Residual chlorine electrode calibration method and water quality detection instrument

A calibration method and technology for water quality detection, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of low system processing efficiency, no consideration of influence, data output interface, single communication mode, etc., to improve measurement accuracy, improve The effect of measuring accuracy, simplifying the calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

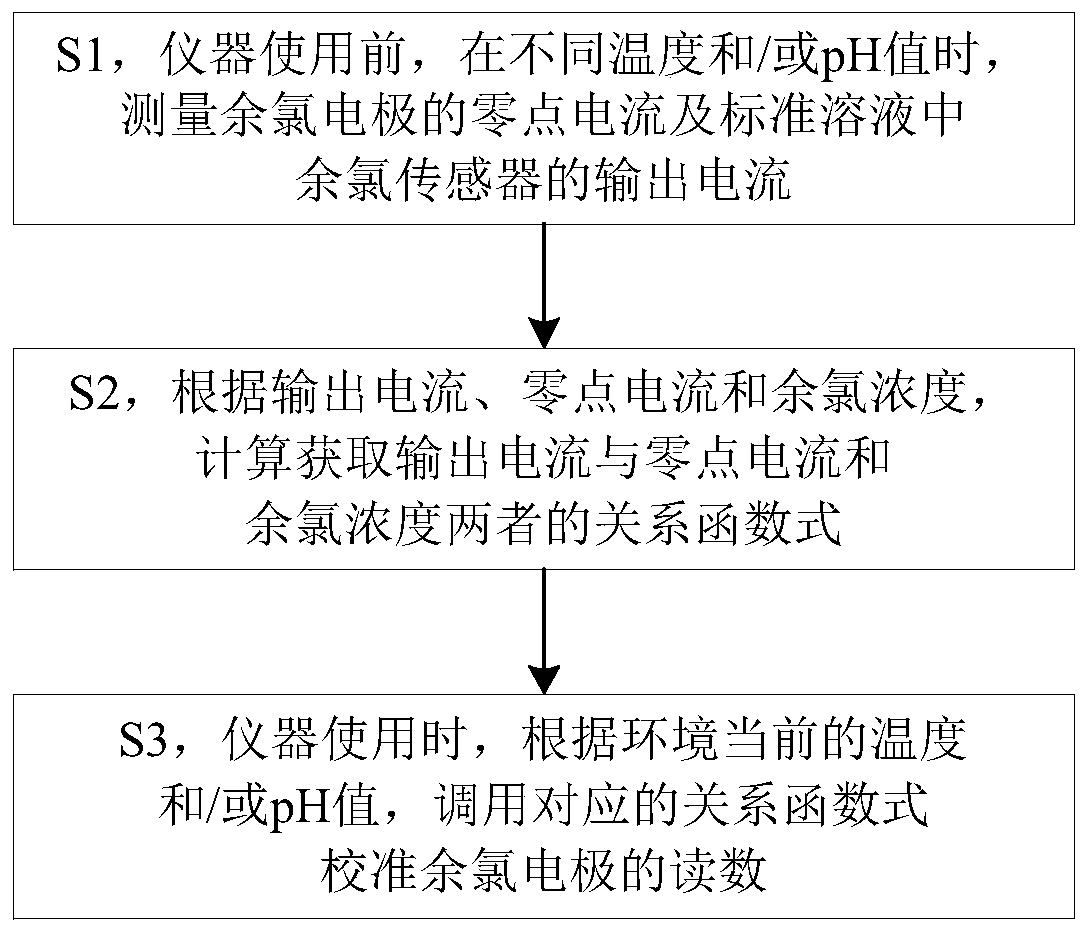

[0033] Such as figure 1 As shown, this embodiment provides a residual chlorine electrode calibration method, including the following steps:

[0034] S1, before using the instrument, measure the zero point current of the residual chlorine electrode and the output current of the residual chlorine electrode in at least one set of standard solutions with known concentrations at different temperatures and / or pH values;

[0035] S2, according to the output current, zero current and residual chlorine concentration, when calculating different temperatures and / or pH values, the constants in the relationship function between the output current and zero current and residual chlorine concentration, to obtain different temperatures and / or pH values When the relationship function;

[0036] S3, when the instrument is in use, according to the current temperature and / or pH value of the detection environment, call the relational function corresponding to the temperature and / or pH value to cali...

Embodiment 2

[0047] This embodiment provides a specific implementation of a method for calibrating a residual chlorine electrode.

