Welding aids for lumbar fatigue relief

An auxiliary device and fatigue technology, applied in auxiliary devices, welding/cutting auxiliary equipment, welding equipment, etc., can solve problems affecting work efficiency and welding quality, and achieve the goal of preventing arc heat damage, reducing production costs, and reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

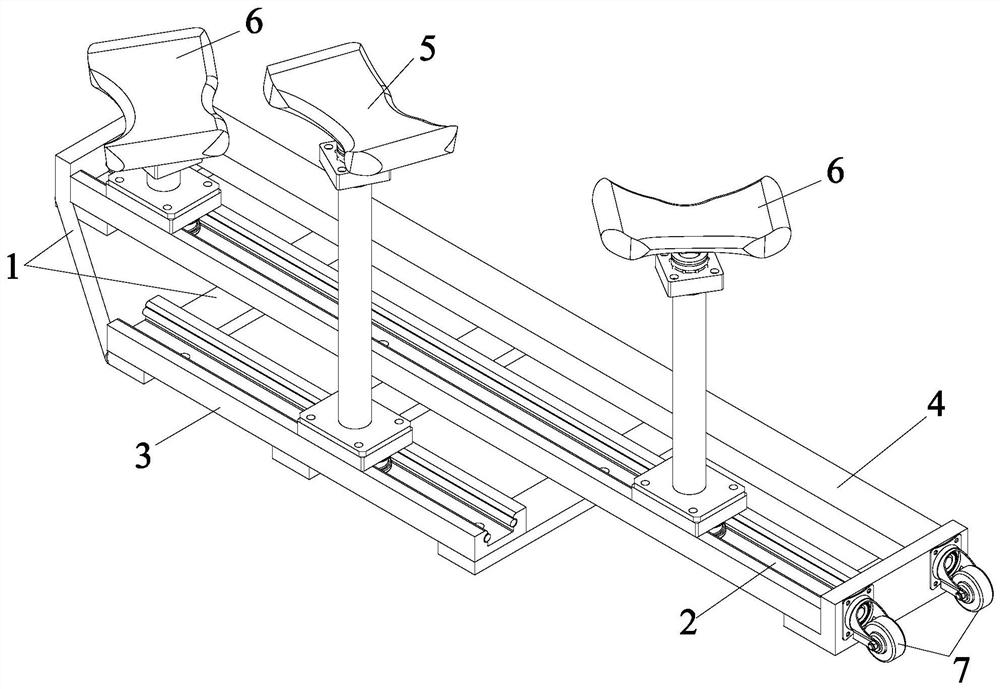

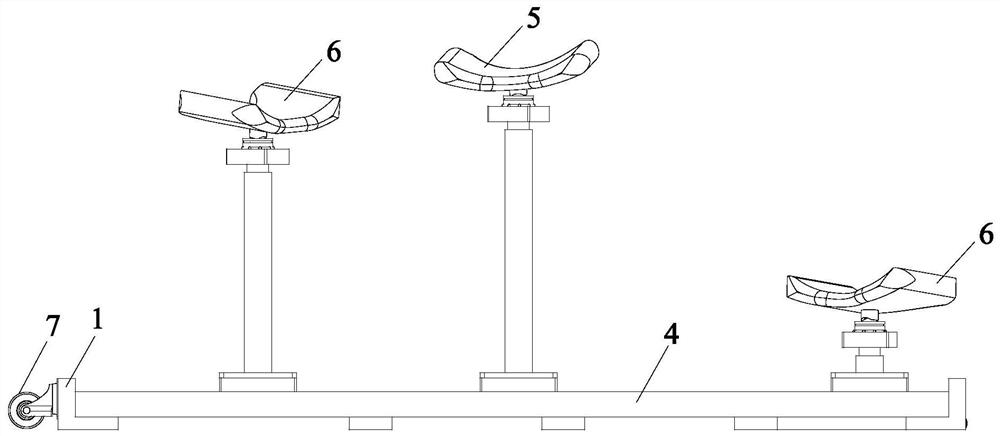

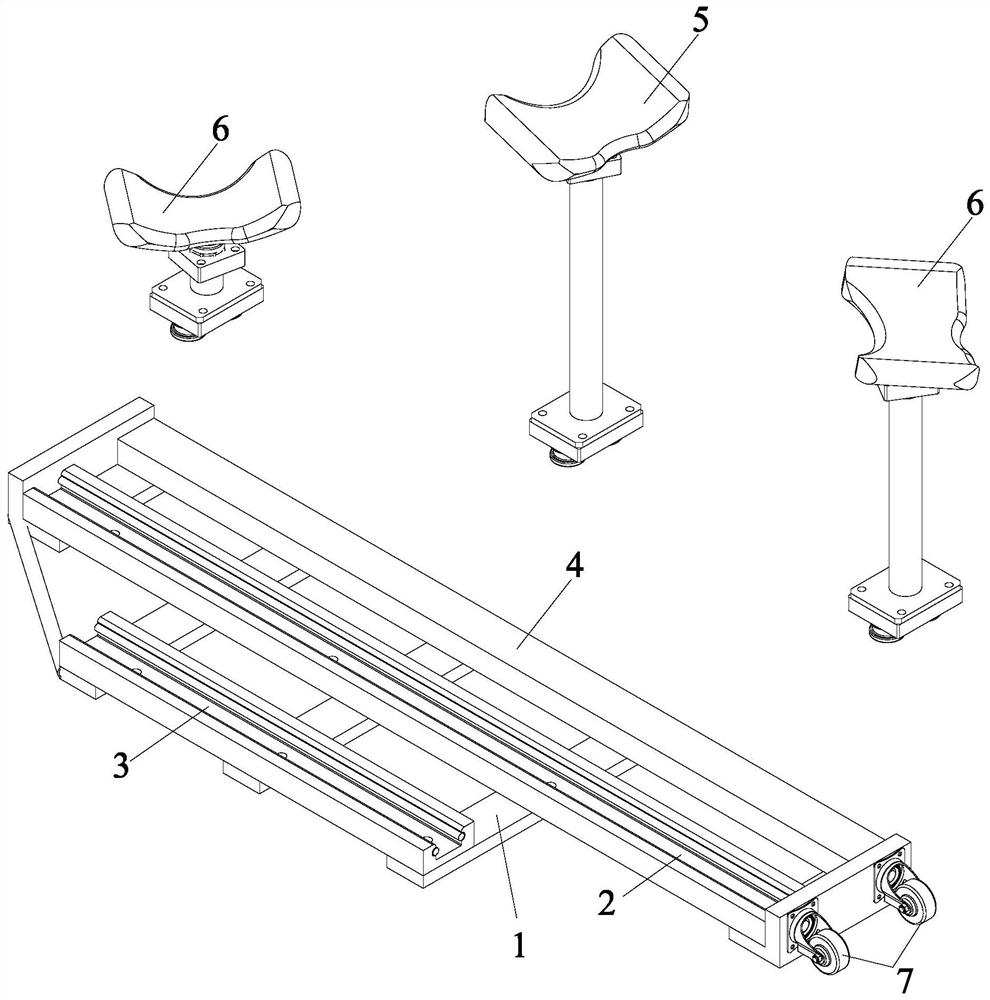

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] Such as Figure 1 to Figure 5 As shown, the welding auxiliary device for relieving waist fatigue of the present invention includes: a fixed base 1, a long guide rail 2, a short guide rail 3, a frame plate 4, an adjustable chest support mechanism 5 and two arm adjustable support mechanisms 6; The guide rail 3, the long guide rail 2, and the frame plate 4 are arranged in parallel in sequence along the length direction of the fixed base 1, and the two ends of the three are fixedly connected with the fixed base 1 respectively; the length of the short guide rail 3 can be designed as 0.5m, and the length of the long guide rail The length of 2 can be designed to be 1m, so that the device of the present invention can not only satisfy the maximum welding seam length, but also not occupy too much operating space. The frame plate 4 is a cuboid flat plate structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com