Digital twin structure test system and method based on a 3D printing platform

A technology of structural testing and 3D printing, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve problems such as geological structure simulation accuracy errors, difficult structural models, unfavorable model tests, etc., to achieve easy operation and avoid light Insufficient, the effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

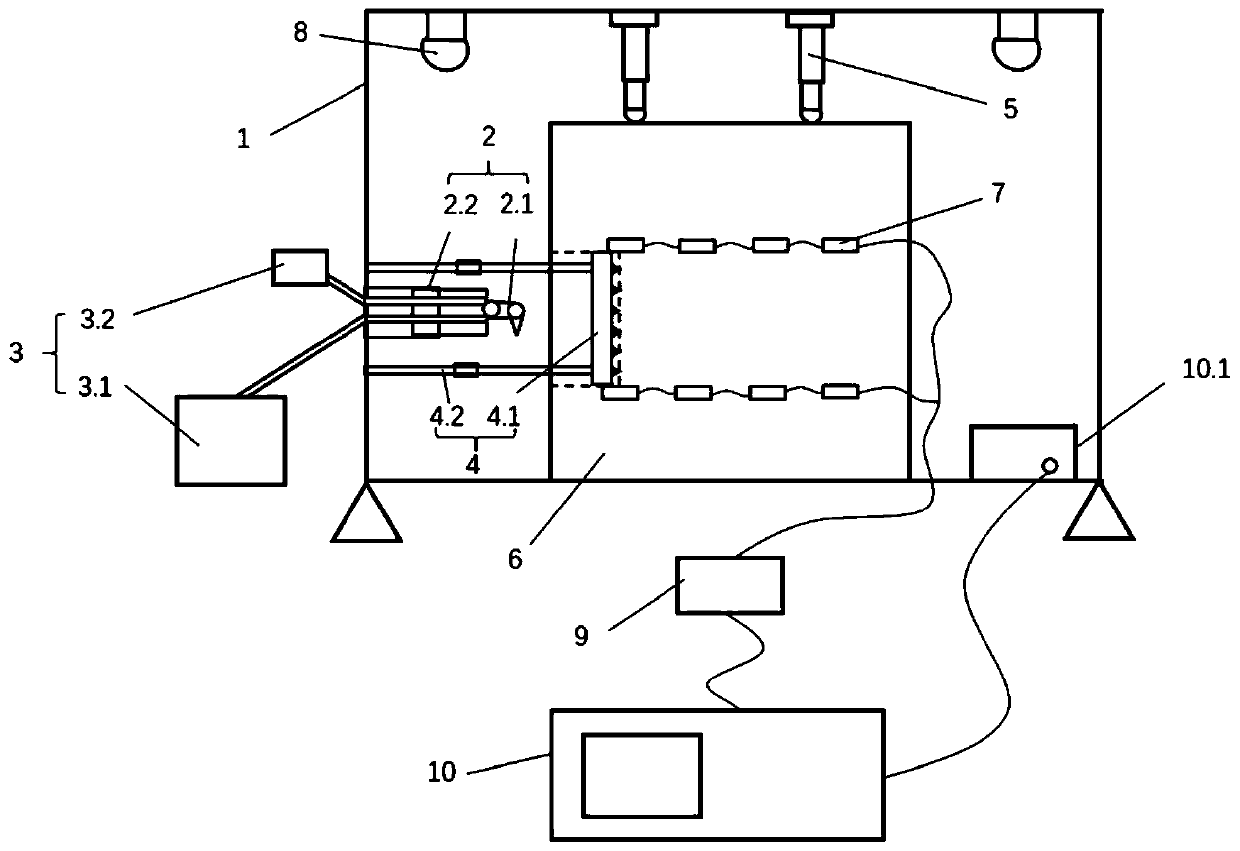

[0046] Embodiment 1 of the present invention provides a digital twin structure test system based on a 3D printing platform, its structure is as follows figure 1 As shown, the digital twin structural test system based on the 3D printing platform includes:

[0047] Printing platform 1, structural printing component 2, feeding component 3, tunneling component 4, loading device 5, structural model 6, micro sensor 7, high-speed camera 8, data acquisition card 9, industrial computer 10.

[0048] The structure and function of each component of the digital twin structural test system based on the 3D printing platform are as follows:

[0049] The printing platform 1 is composed of a 6m×4m×4m steel material frame structure. The bottom of the printing platform 1 is a continuous flat plate, and four beams are arranged horizontally on the top for fixing the loading device 5 and the high-speed camera 8 . A mounting frame is arranged on the left side of the printing platform 1 , and the wid...

