Patents

Literature

197 results about "Computer multitasking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In computing, multitasking is the concurrent execution of multiple tasks (also known as processes) over a certain period of time. New tasks can interrupt already started ones before they finish, instead of waiting for them to end. As a result, a computer executes segments of multiple tasks in an interleaved manner, while the tasks share common processing resources such as central processing units (CPUs) and main memory. Multitasking automatically interrupts the running program, saving its state (partial results, memory contents and computer register contents) and loading the saved state of another program and transferring control to it. This "context switch" may be initiated at fixed time intervals (pre-emptive multitasking), or the running program may be coded to signal to the supervisory software when it can be interrupted (cooperative multitasking).

Network session management

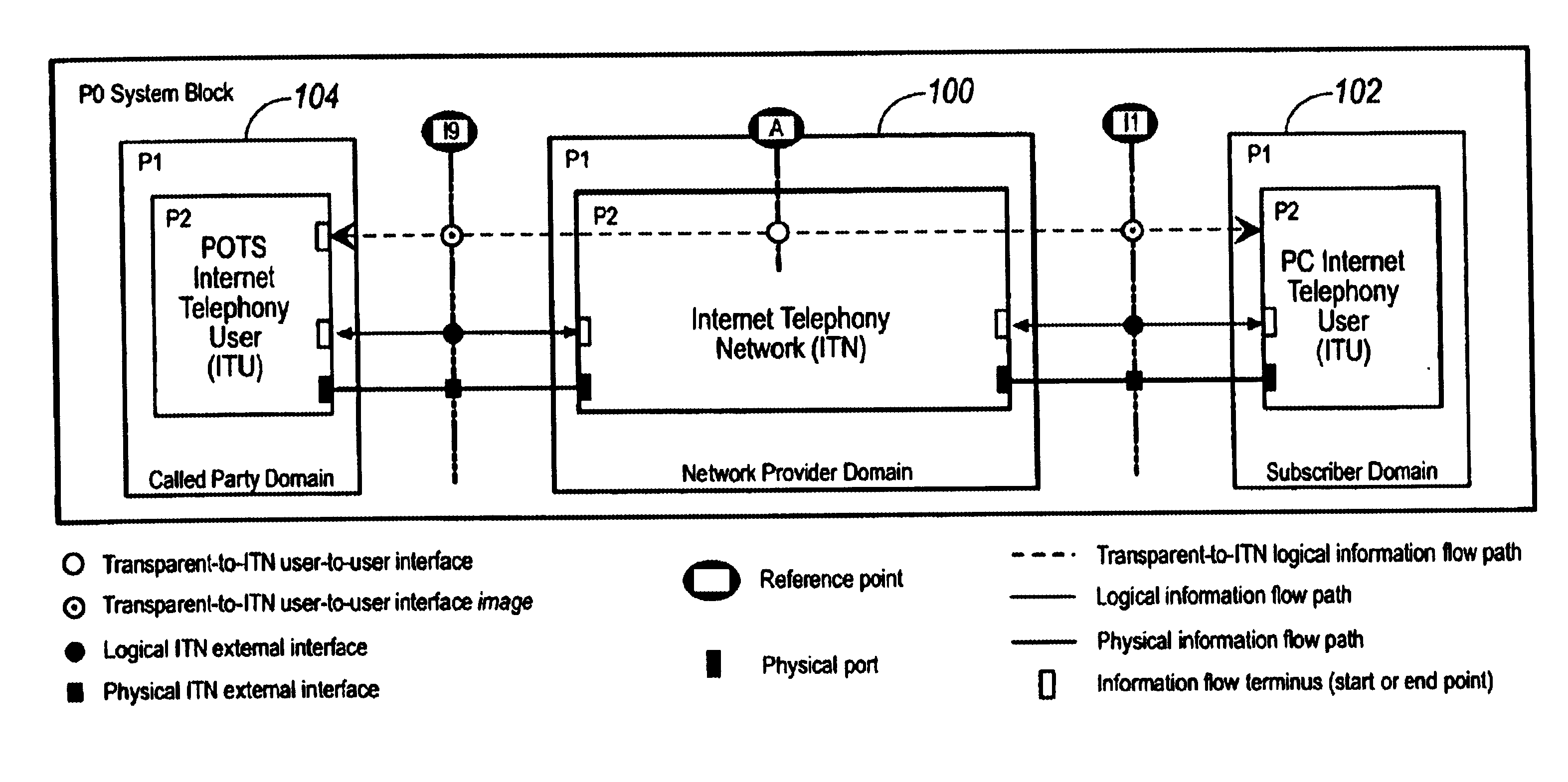

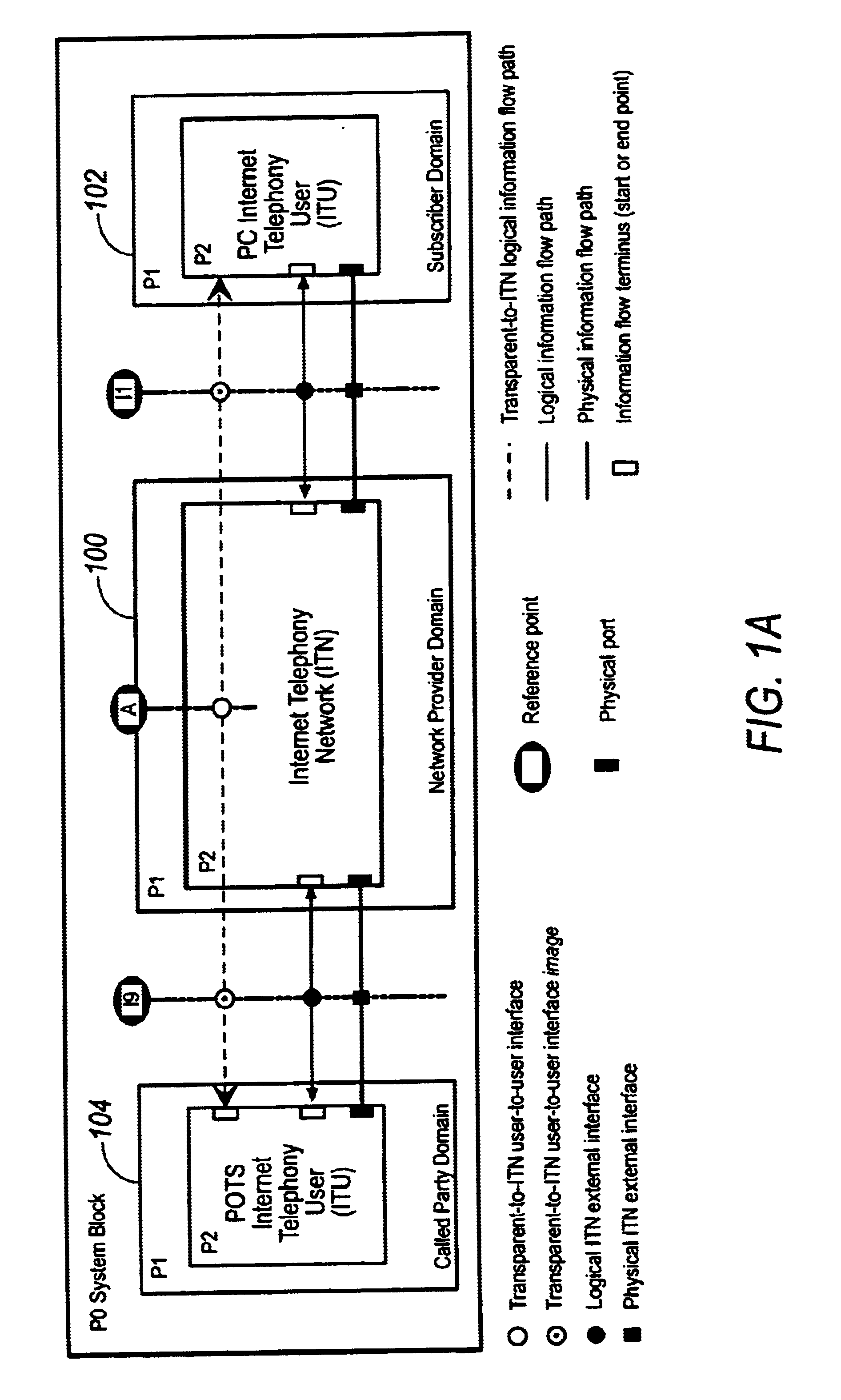

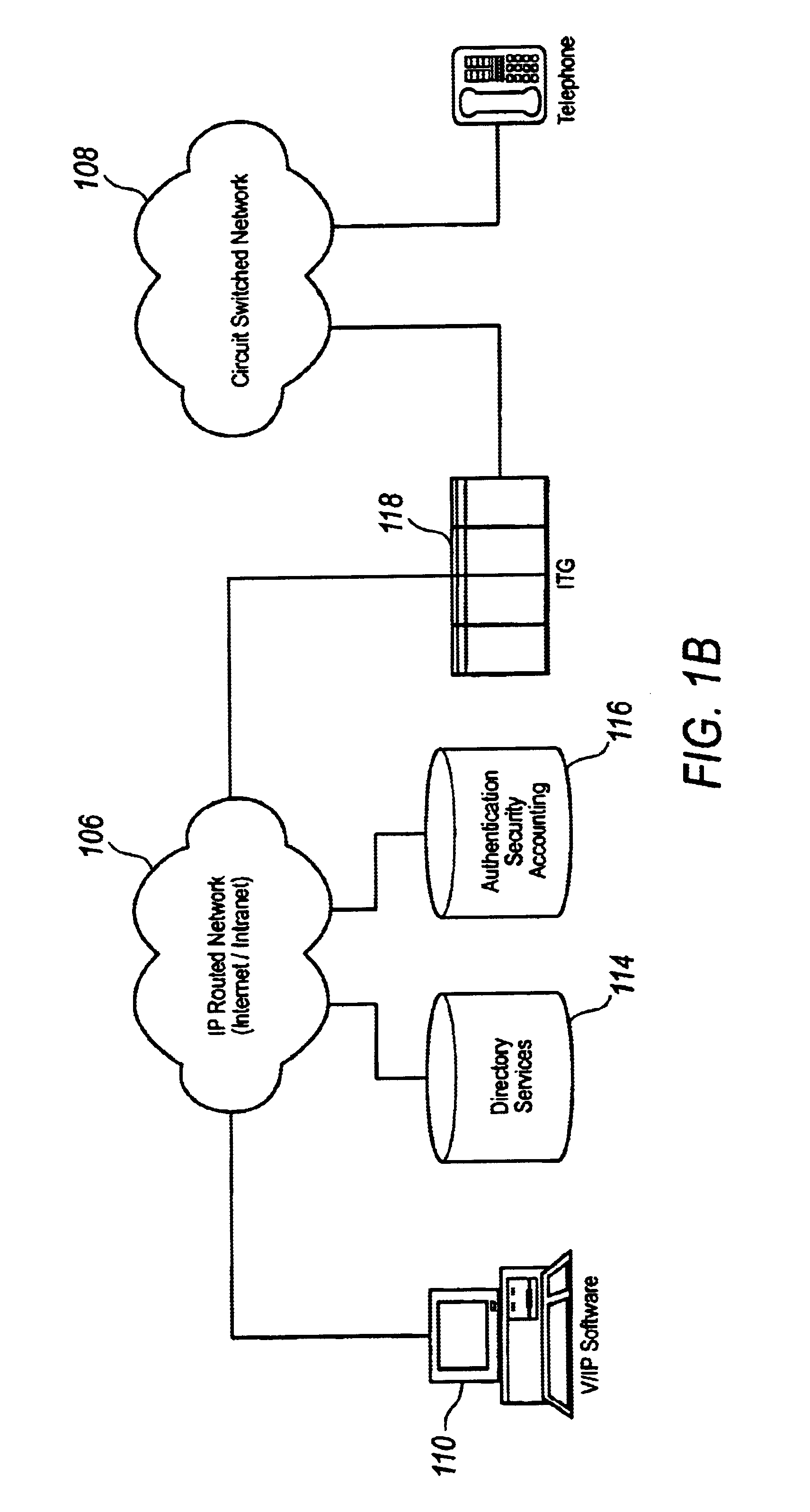

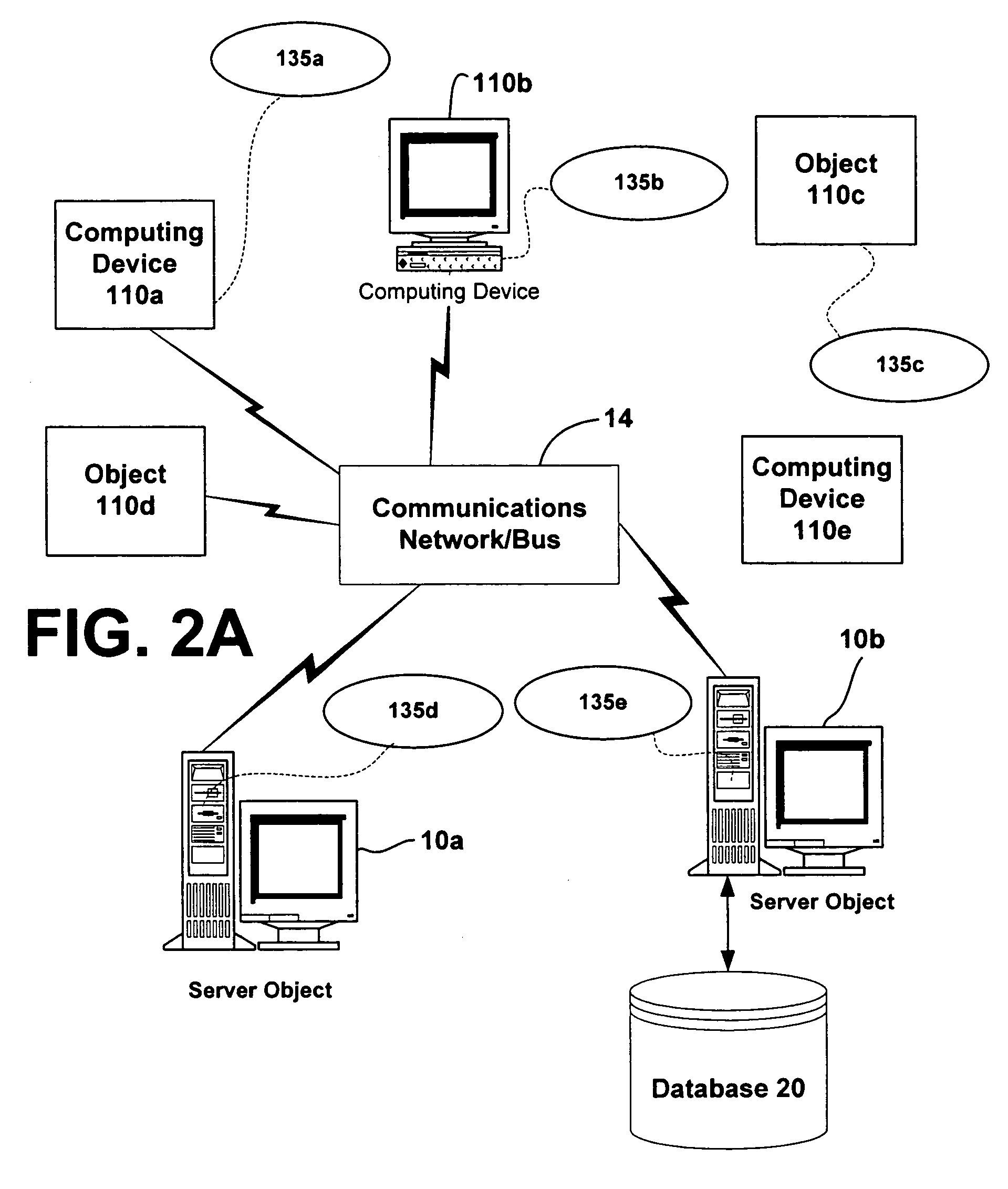

InactiveUS6839340B1Easy accessTelephonic communicationData switching by path configurationTime informationExchange network

A communication system providing telephony communication across combined circuit switched and packet switched networks, such as a telephone network and the Internet, which are connectable to terminals, such as telephones and computers, for selective communication therebetween. The communication system includes an authorization and account control object in the packet switched network, multiple gateways between the circuit switched and packet switched networks providing controlled connectivity between those networks, and an information retrieval object in the packet switched network, wherein the authorization and account control object maintains a substantially real time record of user accounts and usage, and the information and retrieval object provides substantially real time retrieval of selected information from the authorization and account control object. The retrieval object provides on demand to terminals which provide authentication for access to an identified account information regarding that account. The information regarding the account is substantially real time information including information with respect to communications in progress which are chargeable to the account which has been authenticated. The authorization and account control object is preferably a unitary logical object having distributed instances thereof handling multitudinous accounts of widely separated terminals. The retrieval object provides isolation of the authorization and account control object permitting simultaneous multitasking by the authorization and account control object and the retrieval object respectively.

Owner:VERIZON PATENT & LICENSING INC

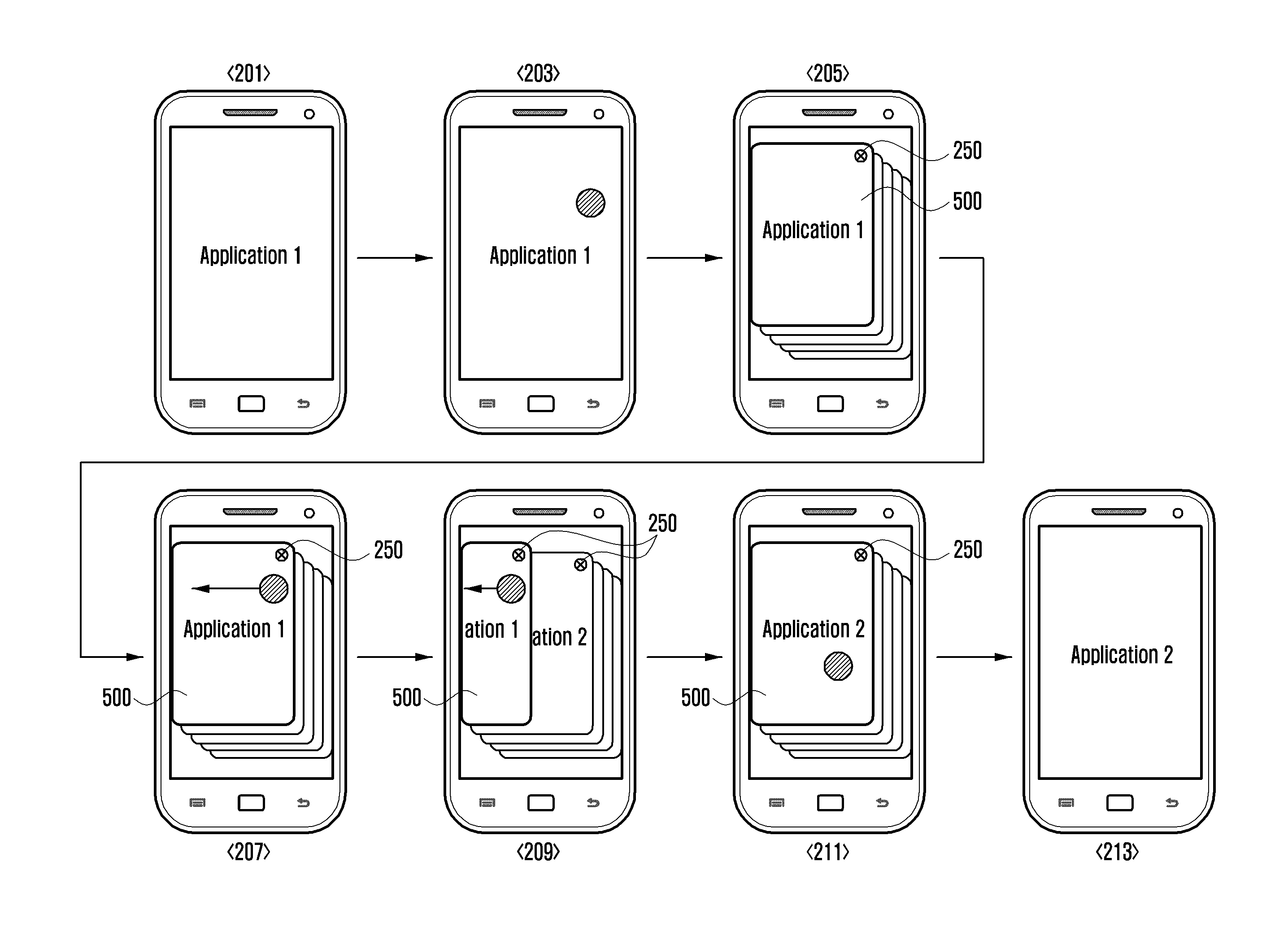

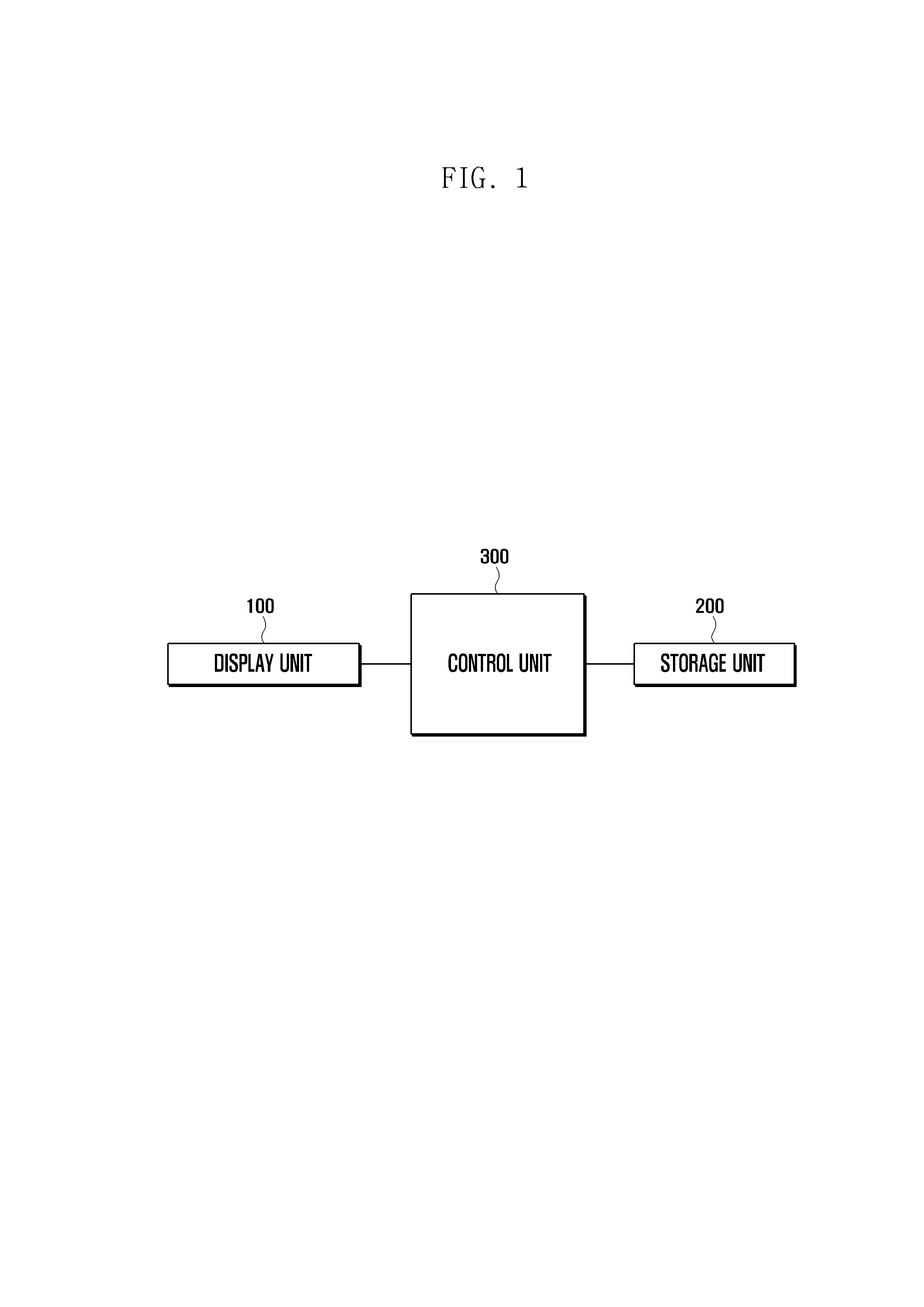

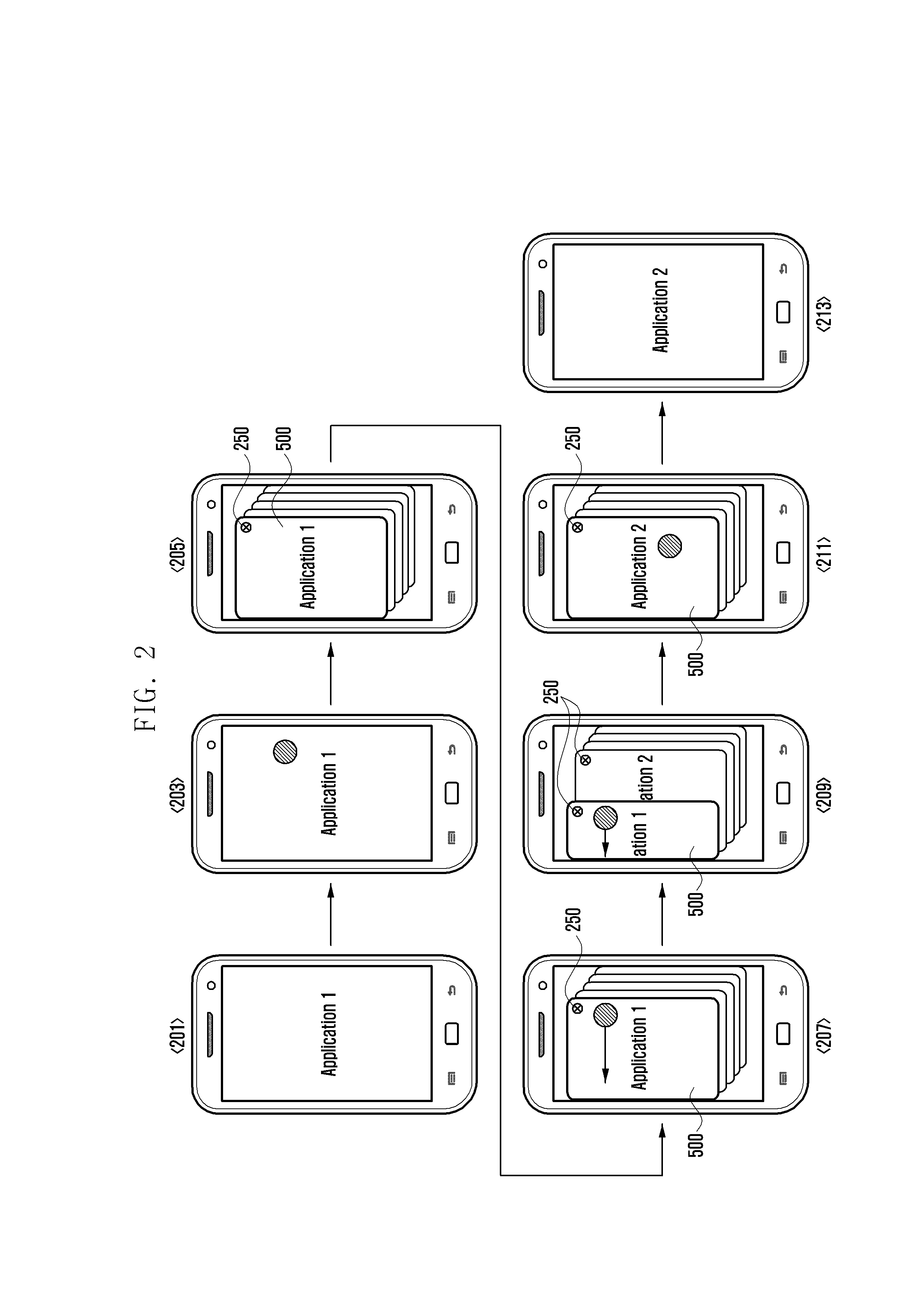

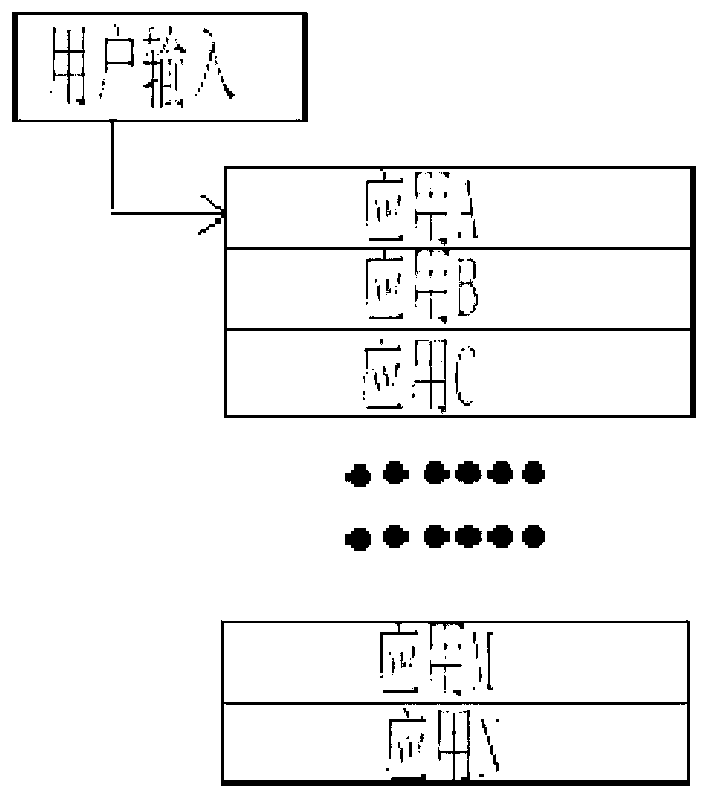

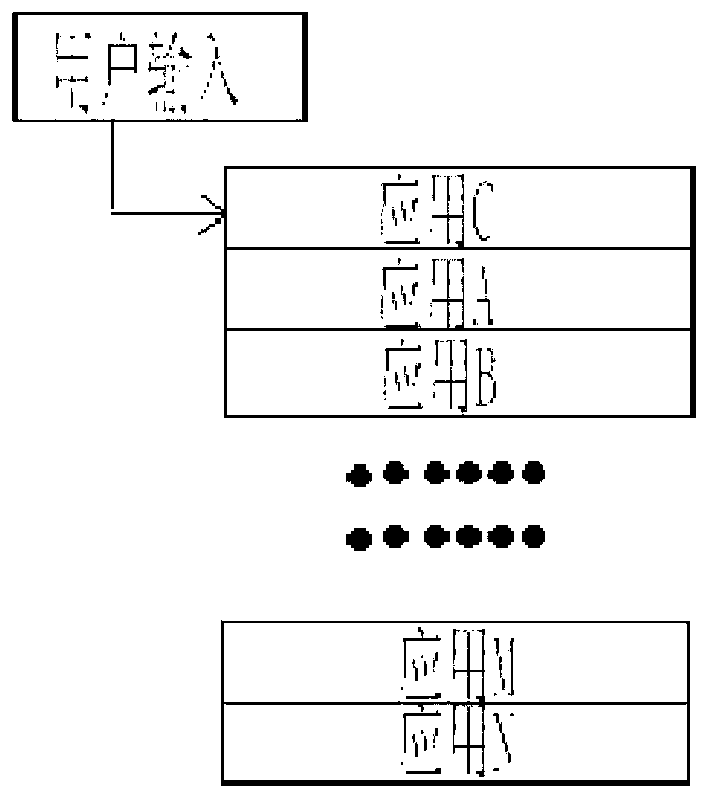

Multitasking method and apparatus of user device

ActiveUS20130174179A1Facilitate functioningQuickly switching among the tasksProgram initiation/switchingExecution for user interfacesUser deviceApplication software

