A support and connection system for assembled non-dismantling composite airgel self-insulation formwork

A composite airgel and self-insulation technology, which is applied in the direction of insulation, walls, buildings, etc., can solve the problems of deformation, large force of airgel composite board, and pouring of thermal insulation wall that cannot be applied to airgel composite board, etc., to achieve The effect of improving the fire resistance limit and improving the frost resistance life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

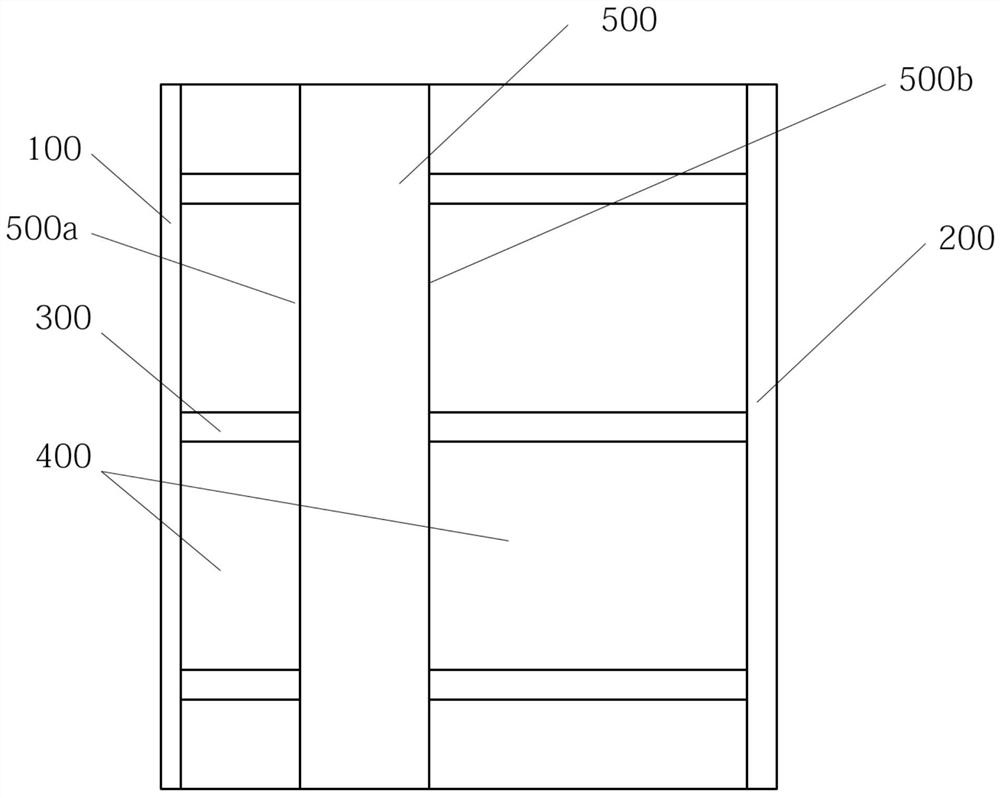

[0043] This embodiment discloses a support connection system containing a composite airgel self-insulation board in a shear wall.

[0044] In the present invention, common terms are as follows:

[0045] Shear wall: A wall in a house or structure that mainly bears horizontal loads and vertical loads (gravity) caused by wind loads or earthquakes to prevent structural shear (shear) damage. Generally, it is made of reinforced concrete.

[0046] Non-load-bearing wall: The non-load-bearing wall refers to the rear wall that does not bear the load of the upper floor, and only plays the role of separating the space. A non-load-bearing wall is not non-load-bearing, and "non" is only relative to a load-bearing wall. For example, a shear wall is a type of load-bearing wall.

[0047] Composite airgel self-insulation board: a nano self-insulation board formed from airgel.

[0048] Concrete: Refers to the engineering composite material in which aggregates are cemented into a whole by cemen...

