A kind of lithium-composite calcium base lubricating grease and preparation method thereof

A technology of complex calcium-based lubricating grease and base oil, which is applied in lubricating compositions, thickeners, and the petroleum industry, and can solve problems such as poor comprehensive performance, unstable performance of lubricating grease products, and serious volatilization of small molecular acids. Achieve the effect of avoiding difficult operation and shortening the reaction time at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

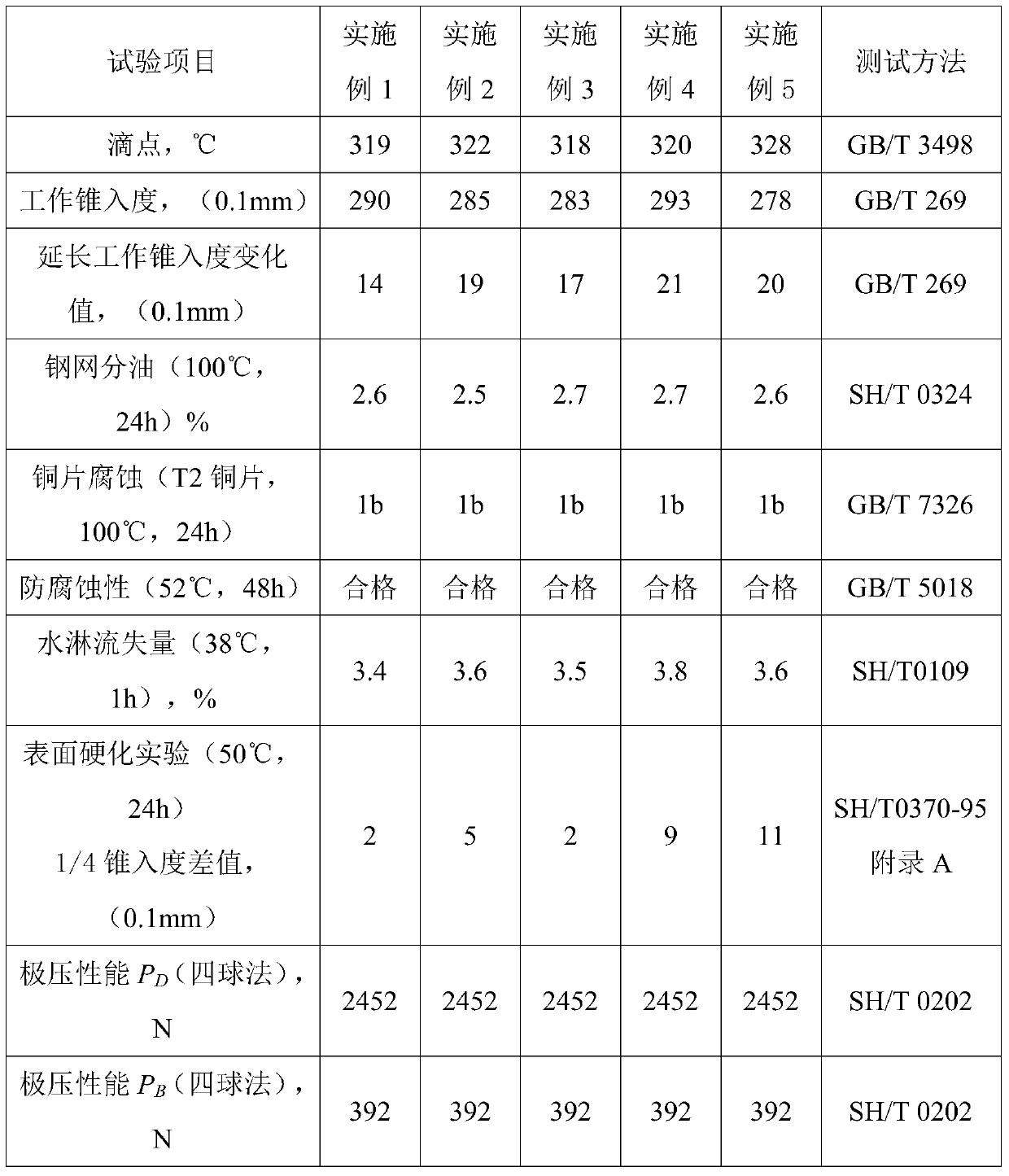

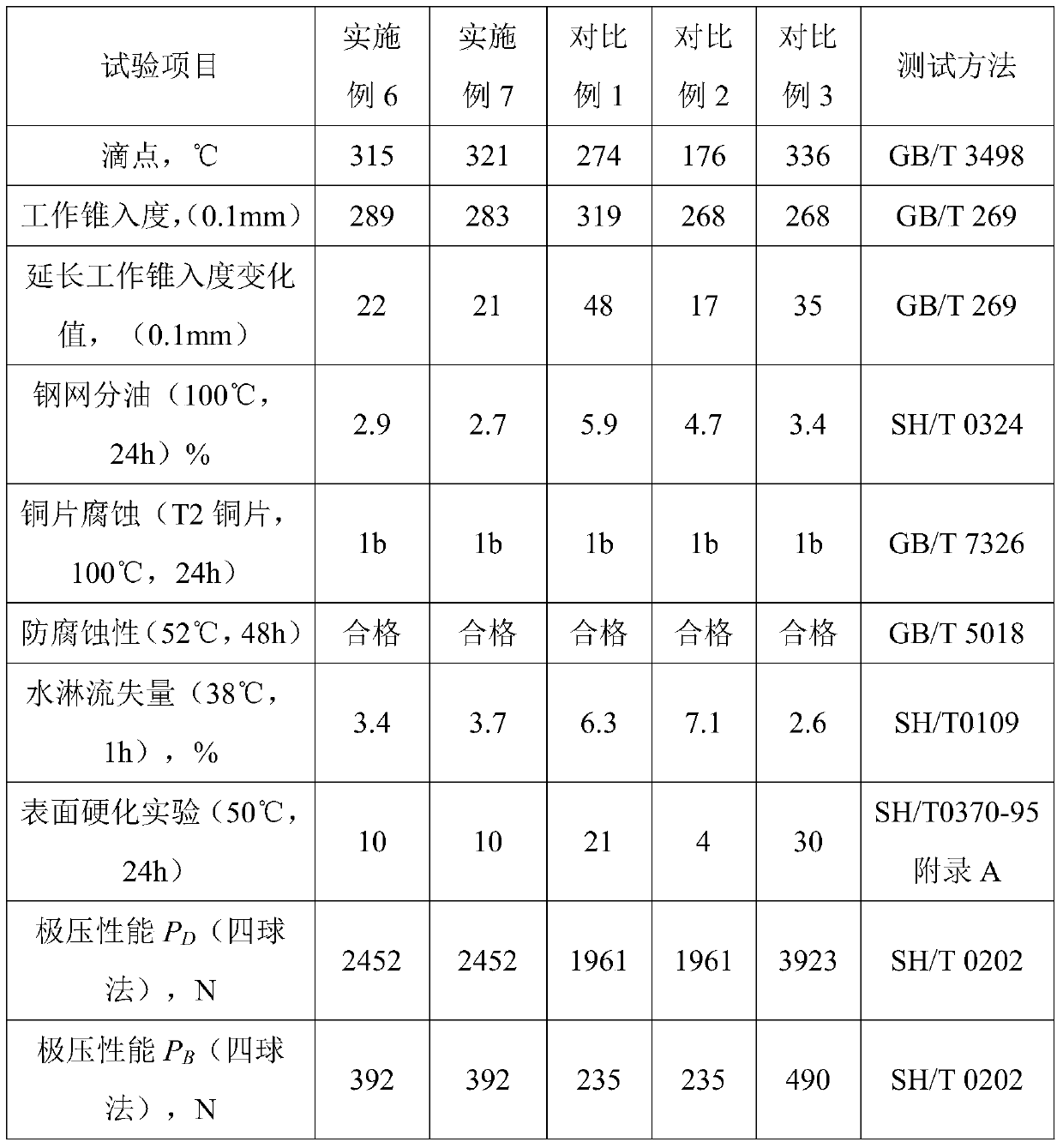

Examples

Embodiment 1

[0029] Prepare 20kg of lubricating grease, the thickener amount is 12%, the mass ratio of complex calcium soap to lithium soap is 1:9, and the mass ratio of calcium hydroxide to lithium hydroxide monohydrate is 1:4.8.

[0030] Raw material components: 12-hydroxystearic acid (1.27kg); acetic acid (0.11kg, content ≥ 99%); lithium hydroxide monohydrate (0.41kg); calcium hydroxide (0.09kg); base oil Daqing 400 (17.6 kg, 100℃ kinematic viscosity 9.7mm 2 / s).

[0031] Add 11kg of mineral base oil Daqing 400 and 0.06kg of calcium hydroxide aqueous solution dissolved in 3 times the amount of water into the saponification reaction kettle, mix and stir evenly, heat up to 38°C, add 0.11kg of acetic acid, react for 30min, then heat up to 87°C, Add 1.27kg of 12-hydroxystearic acid, until the 12-hydroxystearic acid is completely dissolved, add 0.03kg of calcium hydroxide and 0.41kg of lithium hydroxide monohydrate mixed lye dissolved in 8 times the amount of water, and react at 90°C 60min...

Embodiment 2

[0033] Prepare 20kg of lubricating grease, the thickener amount is 20%, the mass ratio of complex calcium soap to lithium soap is 3:7, and the mass ratio of calcium hydroxide to lithium hydroxide monohydrate is 1:1.08.

