Winter grape pruning system suitable for T-shaped cultivation mode

A cultivation mode and pruning technology, applied in the field of grape winter pruning system, can solve the problems of high cost and high difficulty in operation, and achieve the effects of promoting yield, reducing manpower input and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing:

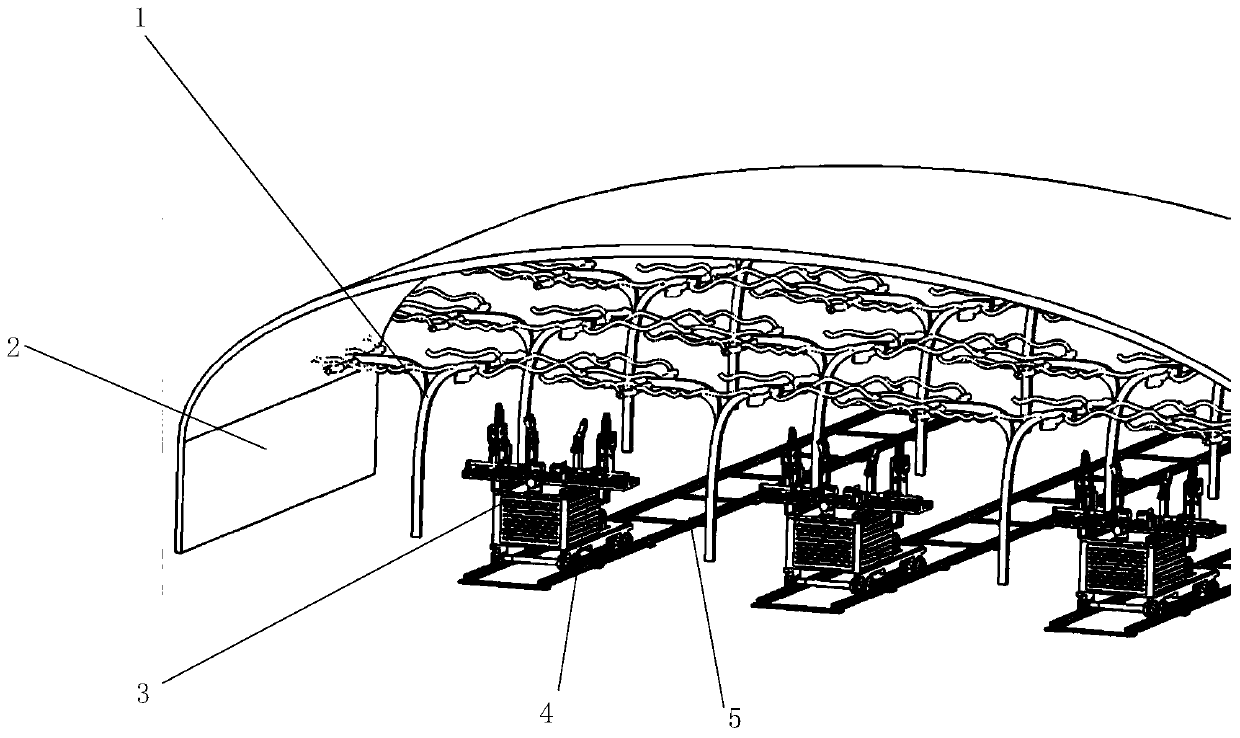

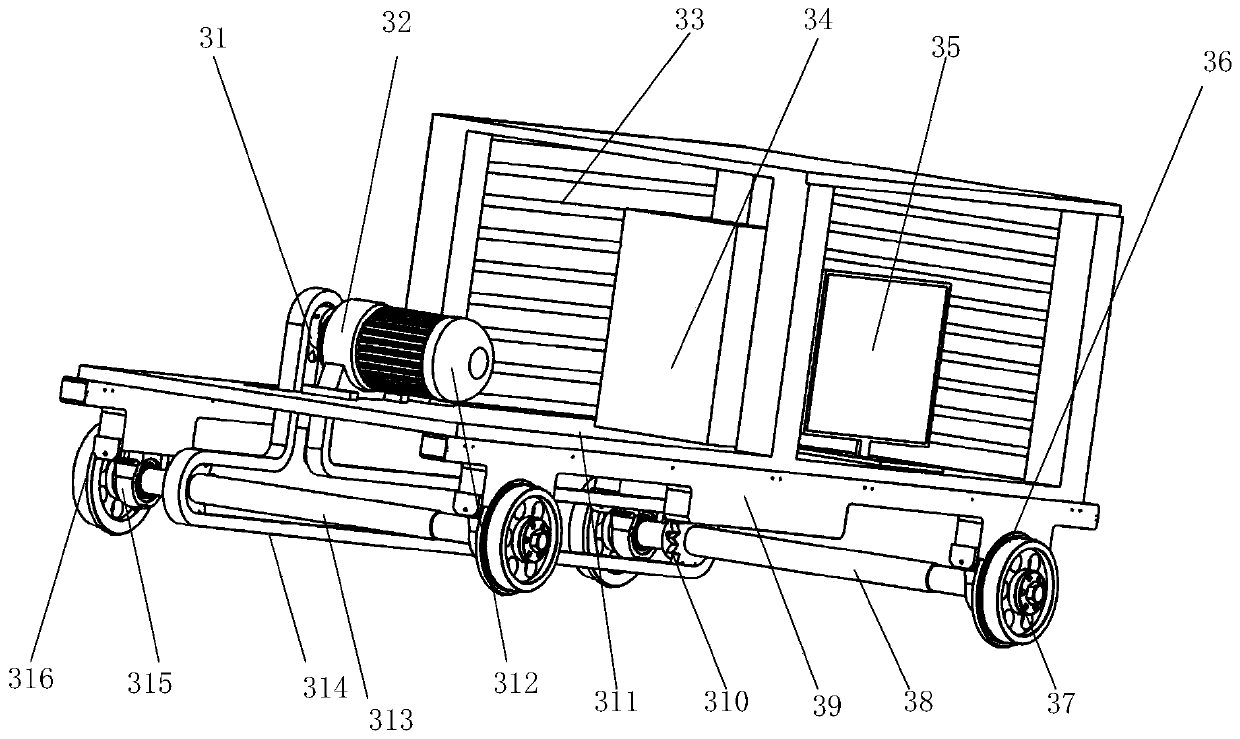

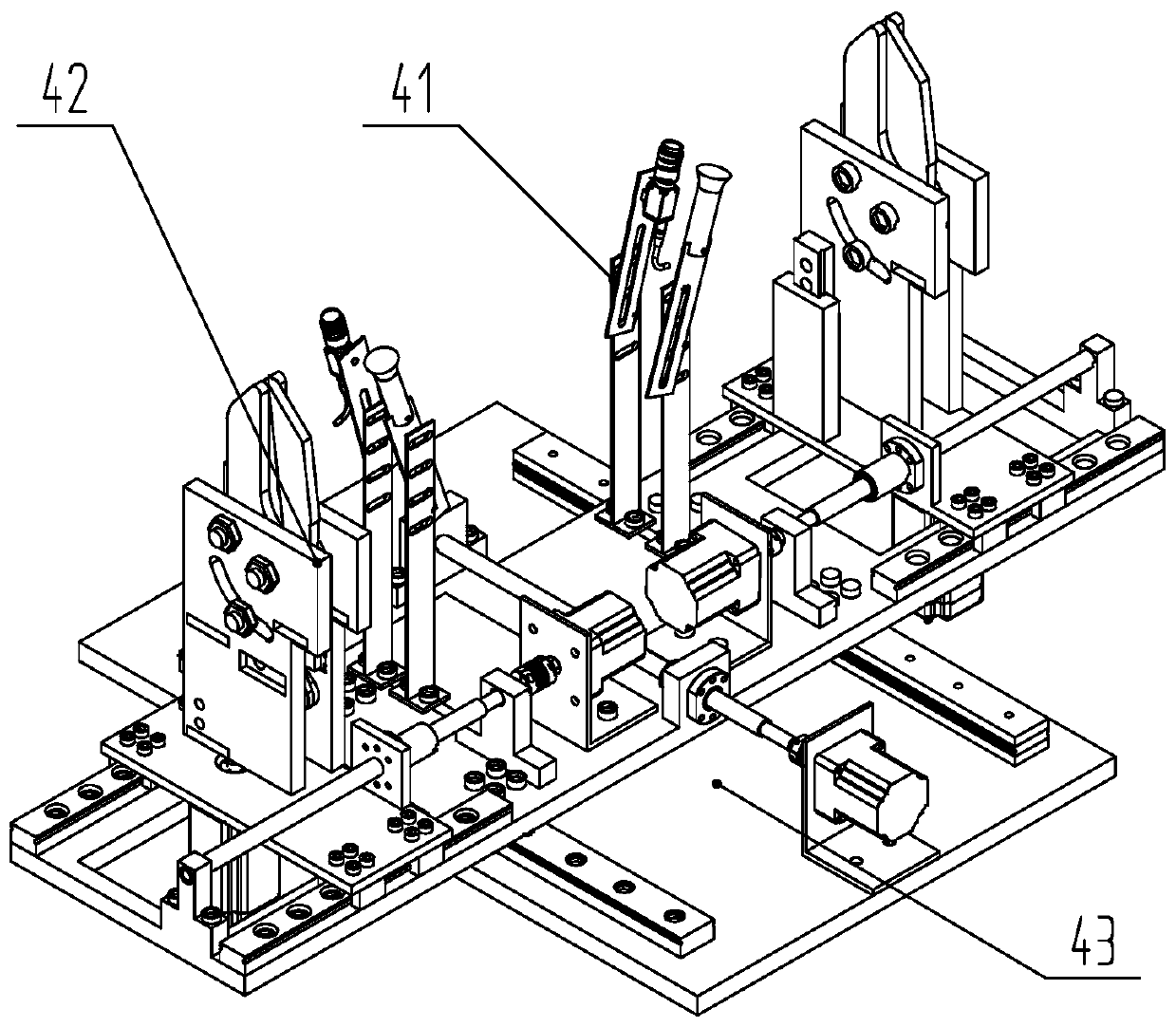

[0037] like Figure 1-6 As shown, a grape winter pruning system suitable for T-shaped cultivation mode, including greenhouse 2, track 5, mobile operation vehicle 3 and pruning device 4, vine 1 is cultivated in T-shaped greenhouse 2, and track 5 is laid Between two adjacent rows of vines 1, the mobile operation vehicle 3 is arranged on the track 5 and moves along the track 5, the pruning device 4 is fixedly installed on the mobile operation vehicle 3, and the pruning device 4 is moving The grape branches are trimmed when the work vehicle 3 moves along the track 5 .

[0038] Greenhouse 2 can control the light conditions in the greenhouse, so that grapes can ensure sufficient light, temperature and good ventilation conditions during normal growth, so as to promote the improvement of grape yield; The difficulty and improve the identification efficiency of pruning points, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com