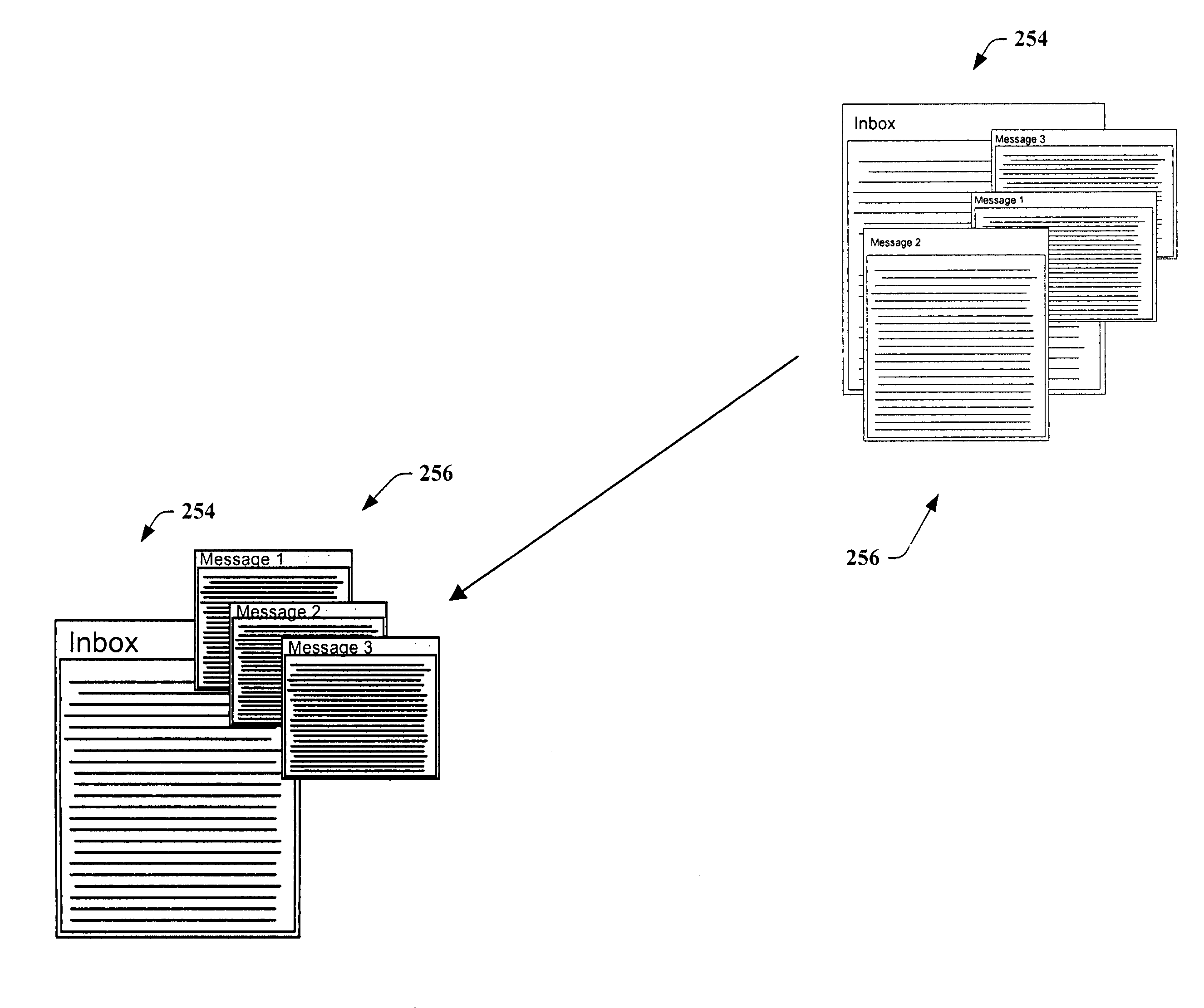

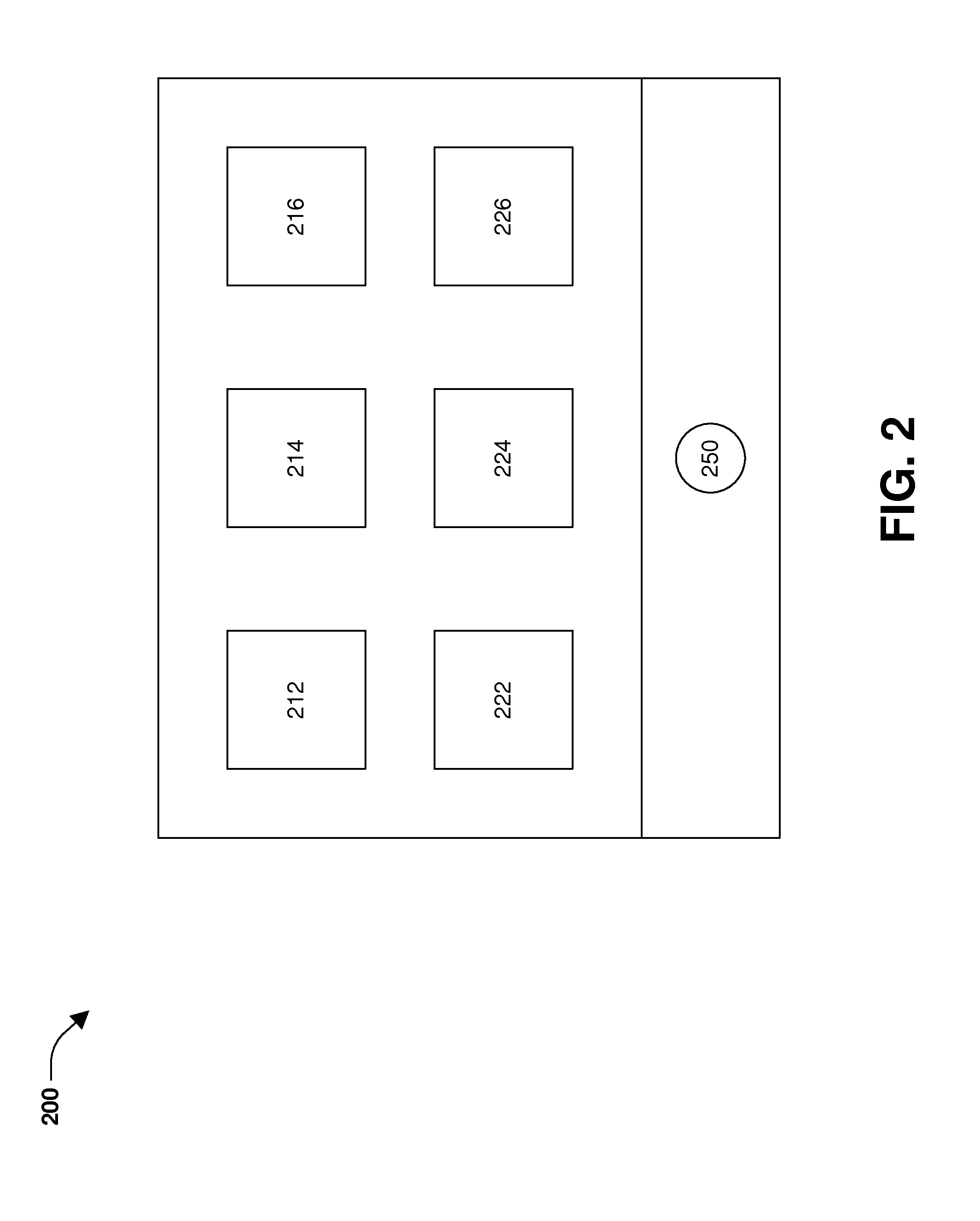

A multitasking method and apparatus of a user device is provided for intuitively and swiftly switching between background and foreground tasks running on the user device. The multitasking method includes receiving an interaction to request for task-switching in a state where an execution screen of a certain application is displayed, displaying a stack of tasks that are currently running, switching a task selected from the stack to a foreground task, and presenting an execution window of the foreground task.

Owner:SAMSUNG ELECTRONICS CO LTD

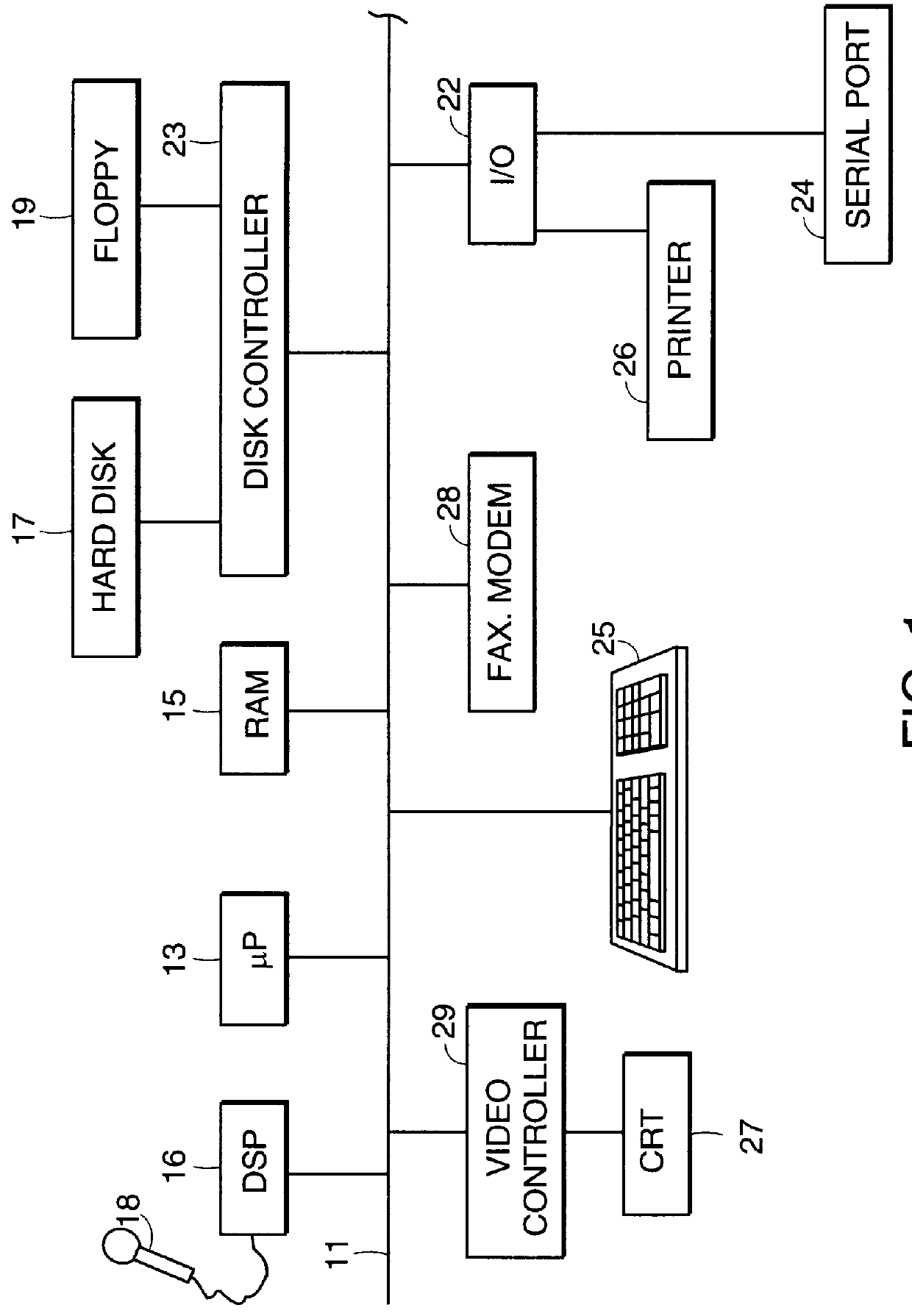

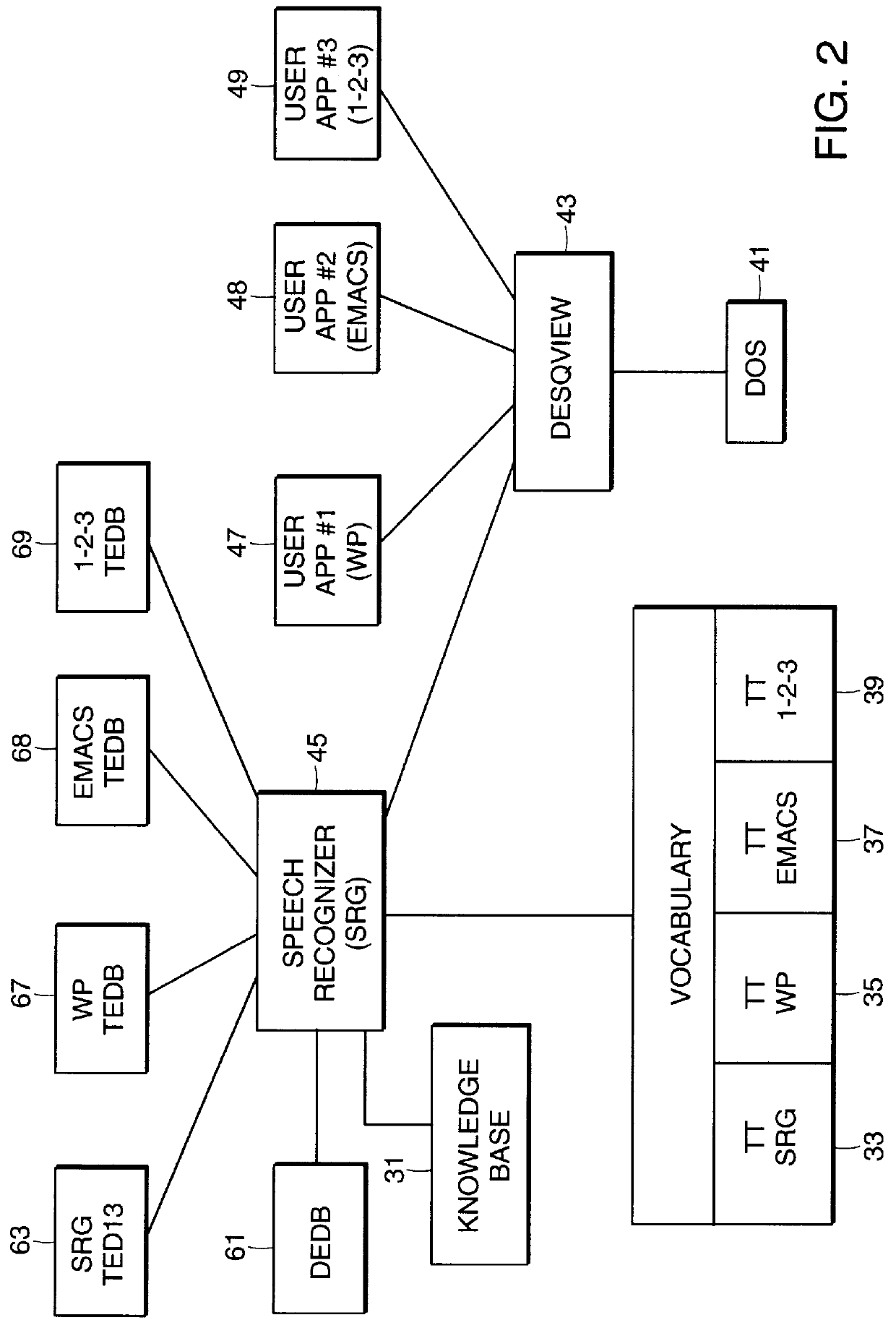

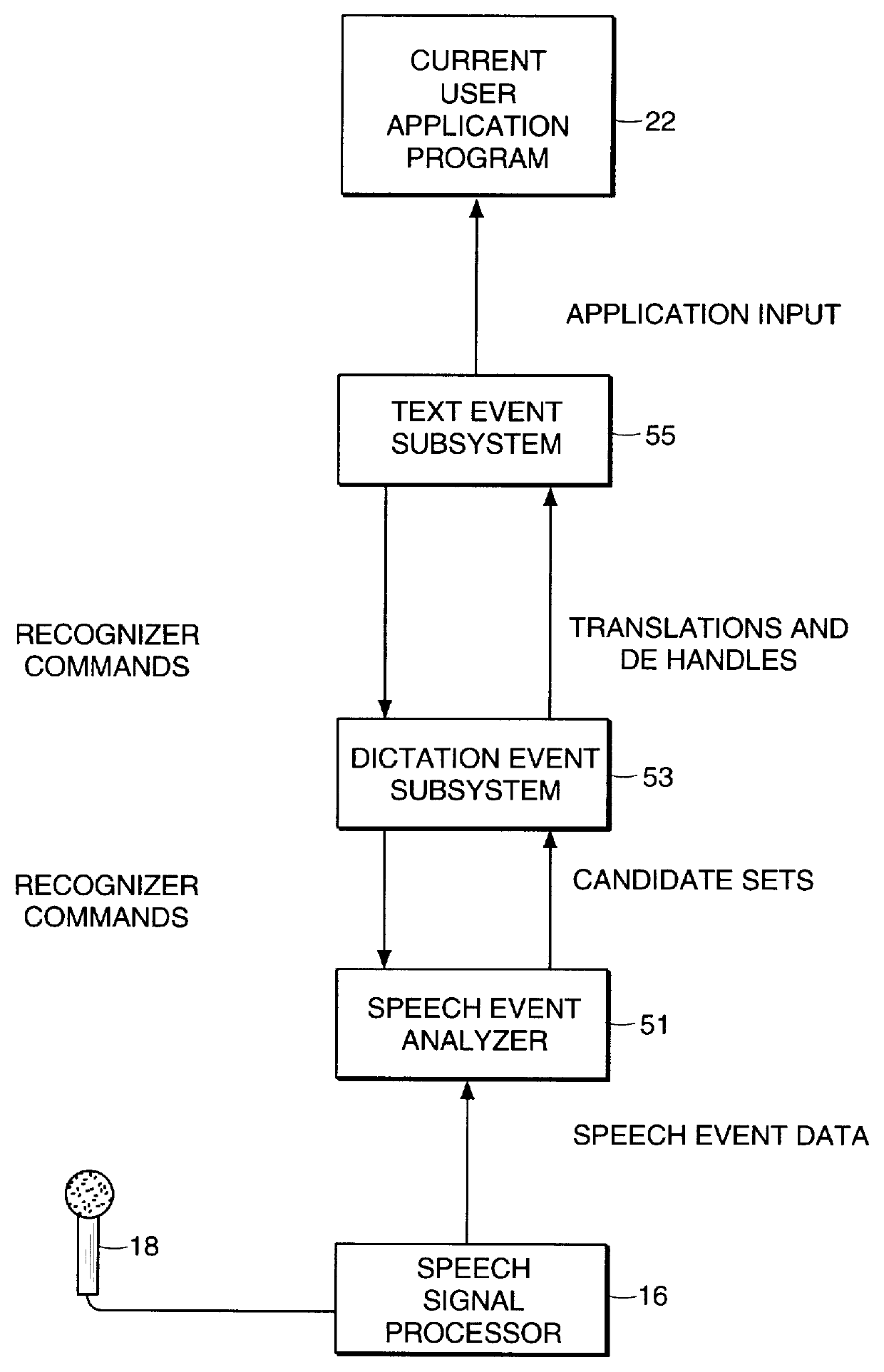

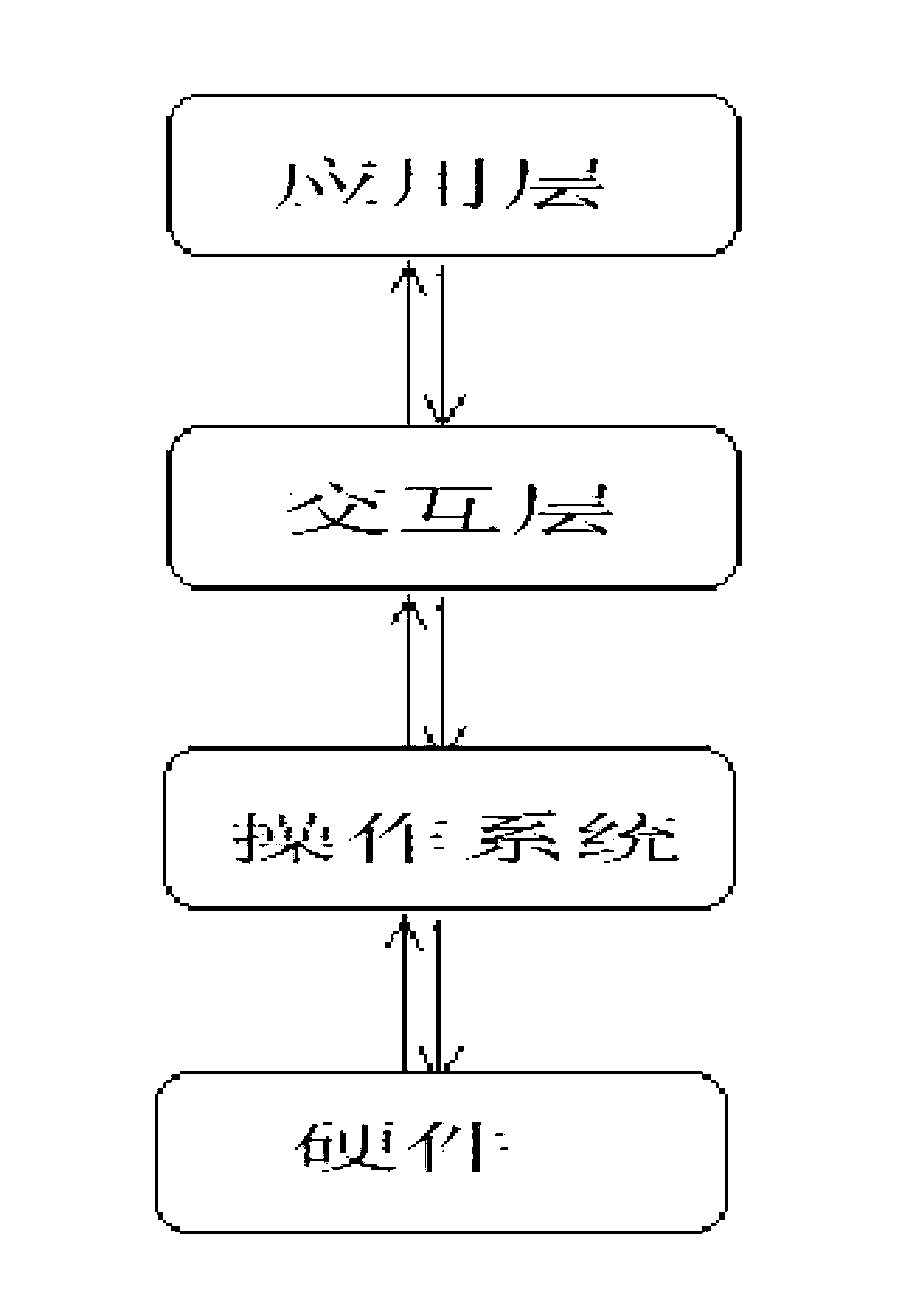

System for controlling multiple user application programs by spoken input

The system described herein facilitates the control, by spoken input, of multiple user application programs running under an operating system providing multi-tasking capability. A speech recognition program runs as one of the multi-tasked programs. The recognition program is operative to provide translation, either text or program commands, of spoken words in accordance with a translation table. Each of the other user application programs which is to be controlled is provided with a respective translation table section. In accordance with the invention, the recognition program includes means for creating a database for each of the other user application programs which is run and stores, in the respective database, a record reflecting each translation which is sent to a running one of the other application programs. These records identify the speech event which was translated and also identifies alternate possible translations of the speech event. Using the databases, the user can undo the effect of a previously sent translation, select an alternate translation and perform other editing tasks.

