Inclined-type extrusion internal-formation device for plastic corrugated pipe

An inner molding and inclined technology, applied in the field of plastic bellows, can solve the problems of long mixing time, uneven mixing, excessive air bubbles in the bellows wall, etc., to avoid uneven mixing, improve product quality, and save water resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

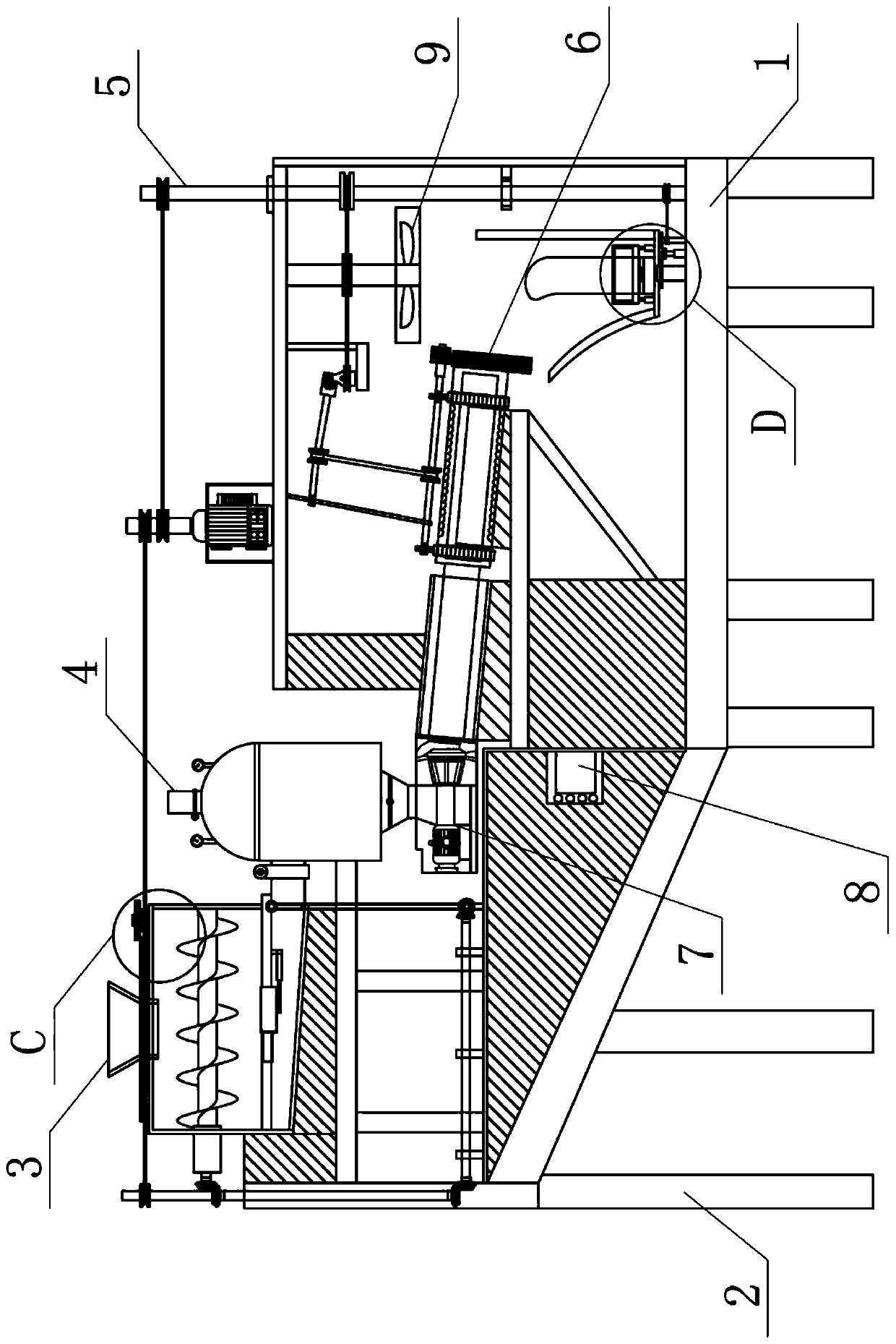

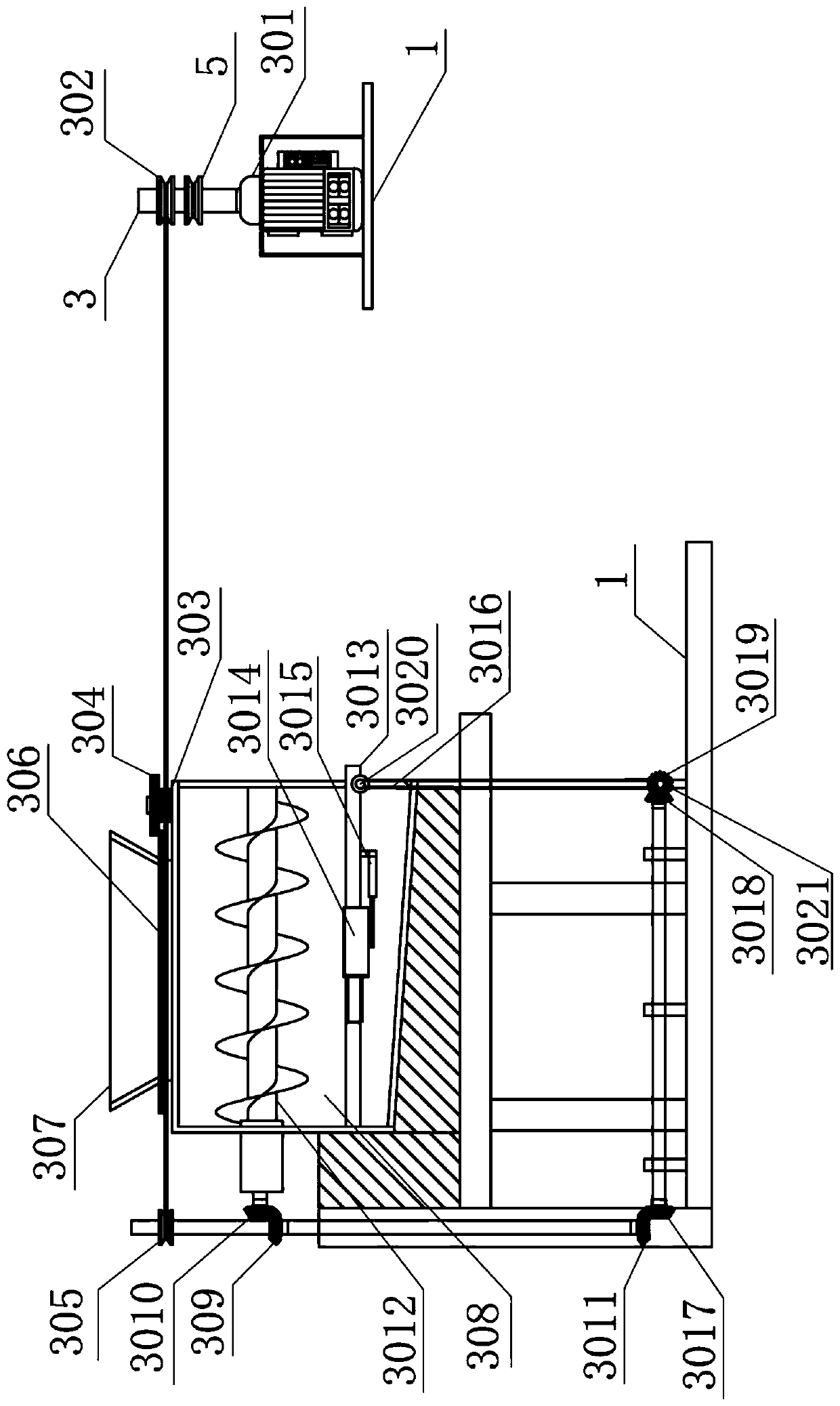

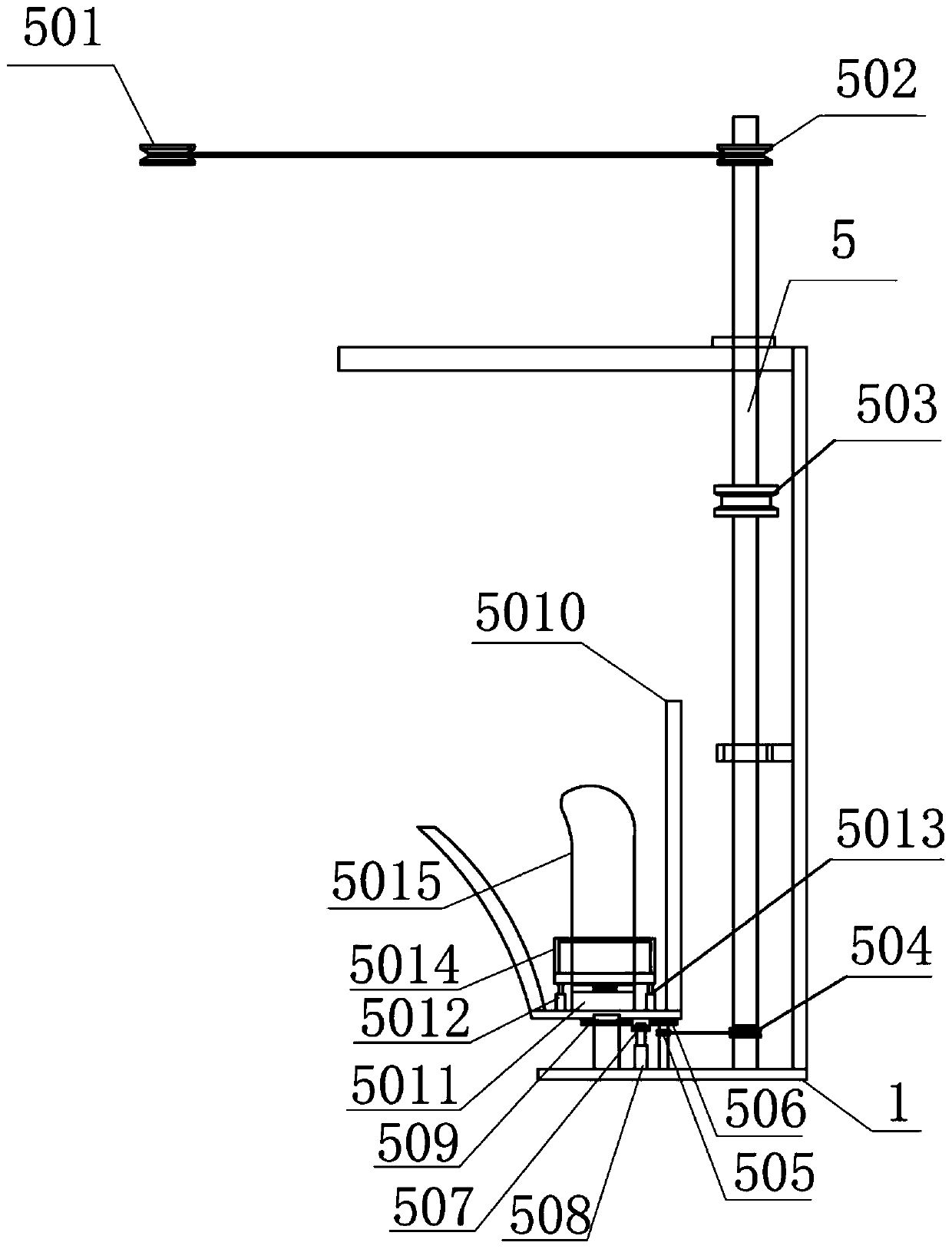

[0029] An inclined plastic corrugated pipe extruding inner forming device, such as Figure 1-8 As shown, it includes a support frame 1, a fixed base 2, a modified plastic raw material separation feeding and stirring mechanism 3, a heating furnace 4, an all-round rotating cooling mechanism 5, an inclined corrugated inner forming mechanism 6, a feeding pump 7, and a control display 8 and strong fan blades 9; the left and right parts of the bottom end of the support frame 1 are welded with the fixed base 2; the top left part of the support frame 1 is provided with a modified plastic raw material separation feeding and stirring mechanism 3; the top right part of the support frame 1 is provided with a full-range rotation Cooling mechanism 5, and the front upper part of the cooling mechanism 5 is connected with the modified plastic raw material separation and feeding stirring mechanism 3 in all directions; the front middle and upper part of the support frame 1 is provided with an inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com