Steam oven with low power consumption

A technology of steam oven and low power consumption, which is applied to steam cooking utensils, roasters/barbecue grids, household appliances, etc. It can solve the problems of inability to adjust steam temperature, high power consumption, and affect the quality of food processing, and achieve steam utilization The effect of high efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

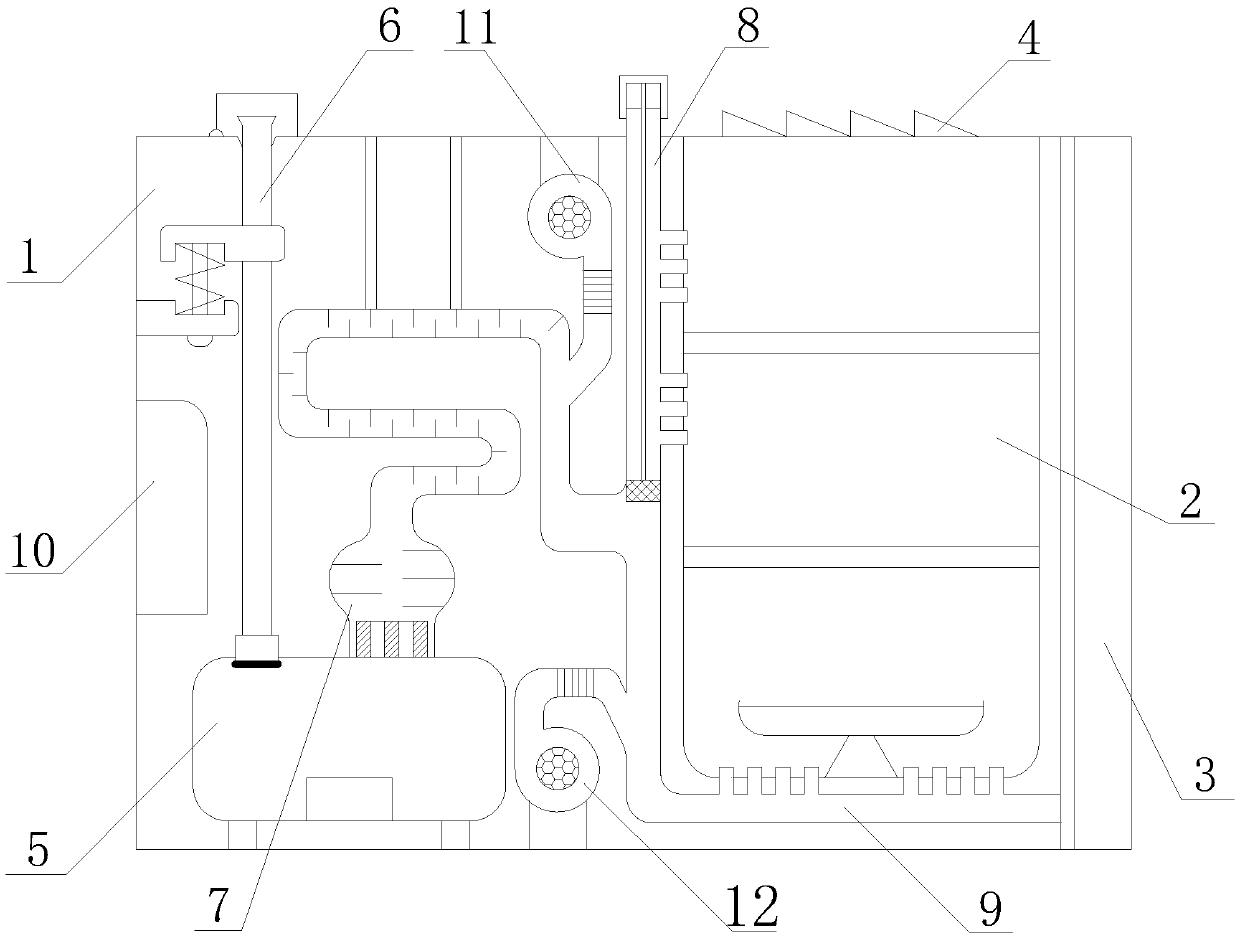

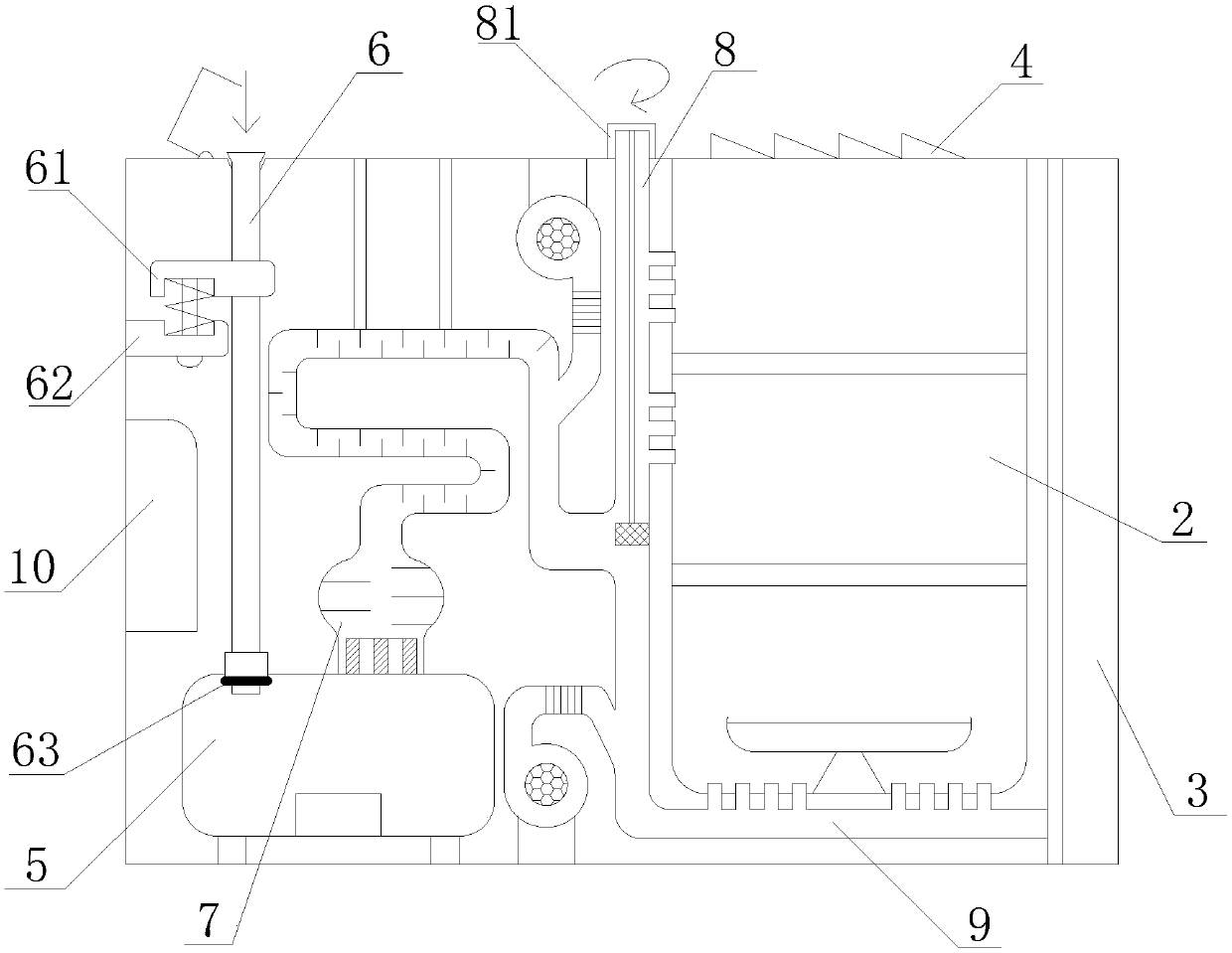

[0022] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

[0023] like figure 1 , 2 As shown, a low-power steaming oven according to the embodiment of the present application includes a box body 1, a steaming room 2 and a door 3, the steaming room 2 is provided with a baking pan and a grill, the box door 3 and the box body 1 It can be rotatably connected, and there is an exhaust hole 4 on the top of the steaming chamber 2. There is a water storage tank 5 inside the box body 1. The water storage tank 5 is provided with a water inlet pipe 6 and a heating pipe 7. The steaming chamber 2 is provided with a side steam Pipe 8 is connected with bottom steam pipe 9, and one end of heating pipe 7 is connected with water stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com