[0034] Raw material components: 12-hydroxystearic acid (2.67kg); terephthalic acid (0.54kg); lithium hydroxide monohydrate (0.39kg); calcium hydroxide (0.36kg); Daqing 400 (16kg, 100 ° C exercise Viscosity 9.7mm 2 / s).

[0035] Lithium complex calcium-based grease was prepared according to the method of Example 1, except that a raw material used in the preparation was changed, the acetic acid used was changed to terephthalic acid, and the thickener content was changed from 12% to 20%. The mass ratio of complex calcium soap and lithium soap in the thickener was changed from 1:9 to 3:7; and the preparation process conditions were changed, and the reaction time between calcium hydroxide and small molecule acid was changed from 30 minutes to 60 minutes. The prod...

Embodiment 3

[0037] Prepare 20kg of lubricating grease, the thickener amount is 30%, the mass ratio of complex calcium soap to lithium soap is 5:5, and the mass ratio of calcium hydroxide to lithium hydroxide monohydrate is 1:0.46.

[0038] Raw material components: stearic acid (4.16kg); boric acid (1.34kg, content ≥ 99%); lithium hydroxide monohydrate (0.44kg); calcium hydroxide (0.95kg); Daqing 400 (14kg, 100 ℃ kinematic viscosity 9.7mm 2 / s).

[0039] Lithium complex calcium-based grease was prepared according to the method of Example 1, the difference being that the two raw materials used in the preparation were changed, the 12-hydroxystearic acid used was changed to stearic acid, the acetic acid used was changed to boric acid, thickened The thickener content was changed from 12% to 30%, and the mass ratio of complex calcium soap and lithium soap in the thickener was changed from 1:9 to 5:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com