Owner:NUANCE COMM INC

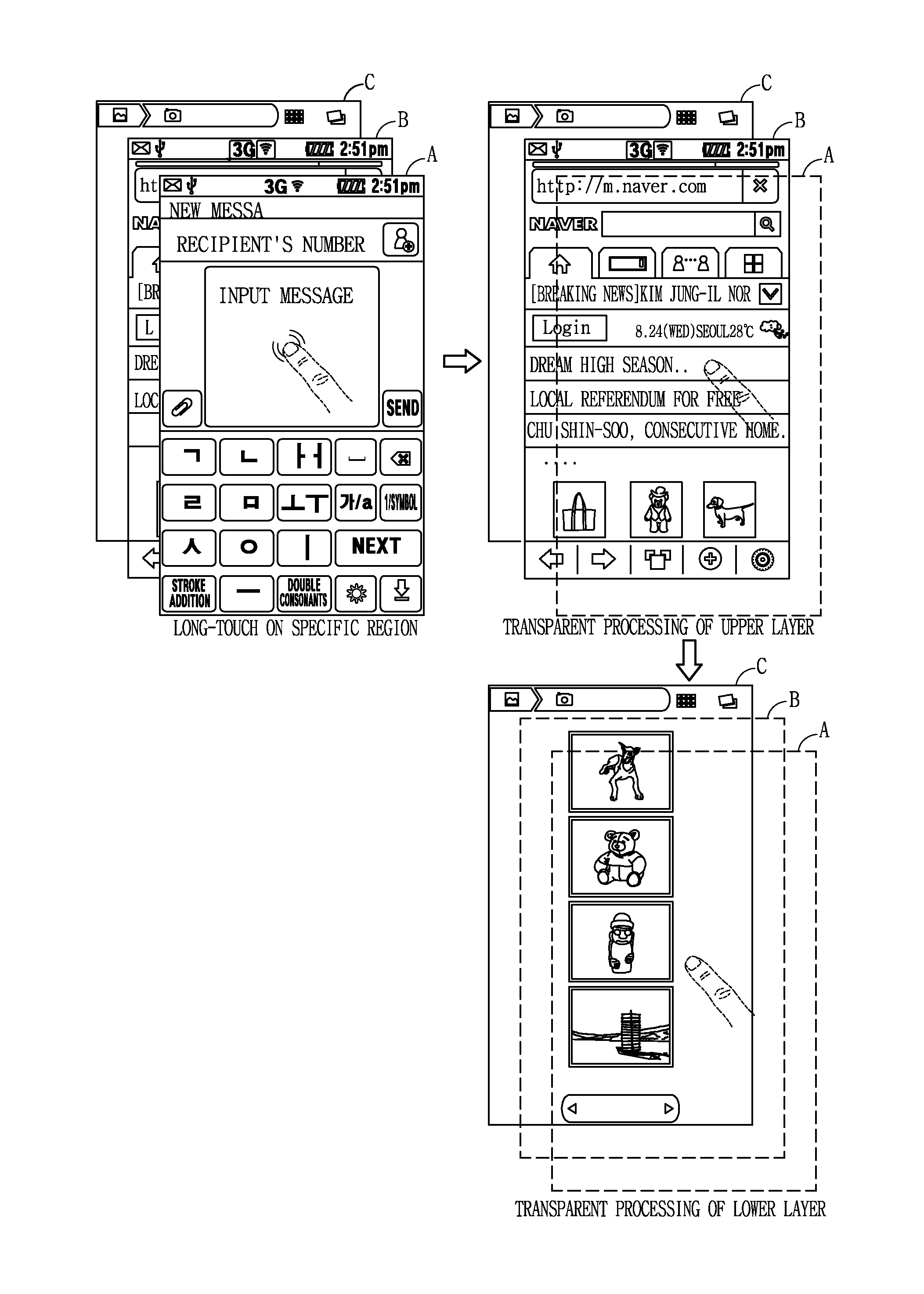

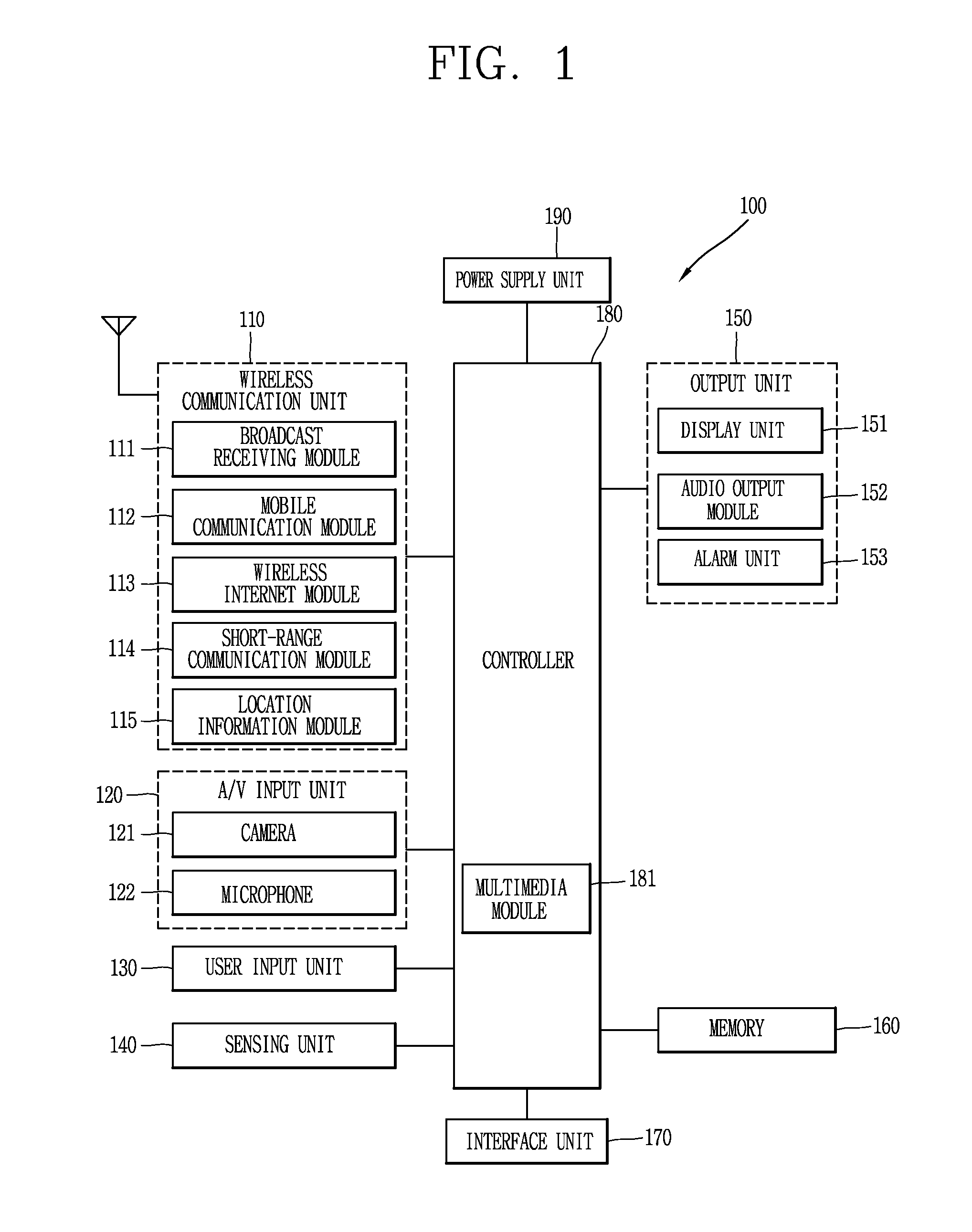

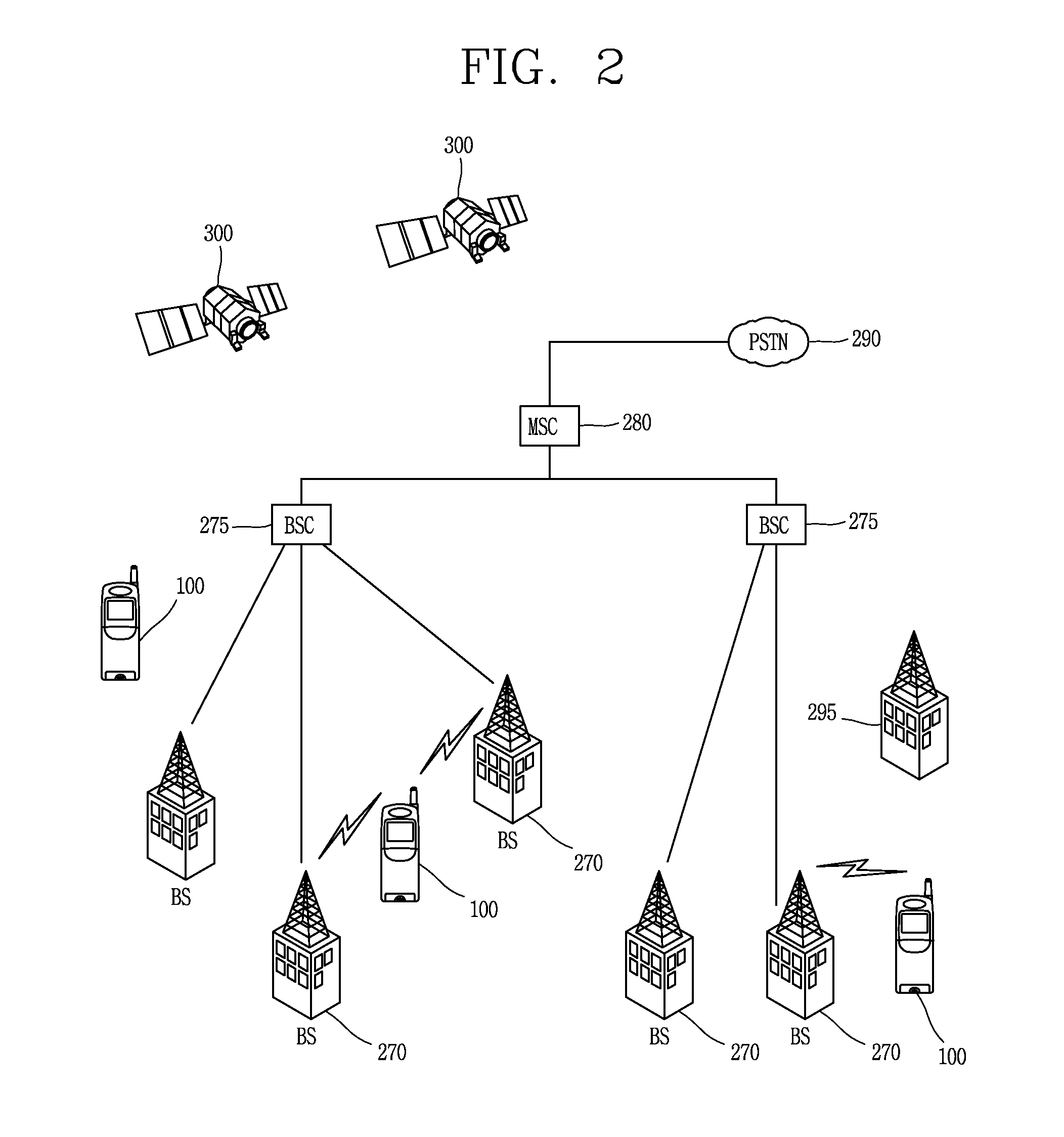

Mobile terminal and multitasking method thereof

InactiveUS20130145313A1Promote sportsEffectively use such informationSubstation equipmentExecution for user interfacesComputer terminalComputer science

Disclosed are a mobile terminal and a multitasking method thereof. In a state where a plurality of layers corresponding to a plurality of applications are displayed on a screen, a user performs an operation through an uppermost application. In this case, a search region of a preset shape through which a lower application can be directly visible is created on the uppermost application. This can allow the user to more rapidly and conveniently search for or select information provided from the lower application, and to apply the information to multitasking.

Owner:LG ELECTRONICS INC

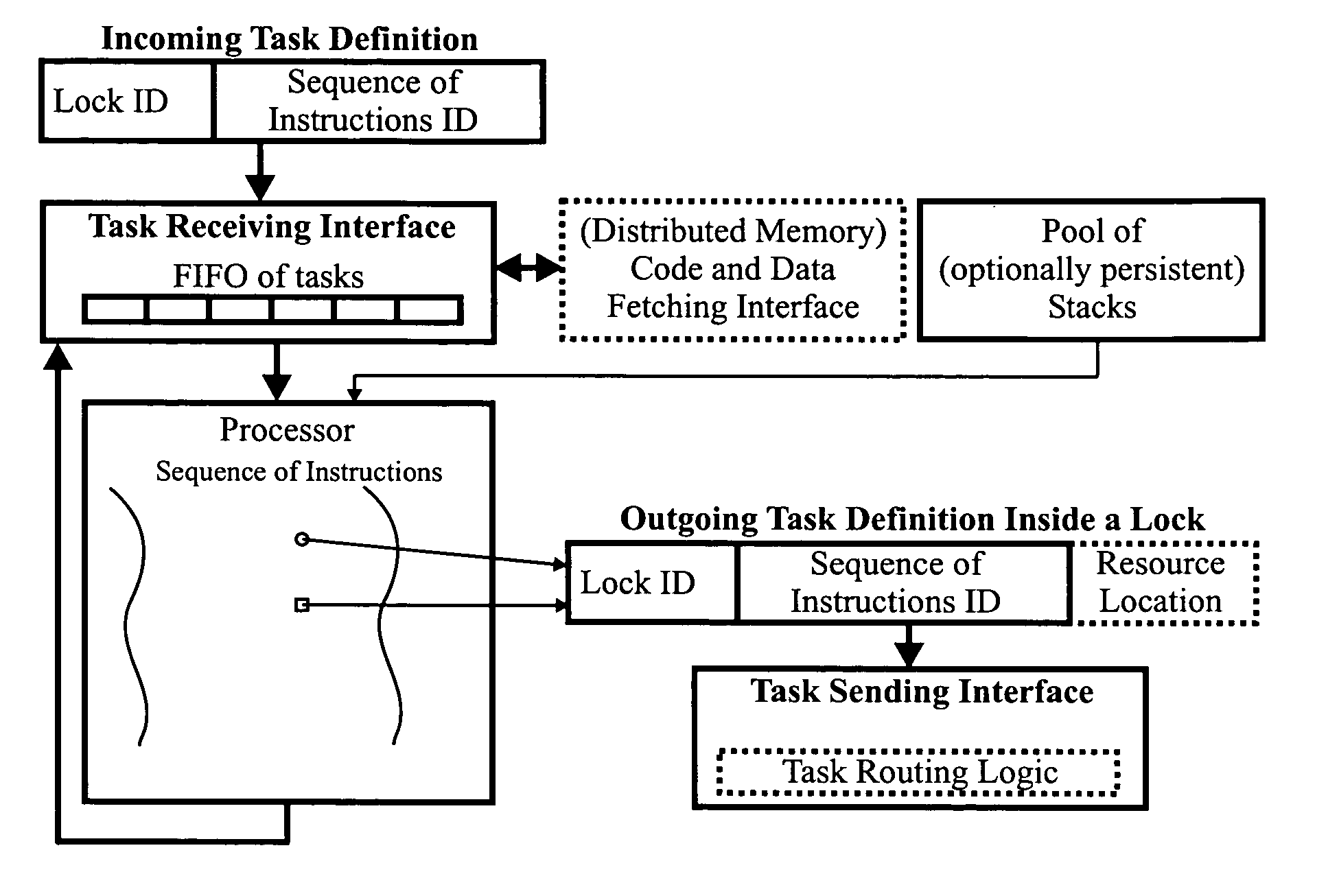

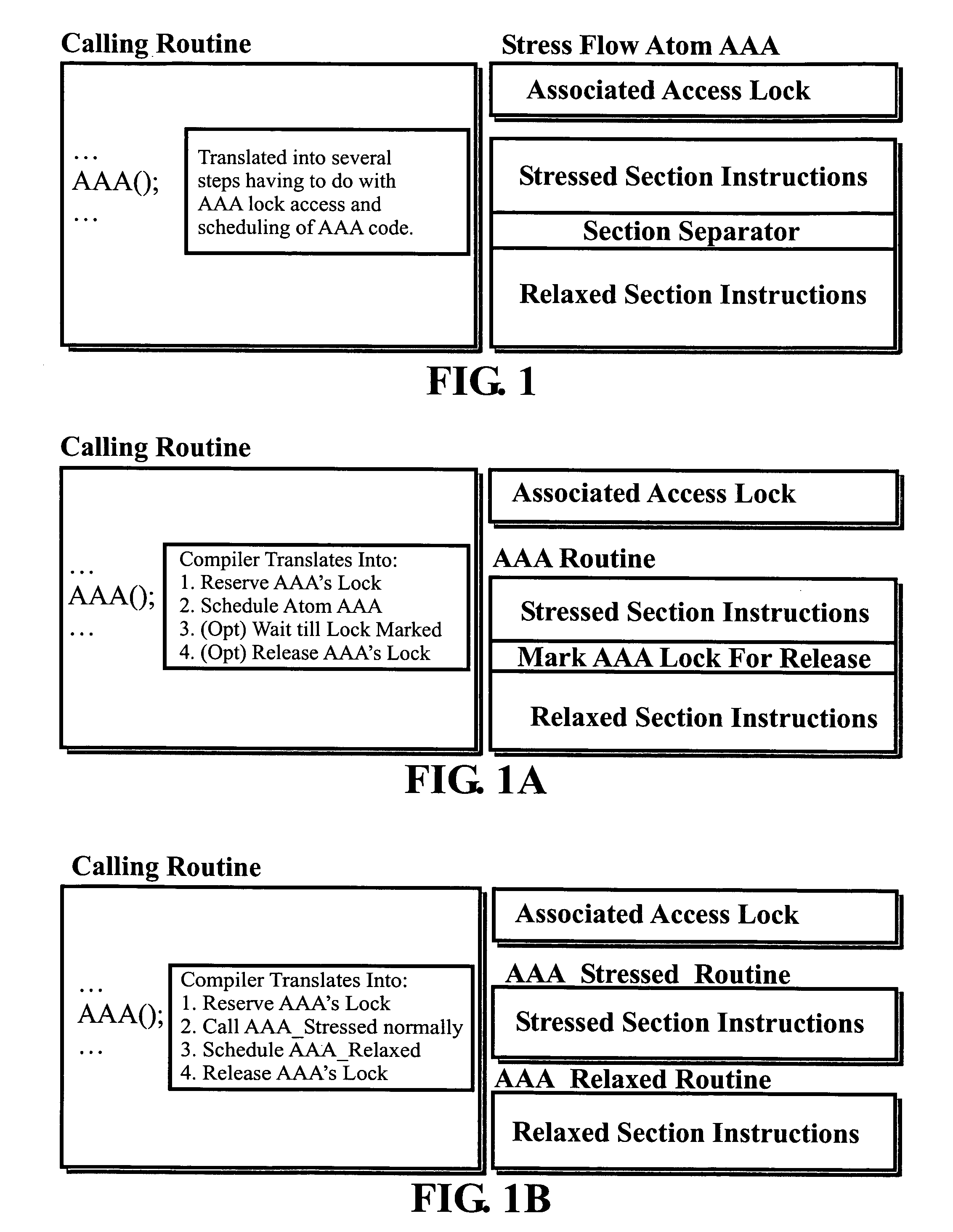

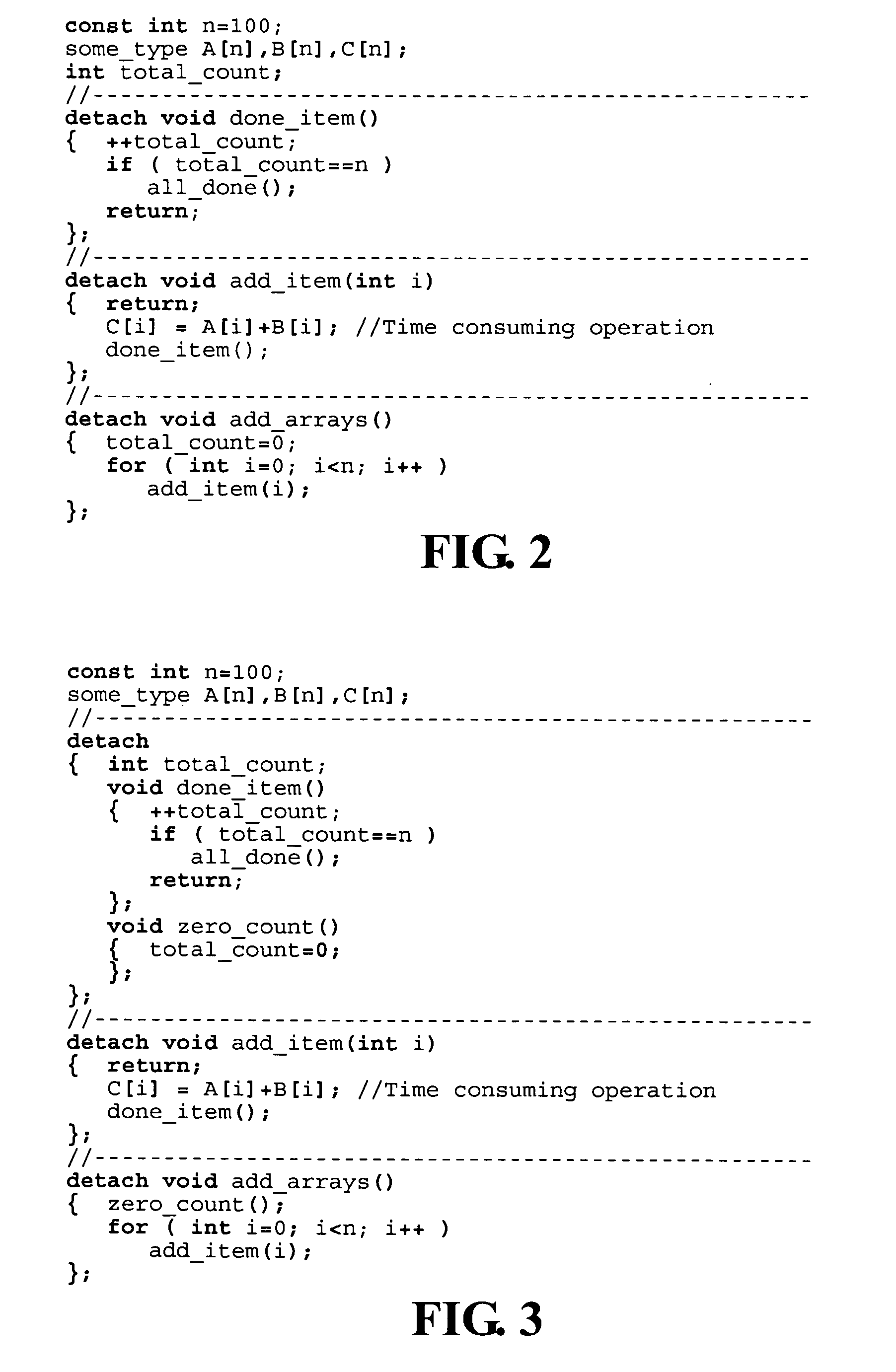

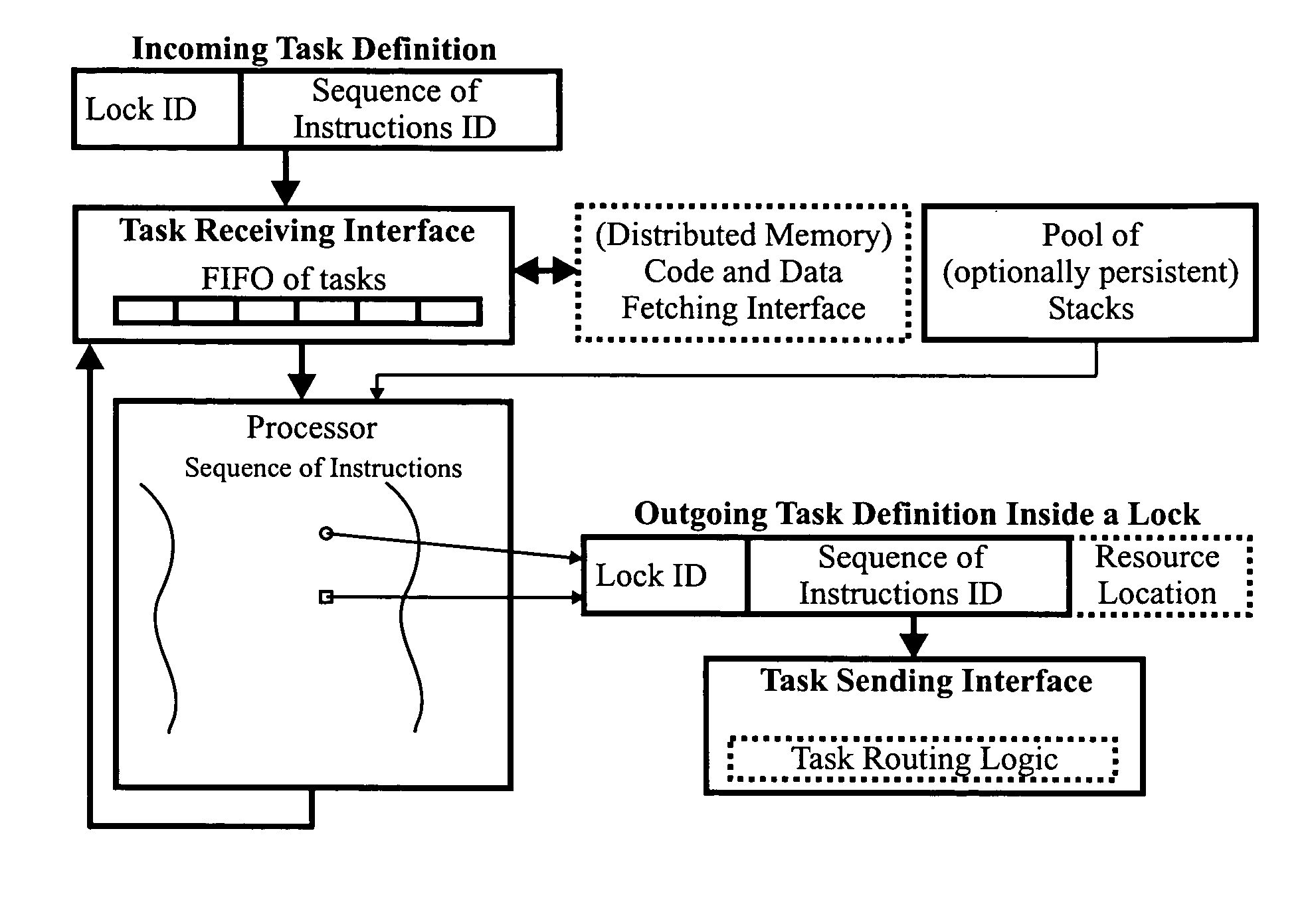

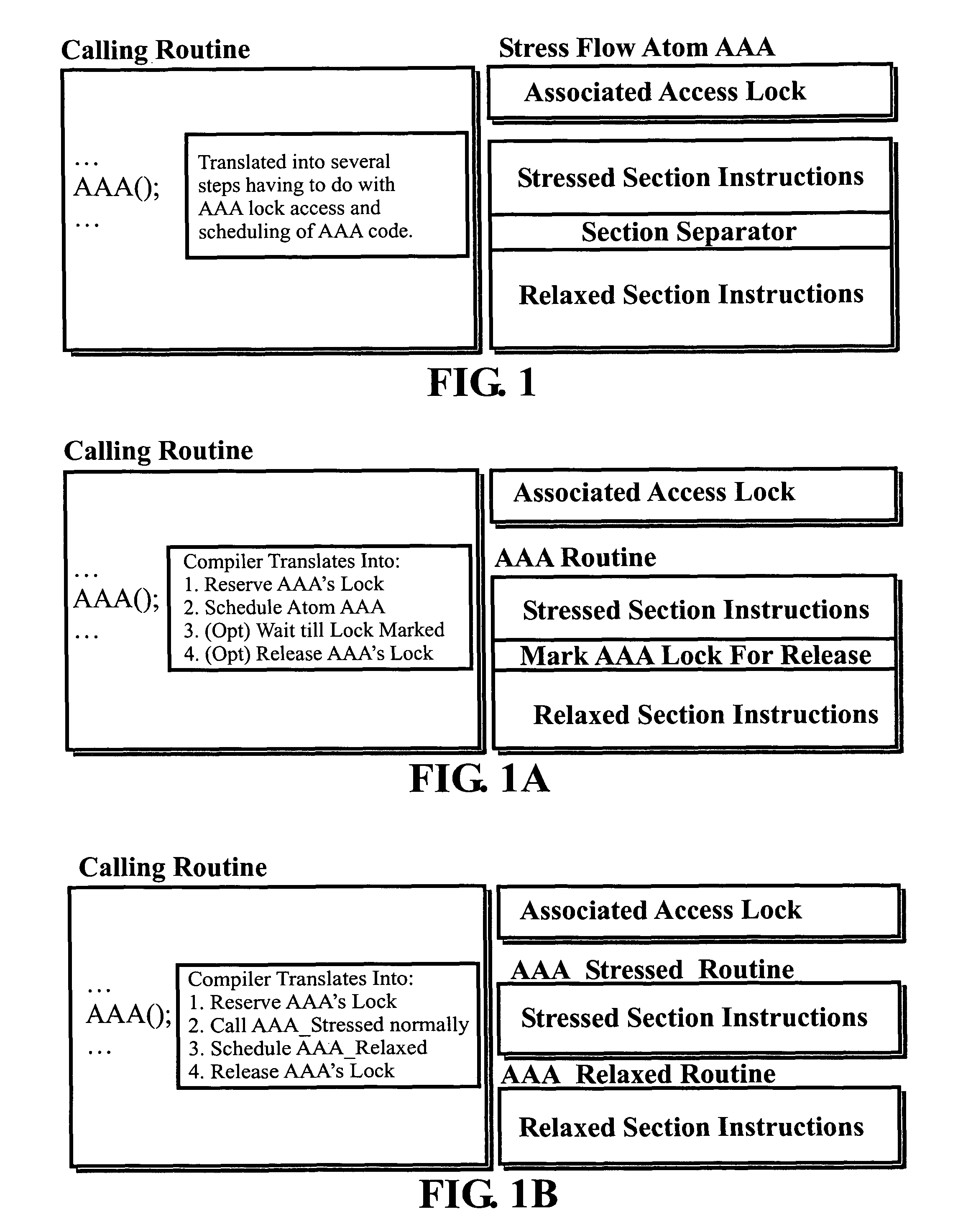

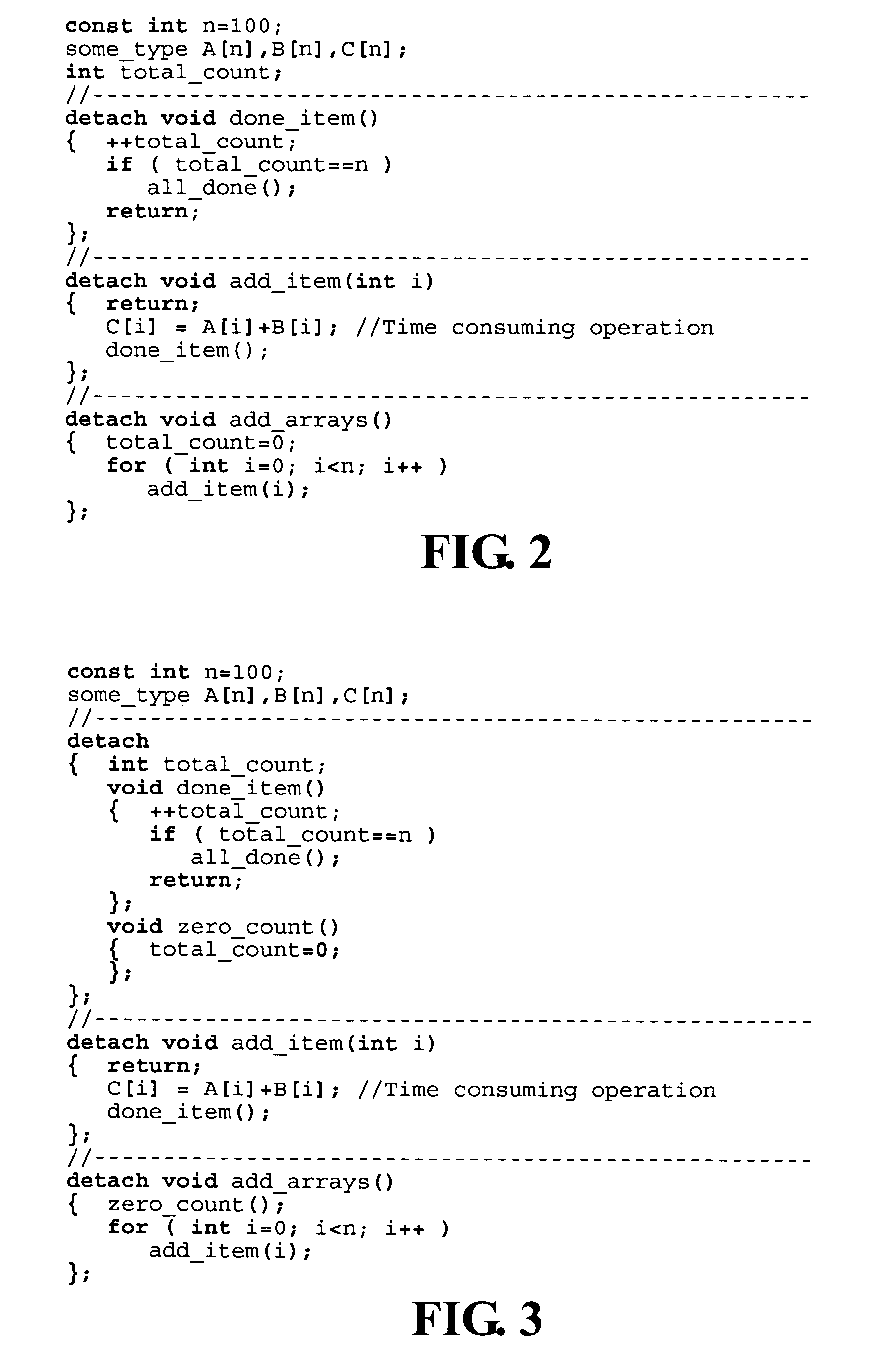

Object-oriented, parallel language, method of programming and multi-processor computer

This invention relates to architecture and synchronization of multi-processor computing hardware. It establishes a new method of programming, process synchronization, and of computer construction, named stress-flow by the inventor, allowing benefits of both opposing legacy concepts of programming (namely of both data-flow and control flow) within one cohesive, powerful, object-oriented scheme. This invention also relates to construction of object-oriented, parallel computer languages, script and visual, together with compiler construction and method to write programs to be executed in fully parallel (or multi-processor) architectures, virtually parallel, and single-processor multitasking computer systems.

