Compressor and air conditioner

A technology of compressors and backstops, applied in the field of compressors, can solve the problems of decreasing cooling capacity and increasing power consumption of compressors, and achieve the effects of preventing backflow, reducing power consumption, and increasing cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

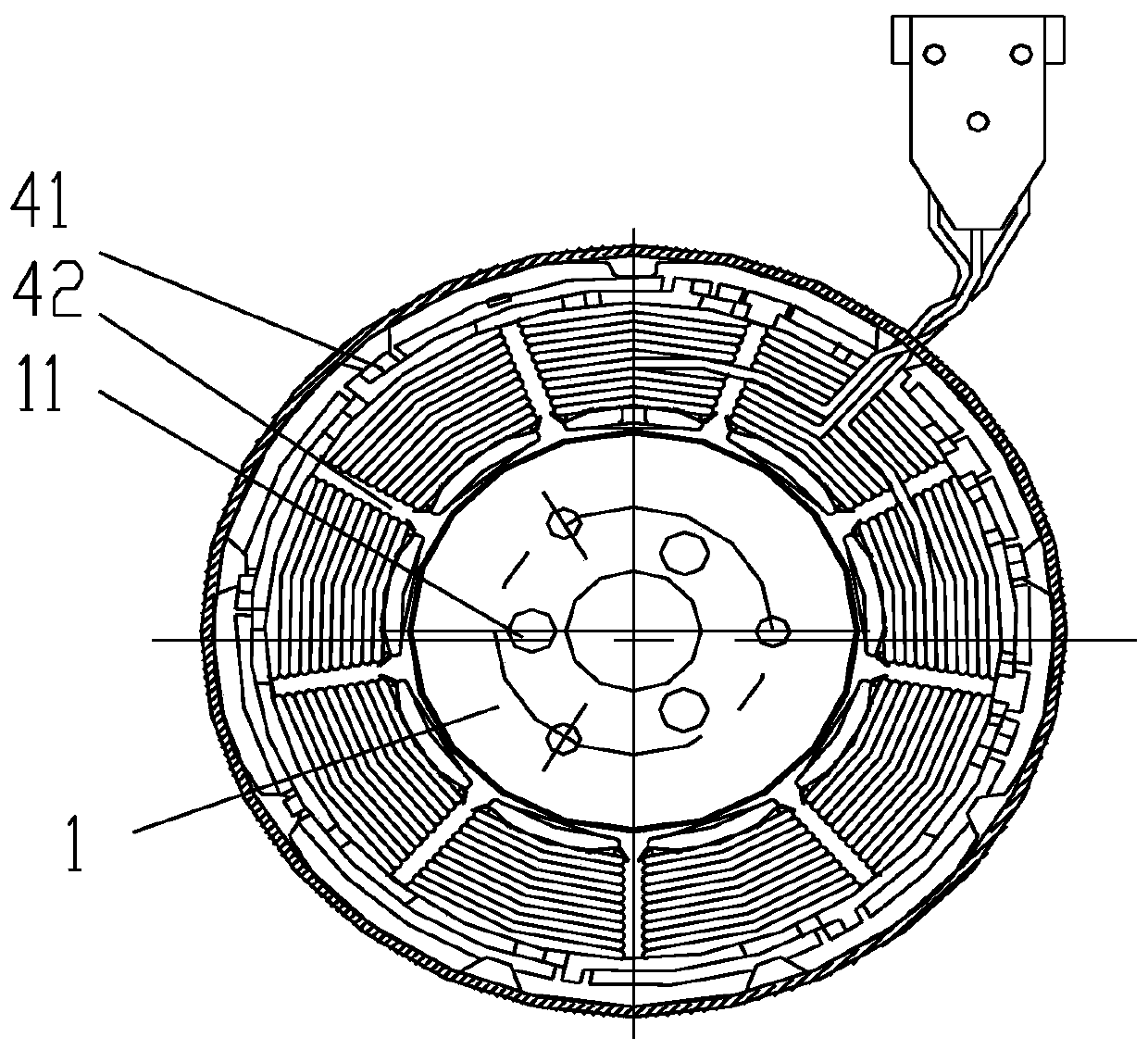

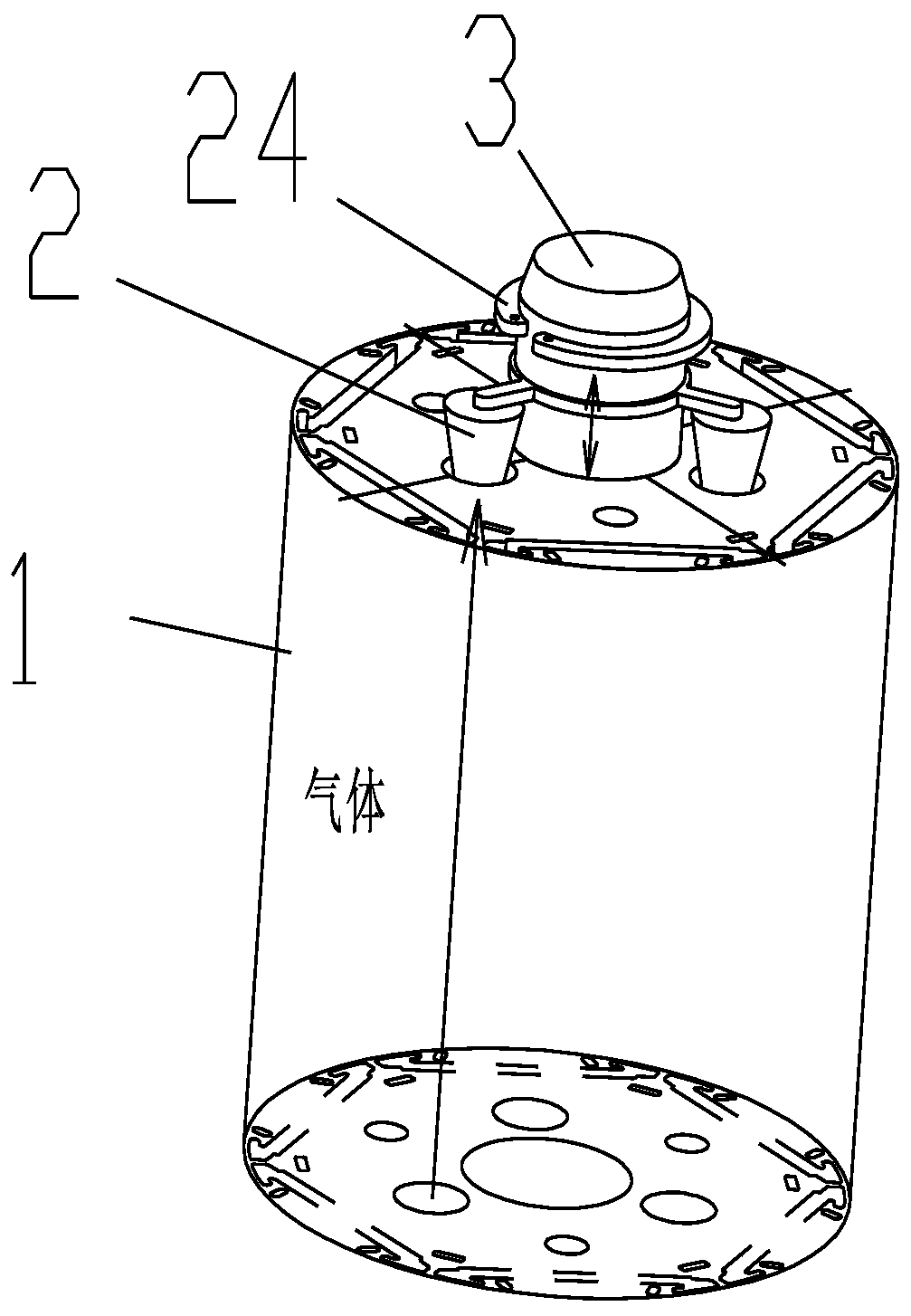

[0065] Implementation method: Design the checker, which is composed of a clamp and a cone valve. The clamp is closely matched with the crankshaft to fix the checker. The lower plane of the checker is attached to the upper end surface of the rotor; the center of the head of the cone valve Align with the center of the rotor flow hole, and completely cover the rotor flow hole, used to control the flow direction of the refrigerant (the conical valve head is used to seal the rotor flow hole to prevent the refrigerant from flowing downward, and the conical valve handle can freely go up and down Bending to ensure that the refrigeration system can lift the head of the cone valve to flow from bottom to top, and it will automatically open and close).