Embodiment 2

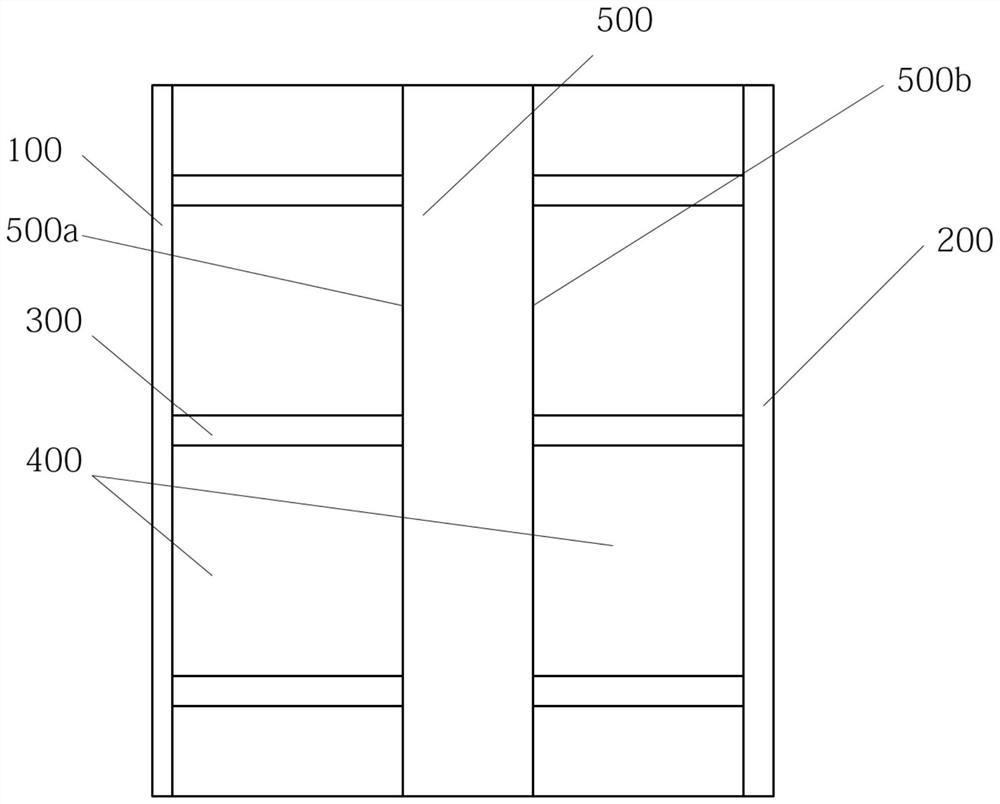

[0061] This embodiment discloses a support connection system containing a composite airgel self-insulation board in a non-load-bearing wall, such as figure 2 shown.

[0062] Non-load-bearing walls do not need to bear as much load as load-bearing walls. In general, the thickness of the protective cavity is equal to the thickness of the structural cavity. During construction, non-load-bearing walls should be based on maximizing the thermal insulation effect. That is: it is necessary to give full play to the function of the composite airgel self-insulating formwork 500, and try not to damage its own structure.

[0063] Preferably, when the thickness of the protective cavity is equal to the thickness of the structural cavity, when the concrete 400 is in the pouring process, the shear stress of the concrete 400 on the first side 500a of the composite airgel self-insulation formwork 500 is equal to that of the concrete 400 is the shear stress generated by the composite airgel from...

Embodiment 3

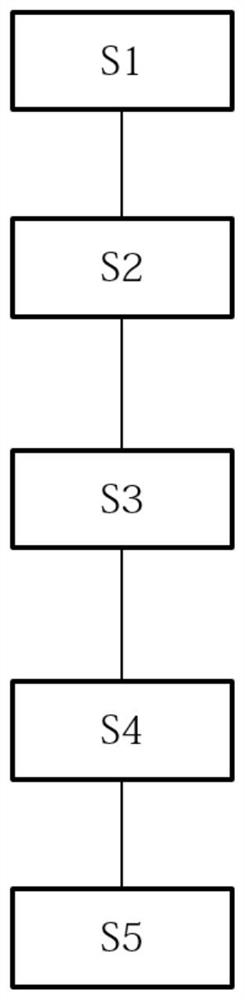

[0066] This embodiment discloses a concrete pouring method for a thermal insulation wall containing composite airgel thermal insulation rods.

[0067] like image 3 As shown, the methods include:

[0068] S1: Set the support net 100 on one side of the composite airgel self-insulating template 500 .

[0069] S2: Arranging the supporting ribs 200 on the other side of the composite airgel self-insulating template 500 .

[0070] S3: Fix the composite airgel self-insulating template 500 between the support net 100 and the support rib 200 by using the connector 300 .

[0071] S4: Use concrete 400 to pour the composite airgel from the protective cavity formed by the thermal insulation template 500 and the support net 100 and pour the composite airgel from the structural cavity formed by the thermal insulation template 500 and the support rib 200 to form an thermal insulation structure Built-in insulation walls.

[0072] S5: The connector 300 is fixed between the support net 100 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com