Owner:JANCZEWSKA NATALIA URSZULA +2

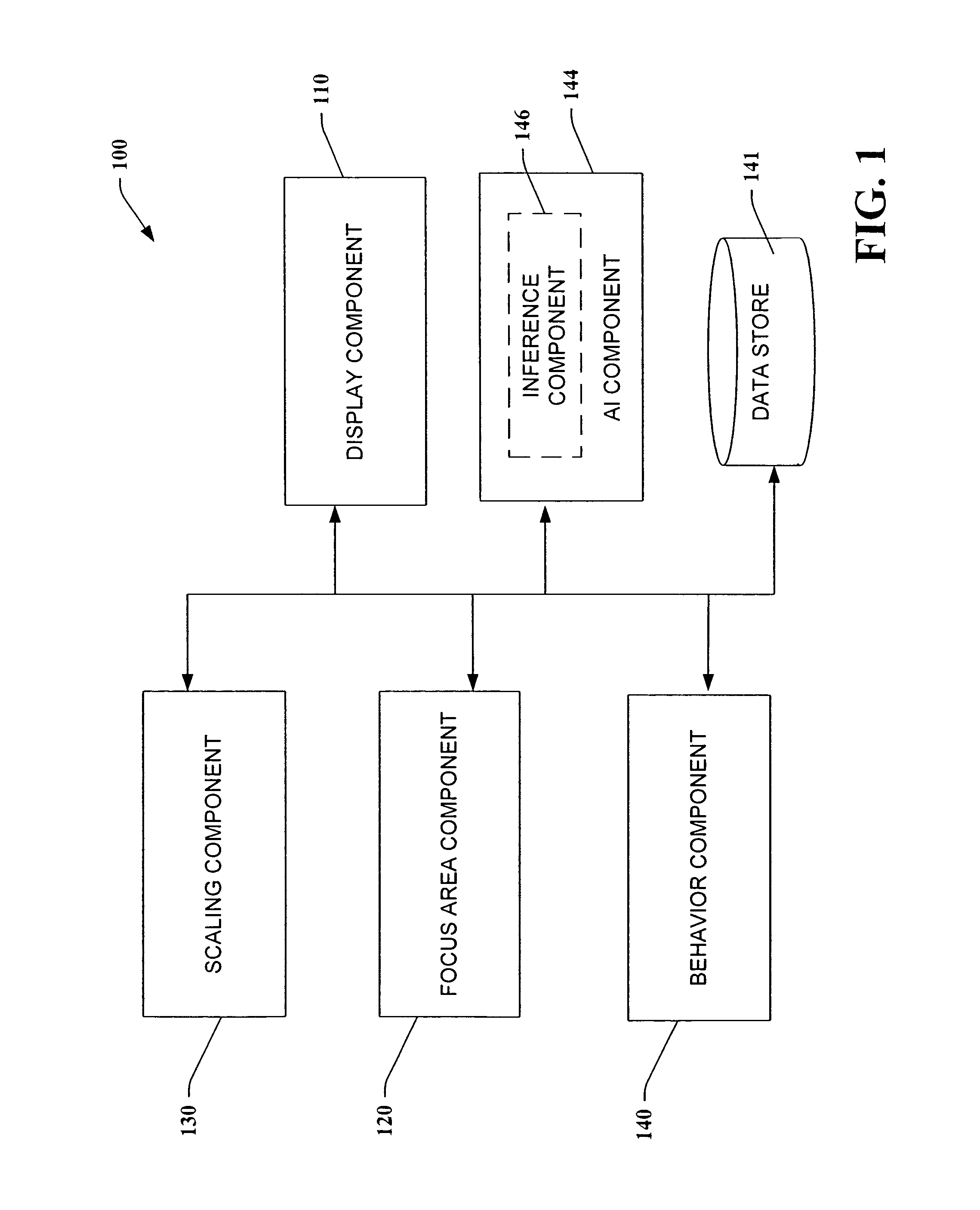

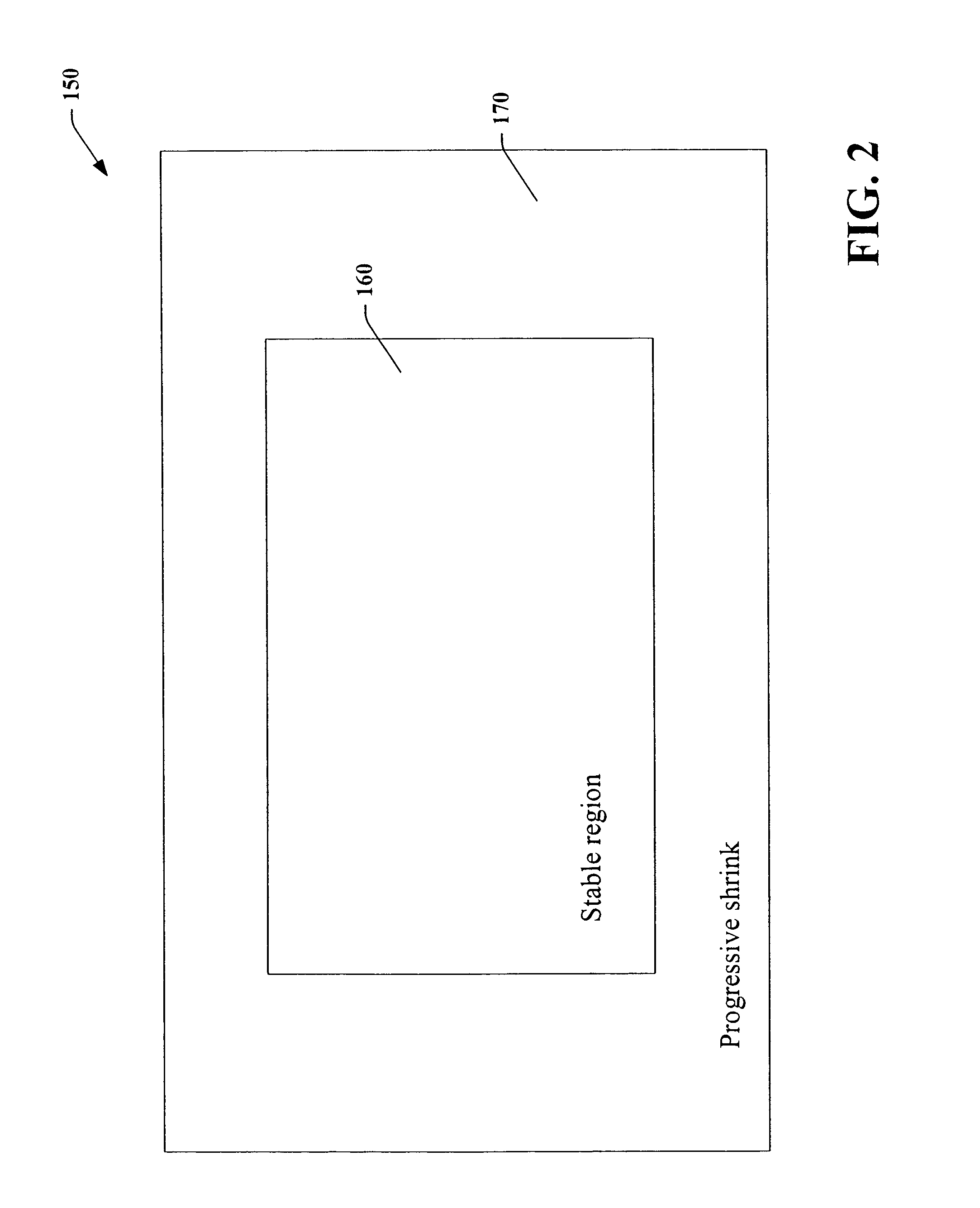

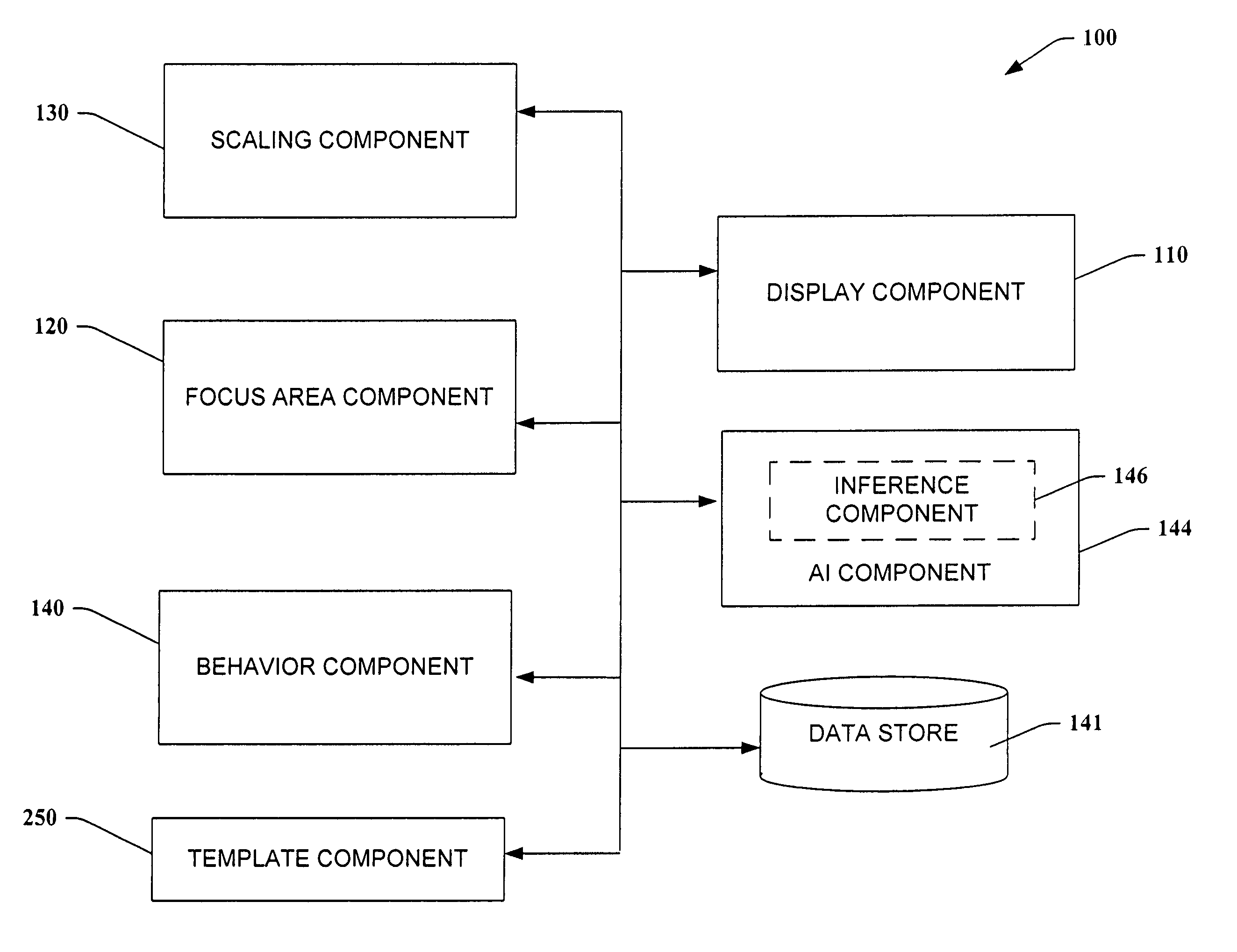

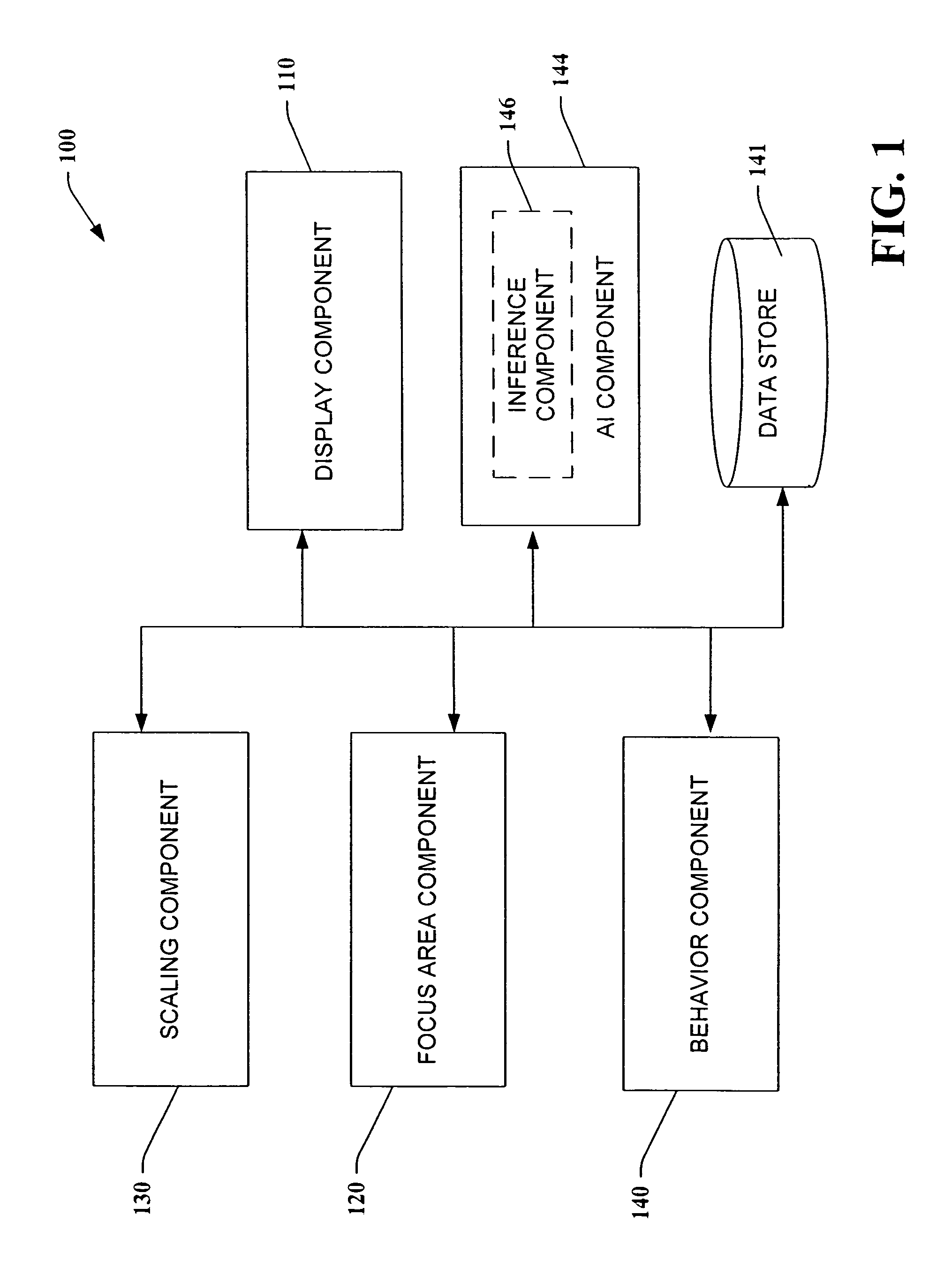

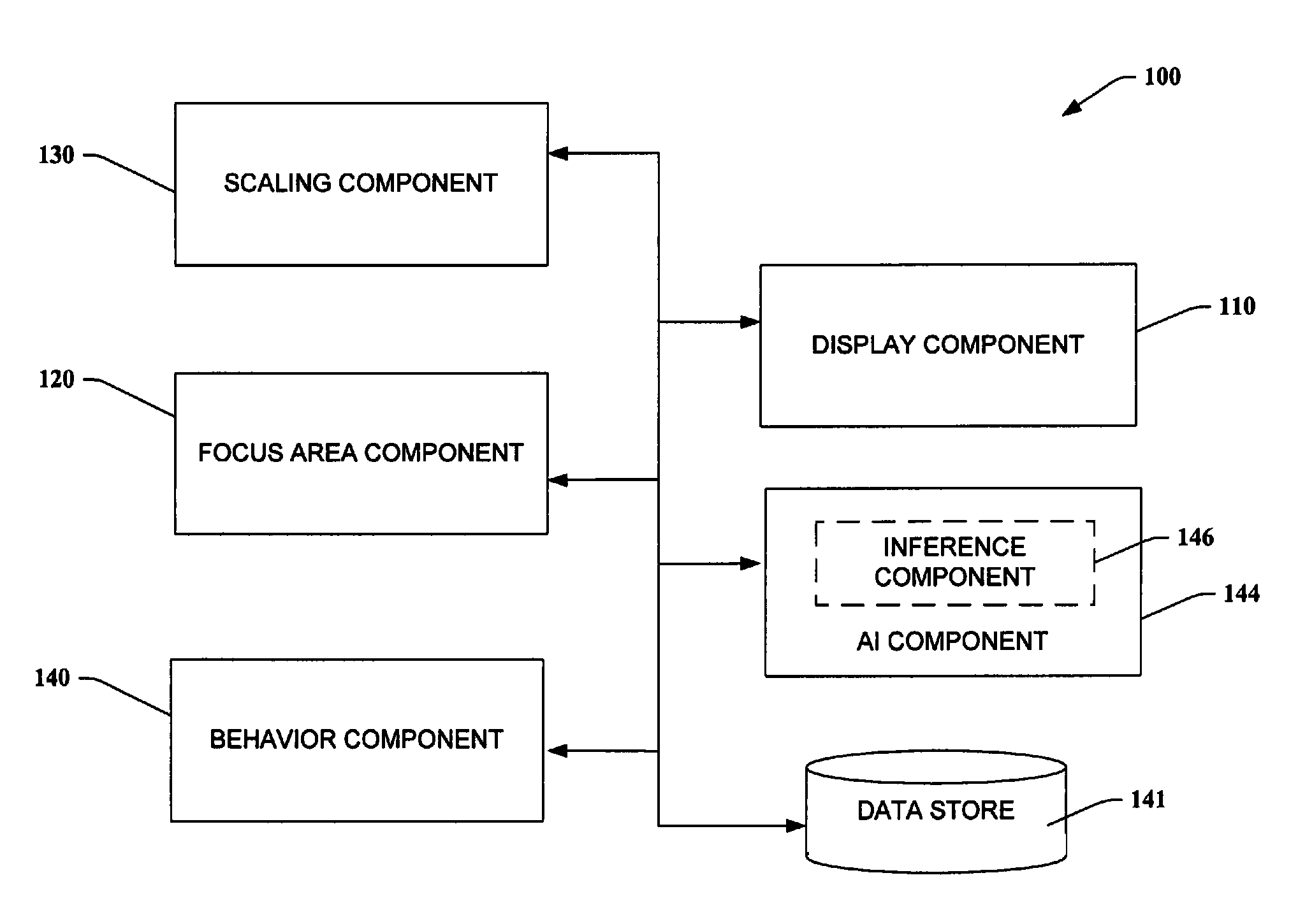

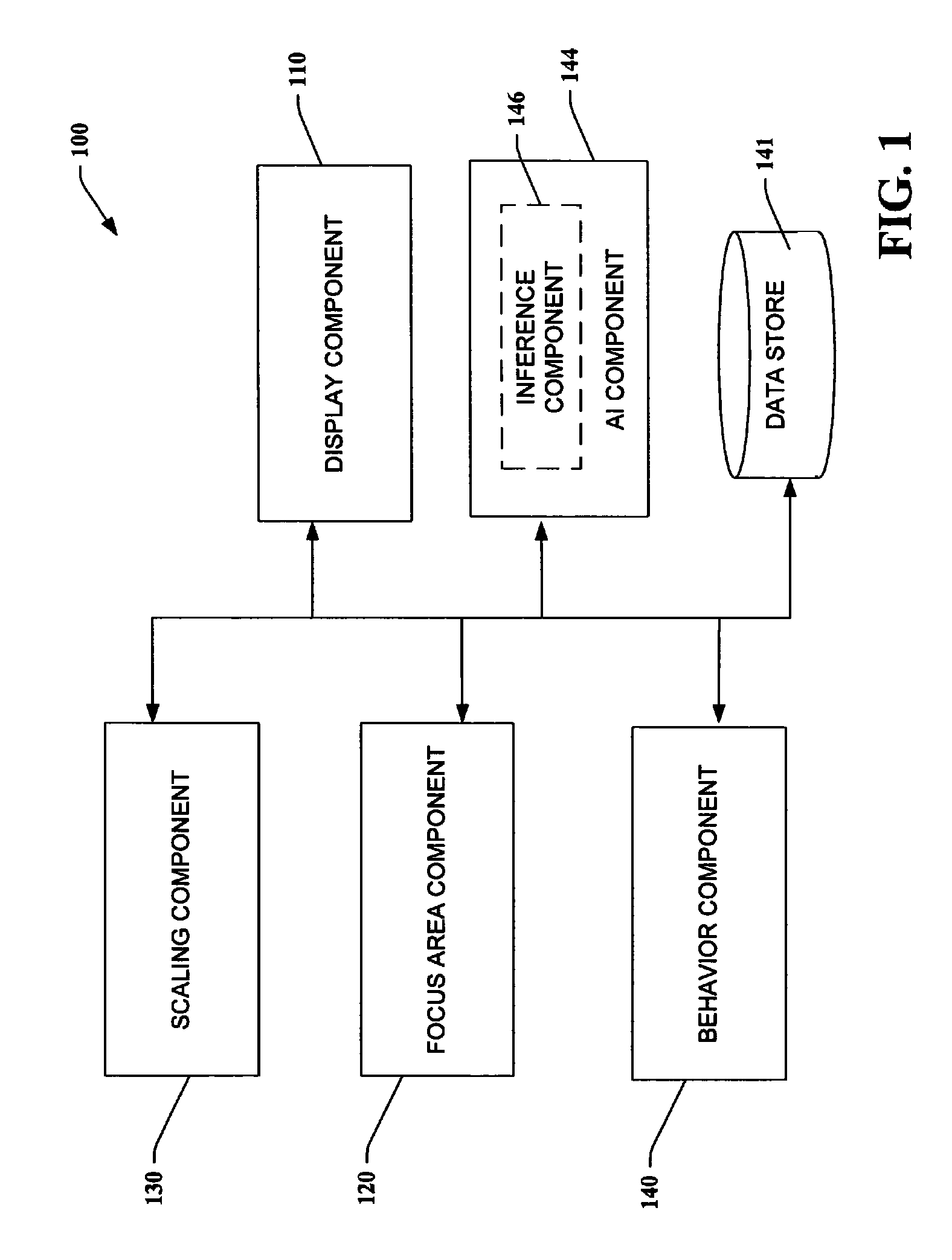

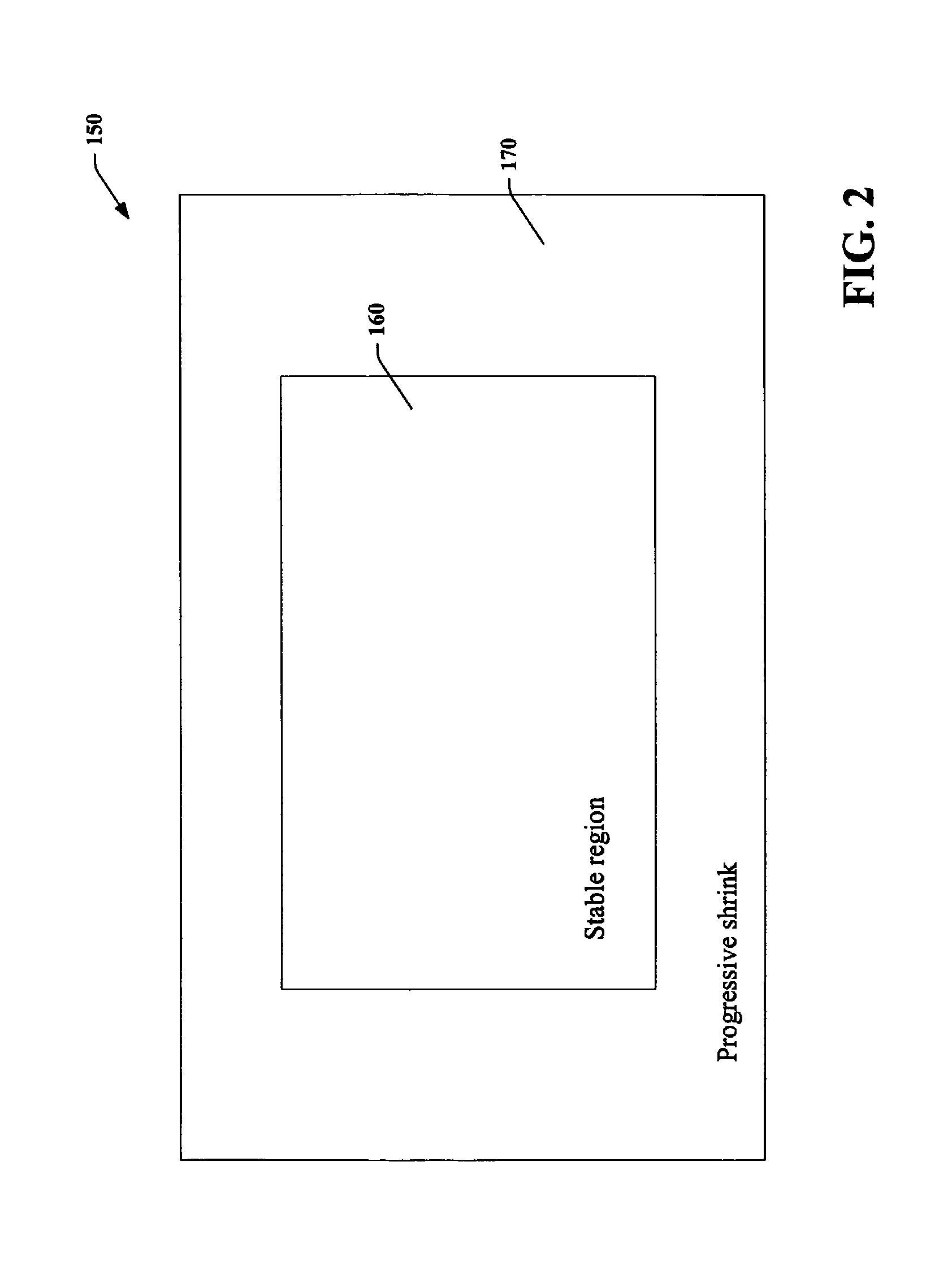

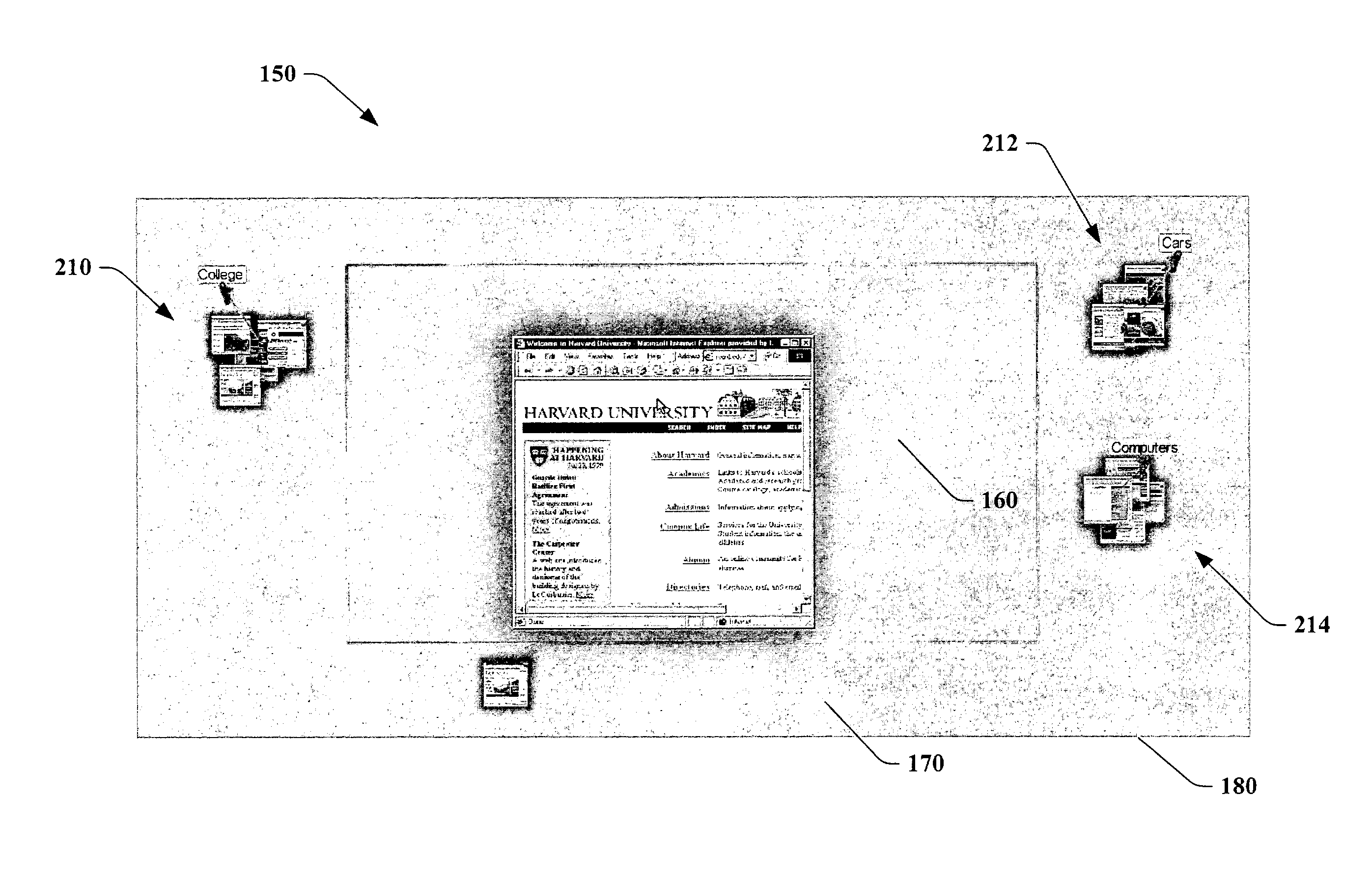

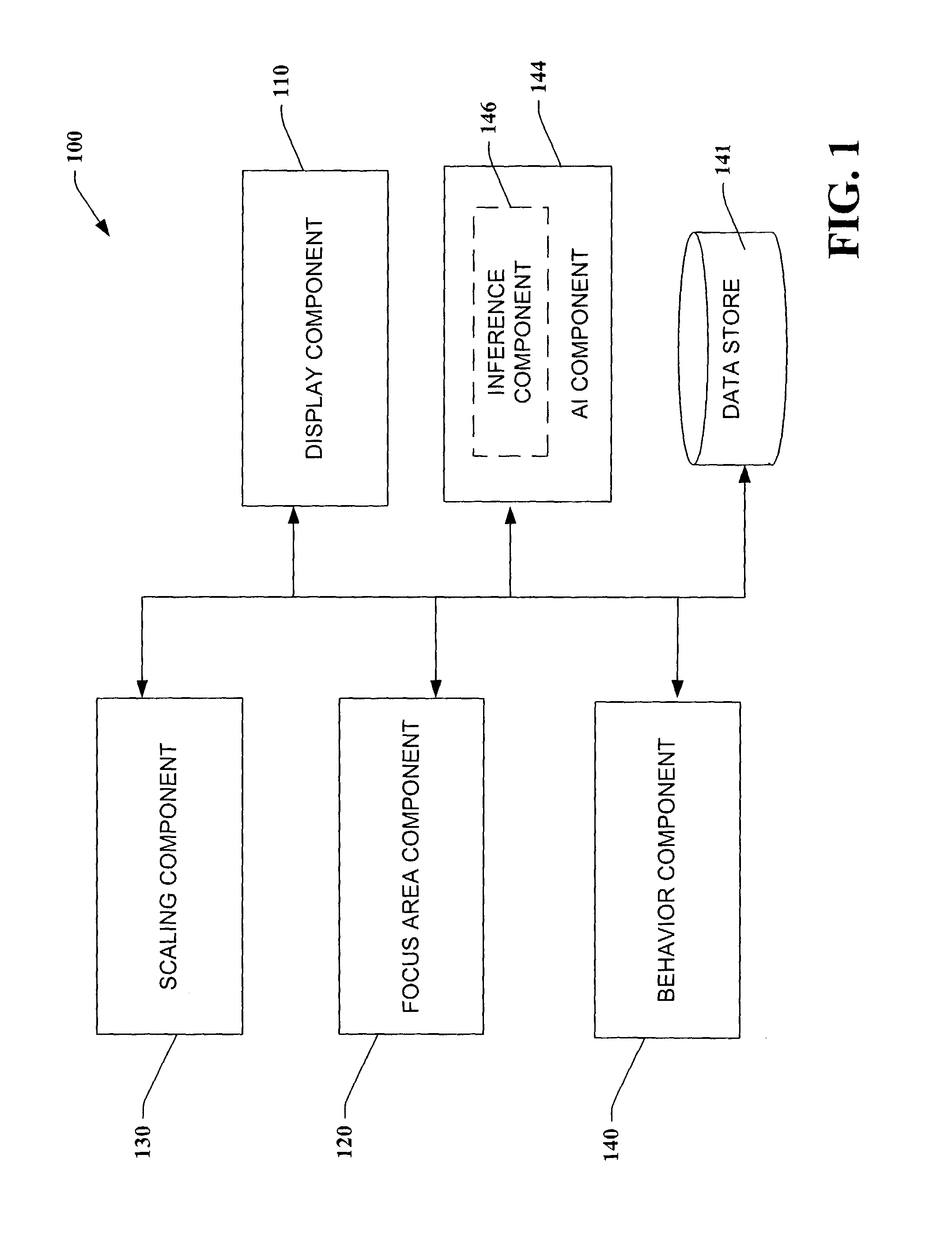

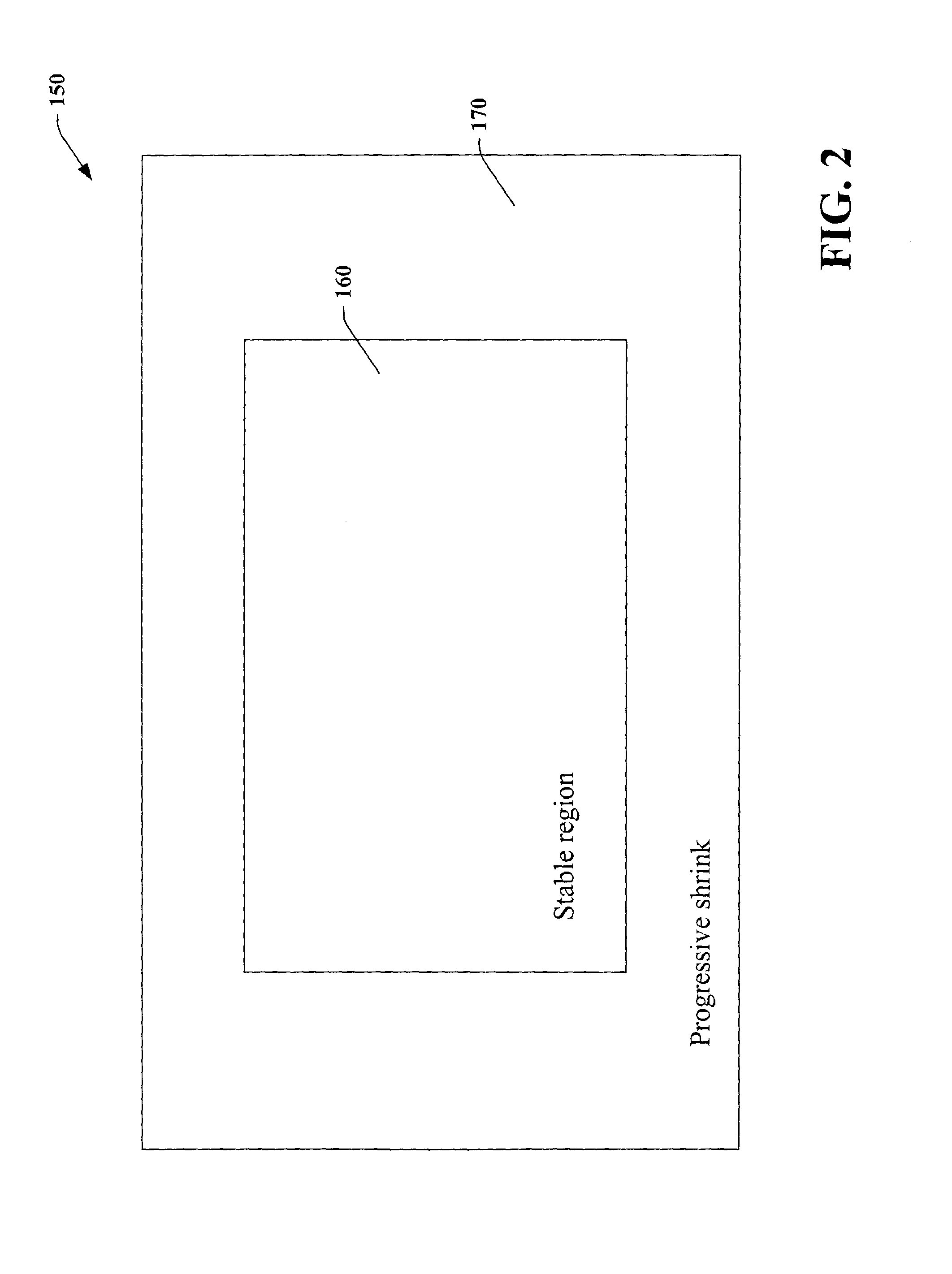

System and method that facilitates computer desktop use via scaling of displayed objects with shifts to the periphery

ActiveUS7386801B1Precise positioningReduce decreaseDigital computer detailsDigital output to display deviceVisibilityObject based

The present invention relates to a system that facilitates multi-tasking in a computing environment. A focus area component defines a focus area within a display space—the focus area occupying a subset area of the display space area. A scaling component scales display objects as a function of proximity to the focus area, and a behavior modification component modifies respective behavior of the display objects as a function their location of the display space. Thus, and more particularly the subject invention provides for interaction technique(s) and user interface(s) in connection with managing display objects on a display surface. One aspect of the invention defines a central focus area where the display objects are displayed and behave as usual, and a periphery outside the focus area where the display objects are reduced in size based on their location, getting smaller as they near an edge of the display surface so that many more objects can remain visible. In addition or alternatively, the objects can fade as they move toward an edge, fading increasing as a function of distance from the focus area and / or use of the object and / or priority of the object. Objects in the periphery can also be modified to have different interaction behavior (e.g., lower refresh rate, fading, reconfigured to display sub-objects based on relevance and / or visibility, static, etc.) as they may be too small for standard rendering. The methods can provide a flexible, scalable surface when coupled with automated policies for moving objects into the periphery, in response to the introduction of new objects or the resizing of pre-existing objects by a user or autonomous process.

