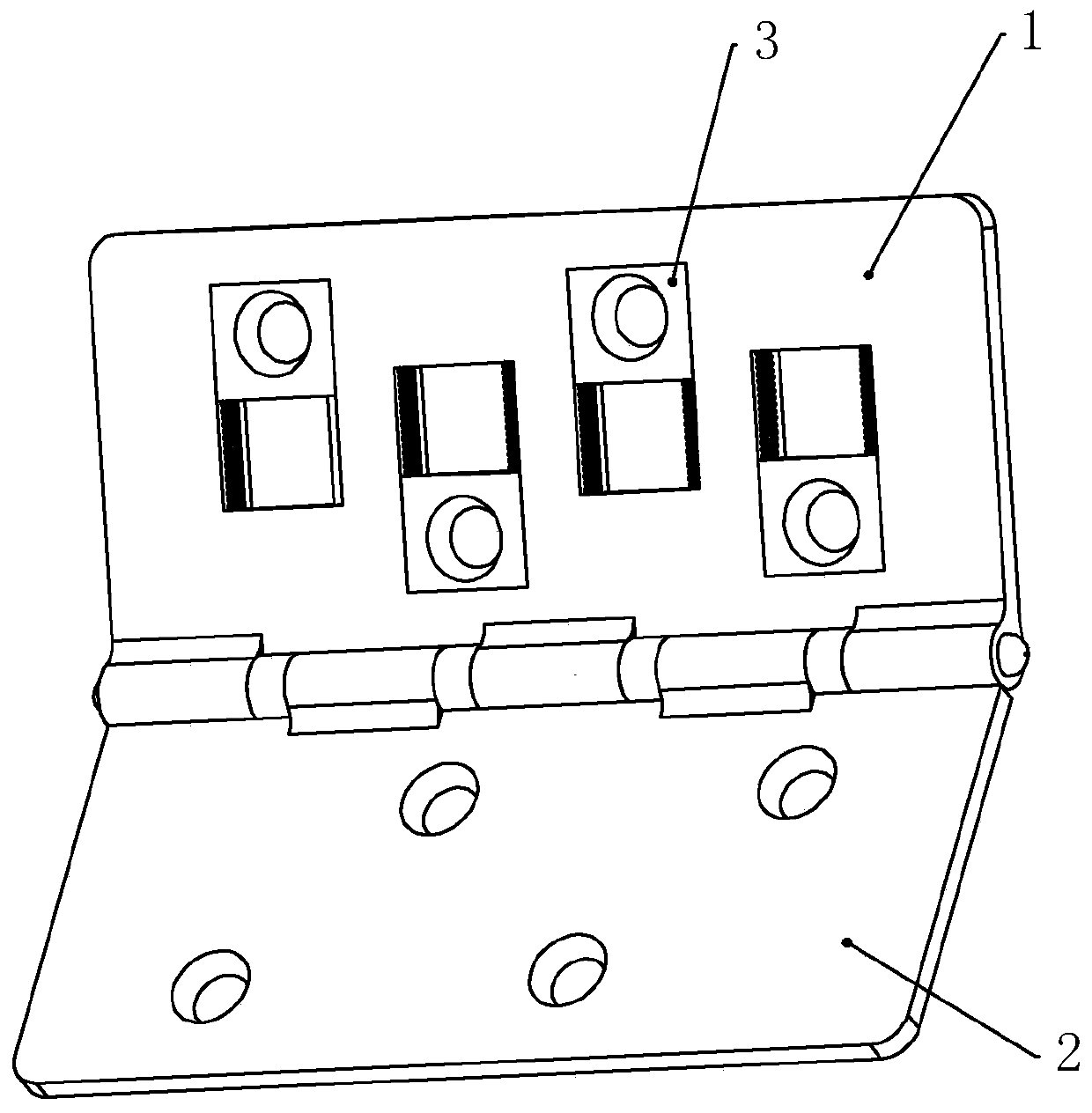

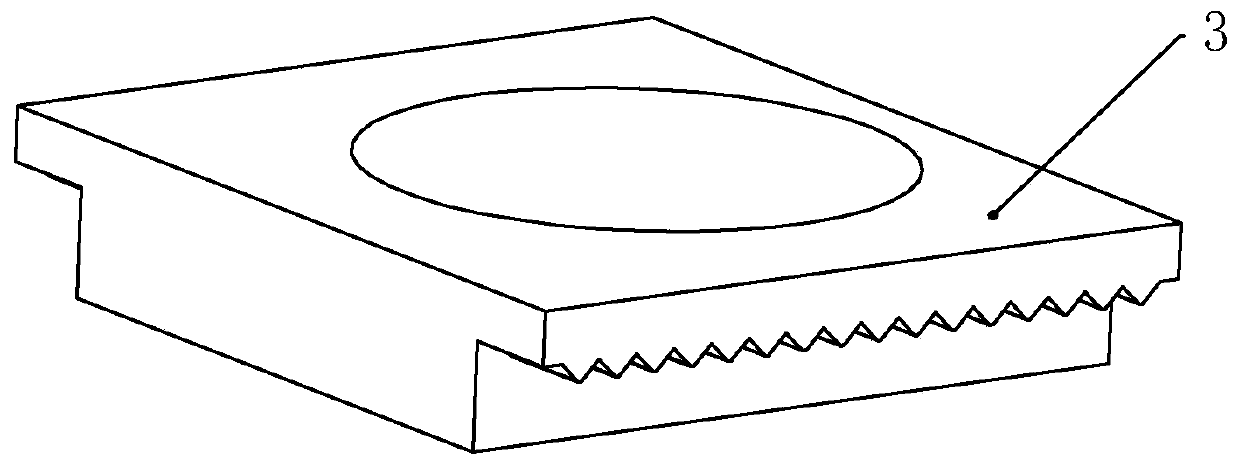

[0033] according to figure 1 As shown, a hinge includes an upper leaf 1, a lower leaf 2 and a hinge shaft, the upper leaf 1 and the lower leaf 2 are hinged through the hinge shaft, and the front of the upper leaf 1 is provided with It is connected to the installation groove on its back side, and a collation 3 is installed in the installation groove. The opposite sides of the installation groove are set as steps, and the collation 3 is provided with screw holes. The opposite sides are also set in a stepped shape, and the tables on both sides of the installation groove and the table on both sides of the collation 3 are provided with rows of teeth for intermeshing. Through the translation of the collation 3 in the installation groove of the upper leaf 1, the distance between the screws on the upper l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com