Adjustable steel structure supporting member

A technology of supporting components and steel structures, which is applied to the preparation of building components on site, pillars, building structures, etc., can solve the problems of difficult adjustment of support rods, achieve the effect of improving practicability and portability, and reducing occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

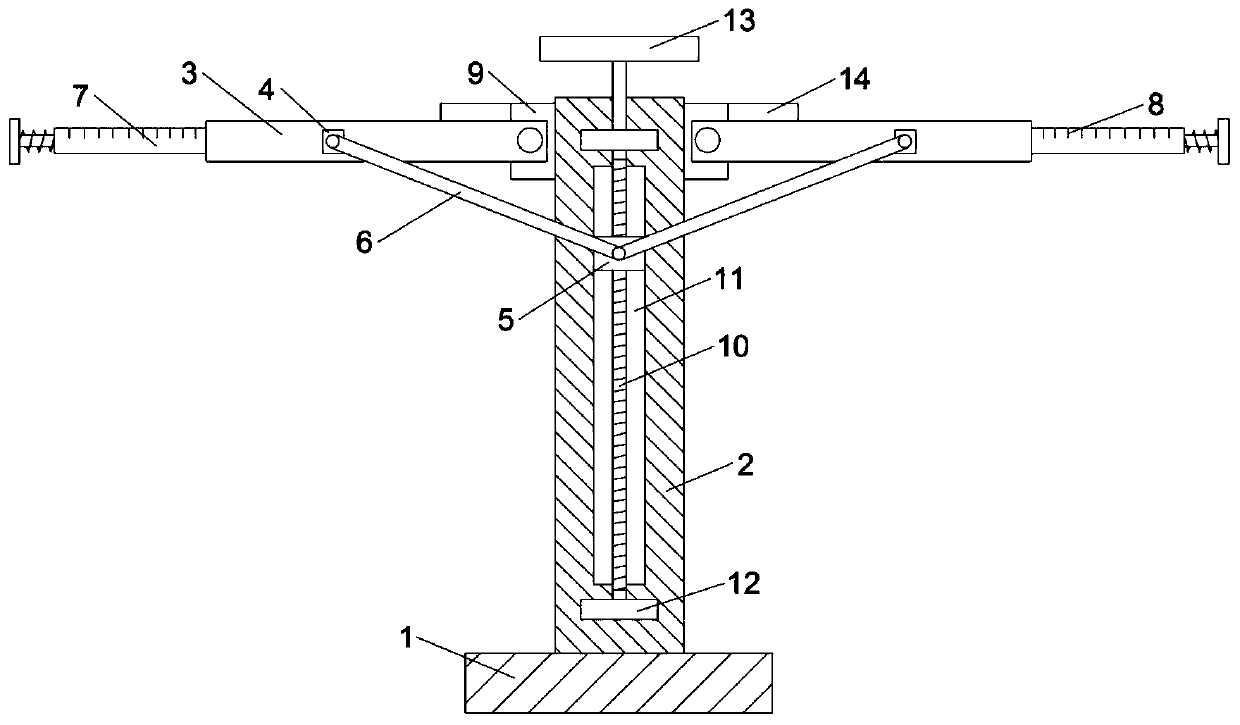

[0025] Refer to attached Figure 1-4 , this embodiment provides an adjustable steel structure support member, including a pillar 2, the pillar 2 can be fixed on the mounting seat 1 by welding or bolting, and the setting of the mounting seat 1 is convenient for installation and placement entire support structure. In addition, two sets of symmetrical first mounting blocks 9 are fixed on the pillar 2, and the support rod 3 is rotatably installed on the first mounting block 9, wherein the mounting seat 1, the pillar 2 and the support rod 3 are all steel material.

