Automatic detection tool for oil hole of piston workpiece and detection method thereof

A technology of automatic detection and detection method, applied in the direction of measurement device, geophysical measurement, radio wave measurement system, etc., can solve the problems of ring groove tool breaking, piston workpiece scrapped, affecting product quality, etc., to avoid missing processing, suitable for strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

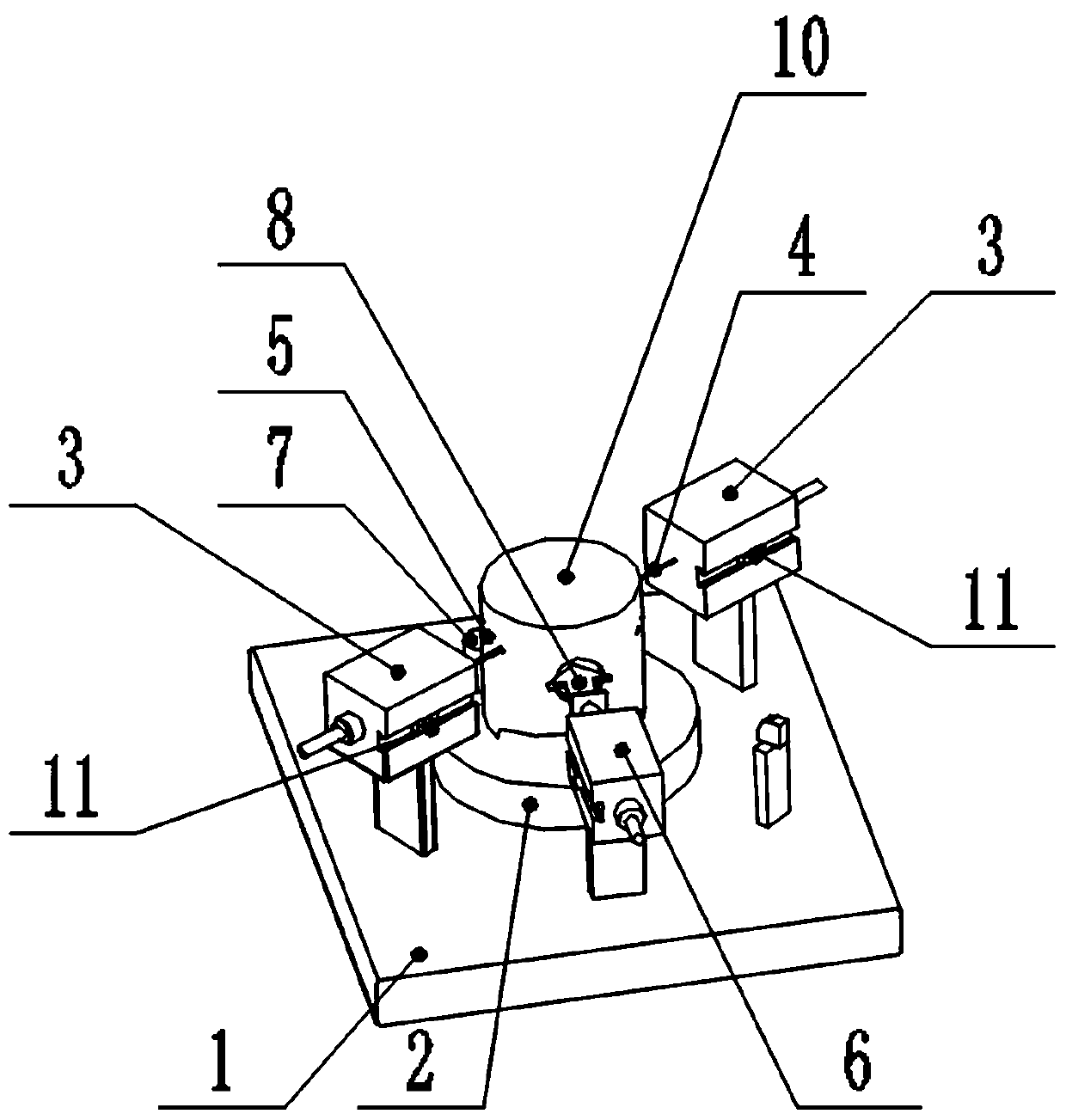

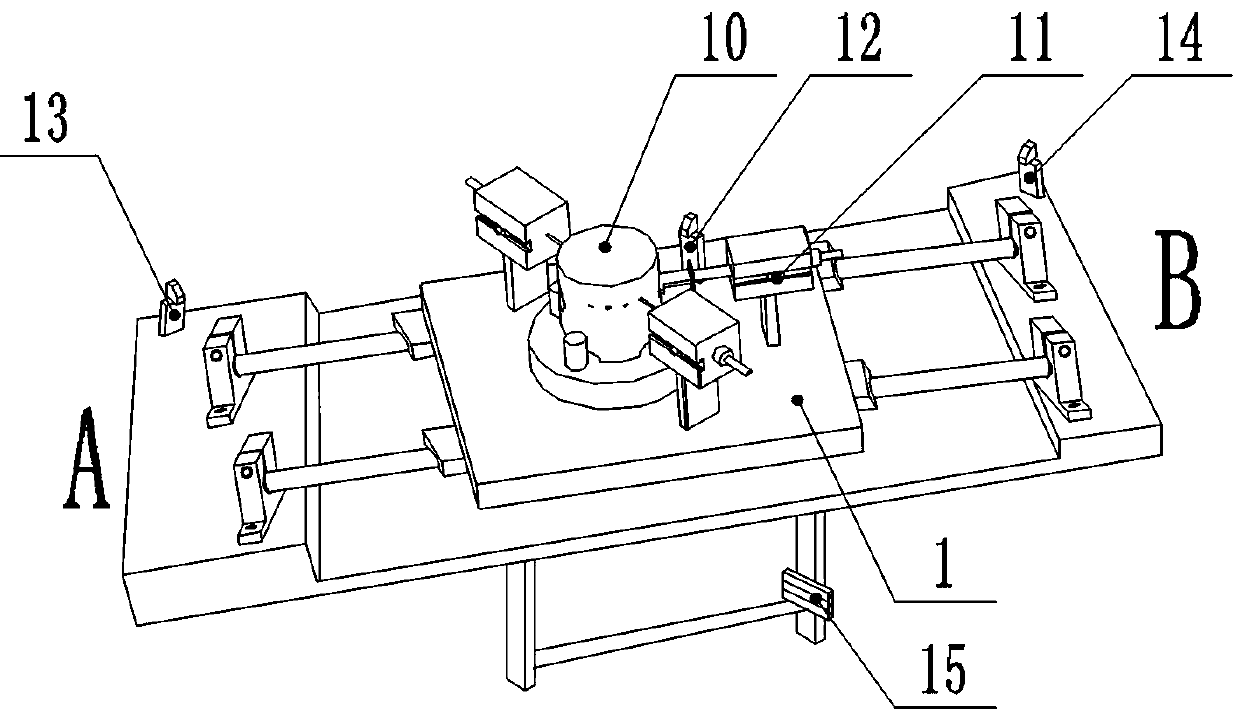

[0023] Such as Figure 1-4 As shown, the automatic detection tool for the oil hole of the piston workpiece provided by the present invention includes a bearing base 2 placed on the transfer platform 1 of the piston workpiece feedway, and a detection unit and a positioning unit arranged on the transfer platform of the piston workpiece feedway.

