Leaf spring and electric connector

A technology of electrical connectors and leaf springs, which is applied in the field of leaf springs and electrical connectors, can solve the problems of affecting the service life of electrical connectors, poor overcurrent capacity, small contact area, etc., achieve low production costs, ensure safe operation, The effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The leaf spring and the electrical connector of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

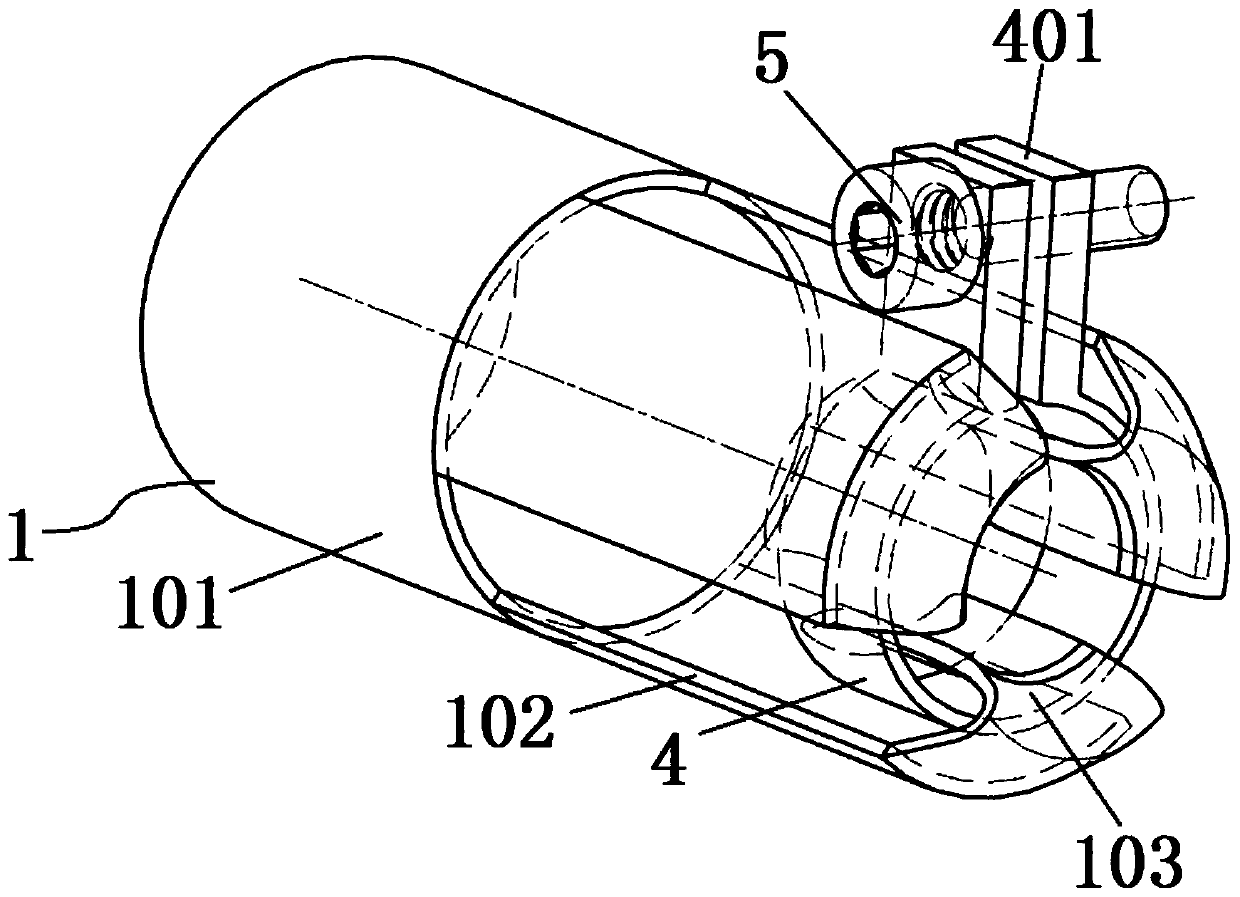

[0024] Such as figure 1 The leaf spring 1 shown includes a cylindrical connecting plate 101 penetrating left and right. The right end surface of the cylindrical connecting plate 101 is uniformly and vertically connected with several elastic pieces 102 along the circumferential direction. The end of each elastic piece 102 is a contact plate 103, each The contact plates 103 are all bent inward. The respective contact surfaces of the plurality of contact plates 103 are located on the same circumferential surface, and the circumferential surface is coaxial with the cylindrical connecting plate 101 . In this embodiment, there are three elastic pieces 102 .