Owner:MICROSOFT TECH LICENSING LLC

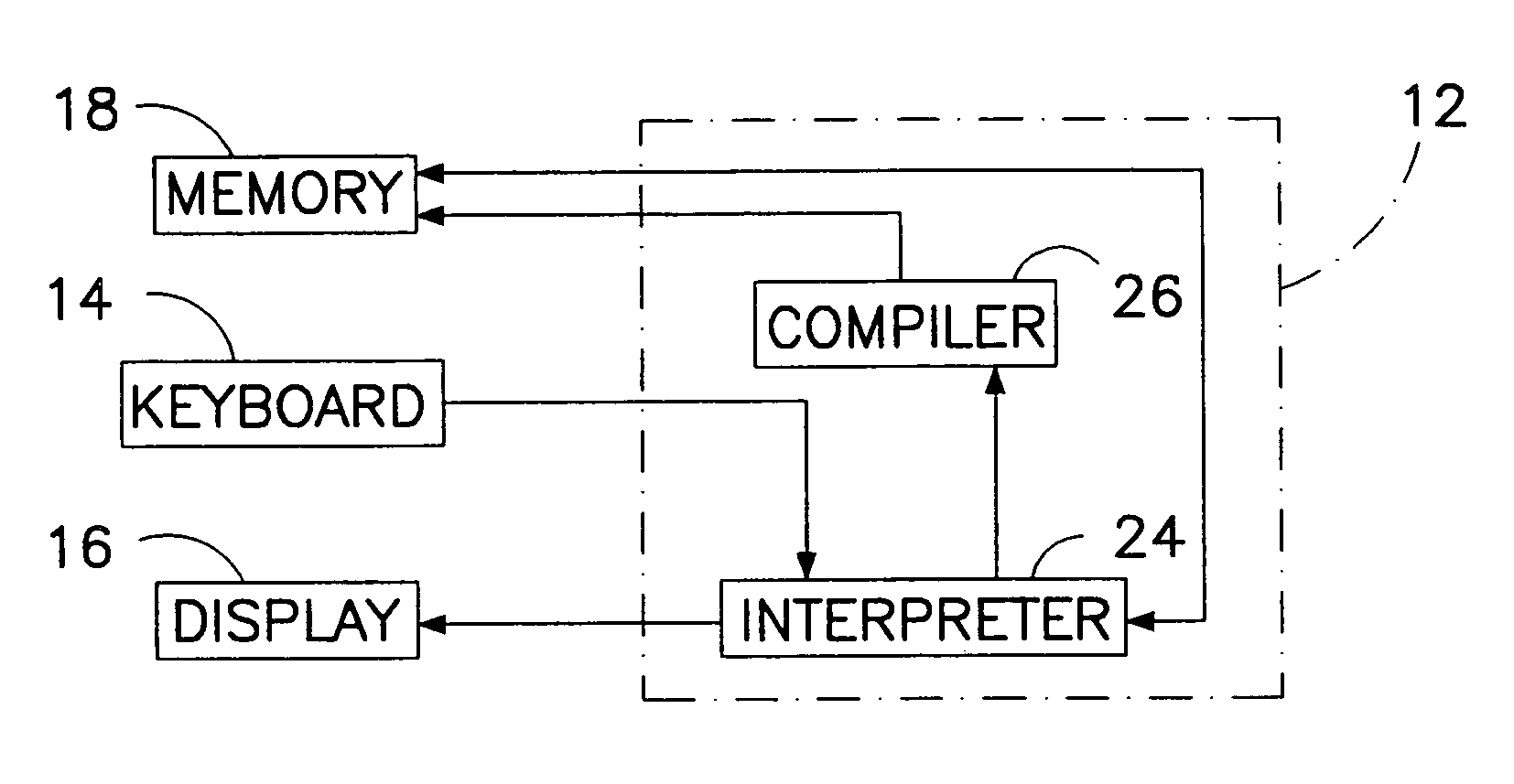

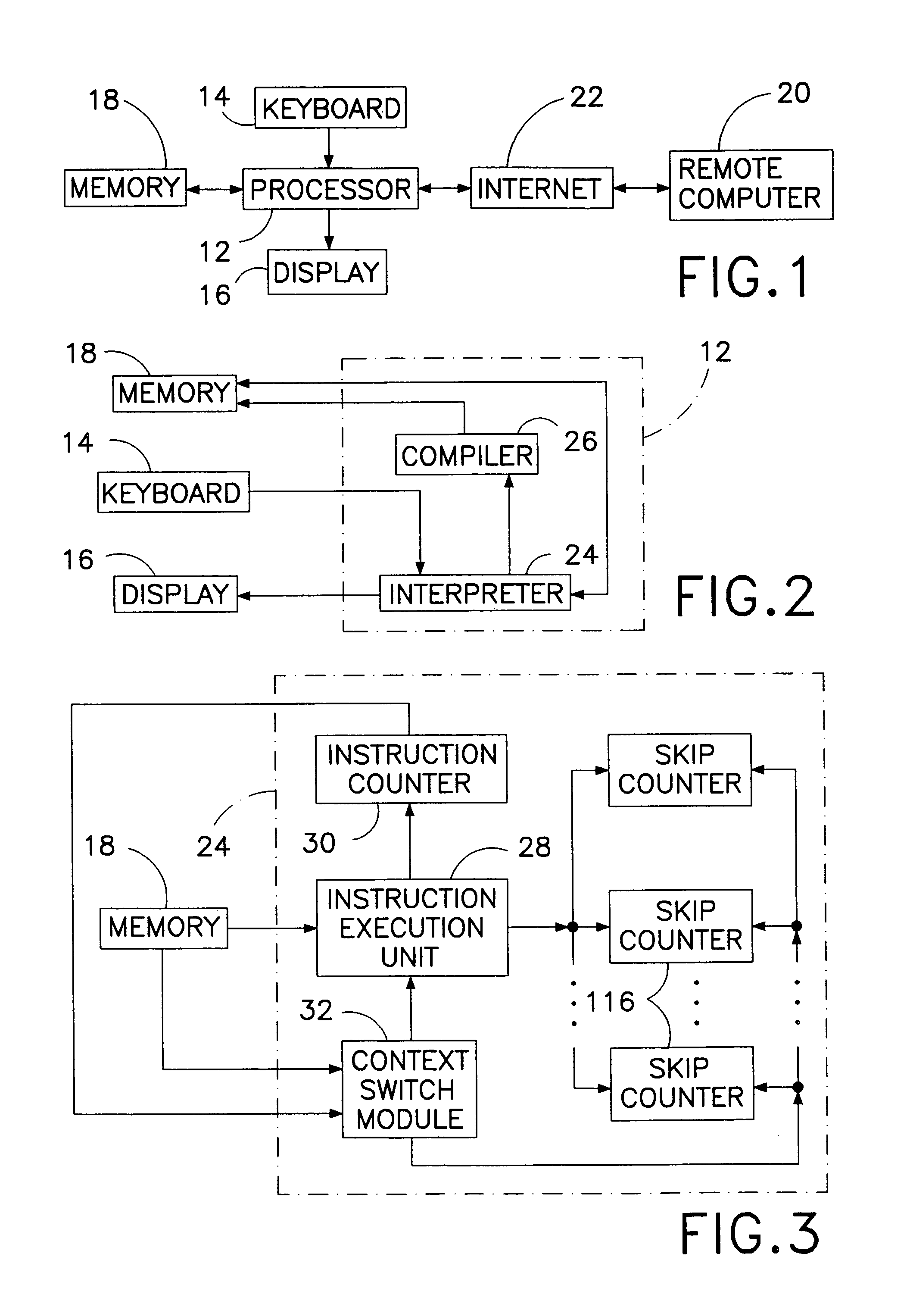

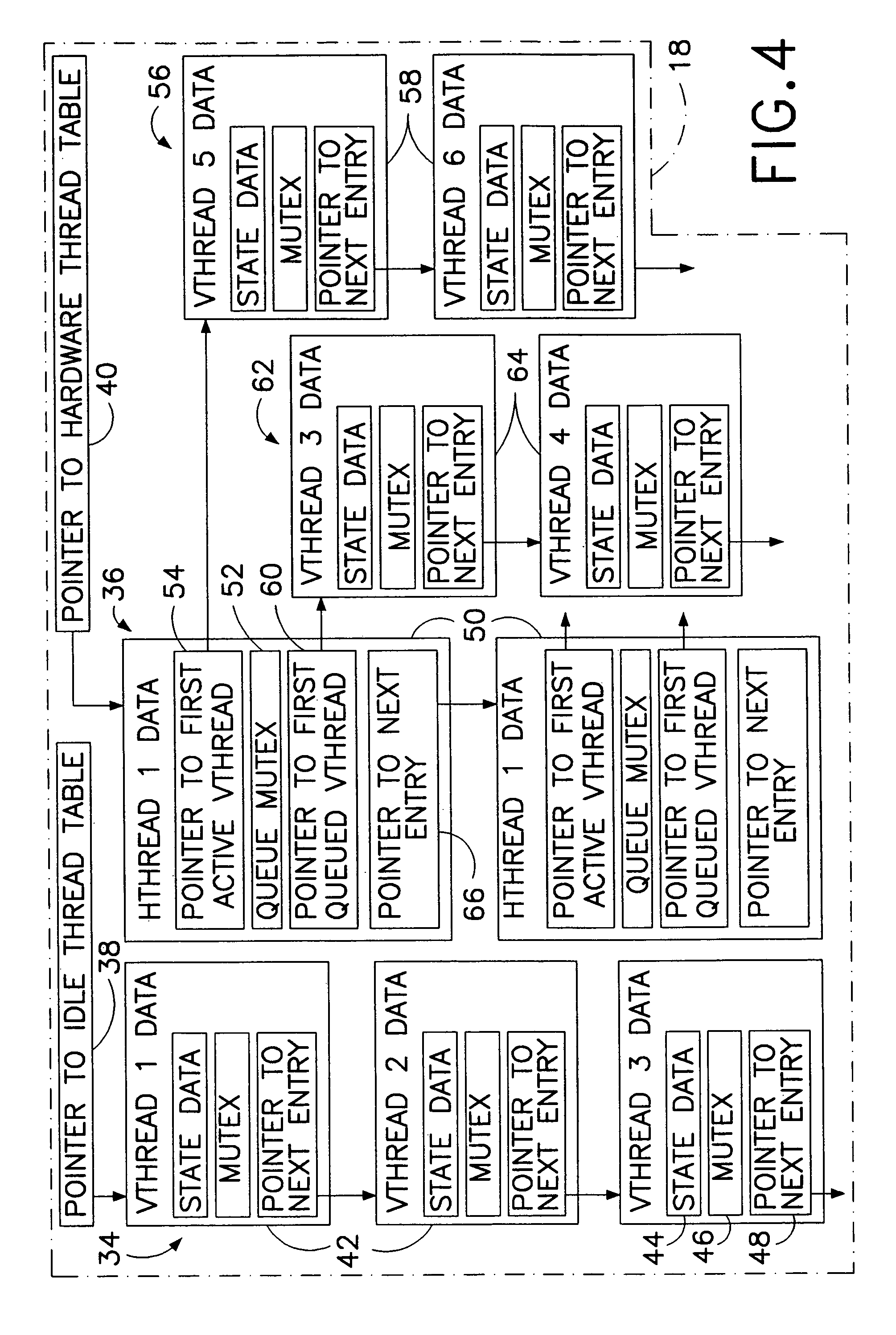

Computer multi-tasking via virtual threading using an interpreter

InactiveUS7234139B1Eliminate dependenciesDifferent operationalProgram initiation/switchingInterprogram communicationLocal variablePseudocode

In the operation of a computer, a plurality of bytecode or pseudocode instructions, at least some of the pseudocode instructions comprising a plurality of machine code instructions, are stored in a computer memory. For each of a plurality of tasks or jobs to be performed by the computer, a respective virtual thread of execution context data is automatically created. The virtual threads each include (a) a memory location of a next one of the pseudocode instructions to be executed in carrying out the respective task or job and (b) the values of any local variables required for carrying out the respective task or job. At least some of the tasks or jobs each entails execution of a respective one of the pseudocode instructions comprising a plurality of machine language instructions. Each of the tasks or jobs are processed in a respective series of time slices or processing slots under the control of the respective virtual thread, and, in every context switch between different virtual threads, such context switch is undertaken only after completed execution of a currently executing one of the pseudocode instructions.

Owner:CERINET USA

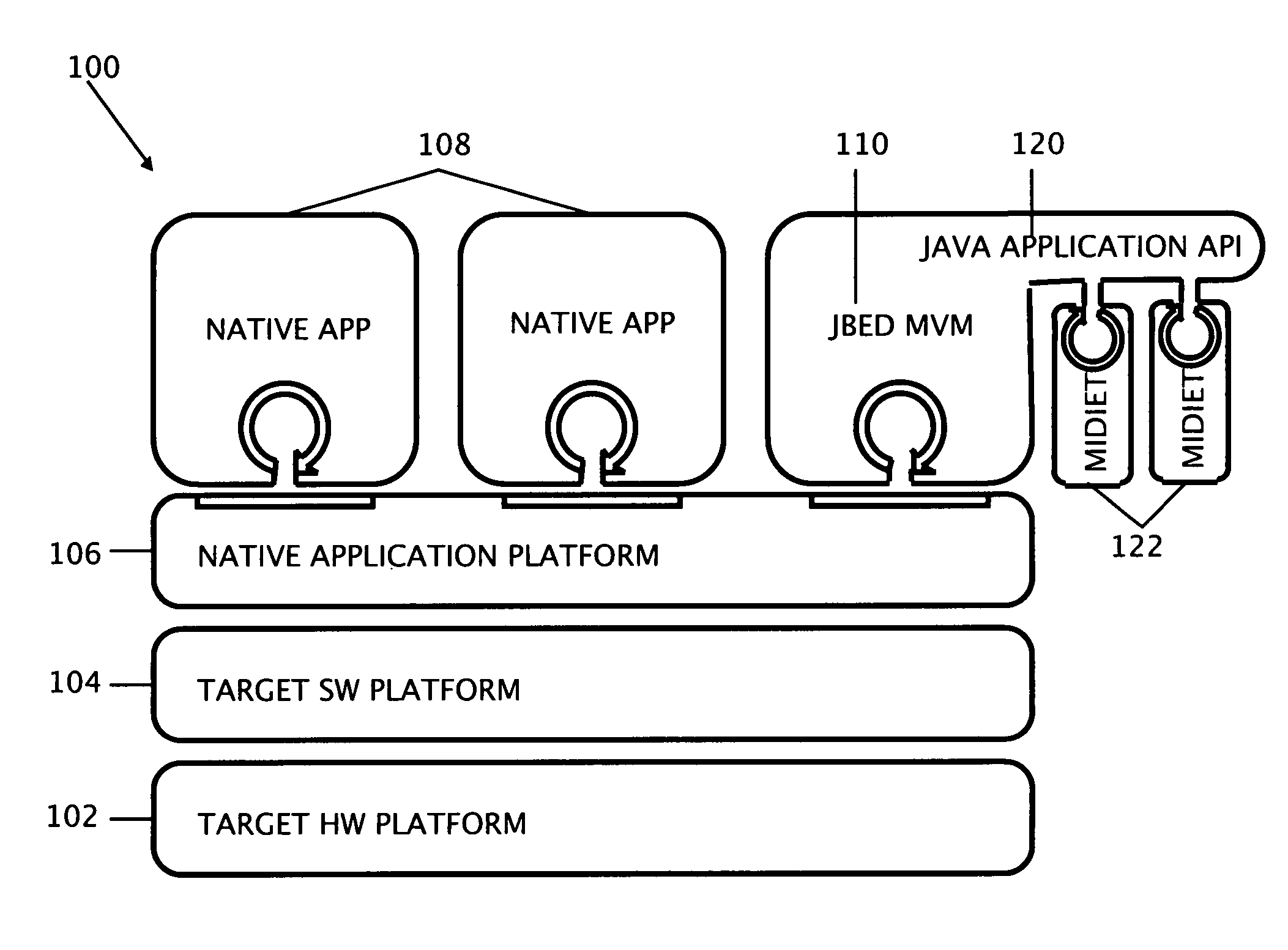

Unified mobile platform

InactiveUS20070168953A1Avoid applicationSpecific program execution arrangementsMemory systemsApplication softwareMobile device

The present invention teaches a variety of systems, platforms, applications, and methods, and relates to mobile platforms, embedded native applications, Java virtual machines, user interfaces, and the like. The present invention discloses a mobile platform which unifies the worlds of the Java virtual machine and native applications to provide a unified and consistent environment for multitasking both Java and native applications within a mobile device.

