A photocatalytic degradation device for water treatment and its preparation method

A photocatalysis and water treatment technology, applied in the application field of 3D technology in water treatment, can solve the problems of high cost, cumbersome installation and assembly process, complex structure, etc., to achieve improved effect, excellent catalytic effect, extended contact area and duration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

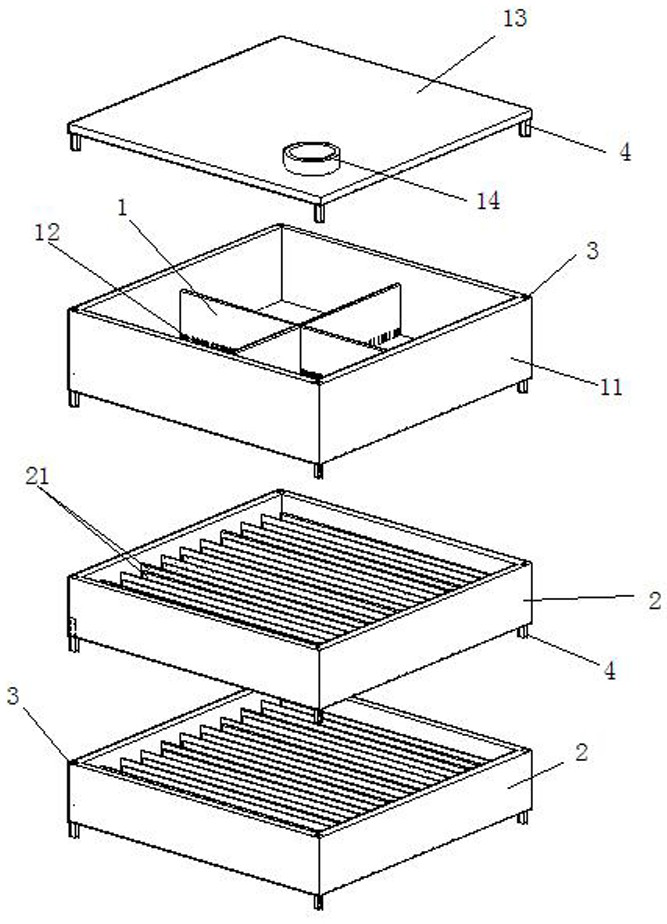

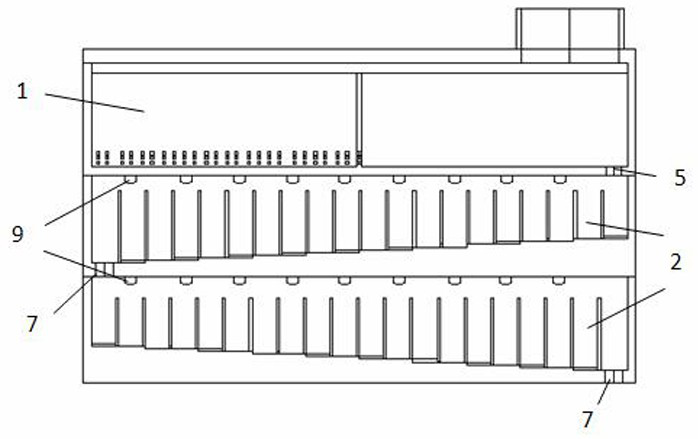

[0029] Such as Figure 1-2 As shown, a photocatalytic degradation device for water treatment, the device includes an upper and lower connected filter part and a photocatalytic part, the filter part is composed of a filter unit with a cover, and the filter unit includes A square box 11 with an open top, a closed bottom, and a water outlet 5. The four corners of the top of the box 11 are respectively provided with insertion grooves 3, and the four corners of the bottom are respectively provided with insertion rods 4. The box 11 is wrapped around the bottom of the box. Four vertical filter plates 1 arranged at equal intervals, and the space in the box is divided into four spaces by four vertical filter plates 1, and the bottoms of the adjacent three vertical filter plates are provided with filter holes 12. The aperture of filter hole 12 is 1mm. .

[0030] The bottom surface of the cover 13 is provided with an insertion rod 4 and is mated with the insertion groove 3 of the filte...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that the photocatalytic part is composed of three photocatalytic units, and the others are the same.

Embodiment 3

[0041]The difference between this embodiment and embodiment 2 is that the preparation method of the photocatalytic degradation device for water treatment is as follows:

[0042] 1) Take 10 parts of nano-titanium dioxide, 90 parts of PLA and 3 parts of TPU in parts by mass, mix and stir after drying to prepare a mixture;

[0043] 2) Heat and blend the mixture in an extruder, extrude and cut into pellets to obtain the mixture and dry it at 80°C for 2 hours;

[0044] 3) Add the dried blend obtained in step 2) into a wire drawing machine and draw to obtain a wire for 3D printing;

[0045] 4) Use the 3D printing wire obtained in step 3) as the raw material, and use the FDM3D printer to print the formed capping frame, filter unit and photocatalytic unit respectively, and of course mating them to obtain the photocatalytic degradation device for water treatment .

[0046] Effect example:

[0047] 1) Take the photocatalytic degradation device for water treatment described in Example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com