A collector plate for a hydrogen fuel cell stack

A fuel cell stack and current collector technology, which is applied to fuel cell components, fuel cells, circuits, etc., can solve the problems of little necessity of loading and unloading screws, unfavorable testing process, and low current, and achieves increased efficiency. Contact area, increase test efficiency, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

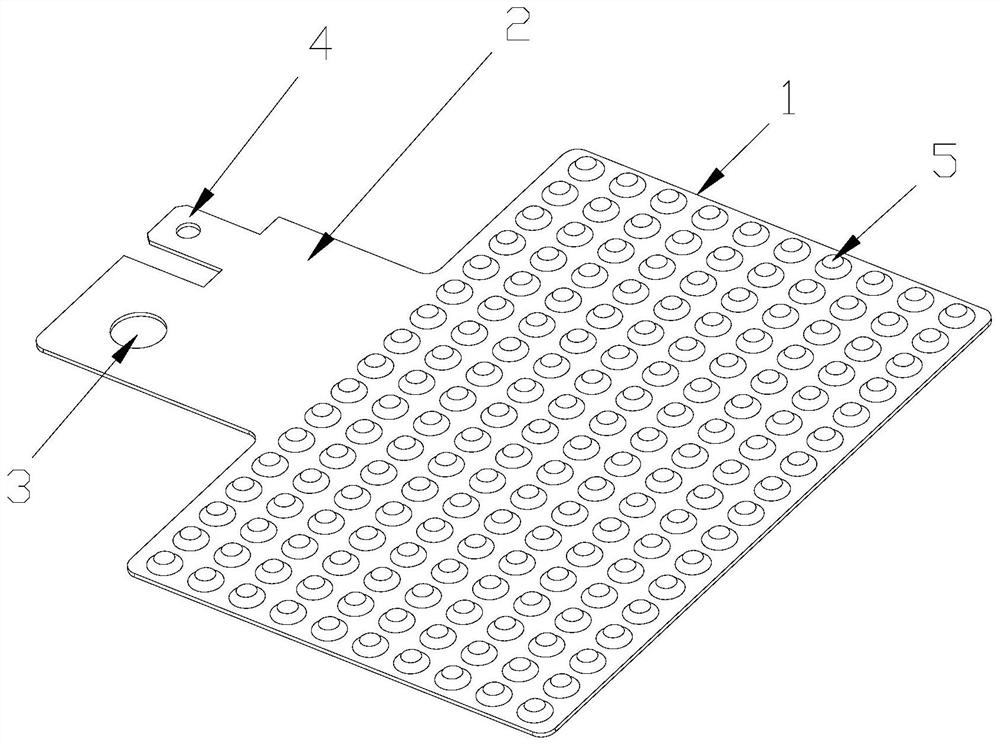

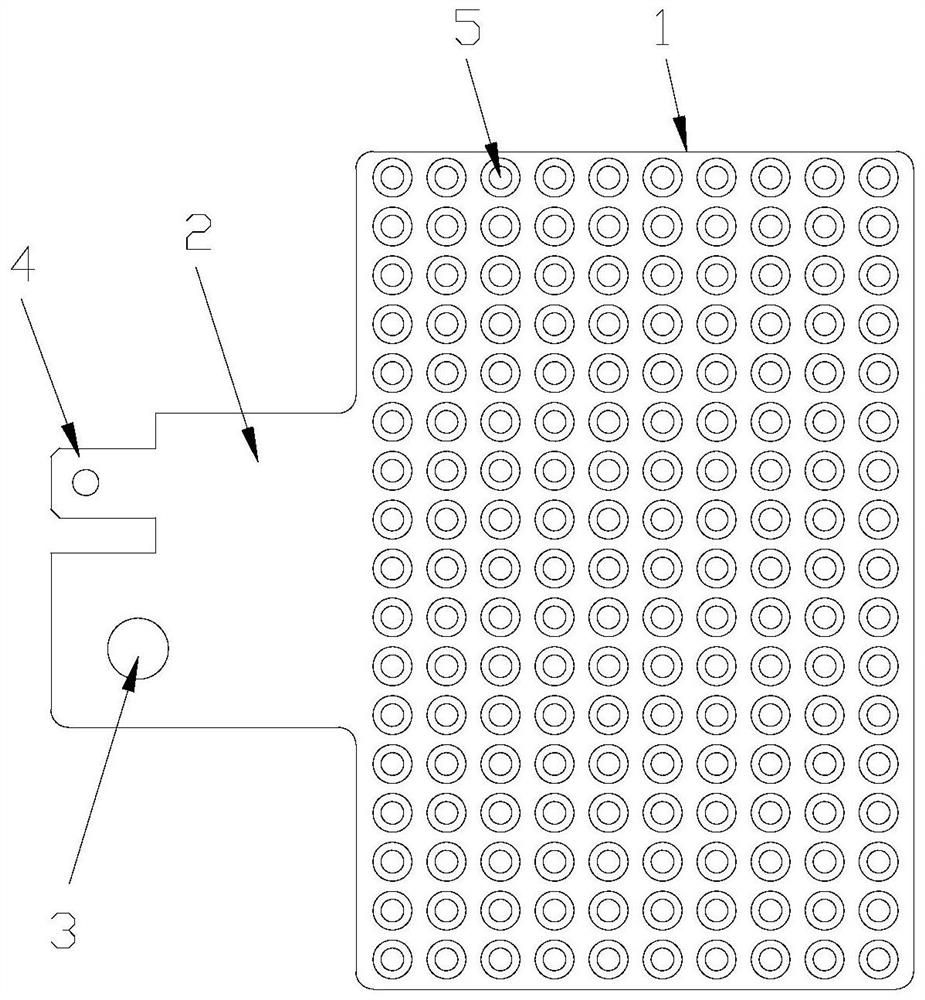

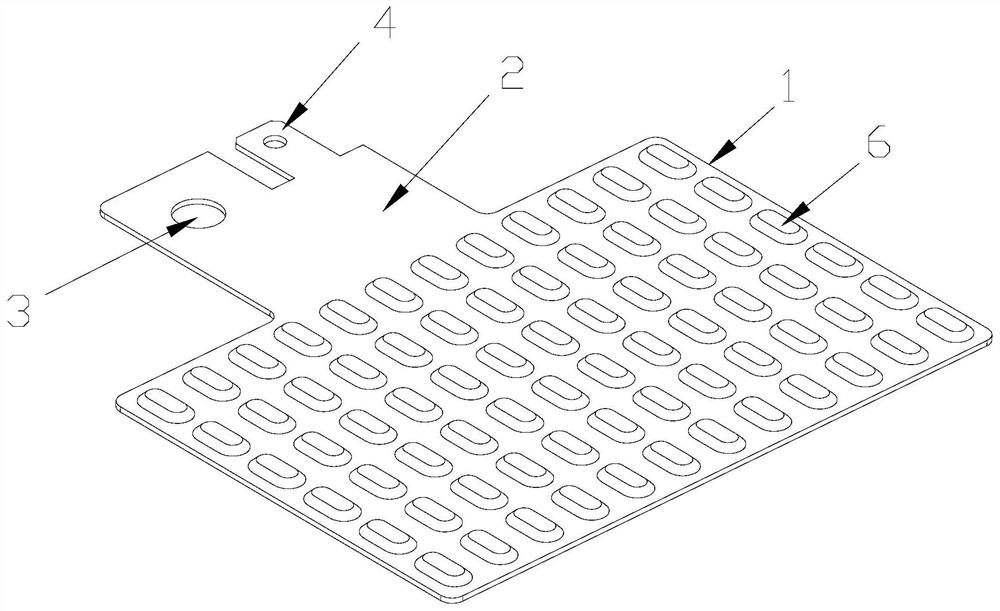

[0016] As shown in the accompanying drawings, the present invention provides a current collector for a hydrogen fuel cell stack, including a current collector body, the current collector body is in the shape of a metal plate, and the current collector body is composed of a collector surface 1 and wiring The terminal 2 consists of two parts. The current collecting surface 1 is used to contact the graphite plate of the electric stack to collect the current of the electric pile. The terminal 2 is used to connect with the test wire. The current collecting surface 1 adopts a non-planar structure and passes through The convex part of the structure is in contact with the graphite plate. The terminal 2 is provided with a screw hole 3 and a quick-plug structure 4. The quick-plug structure 4 cooperates with the quick-plug connector on the test lead to realize quick plug-in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com