Packing machine pushing mechanism

A packaging machine and frame technology, applied in packaging and other directions, can solve problems such as vibration and offset, small installation space for chains, difficult to use requirements, etc., and achieve the goals of reducing noise and impact, good operation stability, and improving service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

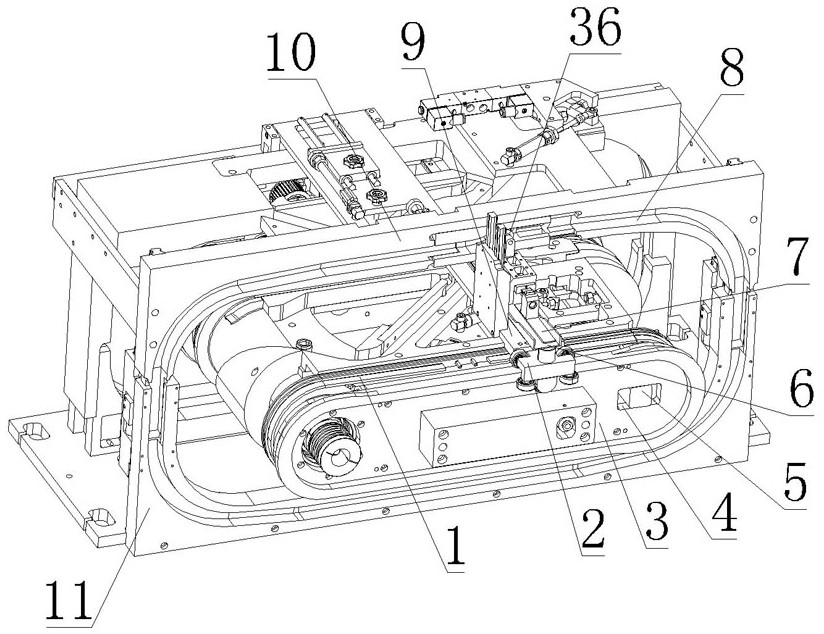

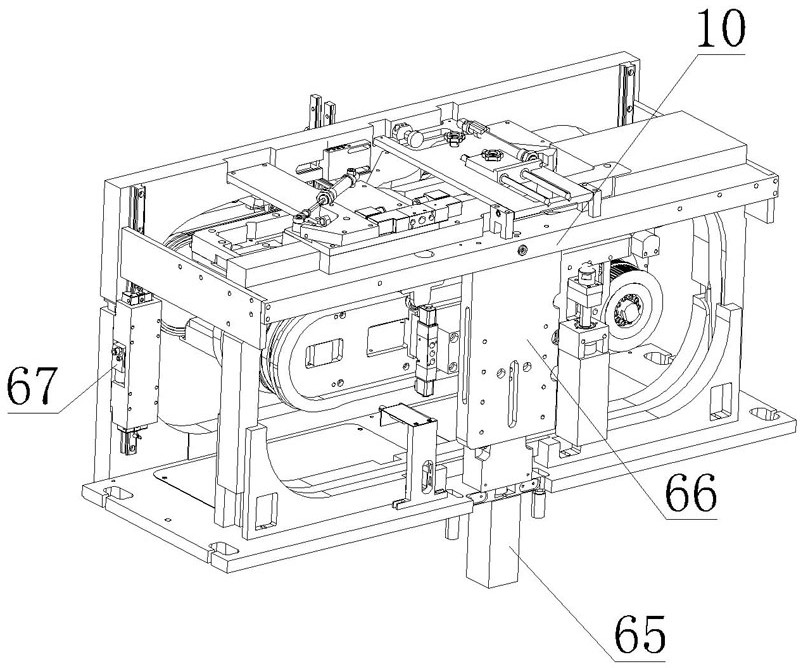

[0037]As shown in the figure, the pushing material mechanism of the packaging machine disclosed by the present invention has a frame and a transmission belt 1, the transmission belt 1 cooperates with the belt wrapping assembly, the transmission belt 1 is connected with the moving frame 9, and the moving frame 9 is provided with a pushing assembly and a press. The material assembly, the mobile frame 9 is connected with a guide seat 2, the guide seat 2 has a first roller 13 and a second roller 15 correspondingly arranged up and down, and a third roller 12 and a fourth roller 14 correspondingly arranged front and back, and the guide seat 2 It is movably arranged on the frame plate 3, and the frame plate 3 is provided with an outer convex portion 16 around its outer edge. The first and second rollers press the upper and lower sides of the outer convex portion 16 respectively, and the third and fourth rollers respectively tighten Press the front and rear sides of shelf plate 3. Thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com