Novel structure capable of monitoring state of large-stroke hydraulic valve

A new type of structure and hydraulic valve technology, applied in valve device, fluid pressure actuating device, fluid pressure actuating system testing and other directions, can solve the problem of limiting the control level and improvement of working performance of large hydraulic systems, and unable to monitor the valve core with sensors. Problems such as motion state, detection and control of large stroke hydraulic valves are difficult to achieve the effect of simplifying the structure, reducing the lateral force and improving the control level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

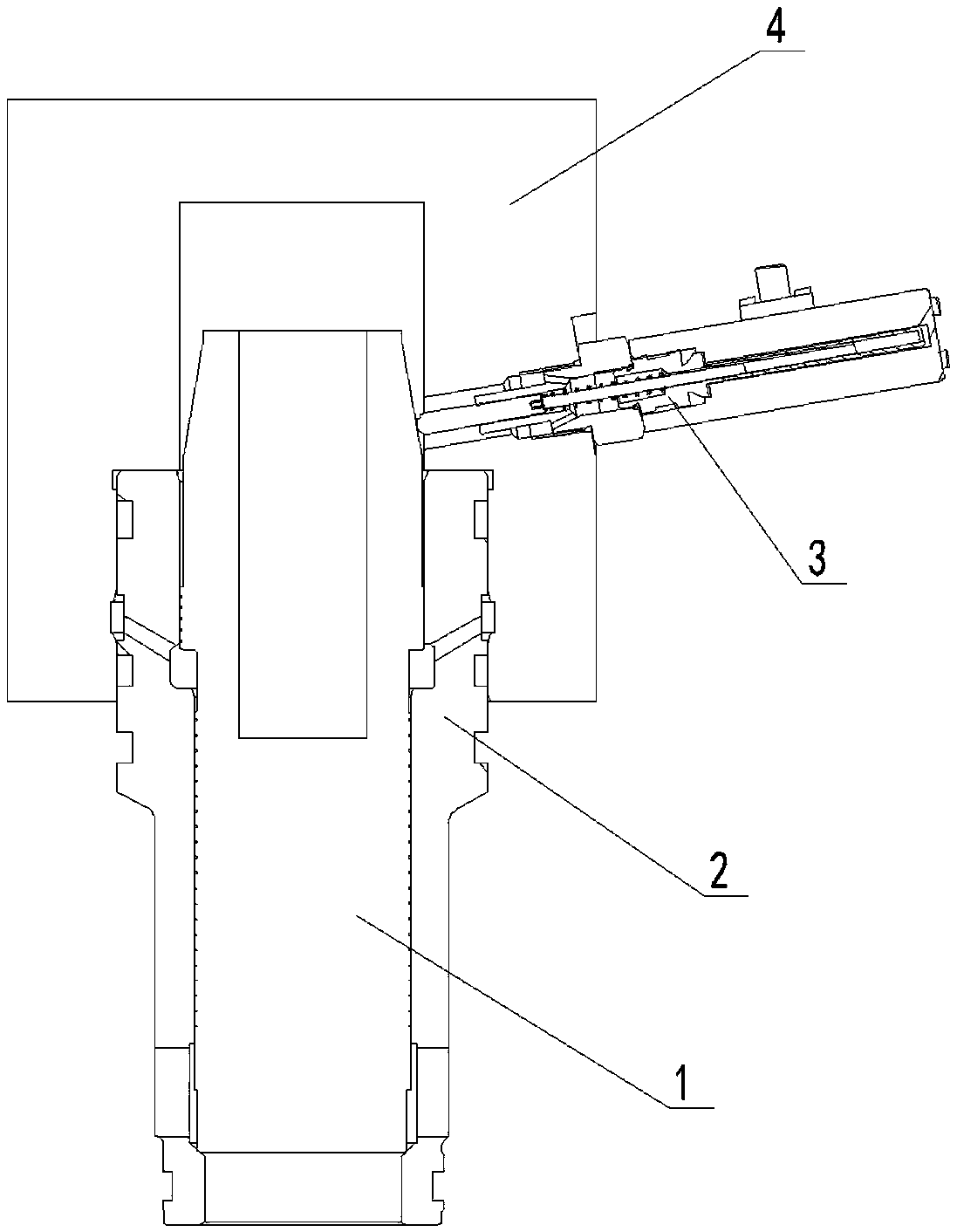

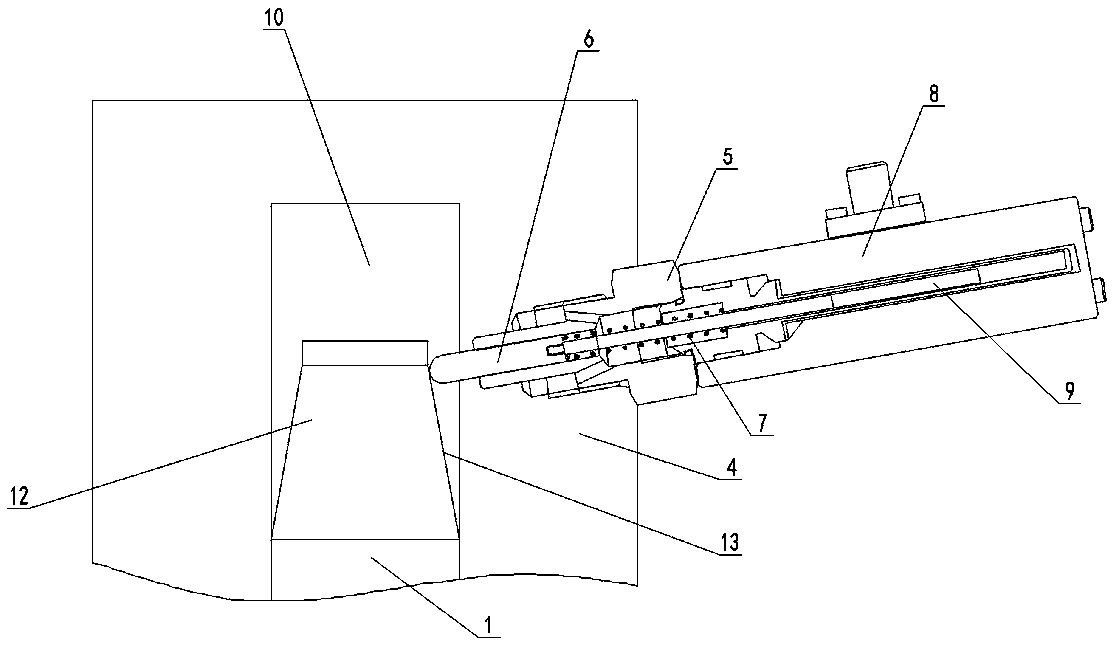

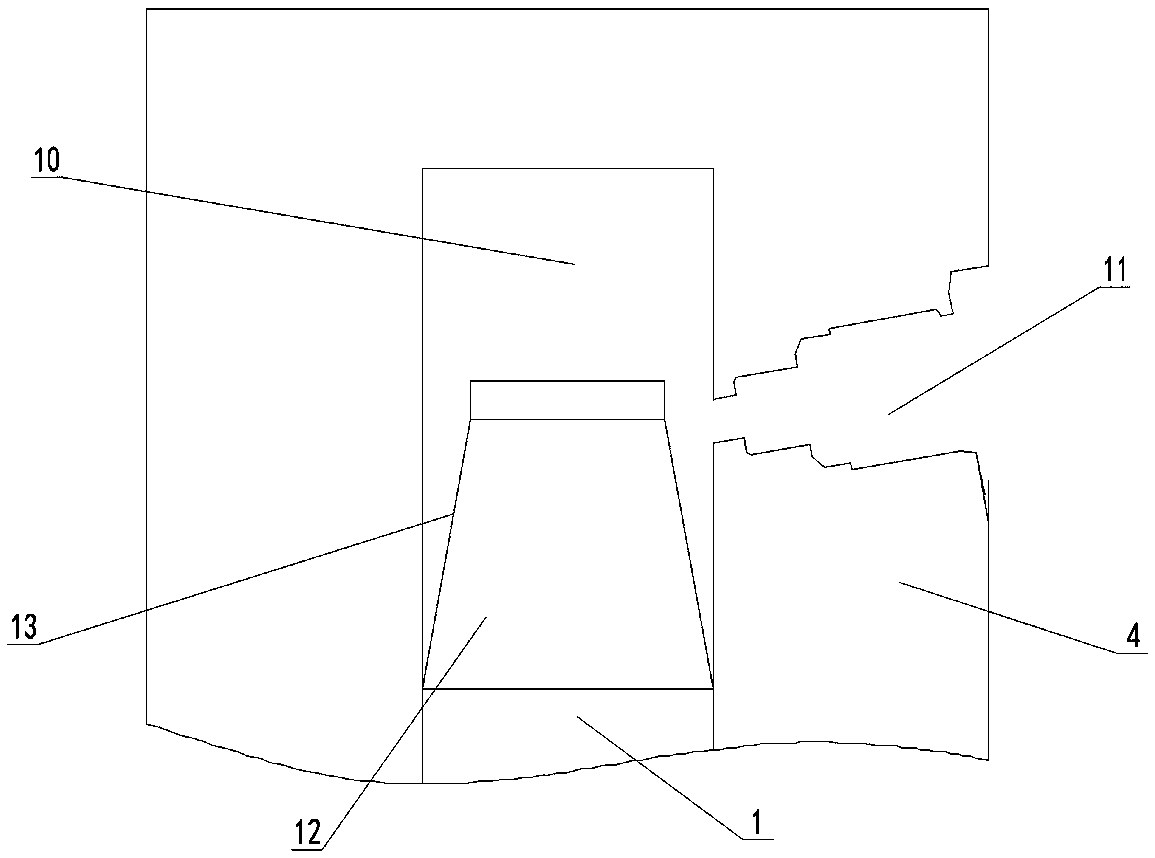

[0022] In order to make the purpose, technical scheme and advantages of the present invention more clear, the following will be combined with the appended figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 And attached Figure 6 , to describe the present invention in more detail.

[0023] The new structure that can monitor the state of the large-stroke hydraulic valve provided by the present invention includes a valve core 1, a monitoring component 3, and a cover body 4; A valve core 1 is provided in a slidable manner; a piston sleeve installation hole 11 is provided on one side of the cover body 4, and a monitoring component 3 is fixedly connected to the piston sleeve installation hole 11; the monitoring component 3 includes a piston sleeve 5, an induction piston 6, Return spring 7, sensor 8, feedback rod 9, piston sleeve central hole 14, sensor central hole 15, oil hole 16, spherical surface 17, central screw hole 18, sensor moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com