Owner:MYRIAD GROUP

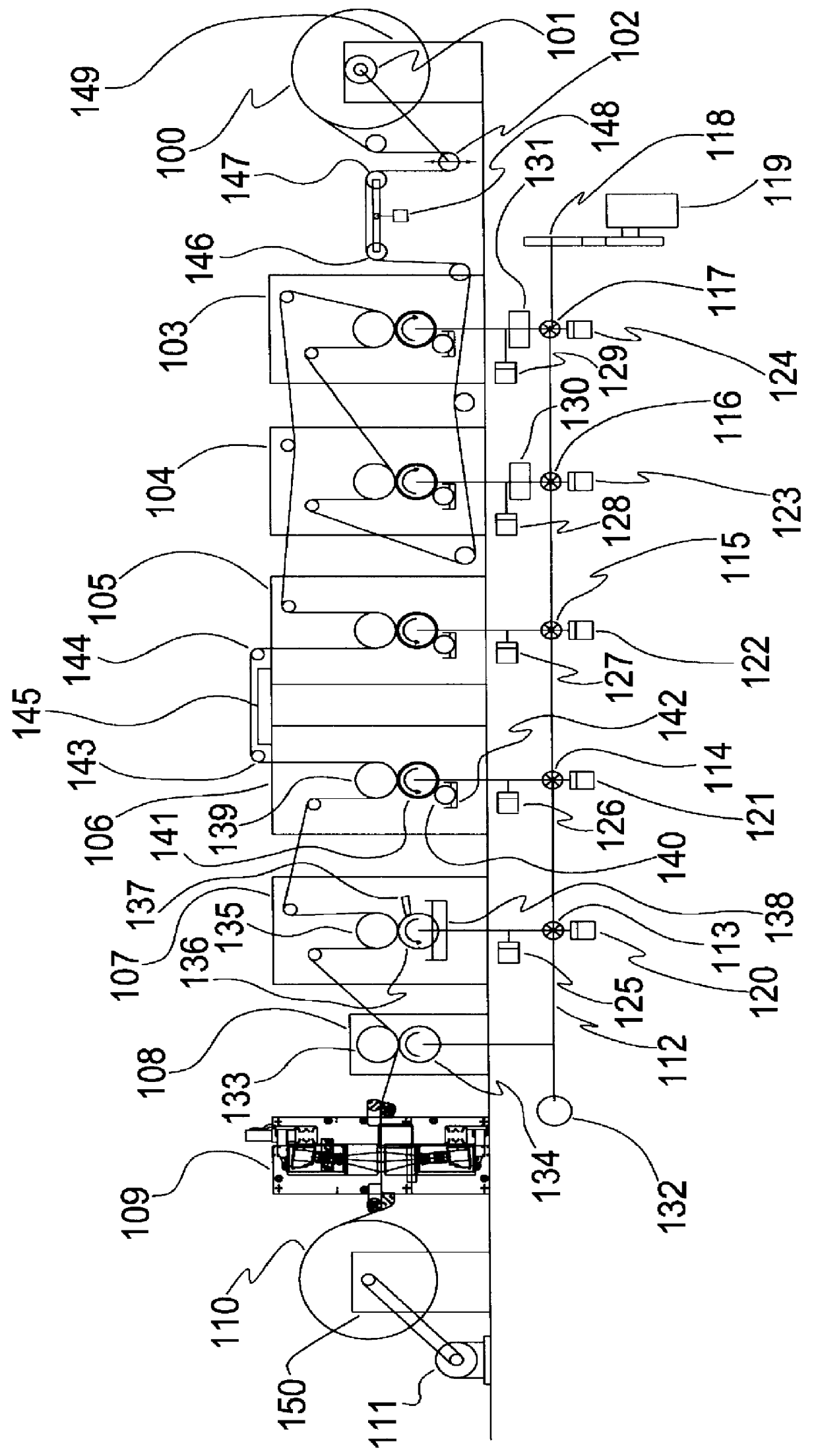

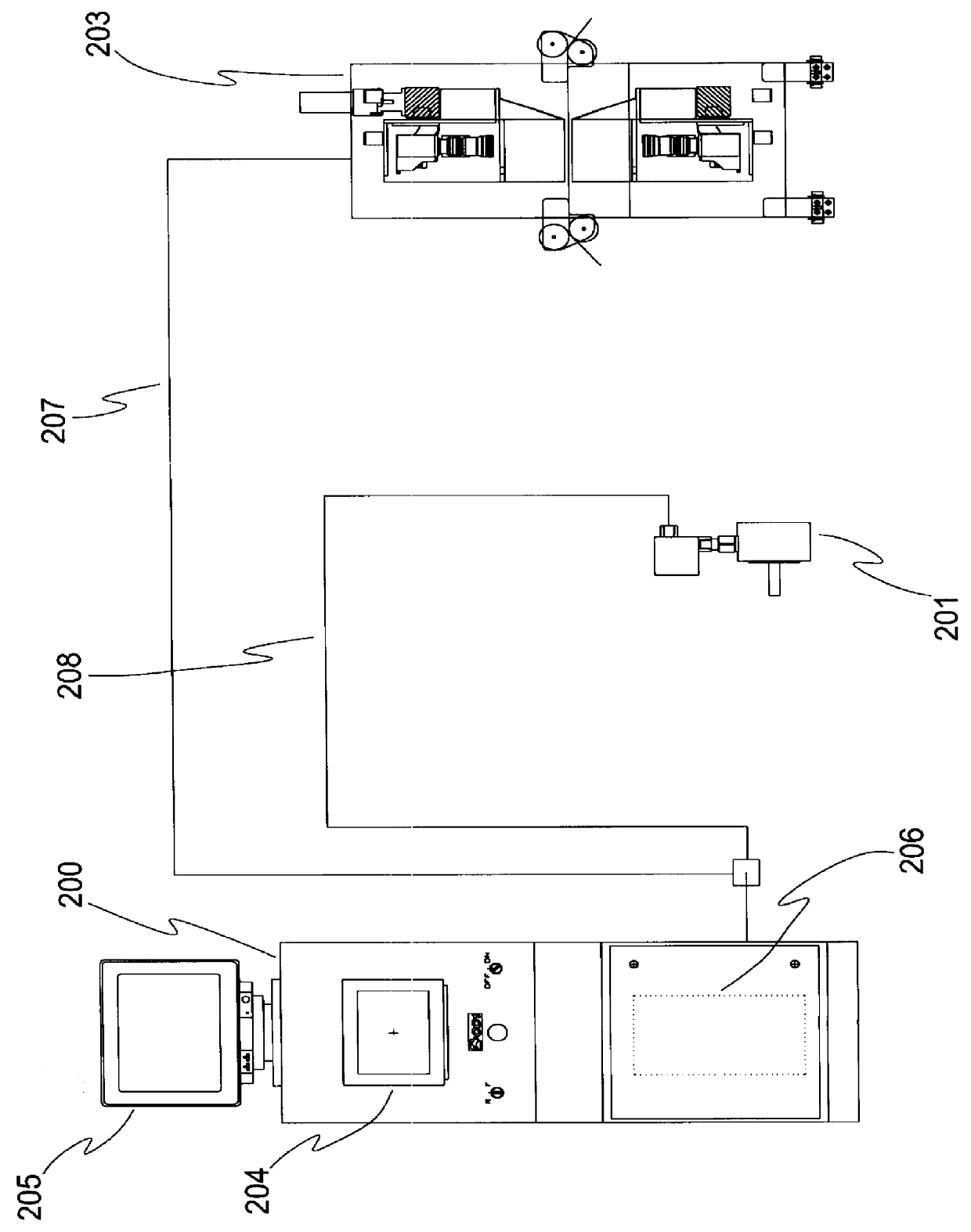

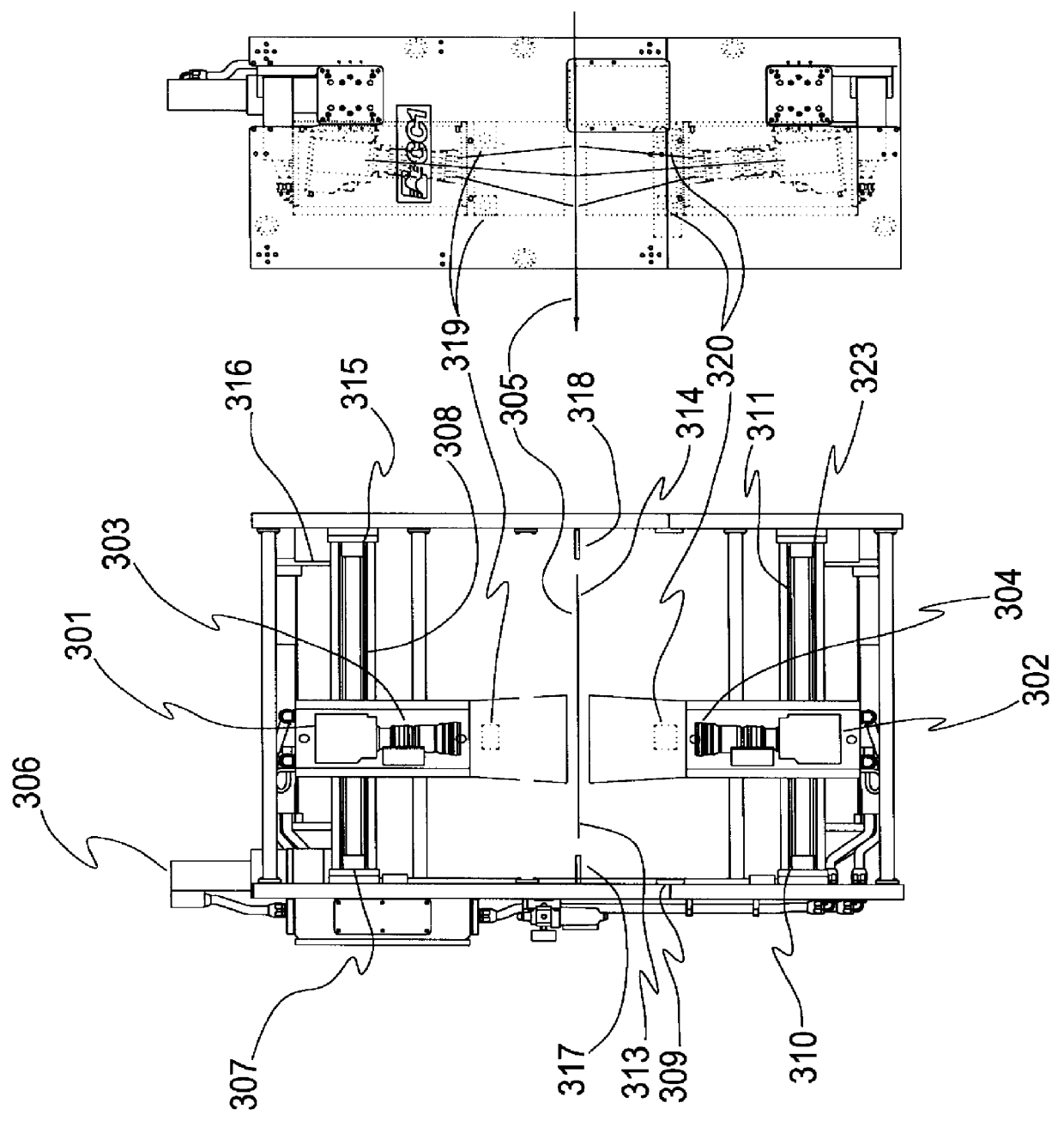

System and method for zoom lens calibration and method using same

Using marks of known dimensions and size, and spacing, a zoom lens may be calibrated in either or both the X and Y spatial directions. A system comprising an image capture device, positioning means, position encoder means, operator interface, and processing unit permits this method to be advantageously applied to a wide variety of web inspection / control functions, including but not limited to initial web registration, multiple color ink registration, lateral web positioning, repeat length calculations, image capture synchronization, thermal / mechanical differential compensation, and accurate registration of objects within an image to other objects within an image or to a mechanical reference on a machine. Since the Zoom Calibration method permits a system to be constructed with both wide / variable field of view and accurate distance measurement positioning and calibration, all of the web inspection / control functions traditionally used in the web printing industry may be implemented with a single inspection / control system using a multitasking approach with the same inspection / control hardware. This permits rapid implementation of old and new web inspection / control functions at a greatly reduced cost as compared to traditional fixed lens systems, as well as permitting a degree of automation, remote access, diagnostic control, quality assurance, and product quality control heretofore not possible with conventional web inspection / control systems.

Owner:CC1

Object-oriented, parallel language, method of programming and multi-processor computer

This invention relates to architecture and synchronization of multi-processor computing hardware. It establishes a new method of programming, process synchronization, and of computer construction, named stress-flow by the inventor, allowing benefits of both opposing legacy concepts of programming (namely of both data-flow and control flow) within one cohesive, powerful, object-oriented scheme. This invention also relates to construction of object-oriented, parallel computer languages, script and visual, together with compiler construction and method to write programs to be executed in fully parallel (or multi-processor) architectures, virtually parallel, and single-processor multitasking computer systems.

Owner:JANCZEWSKA NATALIA URSZULA +2

System and method that facilitates computer desktop use via scaling of displayed objects with shifts to the periphery

InactiveUS7536650B1Precise positioningReduce decreaseInput/output processes for data processingVisibilityObject based

The present invention relates to a system that facilitates multi-tasking in a computing environment. A focus area component defines a focus area within a display space—the focus area occupying a subset area of the display space area. A scaling component scales display objects as a function of proximity to the focus area, and a behavior modification component modifies respective behavior of the display objects as a function their location of the display space. Thus, and more particularly the subject invention provides for interaction technique(s) and user interface(s) in connection with managing display objects on a display surface. One aspect of the invention defines a central focus area where the display objects are displayed and behave as usual, and a periphery outside the focus area where the display objects are reduced in size based on their location, getting smaller as they near an edge of the display surface so that many more objects can remain visible. In addition or alternatively, the objects can fade as they move toward an edge, fading increasing as a function of distance from the focus area and / or use of the object and / or priority of the object. Objects in the periphery can also be modified to have different interaction behavior (e.g., lower refresh rate, fading, reconfigured to display sub-objects based on relevance and / or visibility, static, etc.) as they may be too small for standard rendering. The methods can provide a flexible, scalable surface when coupled with automated policies for moving objects into the periphery, in response to the introduction of new objects or the resizing of pre-existing objects by a user or autonomous process.

Owner:MICROSOFT TECH LICENSING LLC

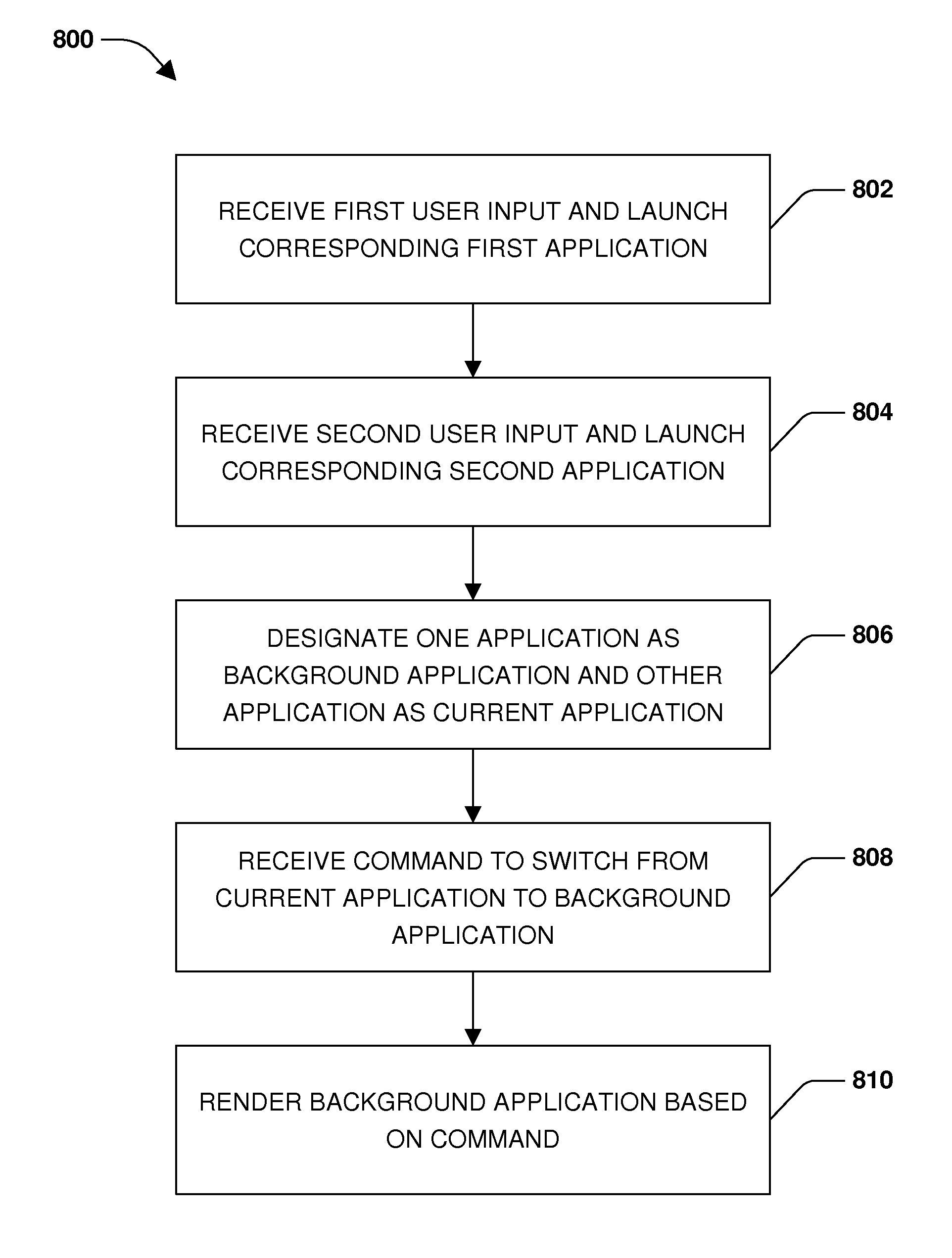

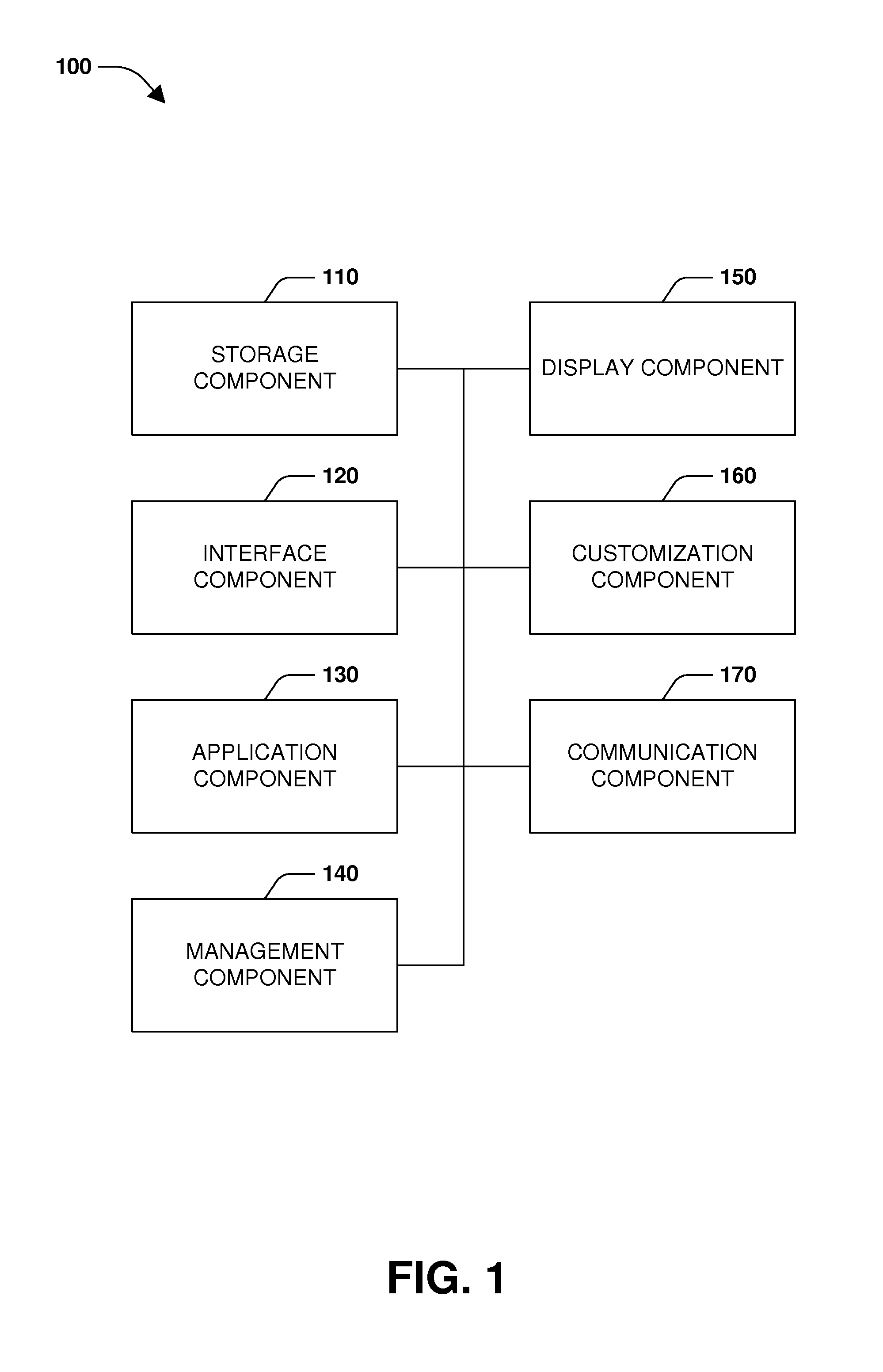

Application management

ActiveUS20160062635A1Quick switchProgramme controlStatic indicating devicesApplication lifecycle managementHome screen

One or more embodiments of techniques or systems for application management are provided herein. For example, a system for application management may launch or execute multiple applications, such as a first application and a second application. The system for application management may provide a user with different ways of multi-tasking or ways to switch between applications, such as providing or generating home screen shortcuts for a most recently utilized application or a most frequently launched application. Additionally, the system for application management may enable multi-tasking or swapping of applications when a user double taps a home button, initiates a swipe gesture, hits a task swap button, speaks a voice command, etc. In this manner, application management is provided such that a user may engage in the use of multiple applications or switching between in a quick or efficient manner.

