Portable drilling tool hydraulic clamp

A technology of hydraulic tongs and drilling tools, applied in the field of hydraulic tongs of drilling tools, can solve the problems of friction plate wear, many power transmission moving processes, and high maintenance requirements, and achieve the effects of small power transmission loss, stable and effective rotation, and simple overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

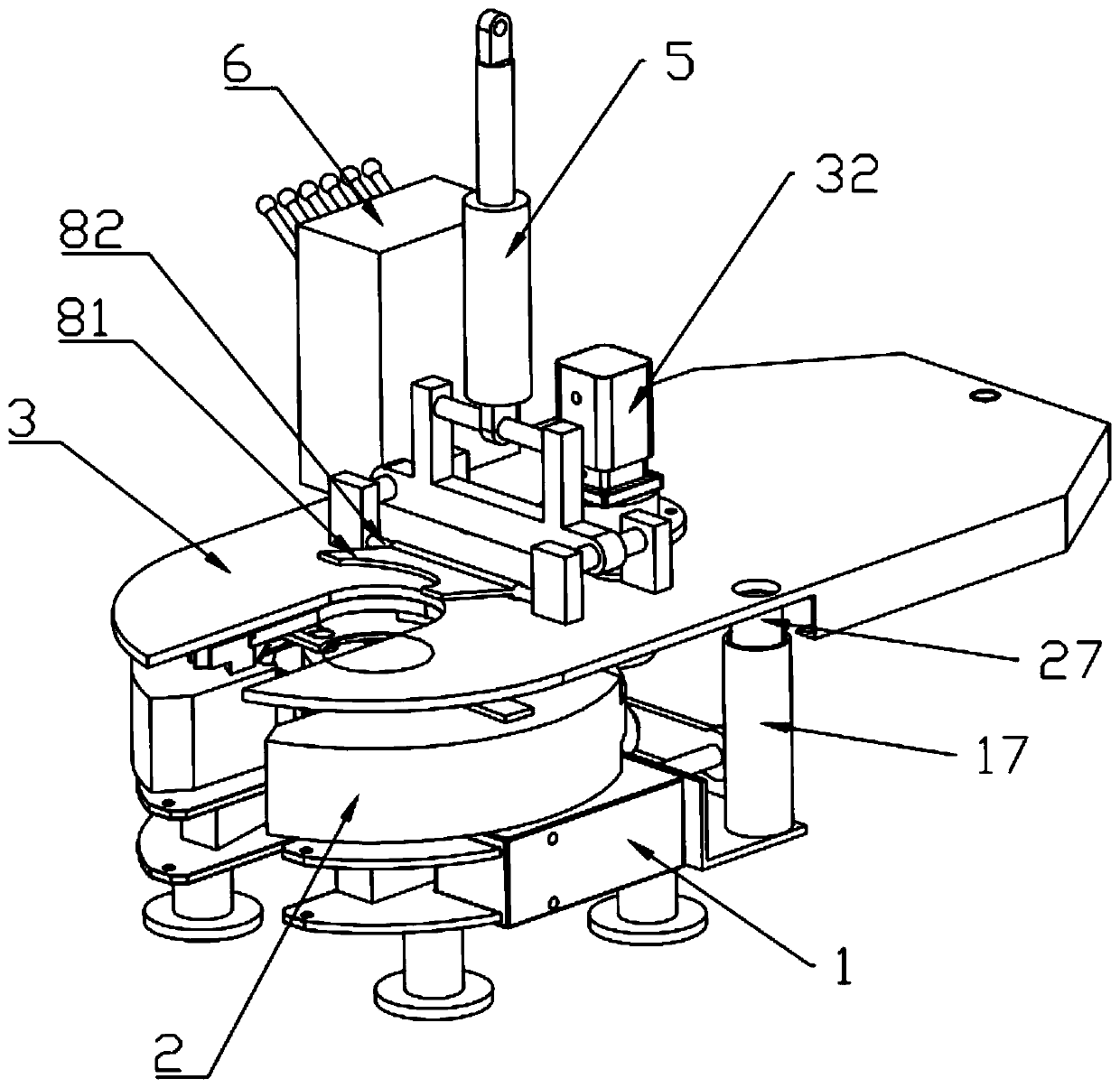

