Water-pressure-resistant waterborne polyurethane resin

A technology of polyurethane resin and water pressure, which is applied in the field of polyurethane resin preparation, can solve the problems of short service life, poor water pressure resistance, and poor corrosion resistance of synthetic materials, and achieve improved water pressure resistance, water resistance, and stretch resistance. The effect of strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

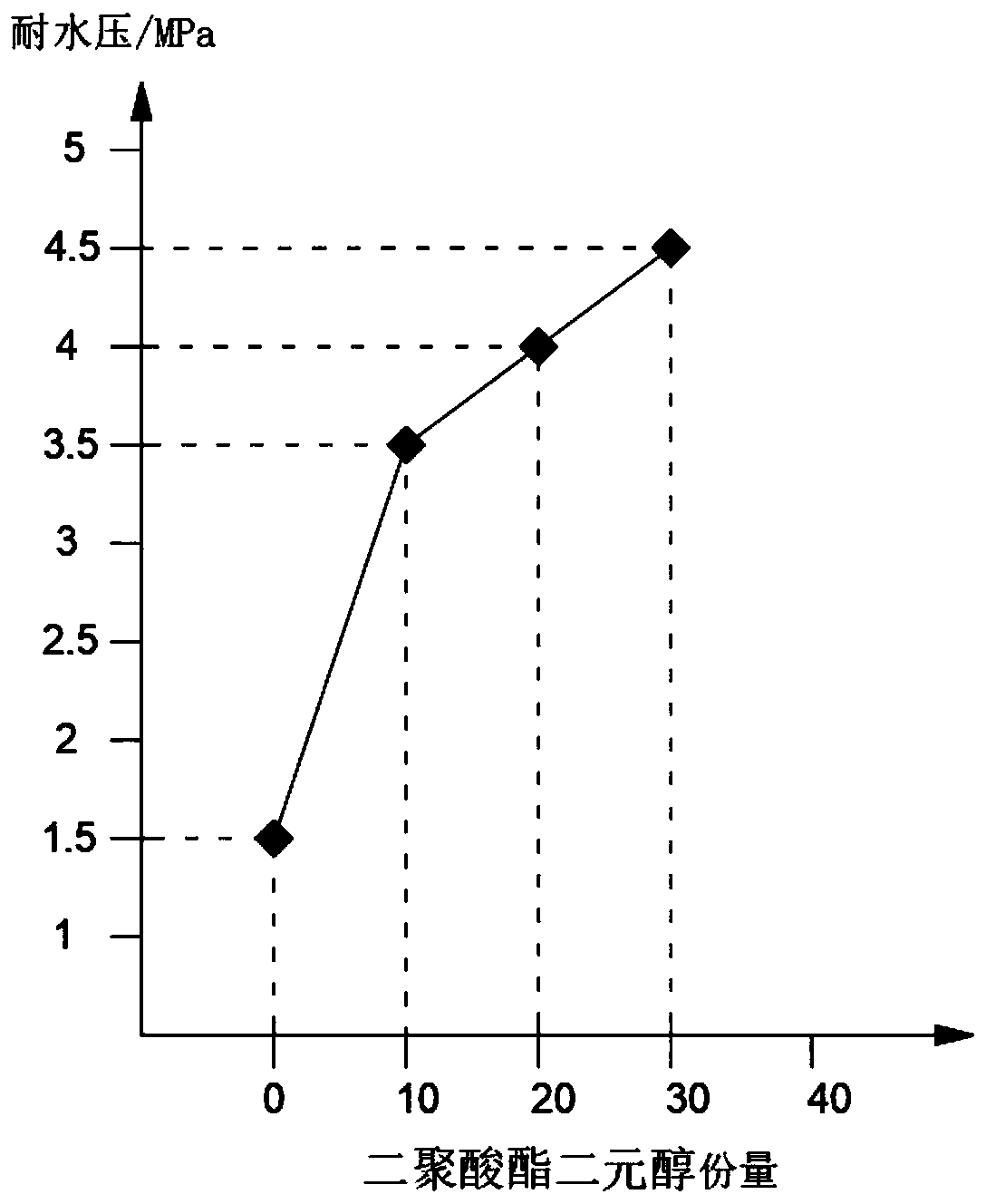

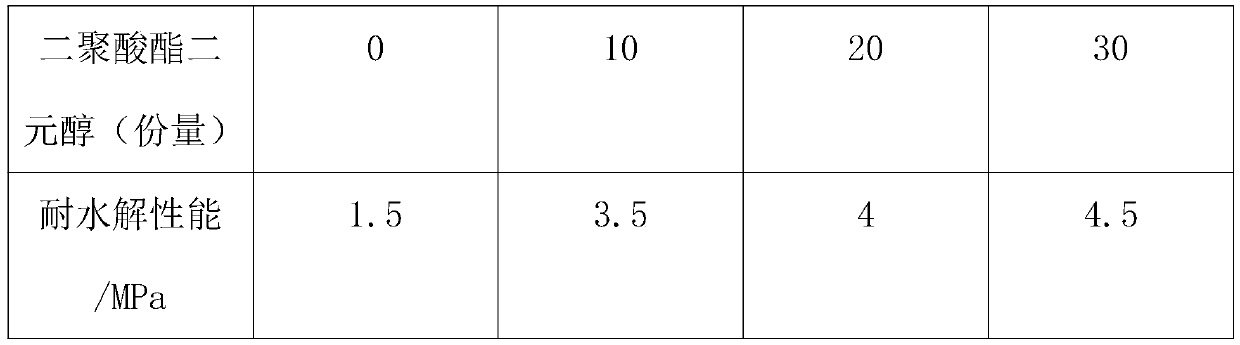

[0018] A water pressure-resistant water-based polyurethane resin, raw materials include polyol, polyisocyanate, hydrophilic carboxylic acid chain extender, polycarbonate diol, dimer ester diol, first neutralizer, second neutralizer Agent, acetone and stabilizer, the specific preparation method adopts the following steps: Step 1: Add polyol, polyisocyanate, hydrophilic carboxylic acid chain extender into the reaction vessel, evacuate the reaction system to vacuum, and then fill it with Nitrogen, carry out vacuum reaction; step 2: start stirring to mix the solvent inside the reaction vessel, and diss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water pressure | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com