Owner:HONDA MOTOR CO LTD

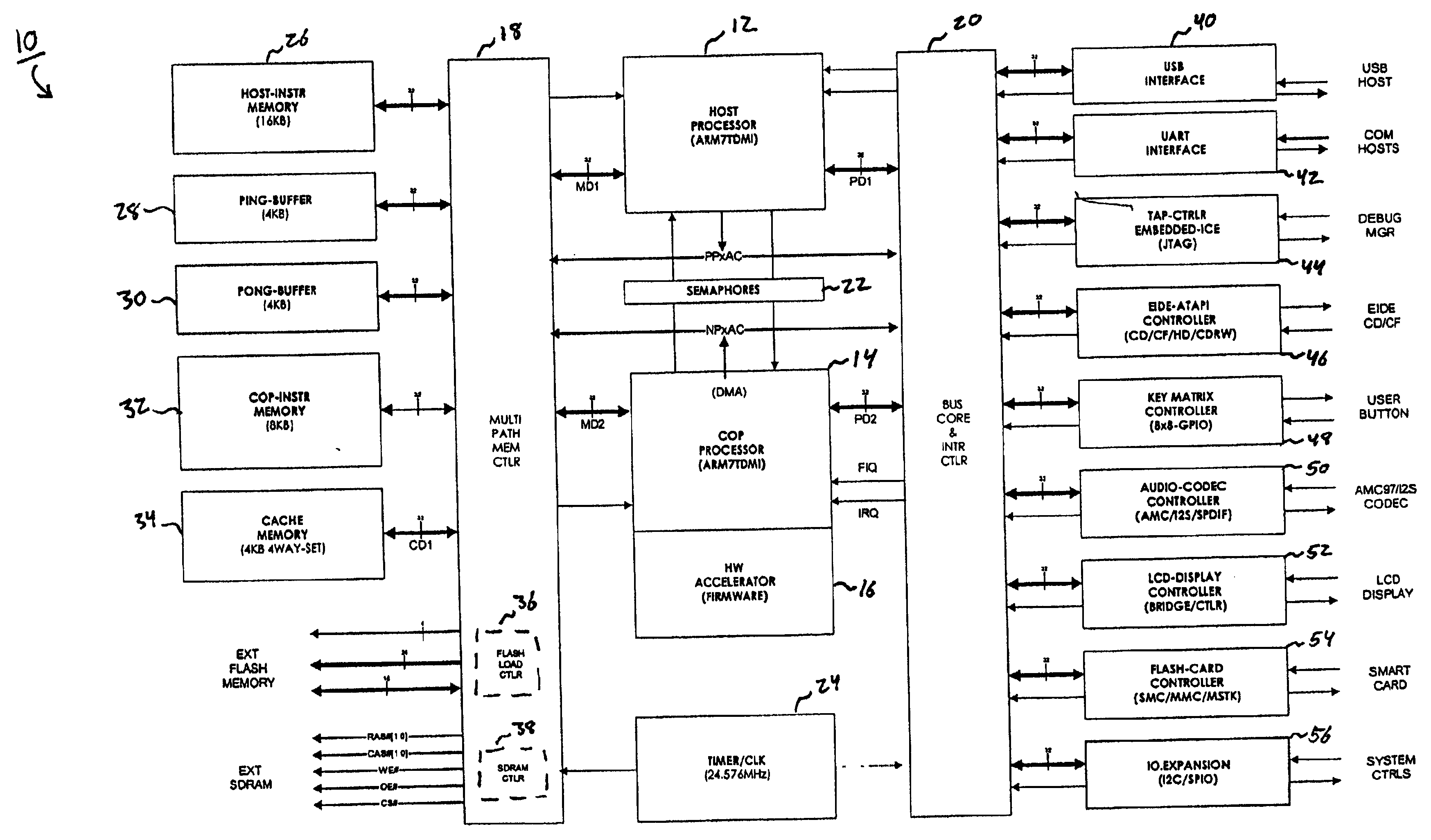

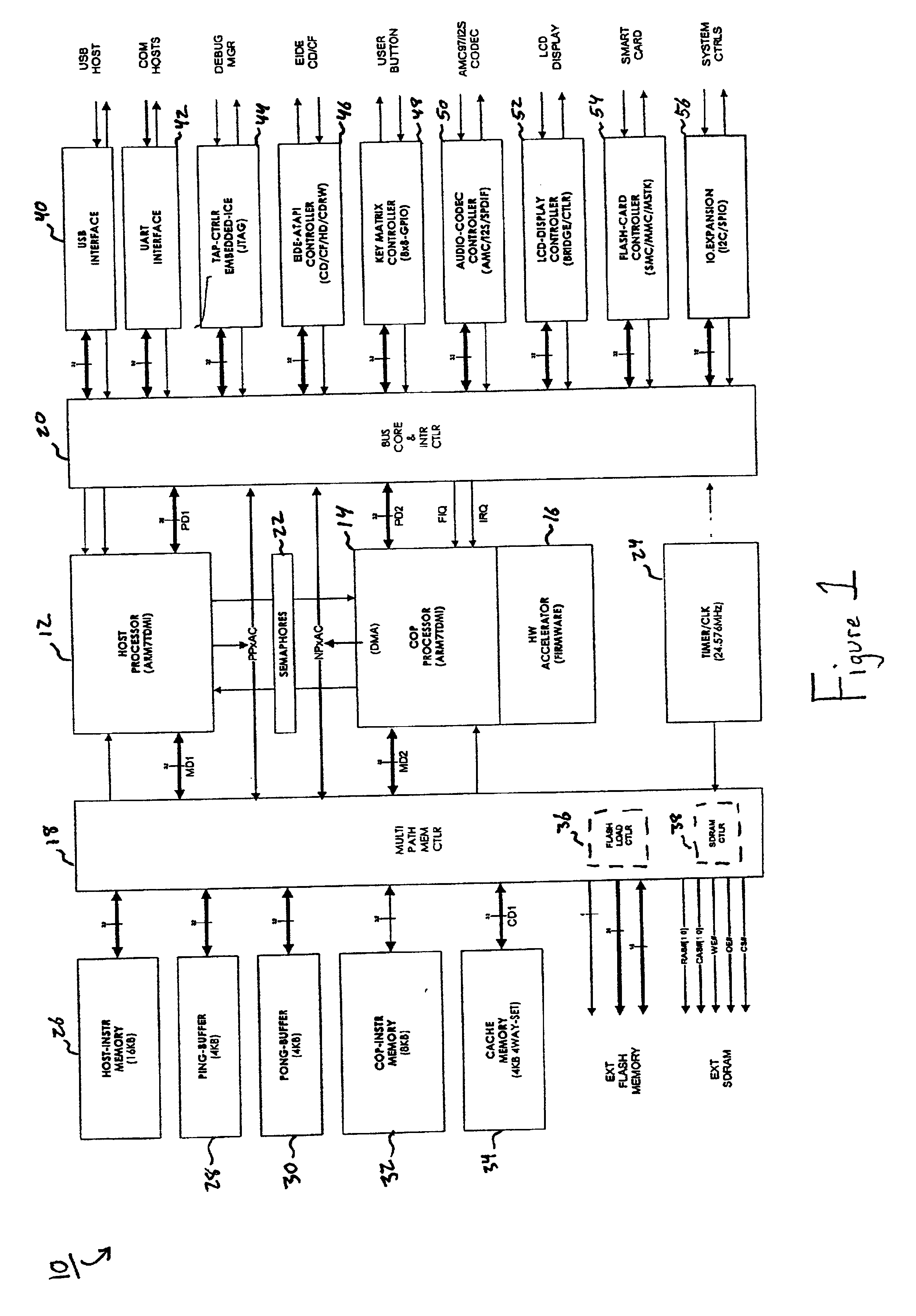

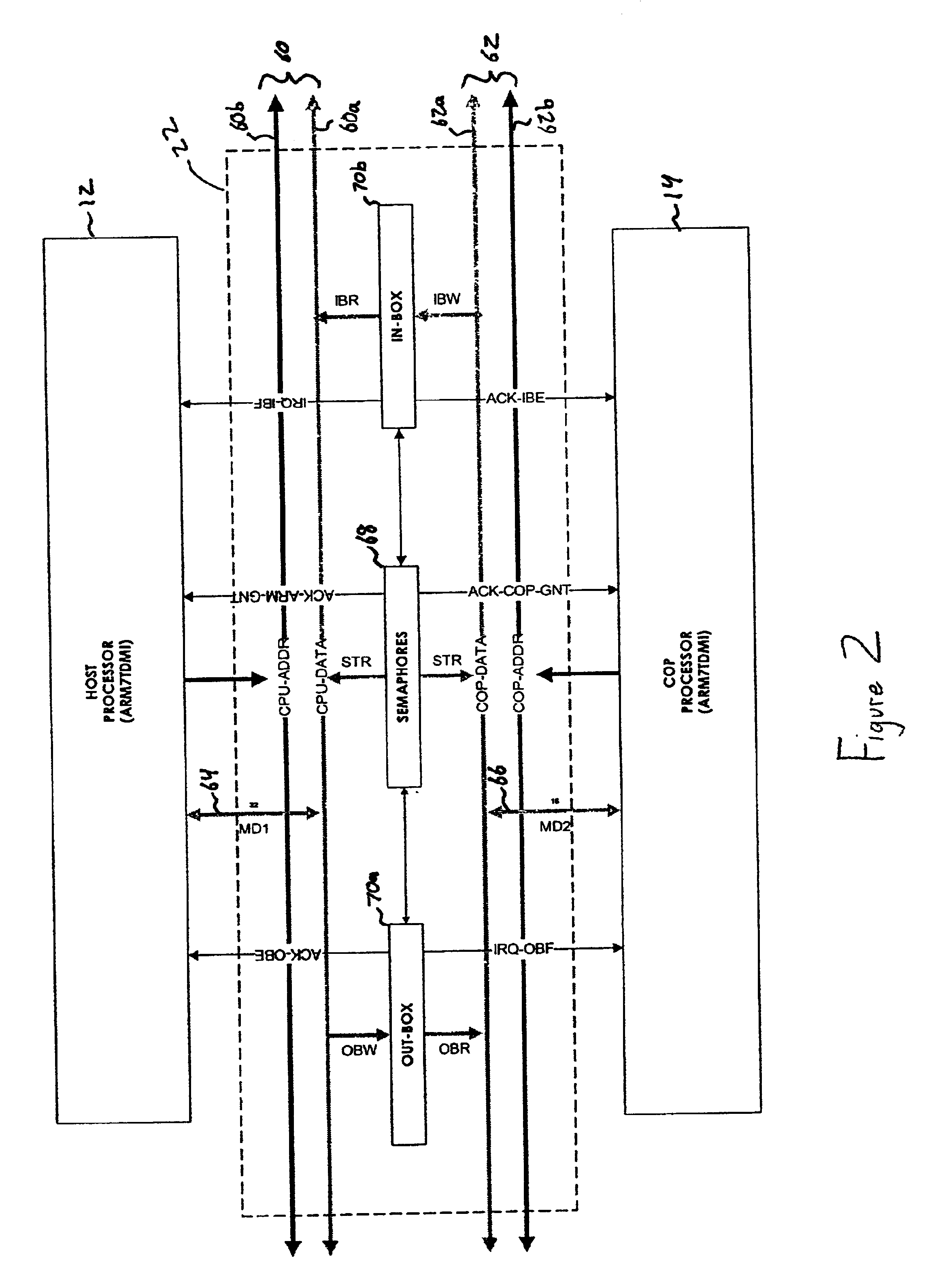

Multiprocessor communication system and method

ActiveUS6938253B2Facilitate inter-processor communicationFacilitating inter-processor communicationProgram synchronisationInterprogram communicationCommunications systemNonpreemptive multitasking

To facilitate inter-processor communication between multiple processors in a computer system and to enable the accessing of a dual port memory, or other system resources, without requiring the memory or the data / address bus to be locked, the present invention provides a semaphore unit that preferably incorporates a shared mailbox architecture that, in combination with a set of hardware semaphore registers, enables inter-process communication among the multi-processors. Cooperative multitasking may be accomplished through the use of shared mailbox communication protocols while a preemptive multitasking may be accomplished through the use of hardware semaphore registers.

Owner:NVIDIA CORP

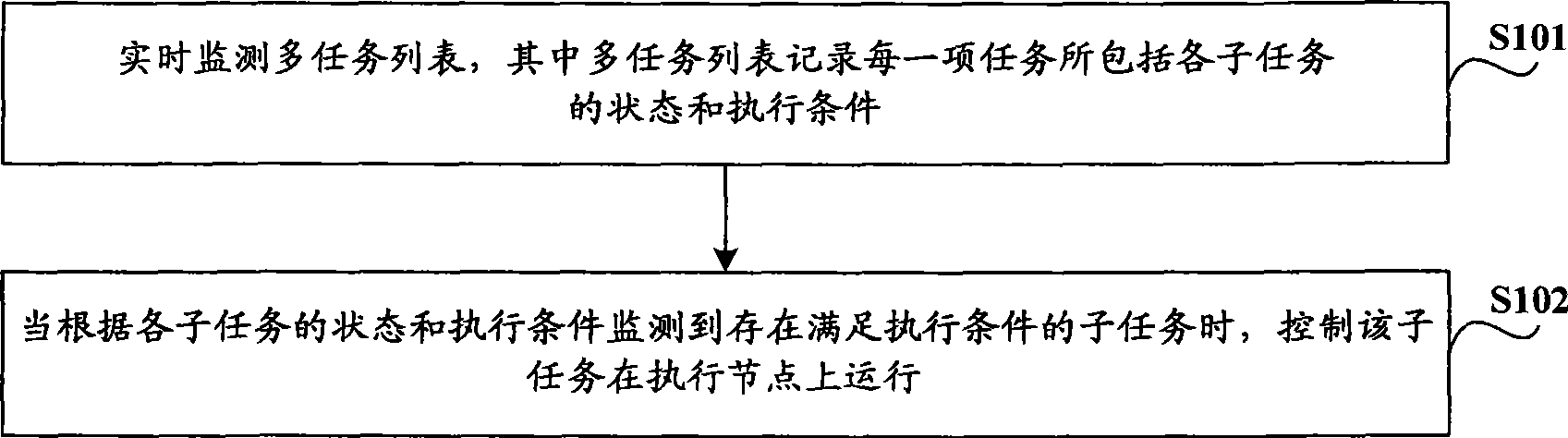

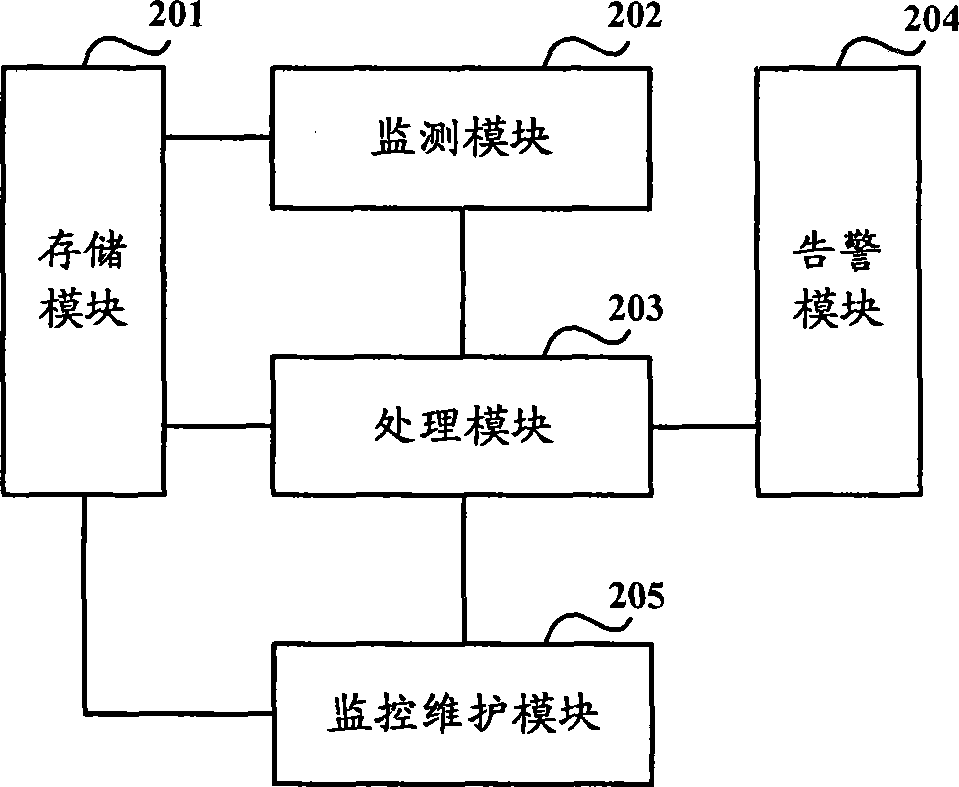

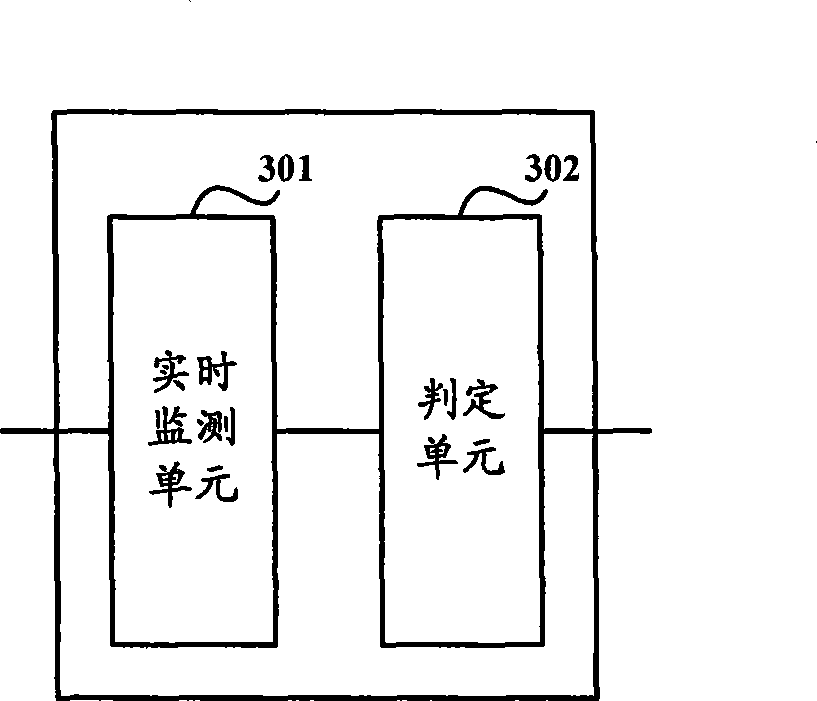

Multitasking method and device

InactiveCN101425024ATo achieve coordinated schedulingMultiprogramming arrangementsTask listComputer multitasking

Owner:CHINA MOBILE GROUP SHANDONG

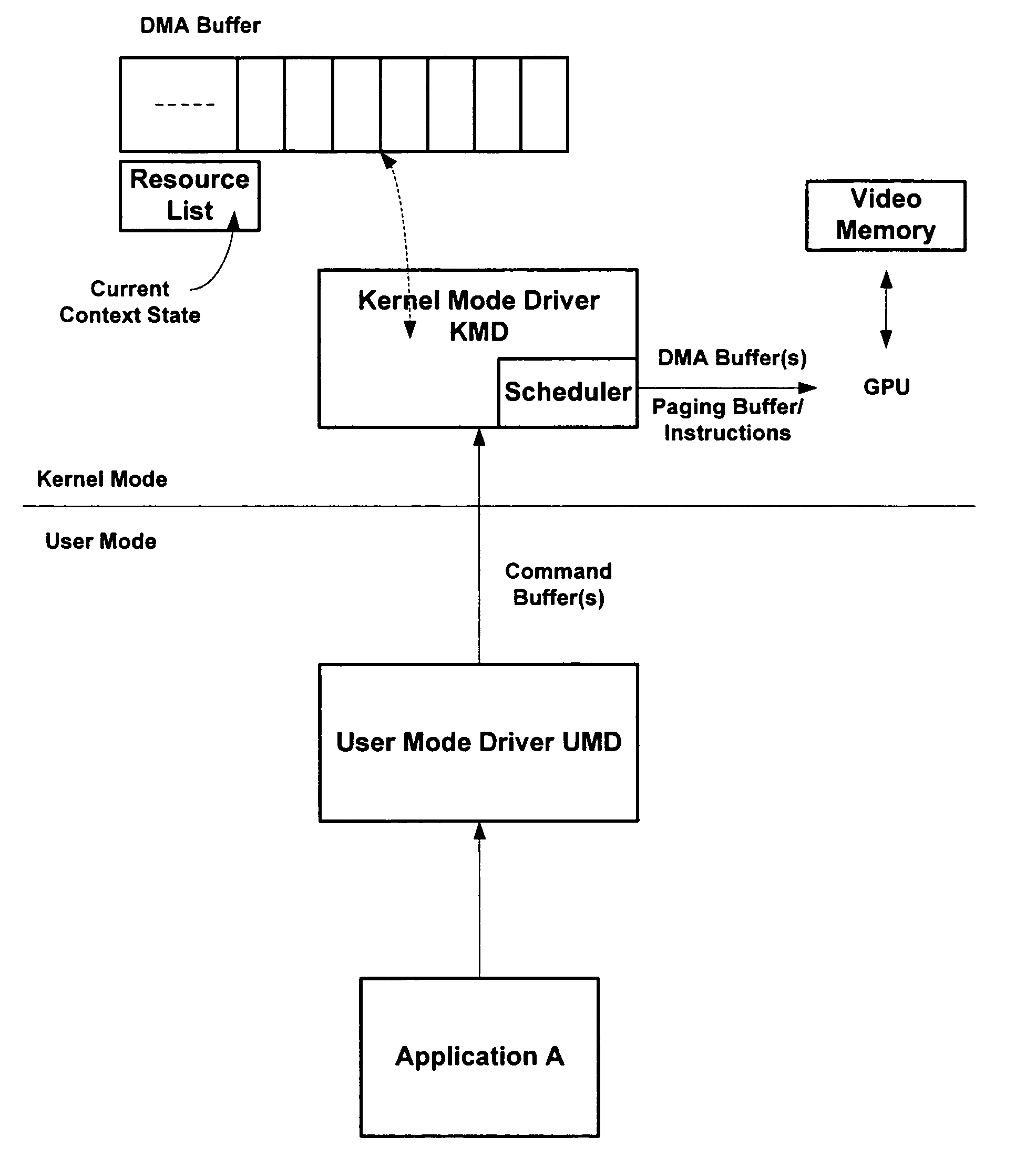

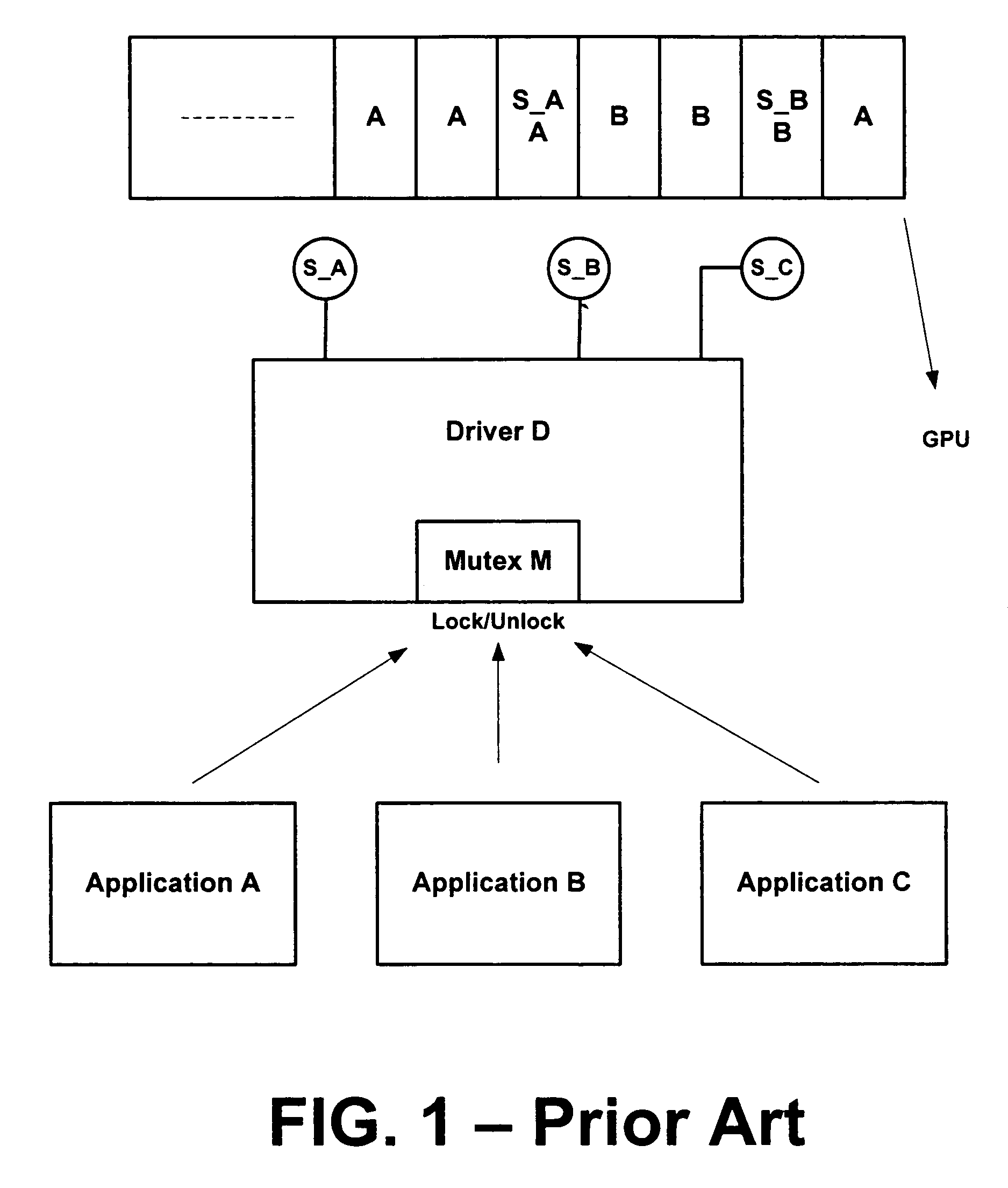

Systems and methods for scheduling coprocessor resources in a computing system

ActiveUS7444637B2Reduce the amount of memoryProgram initiation/switchingGeneral purpose stored program computerCoprocessorNonpreemptive multitasking

Systems and methods for scheduling coprocessing resources in a computing system are provided without redesigning the coprocessor. In various embodiments, a system of preemptive multitasking is provided achieving benefits over cooperative multitasking by any one or more of (1) executing rendering commands sent to the coprocessor in a different order than they were submitted by applications; (2) preempting the coprocessor during scheduling of non-interruptible hardware; (3) allowing user mode drivers to build work items using command buffers in a way that does not compromise security; (4) preparing DMA buffers for execution while the coprocessor is busy executing a previously prepared DMA buffer; (5) resuming interrupted DMA buffers; and (6) reducing the amount of memory needed to run translated DMA buffers.

Owner:MICROSOFT TECH LICENSING LLC

Computer desktop use via scaling of displayed objects with shifts to the periphery

ActiveUS8225224B1Precise positioningReduce decreaseExecution for user interfacesInput/output processes for data processingHuman–computer interactionBehavior modification

The present invention relates to facilitating multi-tasking in a computing environment. A focus area component defines a focus area within a display space—the focus area occupying a subset area of the display space area. A sealing component scales display objects as a function of proximity to the focus area, and a behavior modification component modifies respective behavior of the display objects as a function of their location of the display space. The subject invention provides for interaction technique(s) and other interface(s) in connection with managing display objects on a display surface. One aspect defines a central focus area, such that the display objects are displayed and behave as usual. Also included as a periphery outside the focus area where the display objects are reduced in size based on their location, getting smaller as the display objects near an edge of the display surface with many more objects visible.

Owner:MICROSOFT TECH LICENSING LLC

Multi-task processing method and multi-task processing device

InactiveCN104731649AReduce processing failure rateImprove experienceMultiprogramming arrangementsFailure rateComputer multitasking

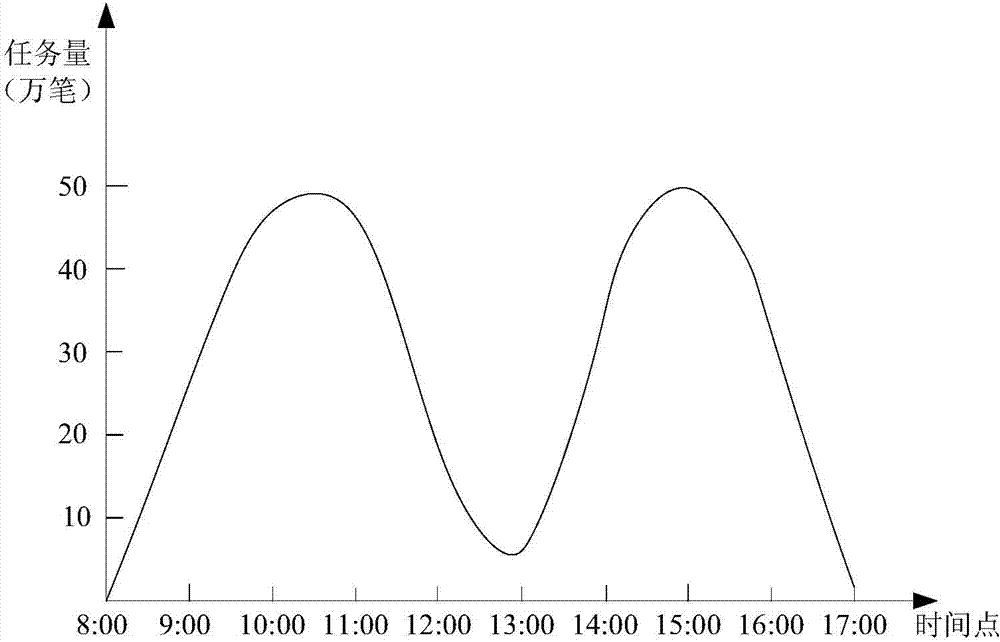

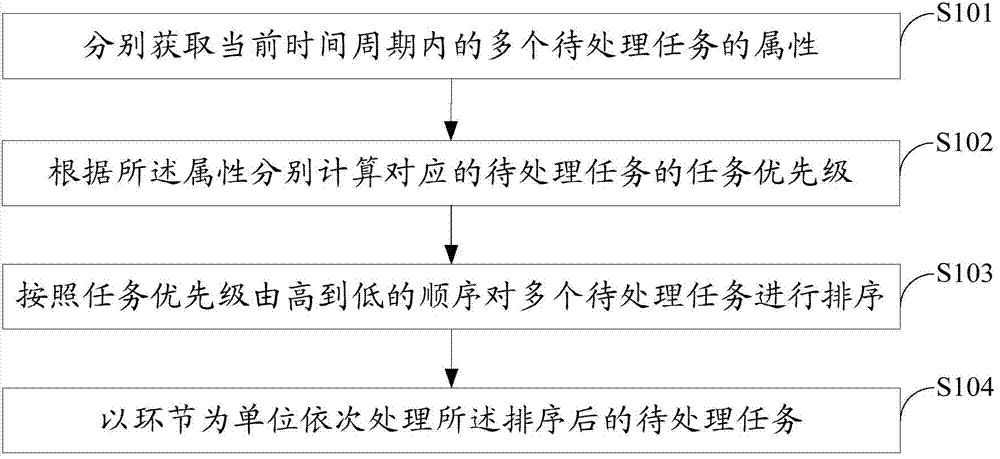

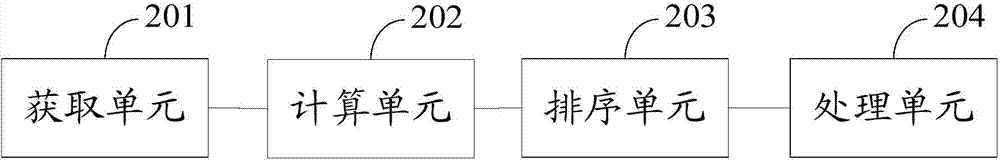

An embodiment of the invention discloses a multi-task processing method. The multi-task processing method includes: acquiring attributes of multiple to-be-processed tasks within a current time period respectively, wherein the attributes include urgency degree and / or importance degree of the to-be-processed tasks; according to the attributes, computing task priorities for the corresponding to-be-processed tasks; ranking the to-be-processed tasks according to a sequence from high task priority to low task priority; processing the ranked to-be-processed tasks in segments sequentially. The embodiment of the invention further discloses a multi-task processing device. The multi-task processing method and the multi-task processing device have the advantages that the to-be-processed tasks higher in the urgency degree and / or the importance degree are processed before the to-be-processed tasks lower in the urgency degree and / or the importance degree, and the purposes of decreasing task processing failure rate, reducing financial loss, improving user experience and the like are achieved.

