Cooling device, stator and wind driven generator

A technology for wind turbines and cooling devices, which is applied in the fields of cooling devices, stators and wind turbines, can solve the problems of high unit cost and low cooling efficiency of liquid cooling technology, and achieves improved cooling efficiency, high reliability, and improved heat exchange. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

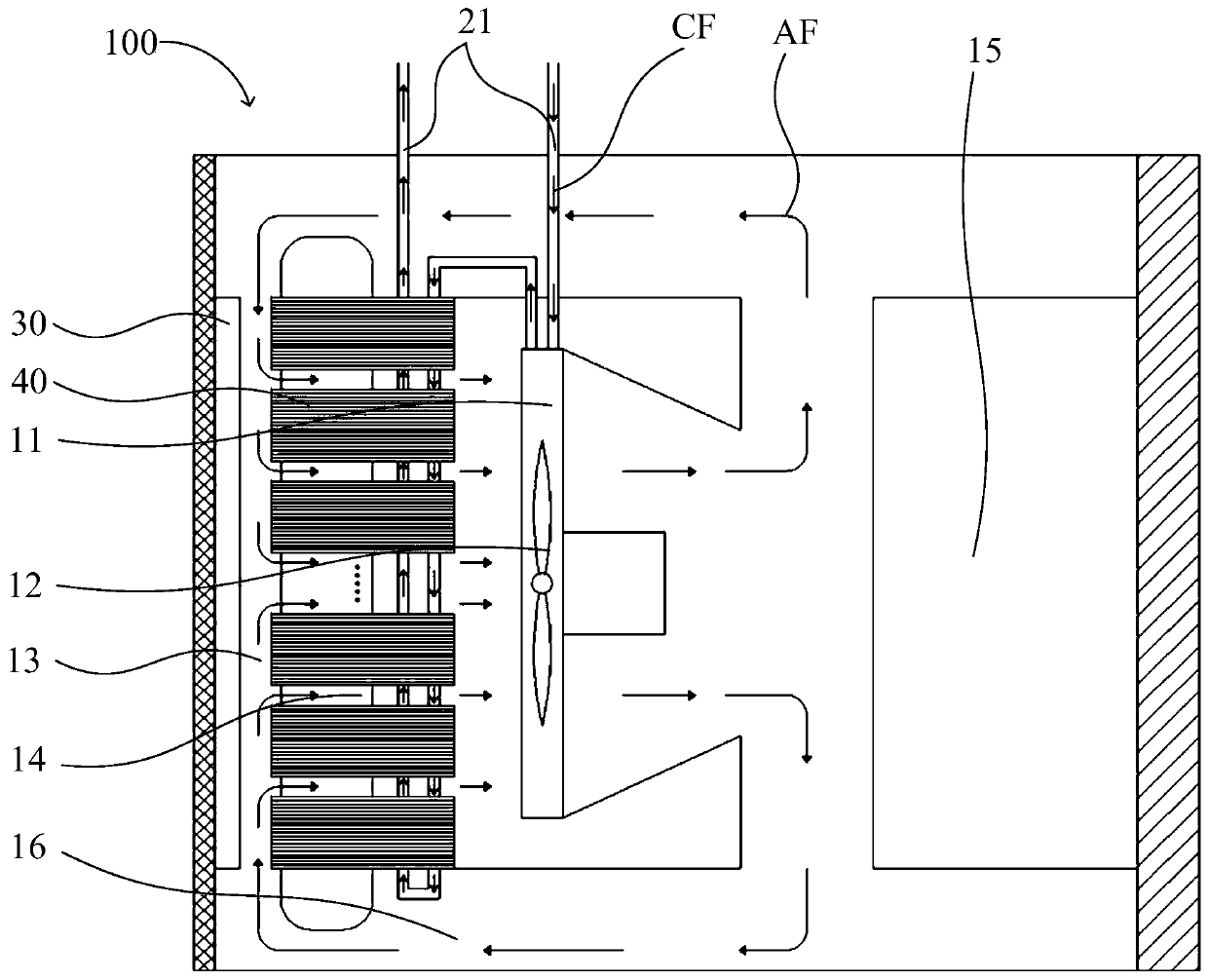

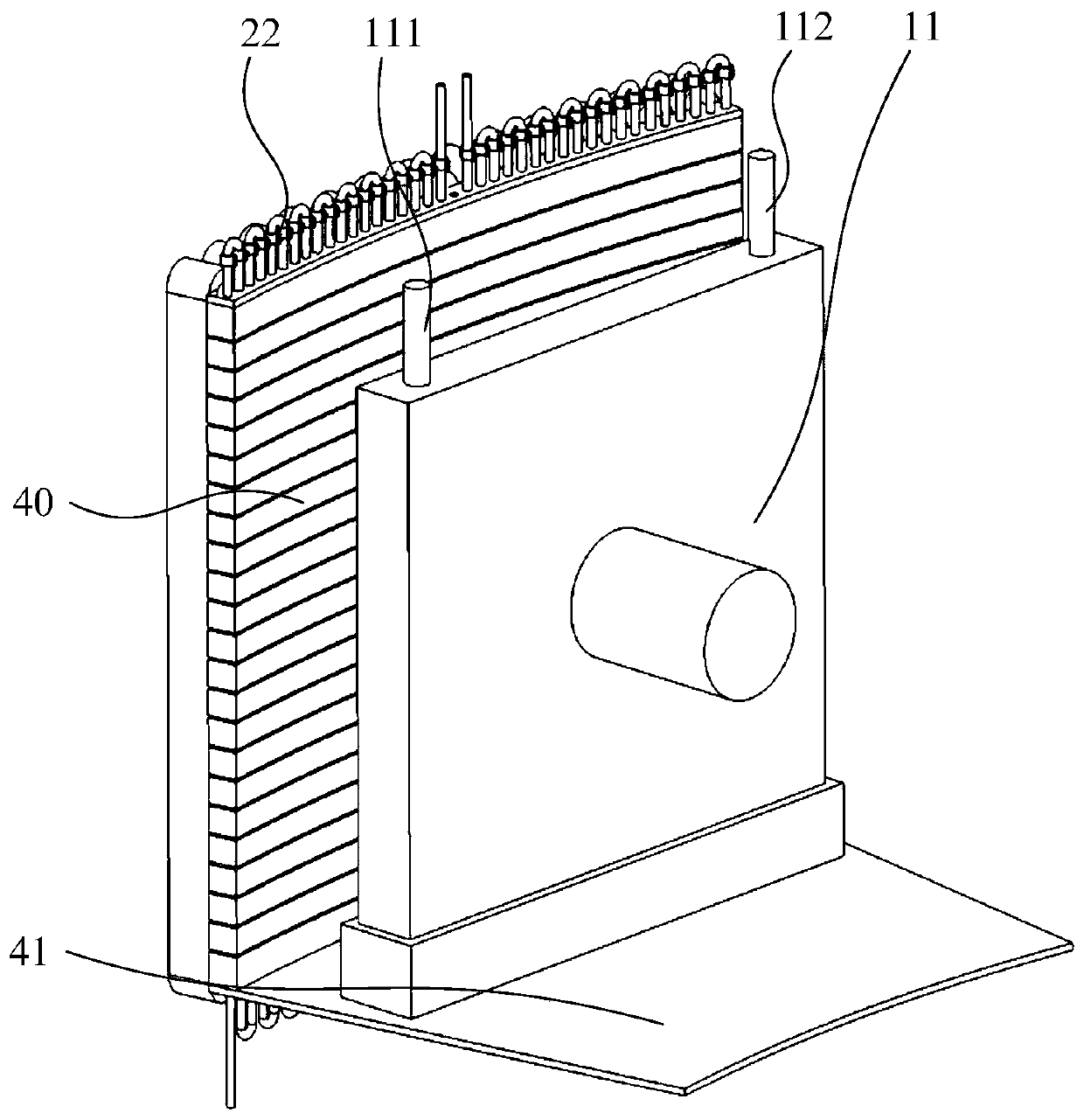

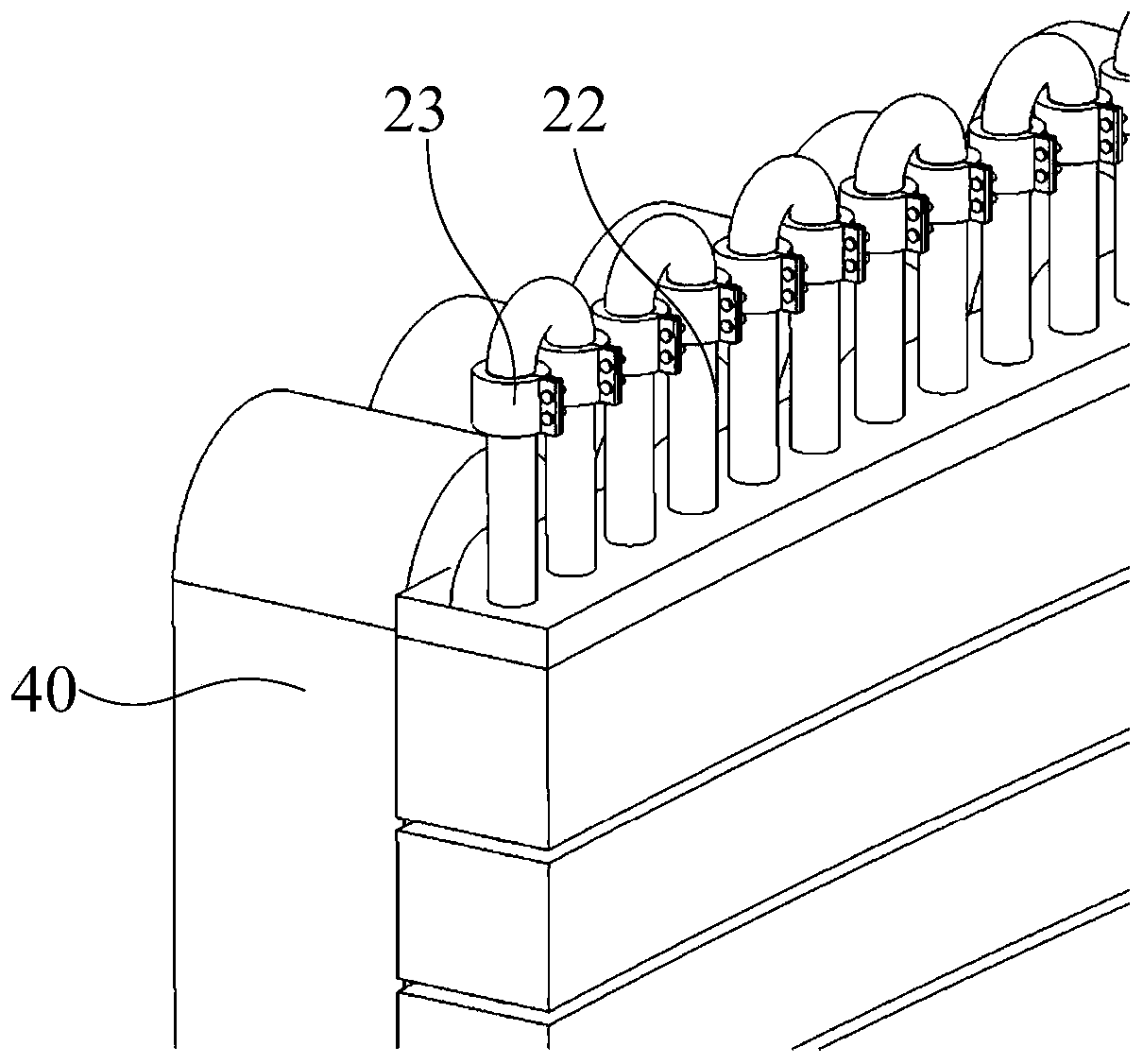

[0071] like Figure 1-4 As shown, this embodiment is a cooling device 100 for a wind-driven generator. The wind-driven generator includes a stator, a rotor 30, an air gap 13 between the stator and the rotor 30, and a cooling device 100 for cooling the wind-driven generator. The cooling device 100 includes an air cooling system and a liquid cooling pipeline; the air cooling system includes a gaseous medium flow path for the gaseous medium to circulate inside the wind turbine and a first heat exchange device 11 arranged on the gaseous medium flow path; the liquid cooling pipeline It includes a first part located inside the first heat exchange device 