Multifunctional permeation piping tester

A technology of permeation pipe and tester, which is applied in soil material testing, permeability/surface area analysis, instruments, etc., and can solve the problems that it is difficult to objectively reflect the permeability characteristics of coarse-grained soil and the change mechanism of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

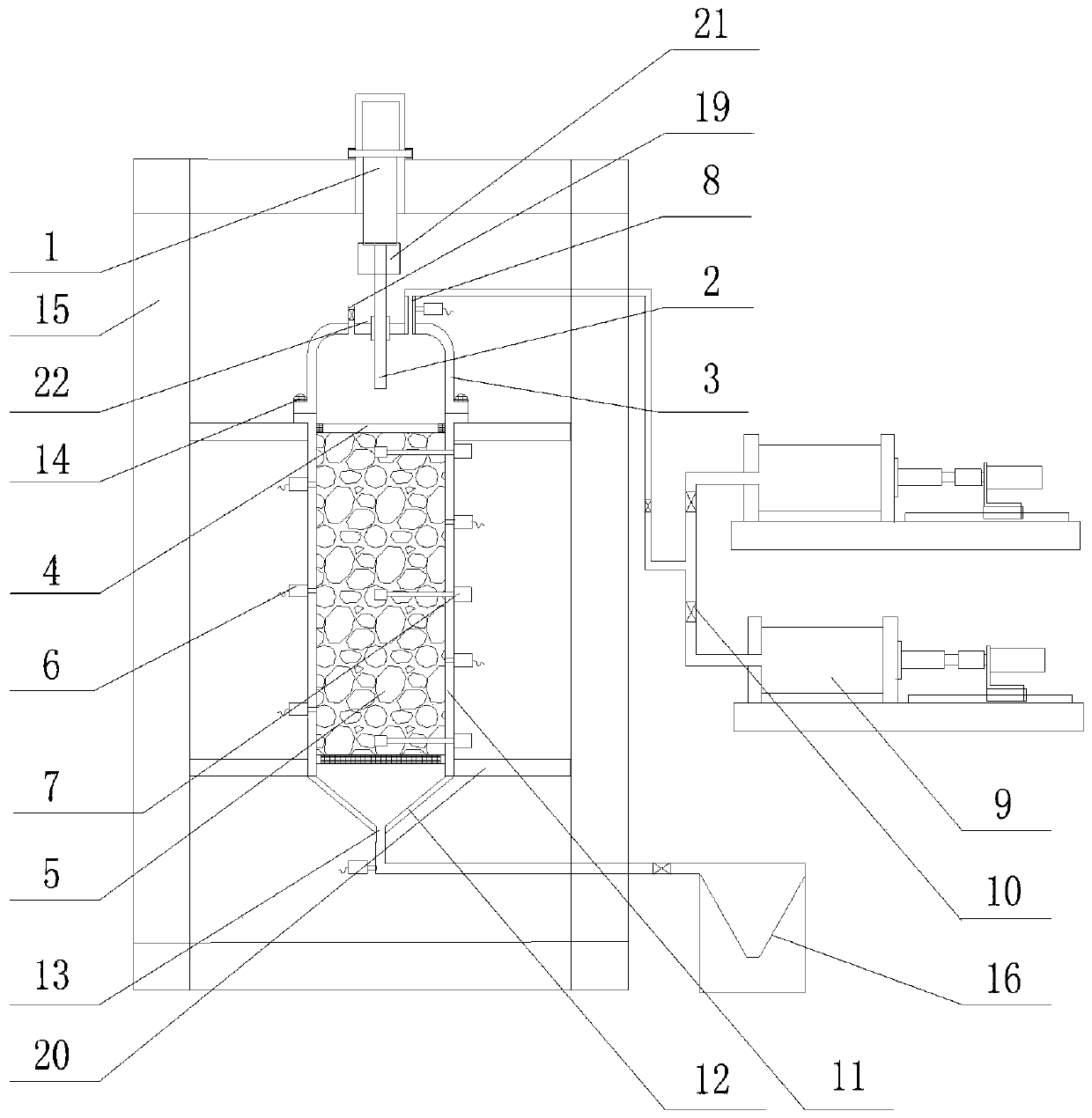

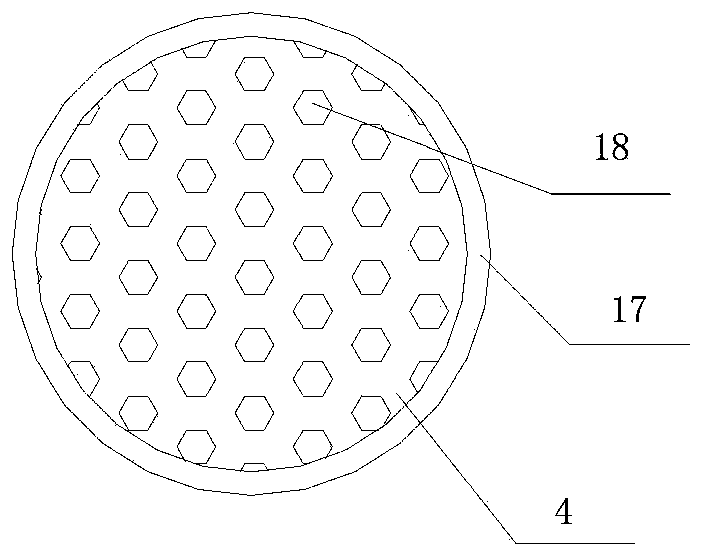

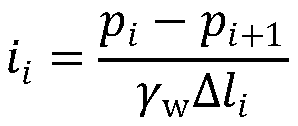

[0052] Such as Figure 1-2 As shown, a multifunctional permeation piping tester includes a loading reaction force frame 15 and a sample cylinder 11. The supporting frame 20 set on the top is fixed, the top of the loading reaction force frame 15 is fixedly provided with an axial presser 1, and the lower part of the axial presser 1 is provided with an axial pressurizing rod 2, and the axial The pressure rod 2 is provided with a displacement sensor 21, and the upper part of the sample cylinder 11 is provided with a sample cylinder top cap 3, and the sample cylinder top cap 3 and the sample cylinder 11 are fixed together by a fixing bolt 14, so The sample tube top cap 3 is provided with a top cap exhaust valve 19, a sample tube top cap water inlet 8, and a central hole 22, the axial pressure rod 2 can pass through the central hole 22, and the sample tube The top cap water inlet 8 is connected with a pressure volume controller 9, and the pressure volume controller 9 is provided wi...

Embodiment 2

[0060] Such as Figure 1-2 As shown, a multifunctional permeation piping tester includes a loading reaction force frame 15 and a sample cylinder 11. The supporting frame 20 set on the top is fixed, the top of the loading reaction force frame 15 is fixedly provided with an axial presser 1, and the lower part of the axial presser 1 is provided with an axial pressurizing rod 2, and the axial The pressure rod 2 is provided with a displacement sensor 21, and the upper part of the sample cylinder 11 is provided with a sample cylinder top cap 3, and the sample cylinder top cap 3 and the sample cylinder 11 are fixed together by a fixing bolt 14, so The sample tube top cap 3 is provided with a top cap exhaust valve 19, a sample tube top cap water inlet 8, and a central hole 22, the axial pressure rod 2 can pass through the central hole 22, and the sample tube The top cap water inlet 8 is connected with a pressure volume controller 9, and the pressure volume controller 9 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com