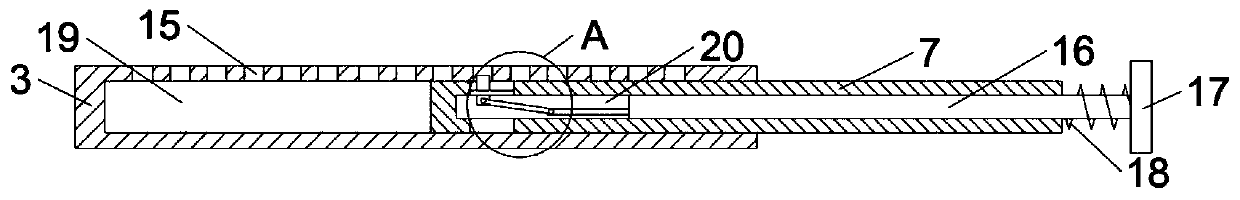

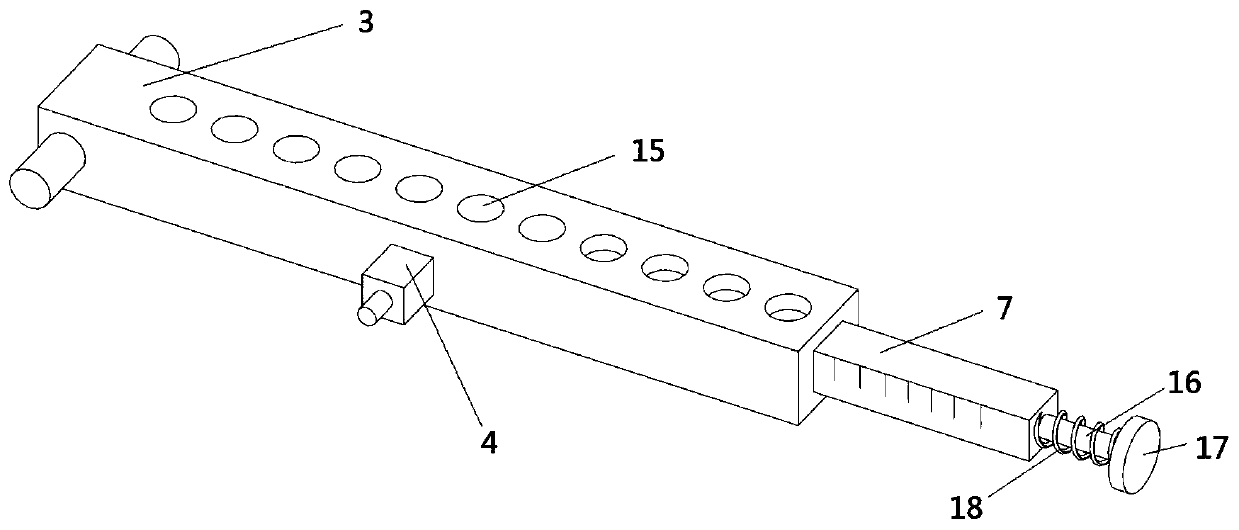

[0026] Further, an adjustment assembly for driving the support rod 3 to rotate and having a self-locking function is provided between the support rod 3 and the pillar 2; Between the rod 7 and the support rod 3 is provided a limiting assembly for restricting the sliding of the movable rod 7 , and the movable rod 7 is provided with a release assembly for releasing the restriction of the movable rod 7 by the limiting ass...

Embodiment 2

[0035] Refer to attached Figure 5 , this embodiment is improved on the basis of Embodiment 1. Specifically, the movable rod 7 is fixed with a mounting plate 29, the mounting plate 29 is fixed with a positioning rod 26, and the support rod 3 A positioning block 27 is fixed on it, and a positioning hole 28 matching the positioning rod 26 is provided on the positioning block 27 . When it is necessary to insert the movable rod 7 into the first mounting hole 19 of the support rod 3, the movable rod 7 can be positioned by inserting the positioning rod 26 into the positioning hole 28, so as to ensure that the stop rod 25 can be aligned with the support Limiting hole 15 on the rod 3.

[0036] To sum up, the steel structure support member provided by the embodiment of the present invention can be adjusted by setting an adjustment assembly with a first connecting rod 6 and a slider 5 between the pillar 2 and the rotatable support rod 3 . The sliding assembly of the screw rod 10 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com