Distance-adjustable contact method detection device

An adjustable and contact technology, applied in the direction of material magnetic variables, can solve the problems of non-adjustable spacing, weak magnetic field in the detection area, and reduced sensitivity, so as to achieve the effect of being easy to carry on site, improving use efficiency, and ensuring full coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

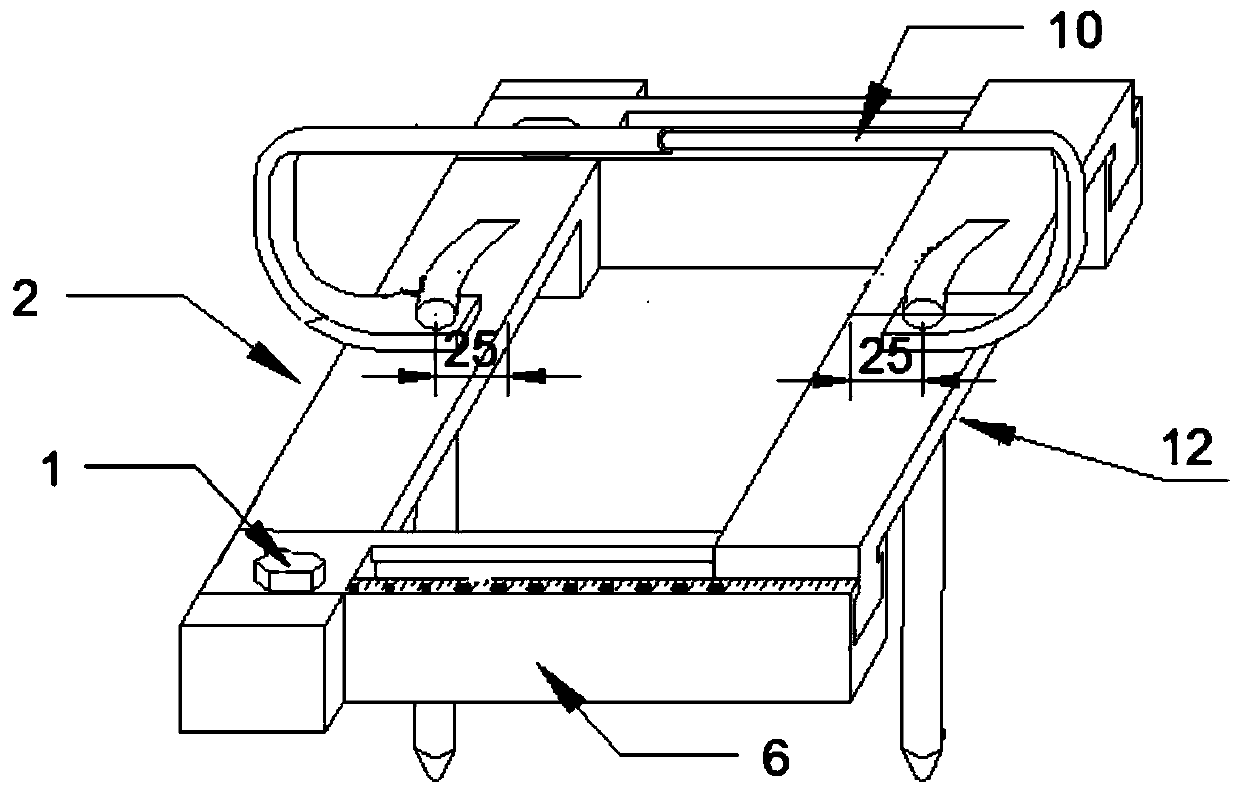

[0018] figure 1 Shown is the structural representation of the present invention.

