Polyester foam board heating welding process and heating welding equipment

A technology of welding equipment and foam board, which is applied in the field of polyester foam board heating and welding technology and its heating and welding equipment, can solve the problems of poor compression and bending resistance, affecting the quality of polyester foam board welding, etc. Improve hot melt stability and ensure long-term cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

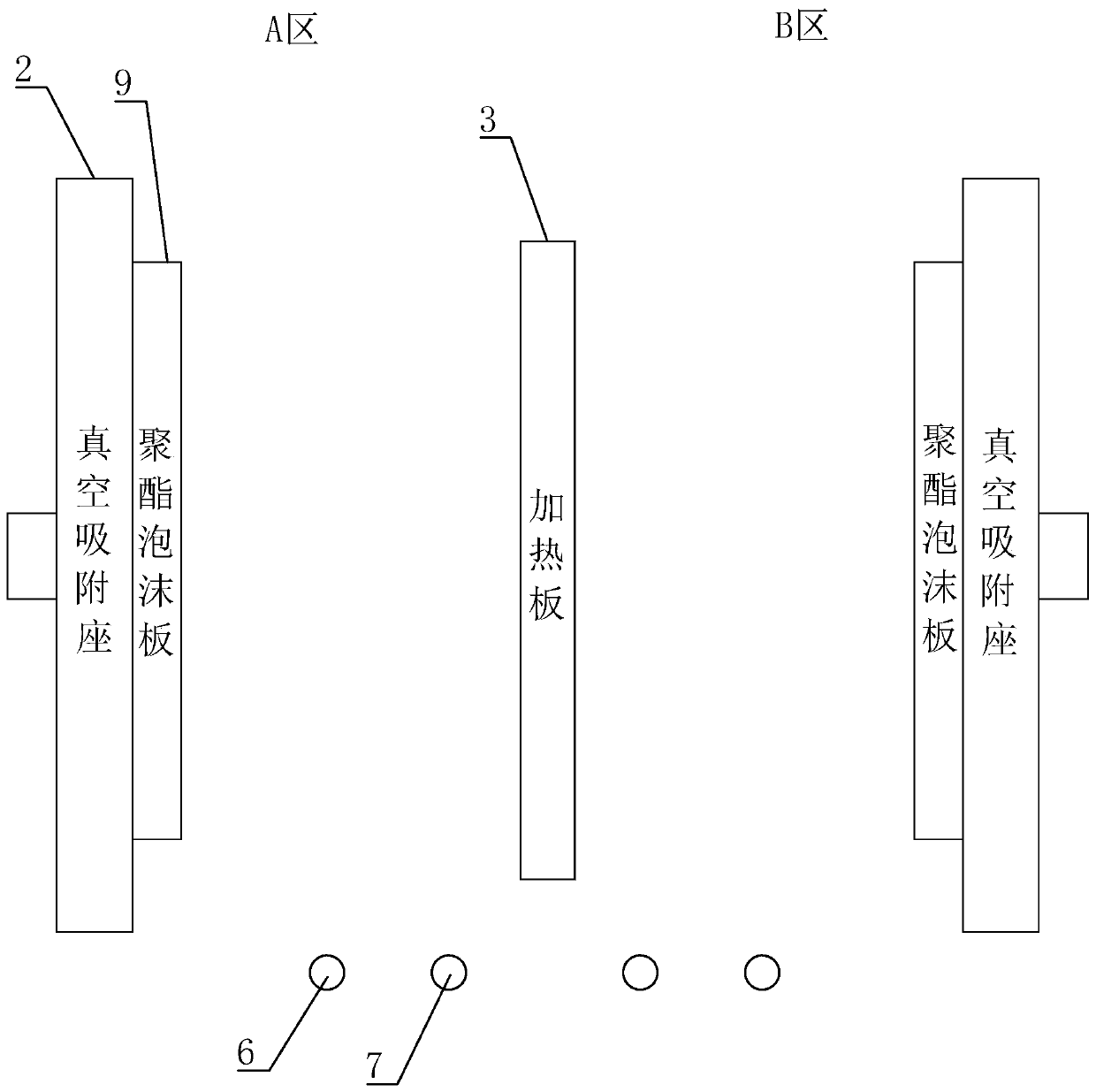

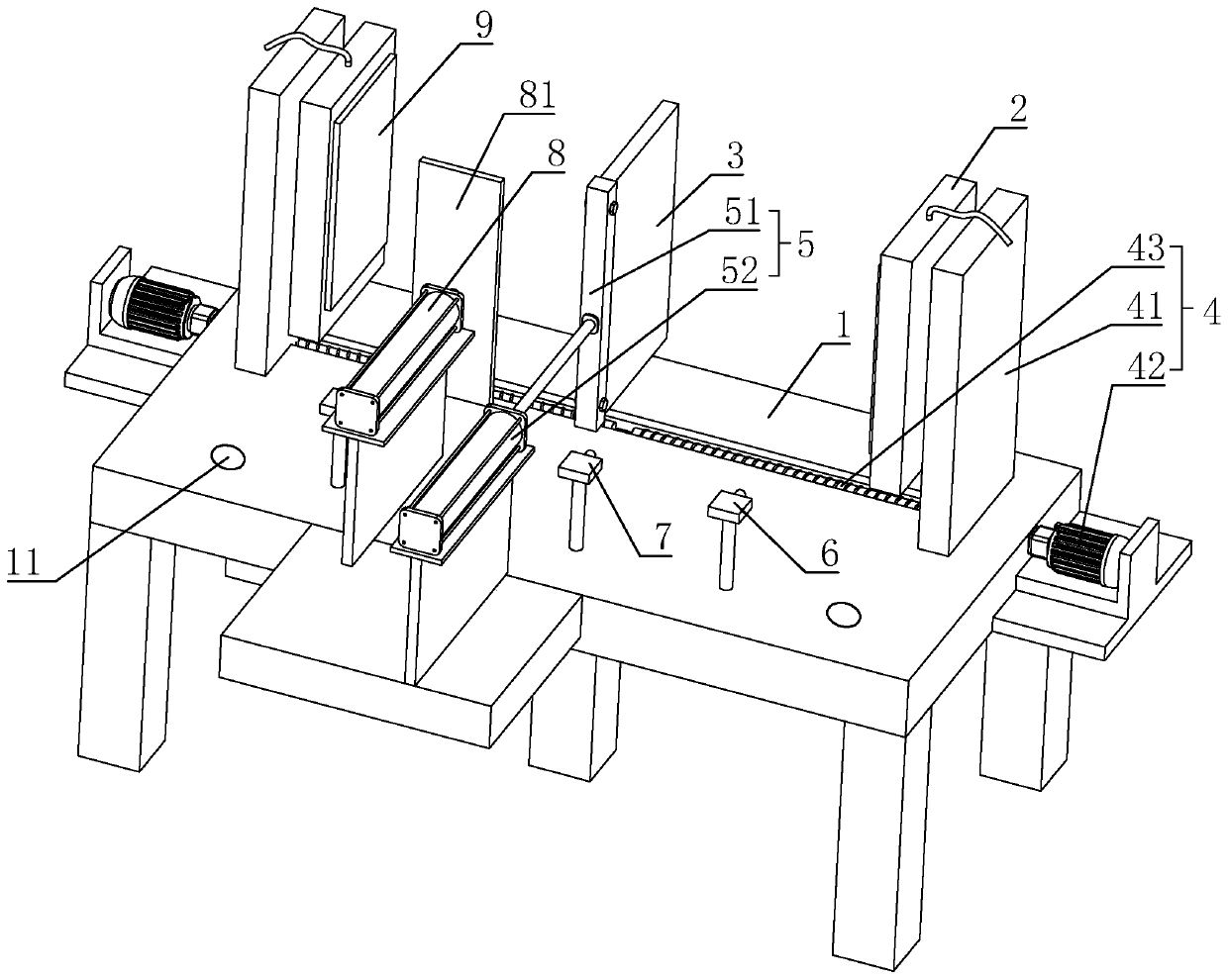

[0031] Embodiment: a kind of heating welding equipment of polyester foam board, as figure 1 and figure 2 , including a rack 1, areas A and B located on the rack 1, and two vacuum suction seats 2 respectively located in areas A and B, and the vacuum adsorption seats 2 are connected to a vacuum pump (not shown in the figure) The frame 1 is provided with two start-stop switches 11 for respectively controlling two vacuum adsorption pumps. The polyester foam board 9 is loaded on the vacuum suction seat 2, and the frame 1 is respectively provided with a first drive member 4 for driving the vacuum suction seat 2 in the A area and the B area.

[0032] Such as figure 1 and figure 2, the first driver 4 includes a positioning plate 41, a servo motor 42 and a screw mandrel 43, the servo motor 42 is fixed on the frame 1, the screw mandrel 43 is arranged along the length direction of the frame 1 and is fixedly connected to the output end of the servo motor 42 On the top, the positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com