Hot pressing sintering machine for packaging high-power semiconductor device

A hot-pressing sintering and device packaging technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as waste of materials, poor contact, wire burnout, etc., to save maintenance time, improve work efficiency, avoid random swing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

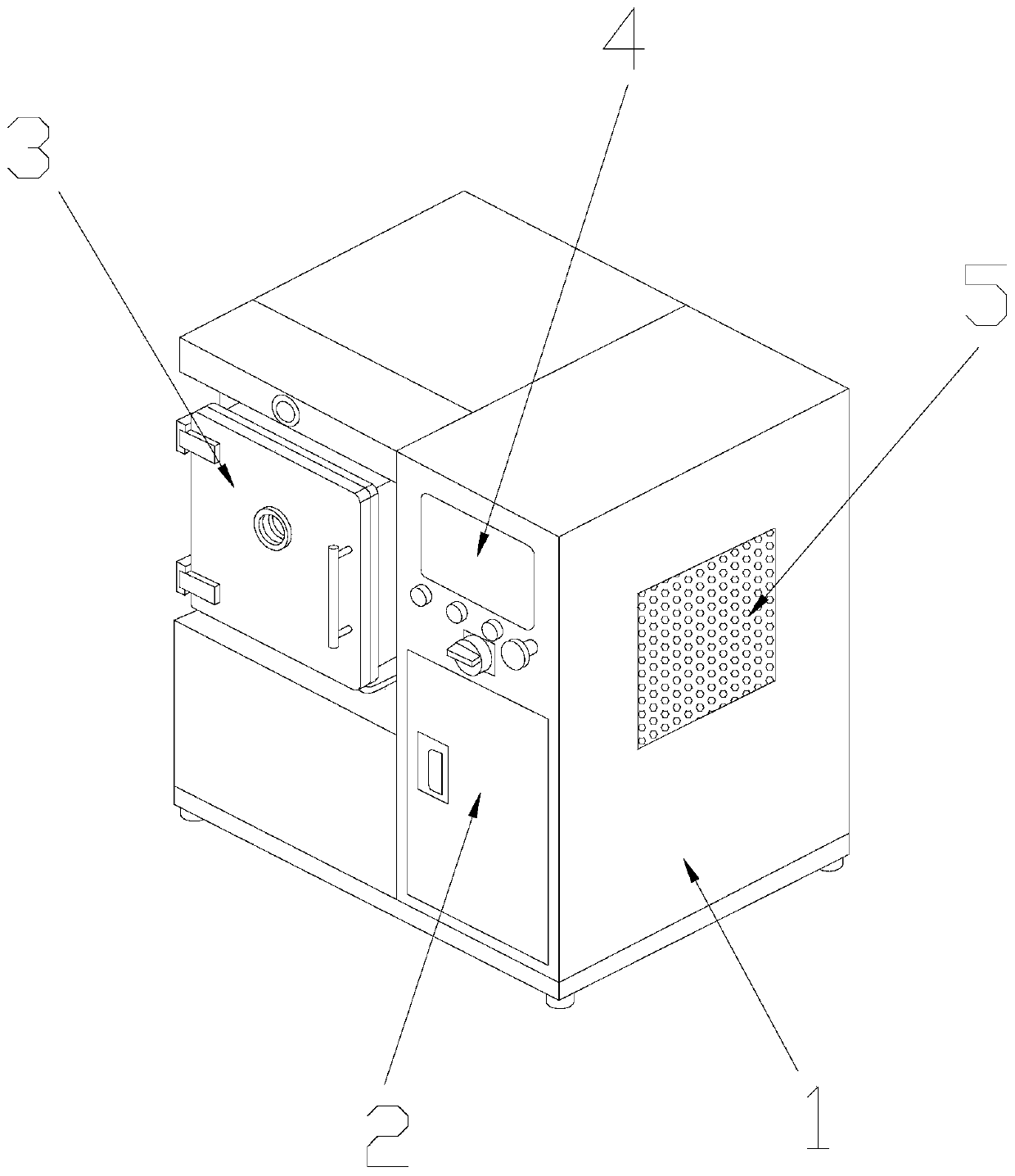

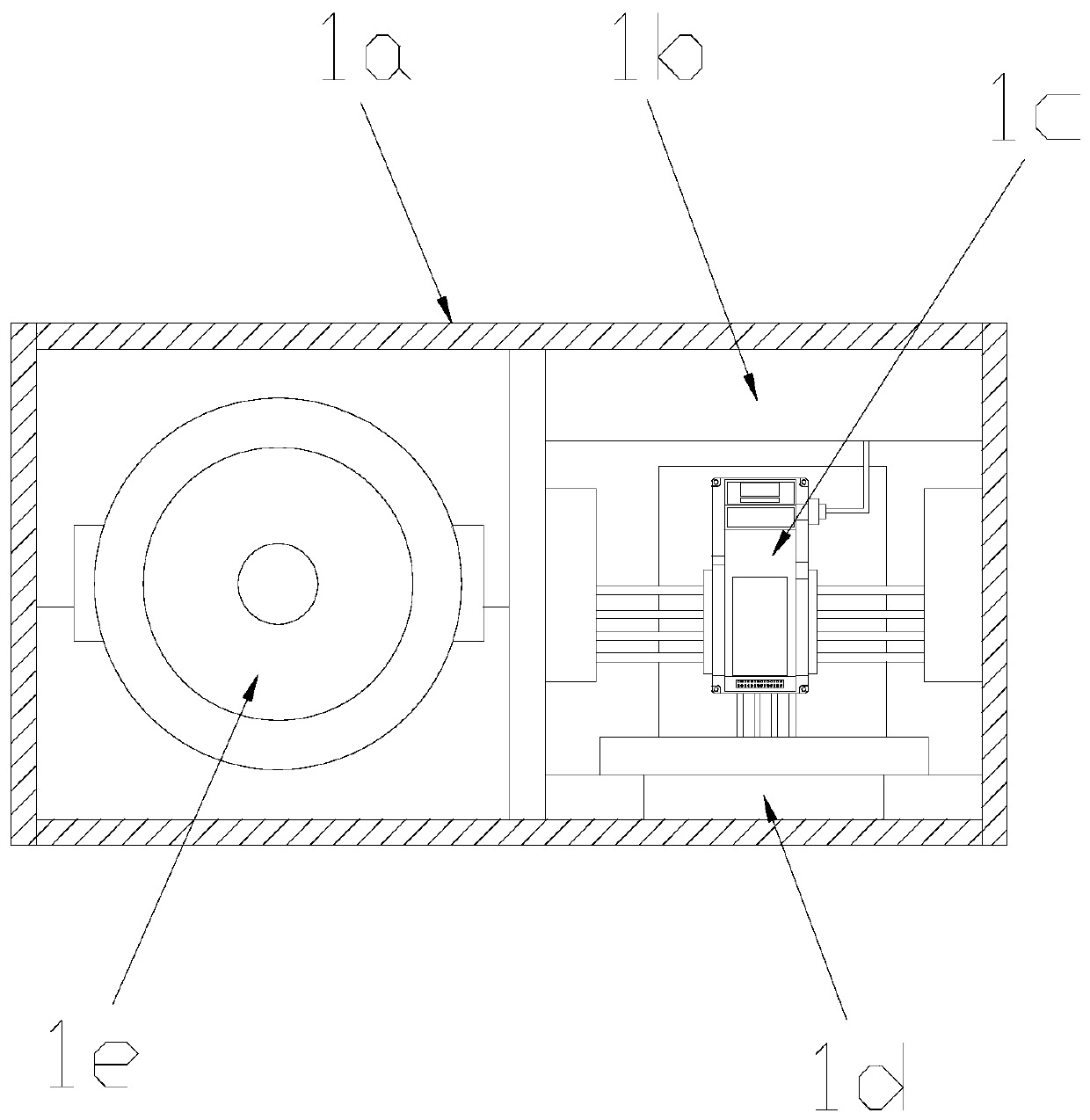

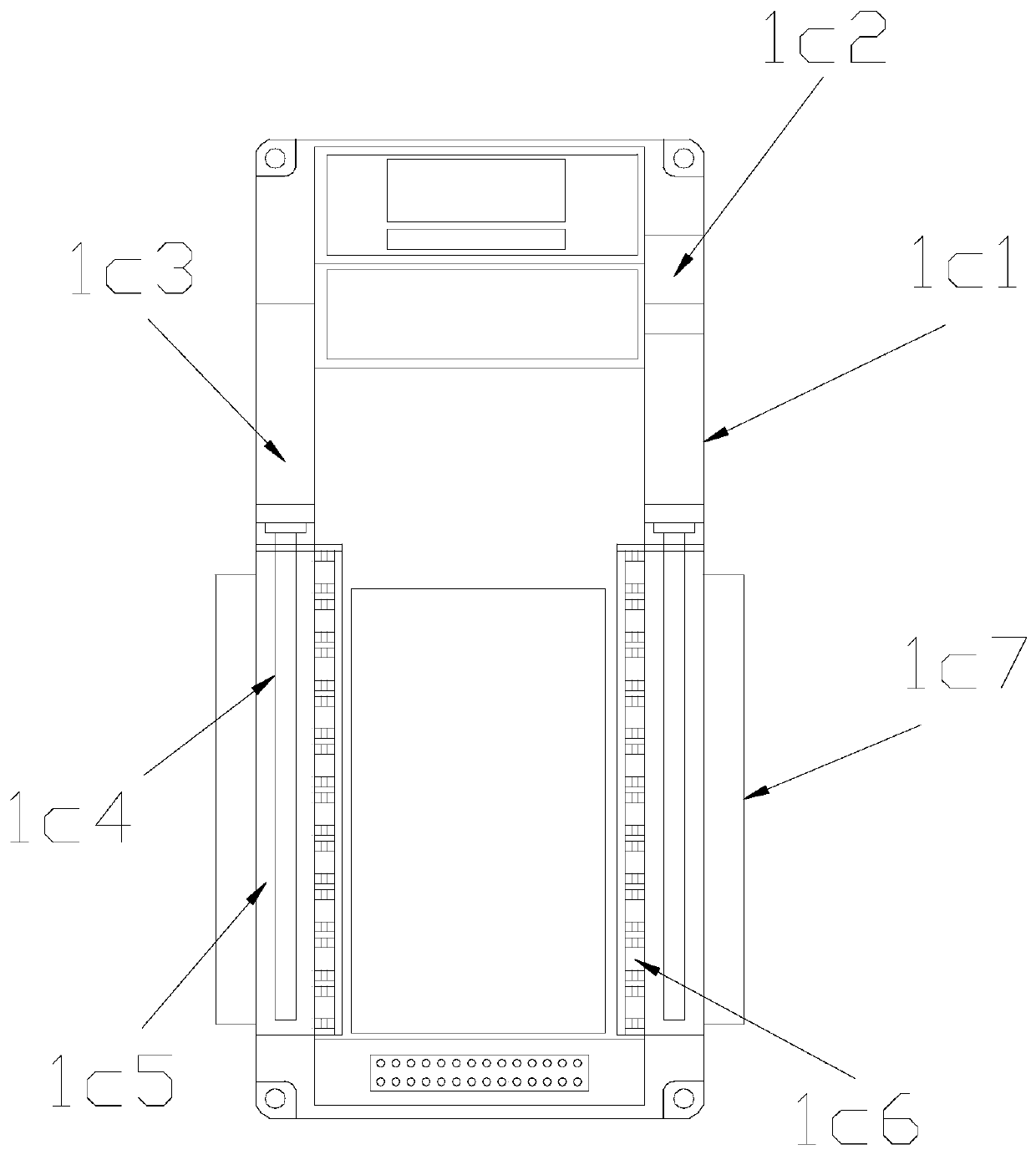

[0027] see Figure 1-Figure 6 , the present invention provides a hot-press sintering machine for high-power semiconductor device packaging, its structure includes a hot-press sintering machine 1, an inspection door 2, a machine door 3, a human-machine interface 4, and a radiator 5. The hot-press An inspection door 2 is provided on the front end of the sintering machine 1, and the hot pressing sintering machine 1 and the inspection door 2 are movably connected. The hot pressing sintering machine 1 is provided with a door 3 on the surface, and the hot pressing sintering machine 1 and The machine door 3 is connected by a hinge, a heat sink 5 is installed on the side of the hot pressing sintering machine 1, a human-machine interface 4 is arranged on the front surface of the hot pressing sintering machine 1, and the hot pressing sintering machine 1 consists of a body 1a, power supply device 1b, PLC programmable controller 1c, display 1d, and hot-pressing furnace 1e, the inside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com