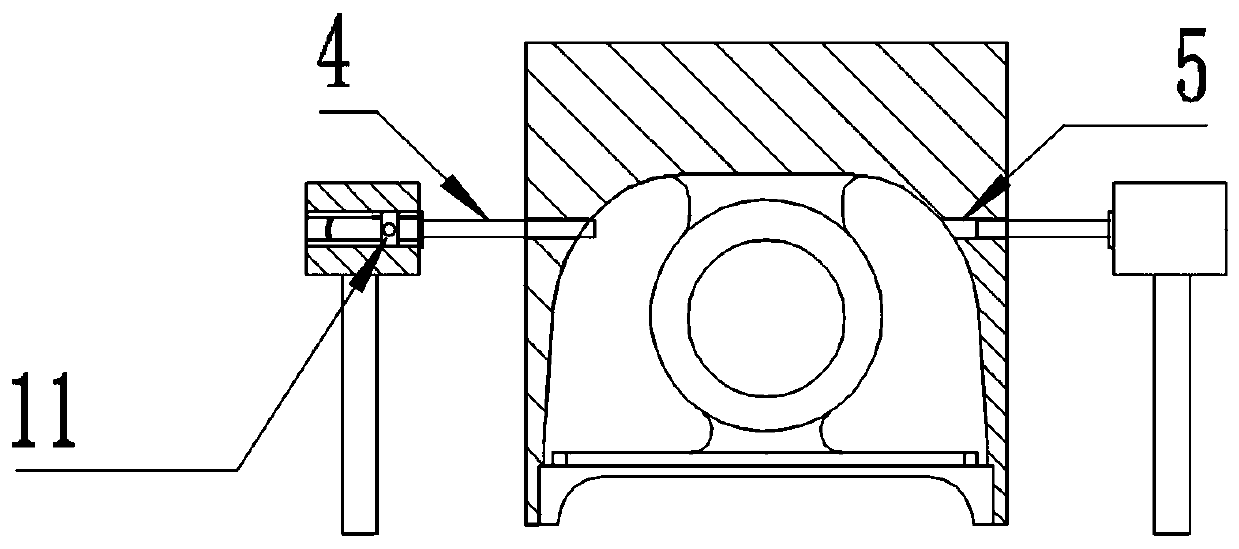

[0024] The detection unit includes two detection cylinders 3 arranged symmetrically. The protruding end of the detection cylinder is connected with a probe 4. The probe is guaranteed to correspond to the last piston oil hole 5 processed on one side of the piston workpiece, and the probe is connected to the piston oil hole 5. The holes are concentric circles. The positioning unit includes a positioning cylinder 6 and a first positioning block 7. The extended end of the positioning cylinder is connected with a second positioning block 8. When the second positioning block cooperates with the piston workpiece pin hole 9, the second position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com