Embodiment 2

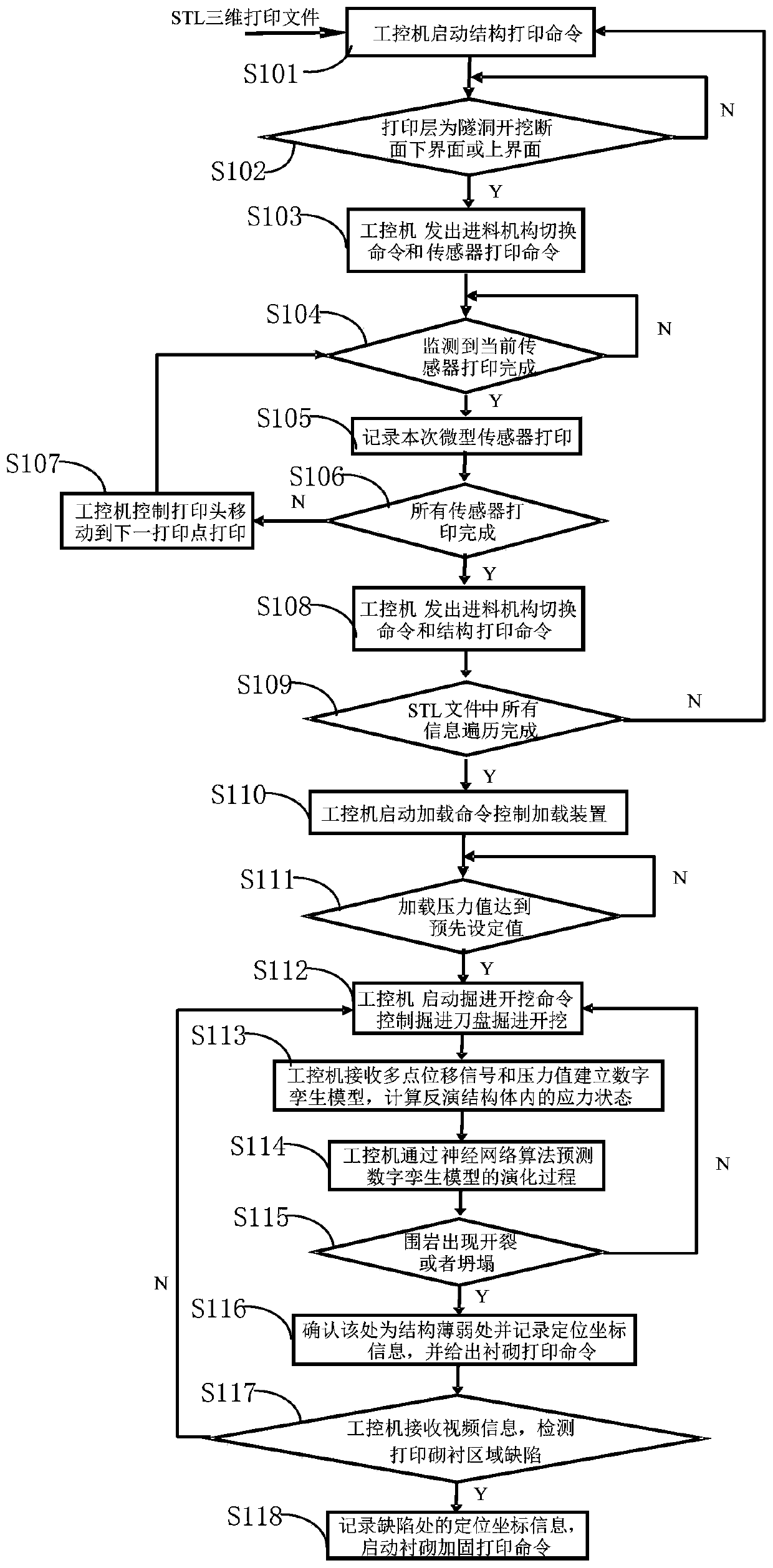

[0072] Embodiment 2 of the present invention provides a digital twin structure test method based on a 3D printing platform, and its implementation process is as follows figure 2 shown, including the following steps:

[0073] In step S101, the working machine 10 starts the structural printing command through the printing controller 10.1 to control the structural printing component 2 to perform hierarchical printing. The structure printing command contains: a structure printing command signal, node units of the structure model, and node unit coordinate information. The node units and node unit coordinate information of the structural model are obtained according to the 3D printing file in STL format acquired by the industrial computer 10 .

[0074] The structural printing component 2 receives the structural printing command, starts printing the large-scale structural model 6 in the space of the printing platform 1, and moves the moving path of the printing head 2.1 according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com