[0048] Before leaving the factory, under the conditions of PH=6, 6.5, 7, 7.5, and 8, the zero point and slope were measured in the laboratory under the three conditions of temperature T=20, 25, and 30°C. The chamber can be configured with multiple solutions at one time for calibration. The measurement of residual chlorine can be expressed by the formula I=a*Cl+b, wherein, I represents the output current, a represents the slope, Cl represents the concentration of residual chlorine, and b represents the zero point current. Then the instrument internally stores 15 sets of slope and zero point current (referred to as zero point). Correspondingly denoted as a 0 ~a 14 and b 0 ~b 14 These 15 sets of data records.

[0049] After completing the measured data, input these 15 sets of data inside the instrument respectively, and then perform linear interpolation cal...

Embodiment 3

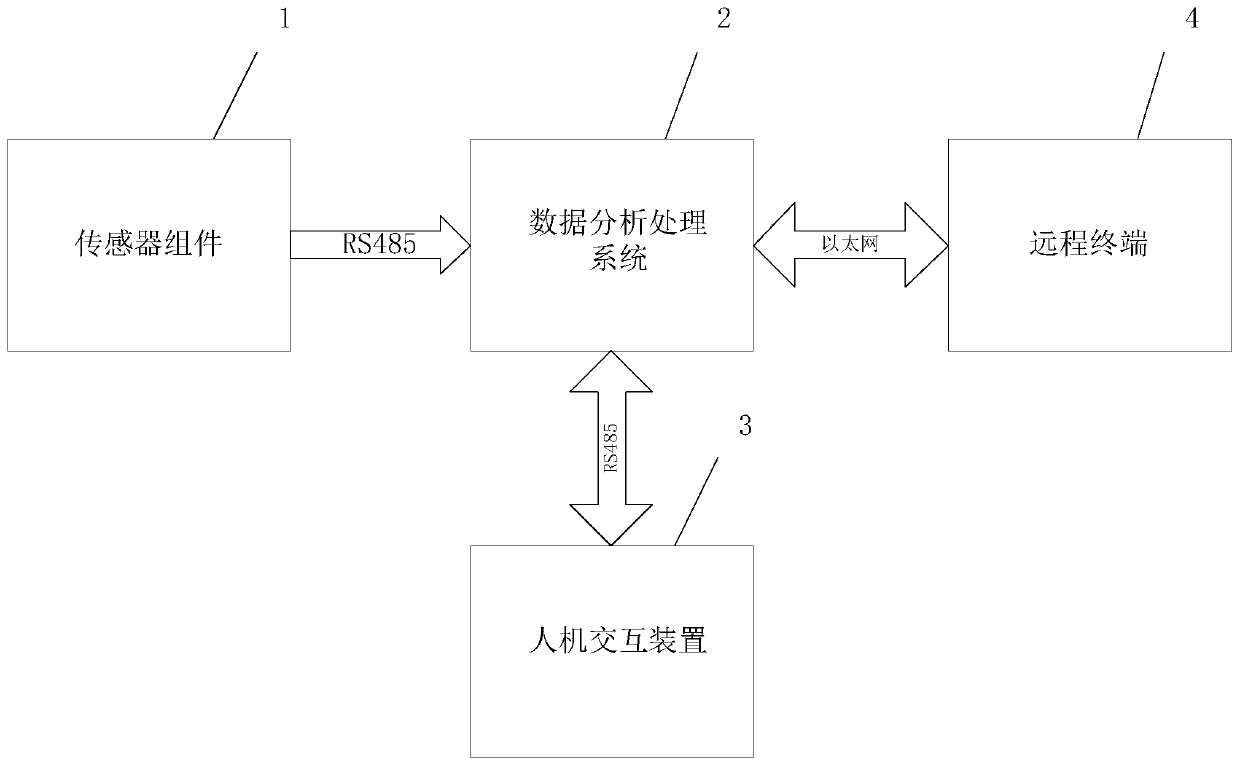

[0055] Such as figure 2 As shown, this embodiment provides a water quality detection instrument, including a sensor assembly 1, a data analysis and processing system 2, a human-computer interaction device 3 and a remote terminal 4;

[0056] The output ends of the sensor assembly 1 are respectively connected to the input interfaces of the data analysis and processing system 2; the output ends of the data analysis and processing system 2 are respectively connected to the input ends of the human-computer interaction device 3 and the remote terminal 4;

[0057] The sensor assembly 1 includes a temperature sensor, a pH electrode, and a residual chlorine electrode; the data analysis and processing system 2 includes an AD conversion module, a calibration module, an analysis module, and a memory; A series of constants obtained by the electrode calibration method, the calibration module uses the residual chlorine electrode calibration method described in Example 1 to calibrate the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com