Automatic injector

A technology of automatic injectors and components, applied in the field of medical devices, can solve the problems of low reliability, difficult assembly, high product cost, etc., and achieve the effects of avoiding repeated use, reducing parts and components, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

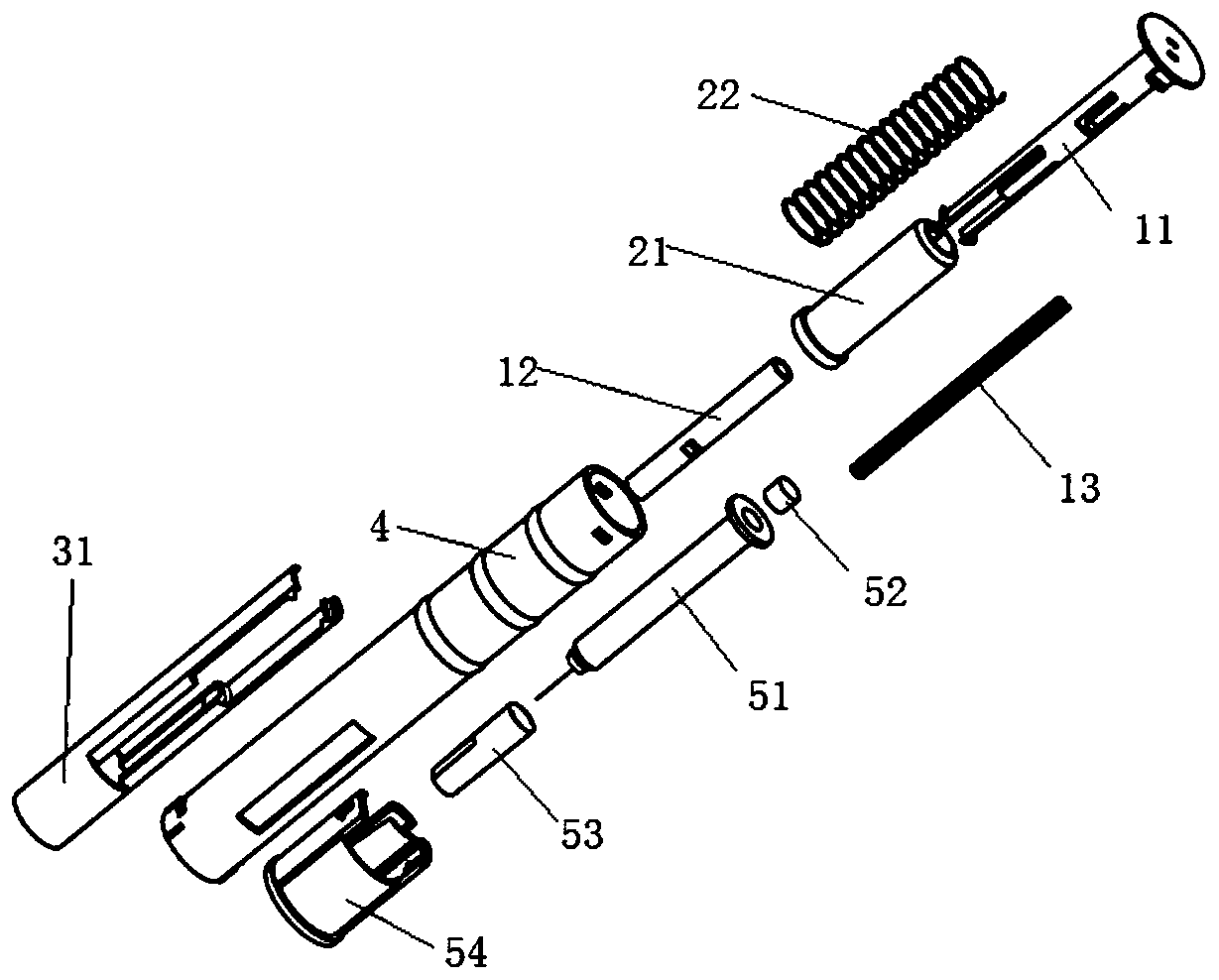

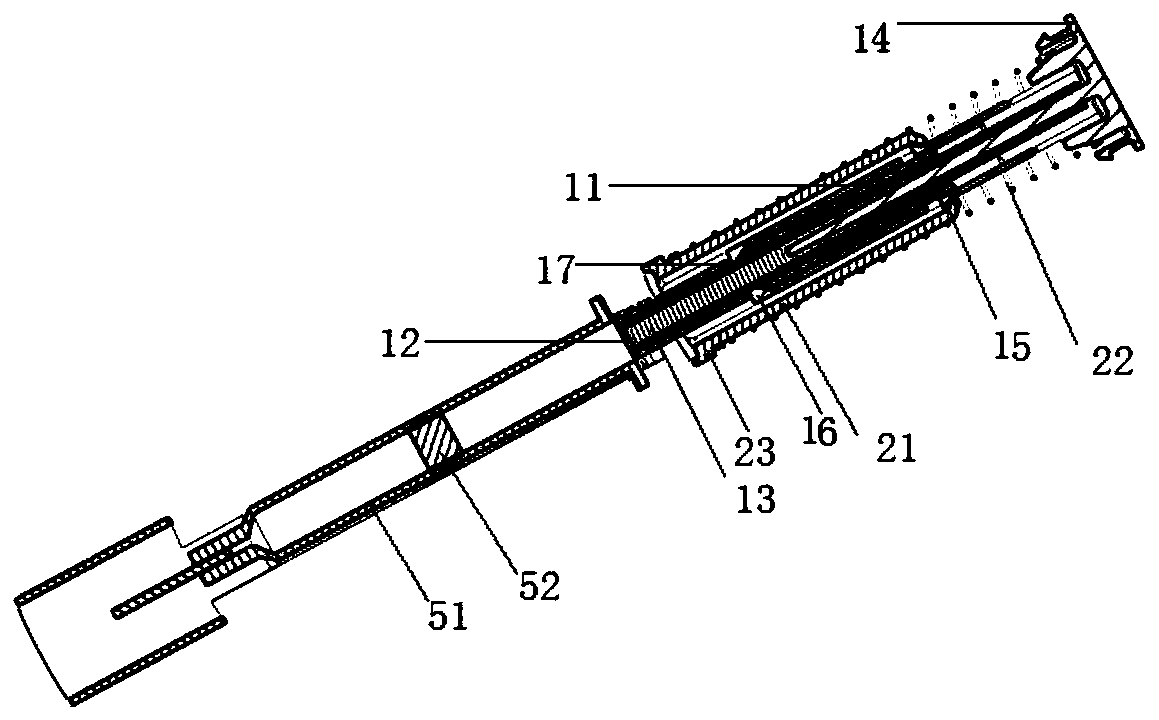

[0049] Such as Figure 1-6 As shown, an automatic injector includes a main shaft 11, a main spring sleeve 12, a main spring 13, an activation sliding sleeve 21, an auxiliary spring 22, a syringe sliding sleeve 31, a housing 4 and a prefilled syringe 51;

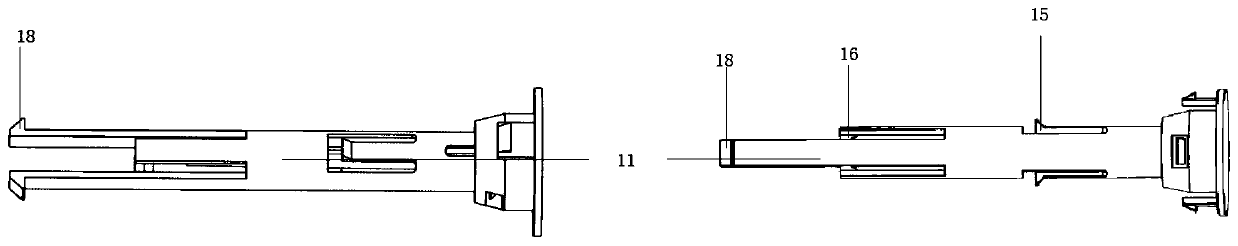

[0050] The shaft body of the main shaft 11 is hollow, one end of which is closed and has a first flange 14, and several elastic first bumps are arranged on the shaft body 11 according to the distance from the first flange 14 from near to far. 15 and the second protrusion 16, the first protrusion 15 protrudes toward the outer surface of the shaft, and has an axial guide slope toward the first flange 14, and the second protrusion 16 protrudes toward the inner surface of the shaft The protrusion has an axial guide slope towards the first flange 14;

[0051] In the assembled state, the main spring sleeve 12 is located in the shaft body of the main shaft 11, one end of which is closed and the other end is open, the closed end can...

Embodiment 2

[0058] Such as image 3 As shown, in this embodiment, the shaft body wall where the first and second protrusions 15, 16 are located is hollowed out to form a strip with elasticity, and the first and second protrusions 15, 16 are located on the strip, When the elastic strips of the first and second projections 15, 16 were in a straight line, the strip width of the second projection 16 was greater than the width of the groove 24 in the starting sliding sleeve 21, so that the second projection The strip of the block 16 will not be entirely located in the space of the groove 24 , so as to ensure that the inner wall of the starting sliding sleeve 21 can press the second protrusion 16 tightly.

Embodiment 3

[0060] In this embodiment, the closed end of the main spring sleeve 12 is perforated, which is conducive to the timely discharge of the air between the main spring sleeve 12 and the piston of the prefilled syringe 51. After the injection is started, the main spring sleeve 12 and the piston 52 quickly Access without barriers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com