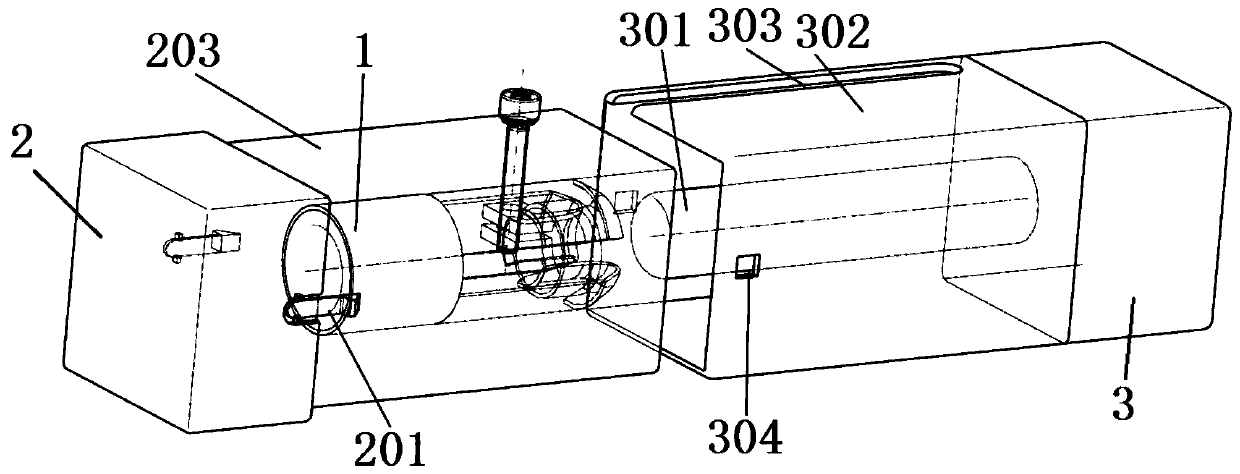

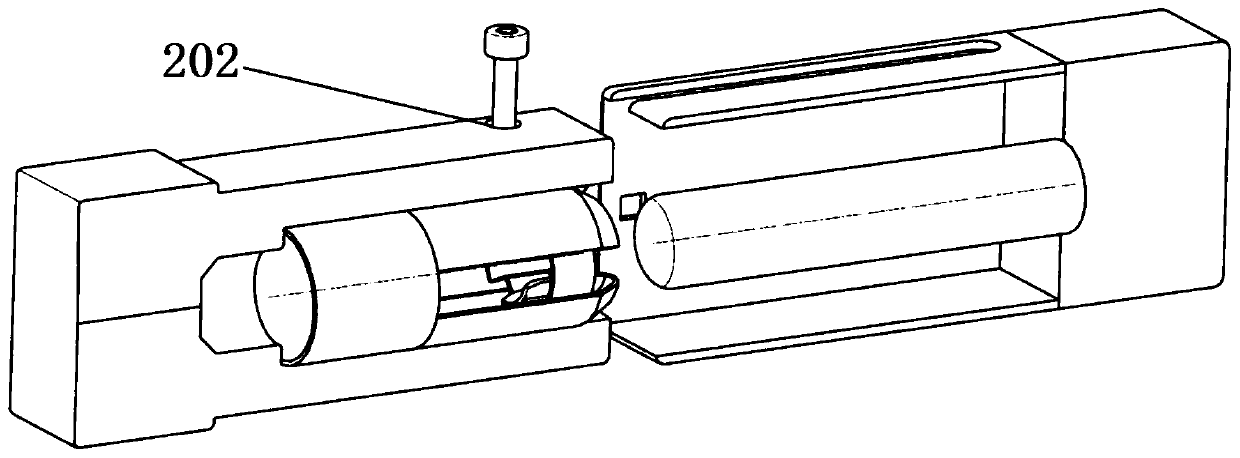

[0025] Such as figure 2 with image 3 The electrical connector shown includes a socket 2, a plug 3 and the above-mentioned leaf spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com