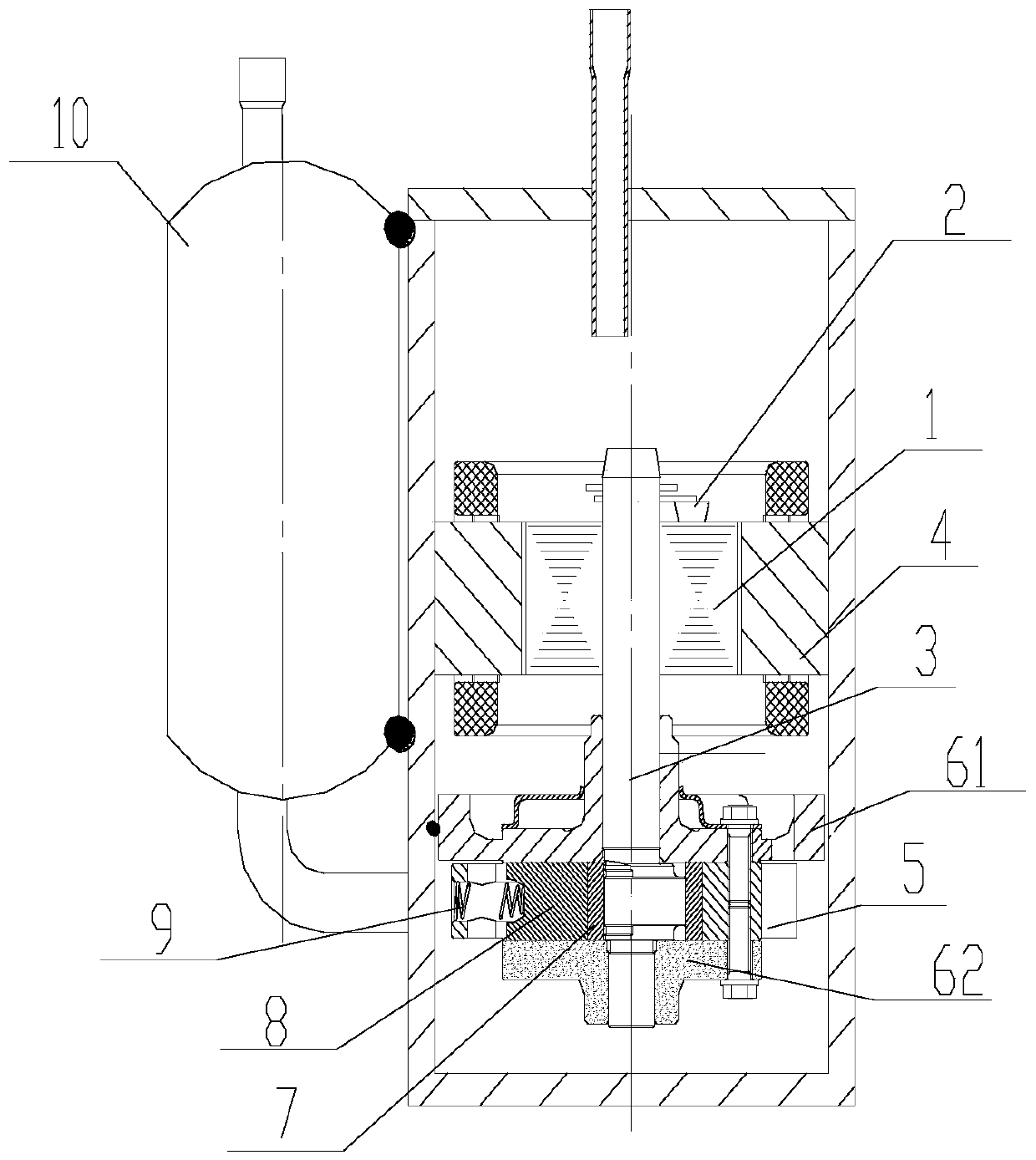

[0066] 1. The stator of the rotary compressor is fixed with the shell, and provides electromagnetic force to make the rotor drive the crankshaft to rotate. The eccentric roller follows the crankshaft and compresses the refrigerant entering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com