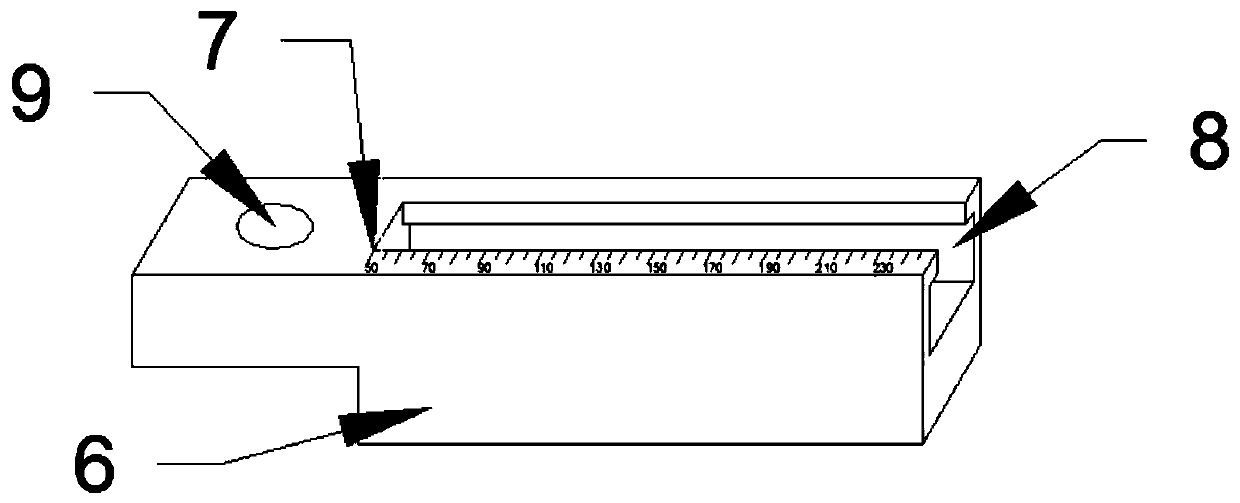

[0019] figure 2 Shown is a structural schematic diagram of the connecting device of the present invention.

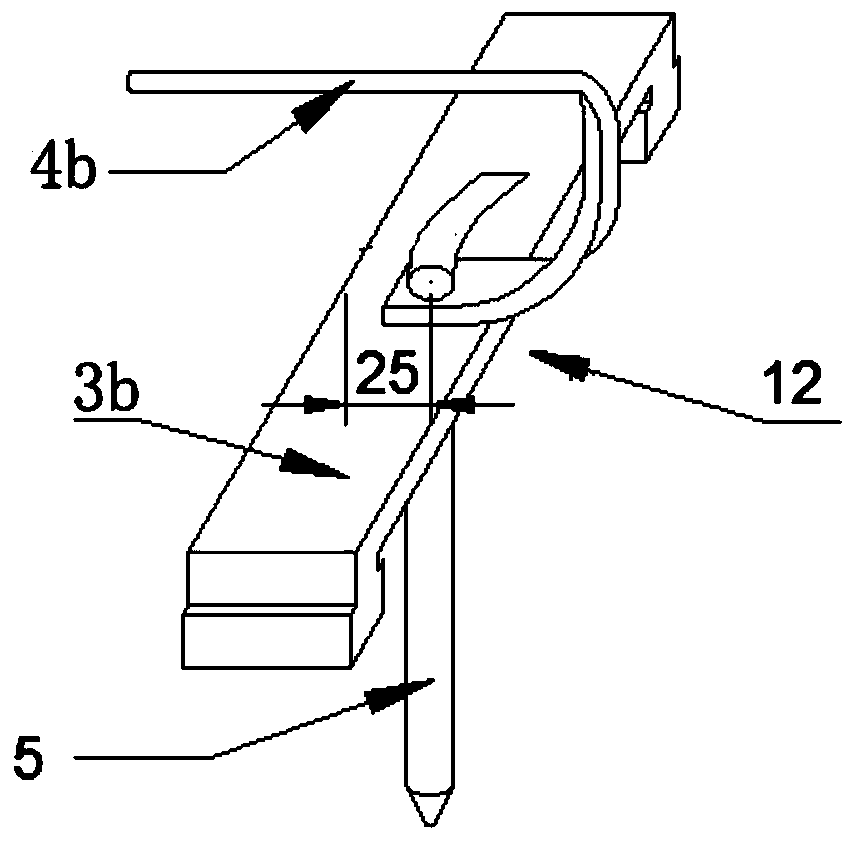

[0020] image 3 Shown is a schematic structural view of the fixed contact device of the present invention.

[0021] Figure 4 Shown is a schematic structural view of the sliding contact device of the present invention.

[0022] The present invention provides a device for detecting the contact method with adjustable spacing, which includes a contact device I2, a contact device II12, a connecting device 6 and a handle device 10, and the contact device I2 and the contact device II12 pass through the connecting device 6 The connection and its spacing can be adjusted freely through the handle device 10 installed on the contact device I2 and the contact devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com