11 and a second part located inside or on the outer surface of the stator; wherein the cooling liquid in the liquid cooling pipeline flows through the first part and the second part successively. In this embodiment, by adopting the above structure, the heat generated by the wind power generator is transferred to the first heat exchan...

Embodiment 2

[0094] This embodiment is a stator. For the convenience of description, this embodiment continues to refer to the reference numerals in Embodiment 1. The stator of this embodiment includes the above wind power generator cooling device 100, the stator is a modular stator and includes a plurality of stator modules 40 distributed along the circumferential direction, each stator module 40 corresponds to at least one first heat exchange device 11 and at least one The second part of a liquid cooling circuit. In this embodiment, the cooling device 100 is used to transfer the heat generated by the stator module 40 efficiently, which is beneficial to reduce the temperature of the stator module 40 and to improve the stability of the wind power generator.

[0095] As an embodiment, at least one stator module 40 includes a plurality of second parts of liquid cooling lines connected in parallel. In other embodiments, all stator modules 40 have the same size, and all stator modules 40 corr...

Embodiment 3

[0097] This embodiment is a wind power generator, which includes the cooling device 100 in Embodiment 1 or includes the stator in Embodiment 2. For ease of description, this embodiment continues to refer to the reference numerals in Embodiment 1.

[0098] The wind-driven generator of this embodiment may include the cooling device 100 in Embodiment 1, and the use of the wind-driven generator containing the cooling device 100 is conducive to maintaining a relatively suitable temperature for the wind-driven generator and improving the stability of the wind-driven generator. It is beneficial to improve the power generation efficiency of the wind power generator.

[0099] The wind-driven generator of this embodiment may include the stator in Embodiment 2, and the use of the stator containing the cooling device 100 is conducive to maintaining a relatively suitable temperature for the wind-driven generator, improving the stability of the wind-driven generator, and improving wind powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com