Anti-glare diffusion plate and preparation process thereof

A preparation process and diffusion plate technology, which is applied in the field of anti-glare diffusion plate and its molding process, can solve the problems of poor dimensional stability, unsatisfactory flame retardant performance, poor optical performance of anti-glare diffusion plate, etc., and achieve excellent optical performance , the effect of reducing glare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

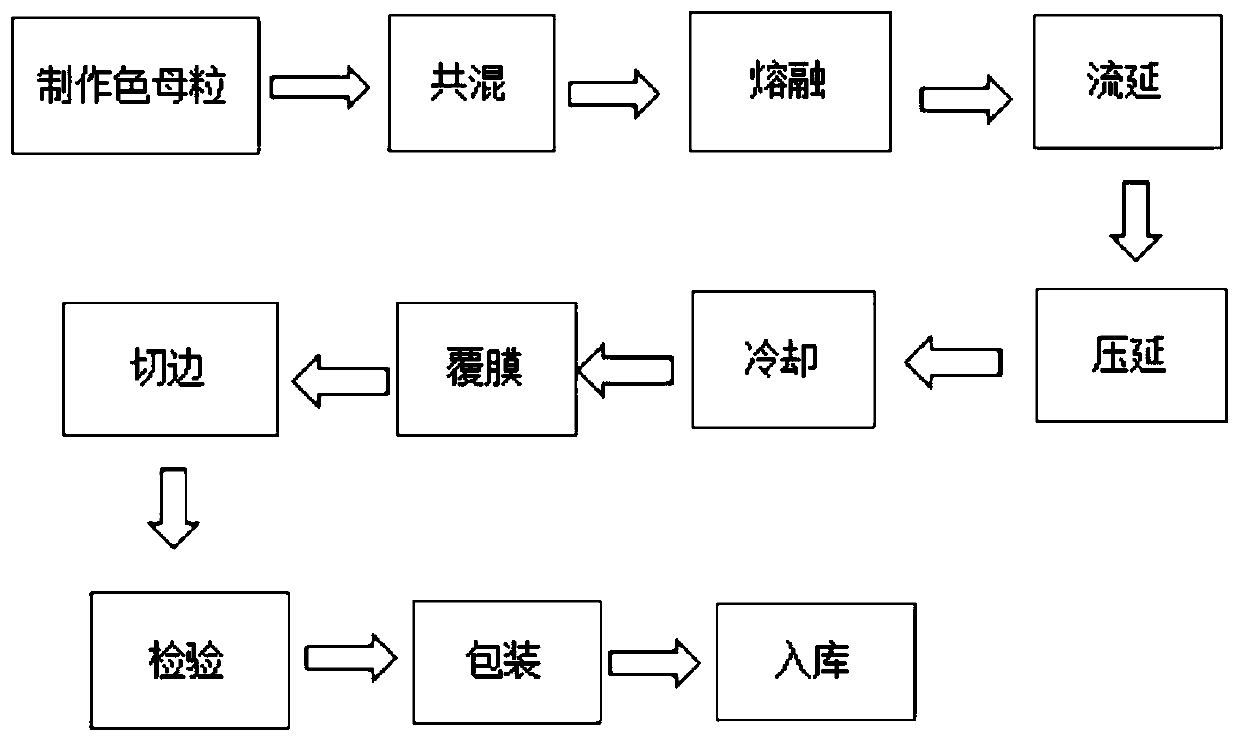

[0035] A preparation process of an anti-glare diffusion plate whose surface is composed of continuous convex semicircles, according to image 3 The schematic diagram of the technological process shown includes the following steps:

[0036] (1) Make masterbatch: Fully mix the flame retardant potassium perfluorobutyl sulfonate accounting for 0.3% of the total mass of raw materials with polycarbonate resin accounting for 33.23% of the total amount of polycarbonate resin, and enter the masterbatch machine. It is melted at a high temperature of 275°C, then extruded and cooled through the melting pipeline, and cut into masterbatches, which are used as auxiliary raw materials for making diffuser plates;

[0037] (2) Blending: mix the color masterbatch obtained in step (1) with the remaining polycarbonate raw materials through a V-shaped mixer;

[0038] (3) Melting: Add the mixture obtained in step (2) into the melt chamber of the equipment at a predetermined speed, and melt at 265°...

Embodiment 2

[0049] A preparation process of an anti-glare diffusion plate whose surface is composed of continuous convex regular pyramids, according to image 3 The schematic diagram of the technological process shown includes the following steps:

[0050](1) Make masterbatch: Fully mix the flame retardant potassium perfluorobutyl sulfonate accounting for 0.05% of the total mass of raw materials with polycarbonate resin accounting for 5.56% of the total amount of polycarbonate resin, enter the masterbatch machine, and It is melted at a high temperature of 275°C, then extruded and cooled through a melting pipeline and cut into color masterbatches, which are used as auxiliary raw materials for making diffuser plates;

[0051] (2) blending: the color masterbatch of step (1) gained and the polycarbonate raw material of remaining part are mixed uniformly by V-shaped mixer;

[0052] (3) Melting: Add the mixture obtained in step (2) into the melt cavity of the equipment at a predetermined spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com