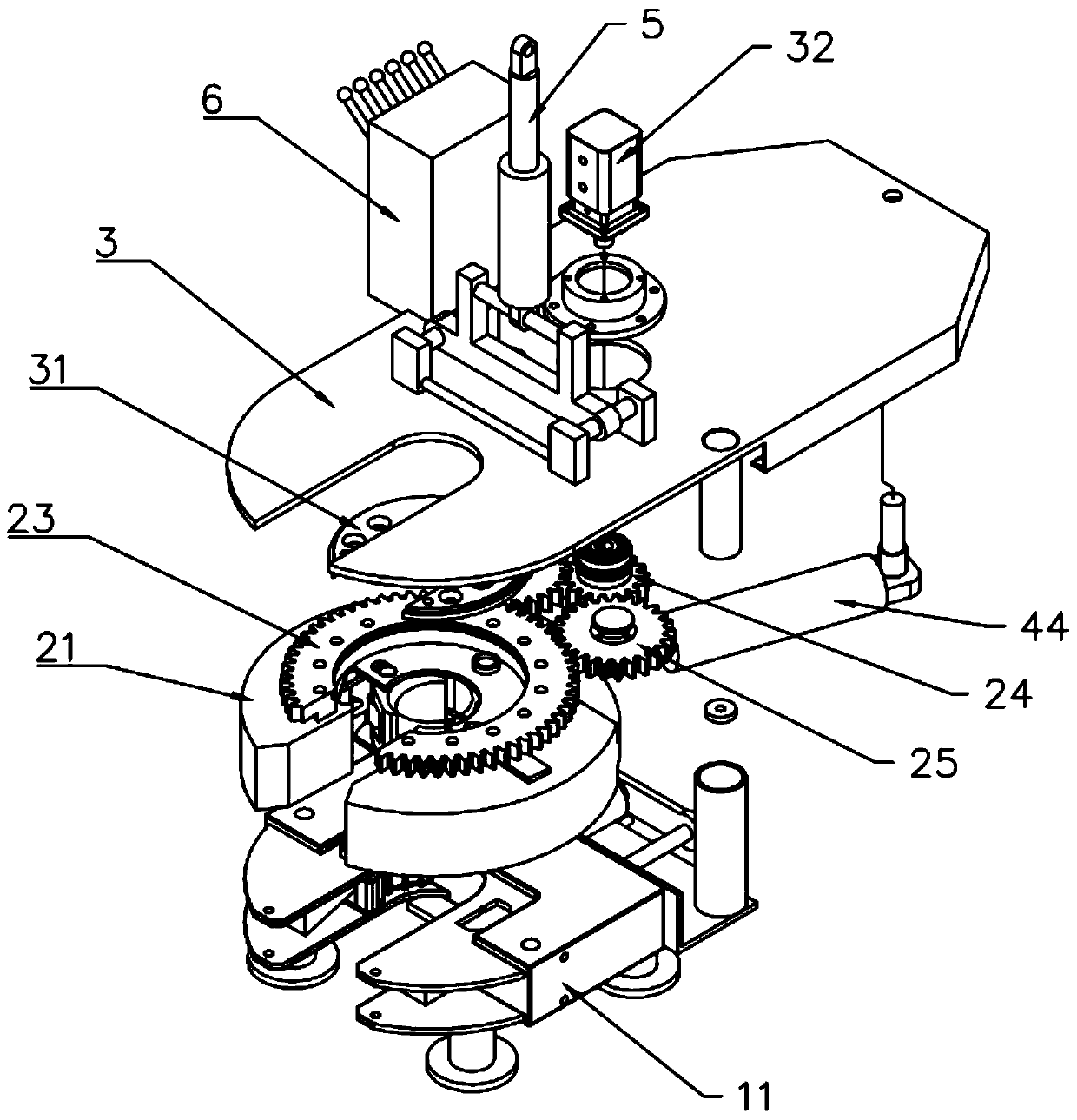

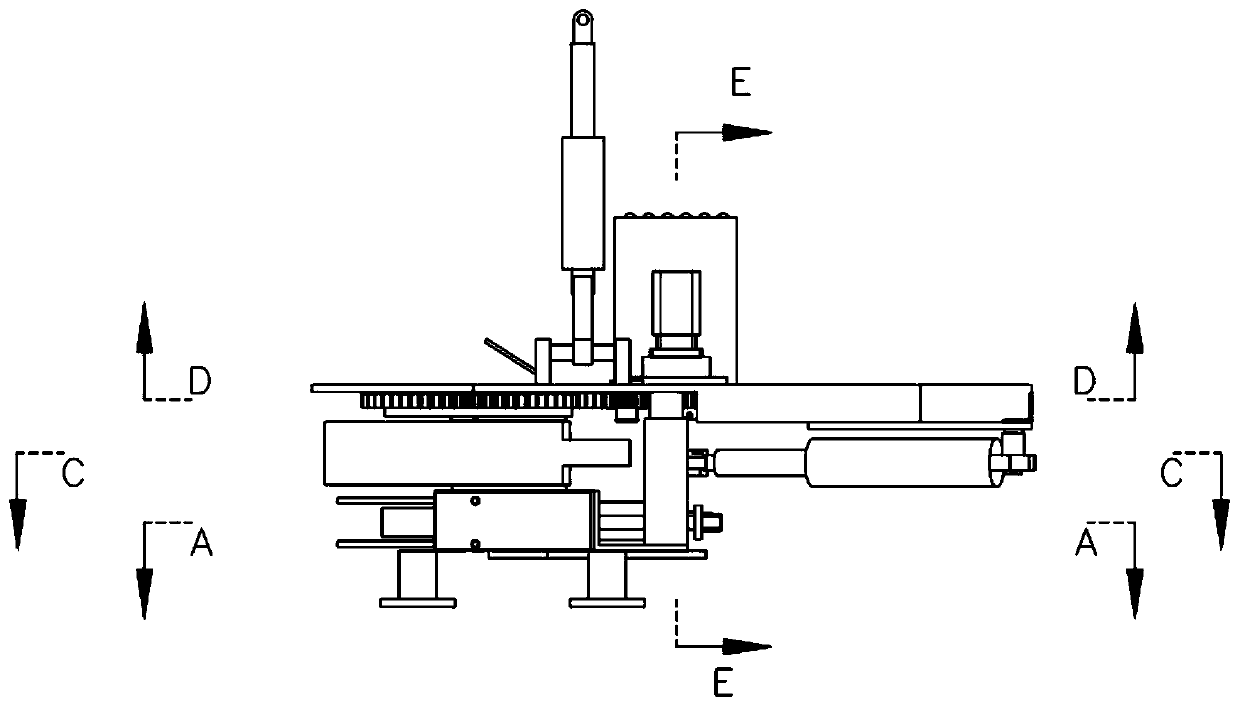

[0063] refer to Figure 1-7 , is a preferred embodiment of a portable hydraulic tong for drilling tools according to the present invention, mainly including: a lower tong body 1, an upper tong body 2, an upper plate 3 and other components.

[0064]Wherein, the lower pliers body 1 has a lower pliers body bracket 11 with a front opening, and the front opening is preferably square. Two anticline jaw plates 12 are arranged symmetrically on the left and right sides of the opening end of the lower caliper body support 11, and a wedge-shaped plate 13 is respectively arranged on the outside of the two anticline jaw plates 12. body clamping oil cylinder 16 and synchronous pull plate 15, two synchronous pull rods 14 are arranged on the left and right sides of the lower clamp body support, and the front ends of the two synchronous pull rods 14 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com