Owner:CHINA CONSTRUCTION BANK

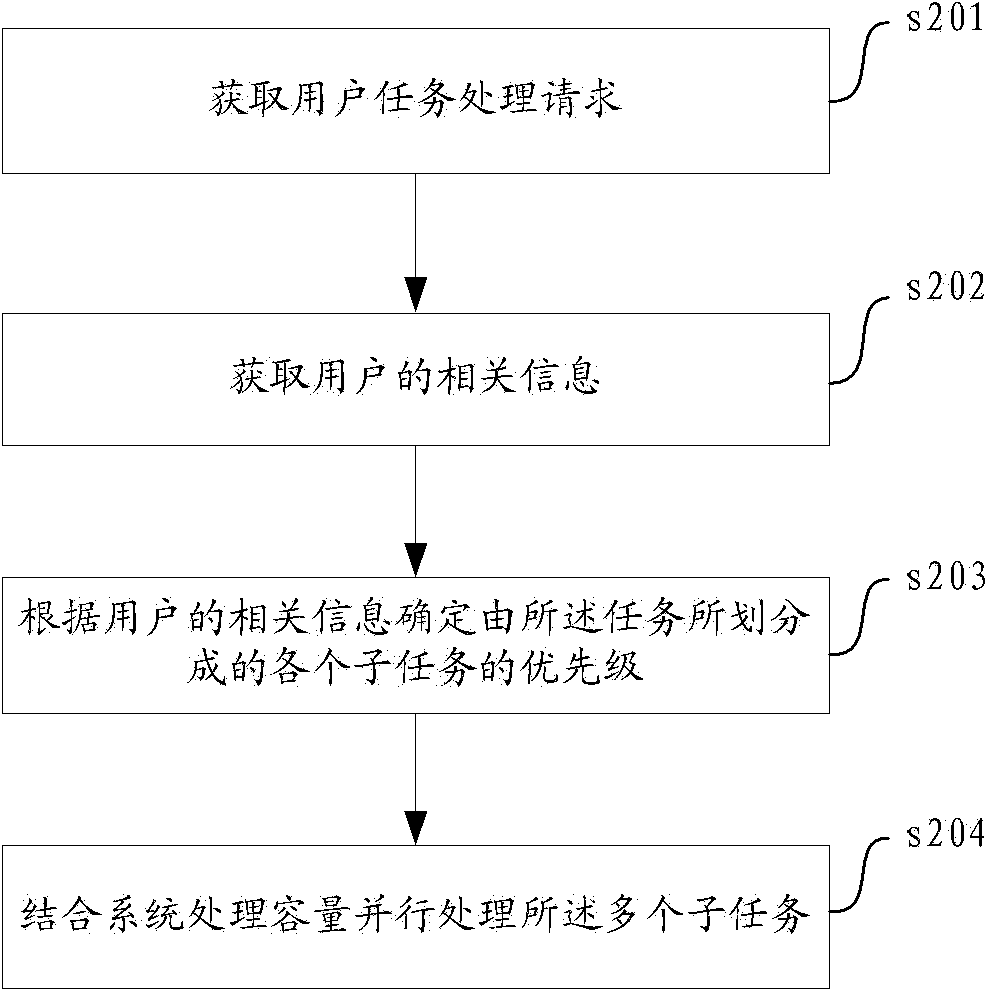

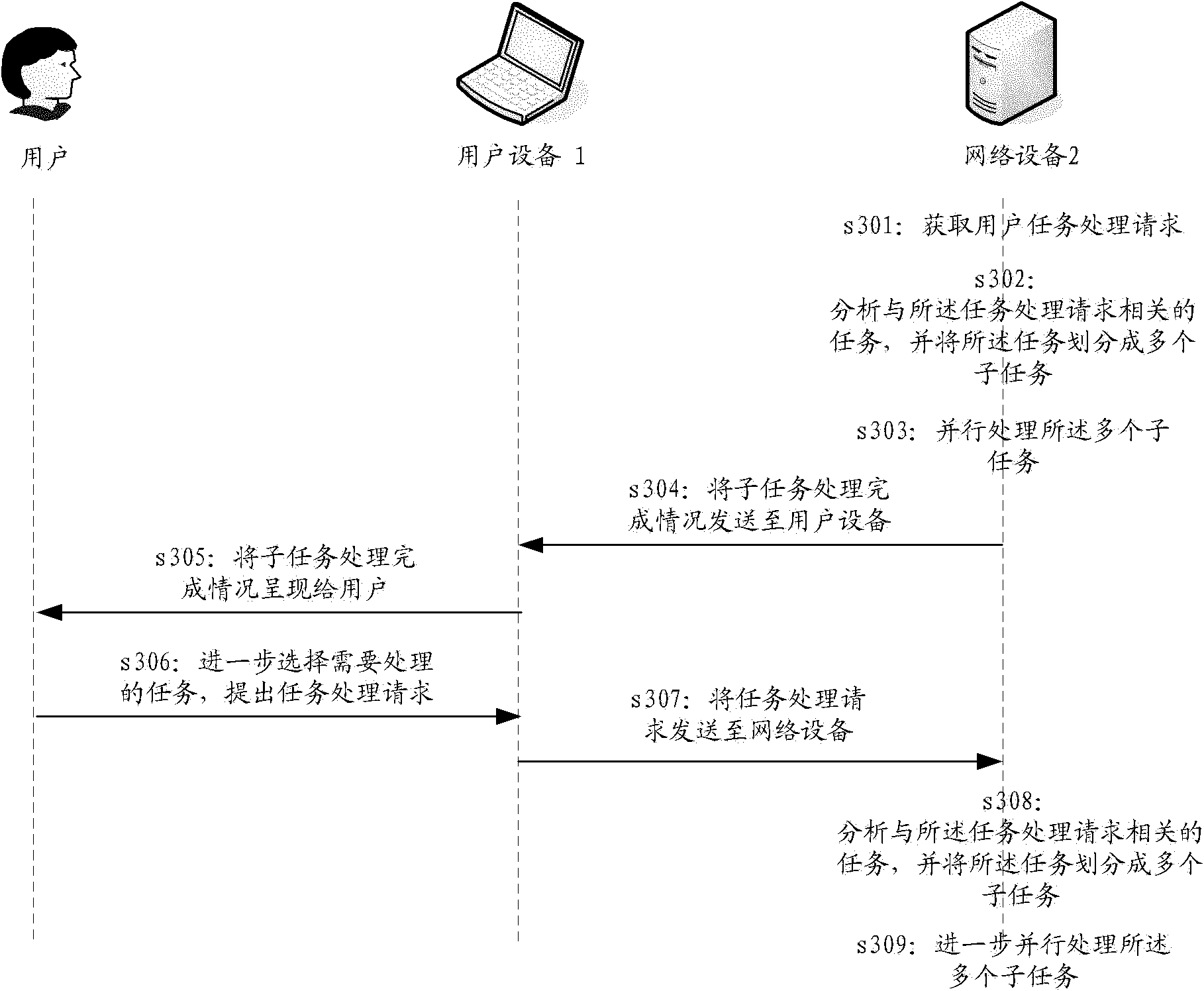

Method and equipment for performing multi-task processing in network equipment

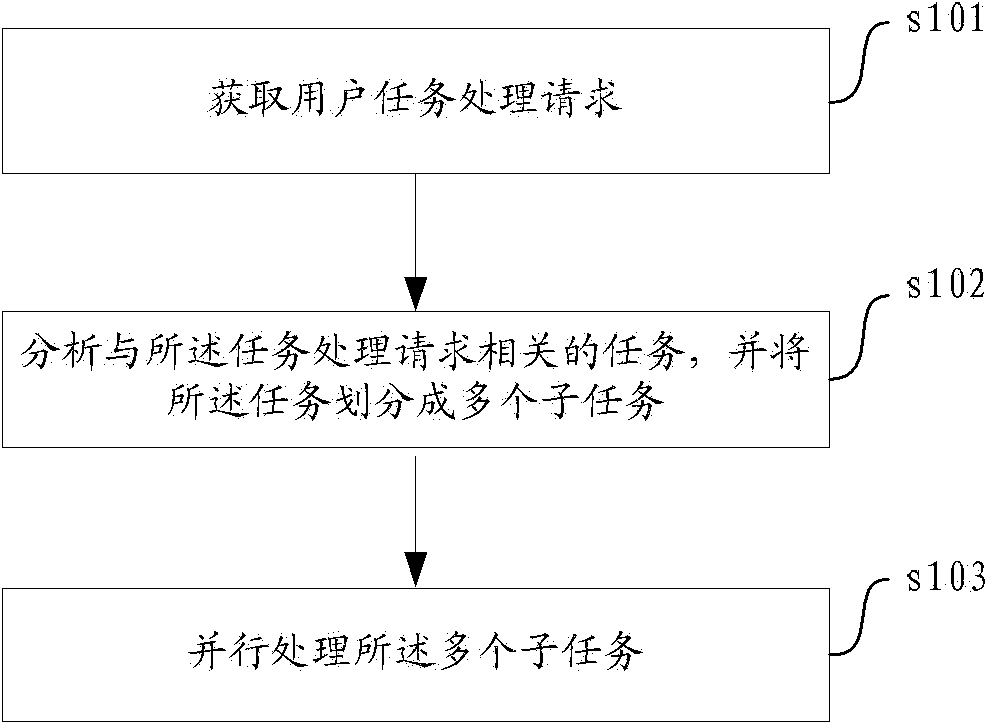

The invention provides a method and equipment for performing multi-task processing in network equipment. The method comprises the following steps of: by acquiring task processing requests from one or more users, analyzing one or more tasks which are associated with the task processing requests; dividing each dividable task into a plurality of sub-tasks; and concurrently processing the plurality of sub-tasks. The invention has the advantages that: 1) optimization items can be concurrently diagnosed and optimized; 2) diagnosis information is provided for a user in real time, if a progress bar is provided before analysis is completed, the user can know the completion progress of diagnosis, and a time stamp is added behind a problem which occurs after analysis of each item is completed, and used for informing a customer of occurrence time of the problem; and 3) according to the severity of the problem in an account and the behavior pattern of the customer, the tasks are subjected to priority sorting so as to deal with simultaneous requesting by a plurality of customers.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

System and method that facilitates computer desktop use via scaling of displayed objects with shifts to the periphery

ActiveUS8230359B2Easy to managePromote exchangeDigital computer detailsDigital output to display deviceBehavior modificationHuman–computer interaction

The system described herein facilitates multi-tasking in a computing environment. A focus area component defines a focus area within a display space—the focus area occupying a subset area of the display space area. A scaling component scales display objects as a function of proximity to the focus area, and a behavior modification component modifies respective behavior of the display objects as a function their location of the display space. Thus, and more particularly the subject invention provides for interaction technique(s) and user interface(s) in connection with managing display objects on a display surface.

Owner:MICROSOFT TECH LICENSING LLC

Method and device for processing multiple foreground tasks on screen

ActiveCN102841804ASolve the problem of fair distributionFix simultaneous display issuesResource allocationExecution for user interfacesTyping ClassificationSoftware engineering

The invention discloses a method for processing multiple foreground tasks on a screen. The method comprises the following steps that: a plurality of application windows are operated on the same display screen through a multitasking mechanism; user events are received; the received user events are subjected to type classification; and a task management module is used to allocate the received user events with marks to different tasks to be processed, and the corresponding results are returned to the corresponding application windows. The method and device for processing multiple foreground tasks on the screen provided by the invention are used for realizing that the user events among a plurality of foreground tasks on the same screen are reasonably allocated and the task windows are displayed at the same time, and thus the plurality of foreground tasks can be operated on the same screen at the same time.

Owner:BEIJING SAMSUNG TELECOM R&D CENT +1

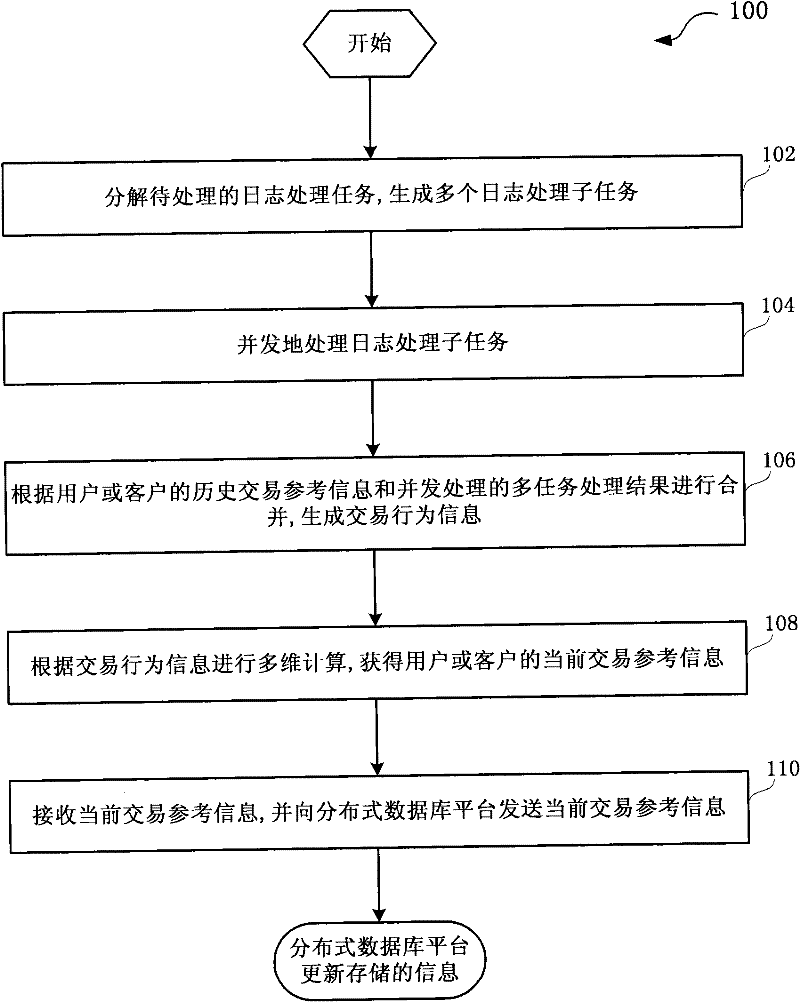

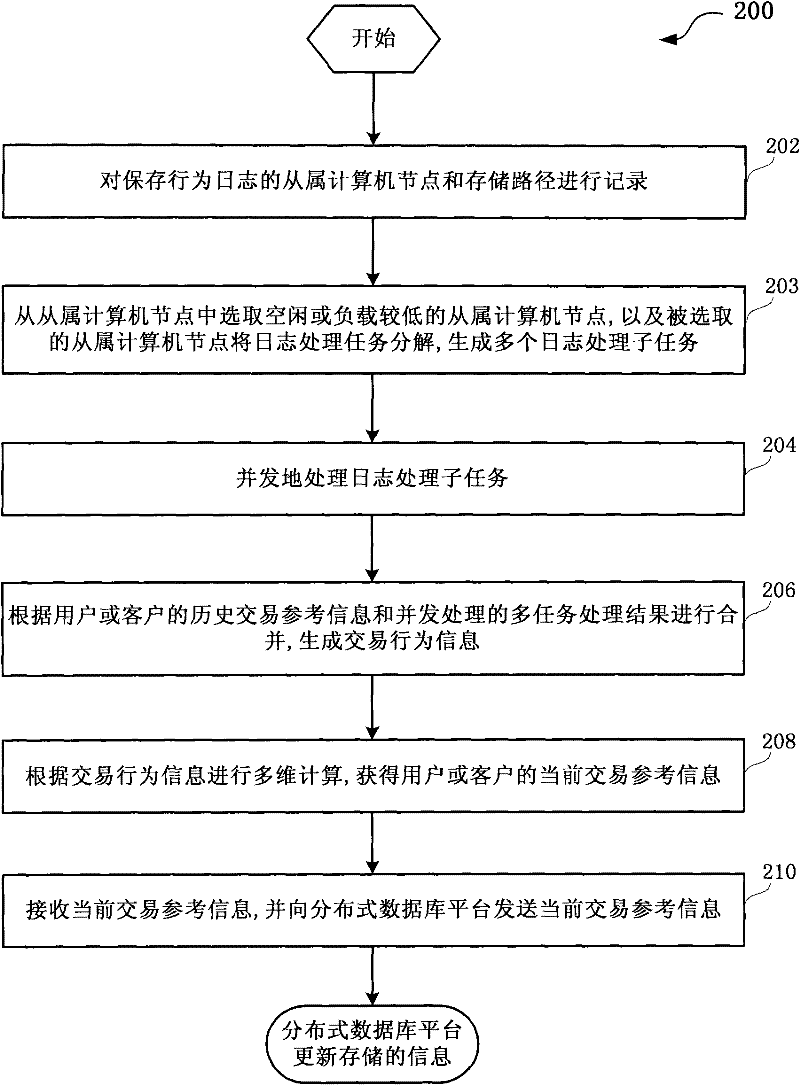

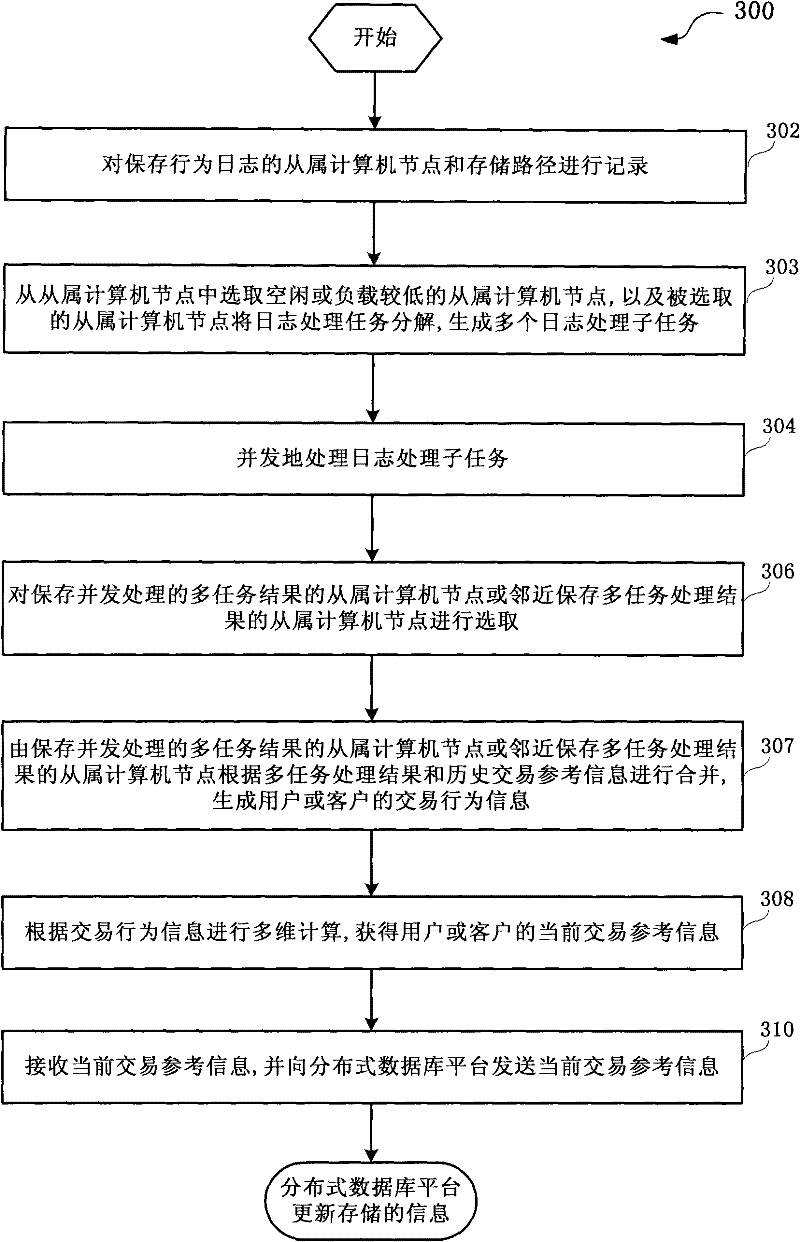

Real-time computation method and system of multi-dimensional credit system based on user empowerment

ActiveCN102236851AStrong scalabilityAddressing Mass SurgesCommerceSpecial data processing applicationsCredit systemMulti dimensional

This invention discloses a real-time computation method and system of a multi-dimensional credit system based on user empowerment. The method comprises the steps of: decomposing a to-be-processed log processing task to generate a plurality of log processing sub-tasks; concurrently processing the log processing sub-tasks, merging according to historical transaction reference information of a user or a client and a multi-task processing result obtained by concurrent processing to generate transaction behavior information; according to the transaction behavior information, performing multi-dimensional computation to obtain the current transaction reference information of the user or the client; and receiving and sending the current transaction reference information to a distributed database platform. The method of the invention solves the technical problem of unavailable real-time transaction reference information caused by massive and sharp increase of transaction platform log data and mining of multi-dimensional information at present, thus being favorable for providing users with more accurate and credible transaction reference information.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

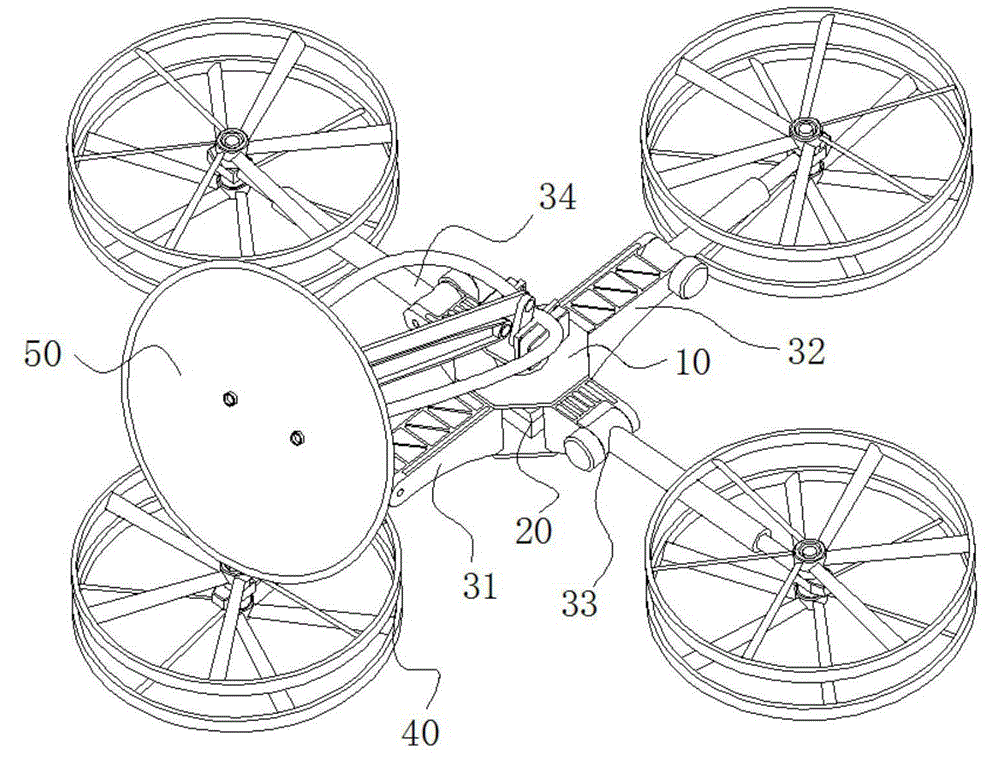

Deformable multi-mode ground and air flying robot

ActiveCN105034729ALose weightReduce power consumptionAircraft convertible vehiclesElectric machineryEngineering

A deformable multi-mode ground and air flying robot comprises a body, an automatic pilot, wing arm devices, hub devices and a suction device. The body is provided with the four sets of wing arm devices in a cross shape. The wing arm devices comprise large wing arms, small wing arms, rotation joints, installation supports, motors and damping sleeves. The hub devices are installed on the four sets of wing arm devices respectively and are driven to run through motors. The suction device is installed on the upper portion of the body and used for being sucked to the surface of an object with the assigned angle. The automatic pilot is installed on the body and drives the hub devices and the suction device to run. The automatic pilot drives the rotation joints of the wing arm devices to rotate so that the small wing arms can drive the hub devices to rotate to the assigned angle, and thus switching of a flying mode and a ground walking mode is achieved. The deformable multi-mode ground and air flying robot has the advantages of being low in power consumption, high in environment adaptability and multi-task handling capability, good in structural stability and high in mobility, and is suitable for multi-mode operation and capable of meeting various task requirements under various complex severe environments.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Data processing system and method for high-efficiency multitasking

InactiveUS7089557B2Shorten the lengthReduce frequencyProgram initiation/switchingSpecific program execution arrangementsData processing systemComputer multitasking

A method and data processing system are presented for multitasking a plurality of simultaneous tasks over one or more data processors. The invention significantly reduces the overhead required for multitasking without sacrificing responsiveness or flexibility. Both the number and length of context switches are reduced. The resulting environment is also capable of providing real-time operation and memory protection to tasks. No modifications to the tasks are required to make use of the invention.

Owner:XENOGENIC DEV LLC

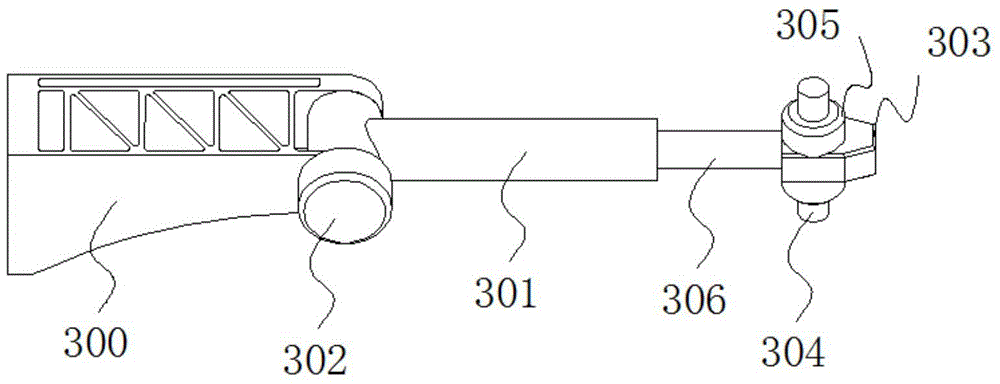

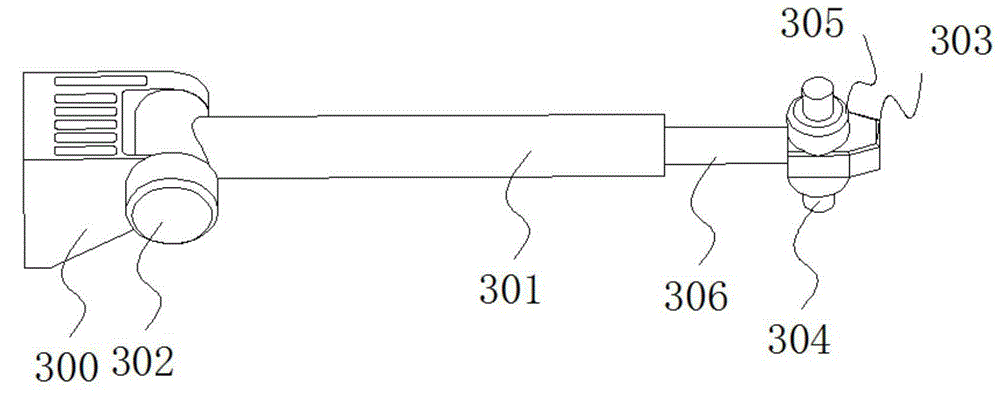

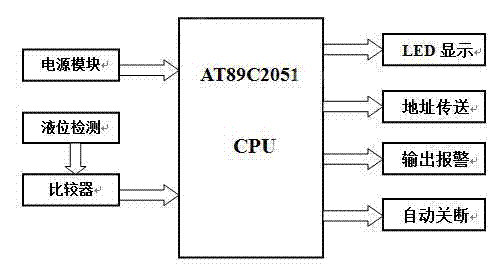

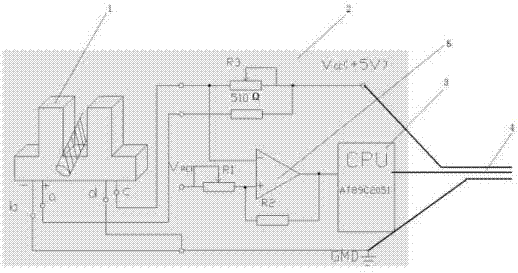

Infusion alarm device

The invention is an infusion alarm system centered on liquid level detection and a single-chip microcomputer, including a power supply module, a photoelectric sensor, a comparator, a single-chip microcomputer, an LED lamp, a sound alarm device and an executive mechanism. Among them, the liquid in the infusion tube is detected by a photoelectric sensor (photoelectric interrupter), and the infusion alarm system is controlled by a single-chip microcomputer. The device uses a photoelectric sensor to detect whether there is liquid in the infusion tube sensitively, quickly and accurately, and reduces the workload of escorts during infusion. Combined with the multi-task processing capability of the single-chip microcomputer, it can complete sound and light alarm, position display, address transmission and automatic clamping Infusion tube and other functions. The entire control system not only has low cost, less external interference, and sensitive liquid level detection, but also has the advantages of small size, easy installation and operation, and no need to remove drugs. It can be used in small-scale decentralized or large-scale centralized use in hospitals and other places where intravenous infusion is common.

Owner:SHANGHAI DIANJI UNIV

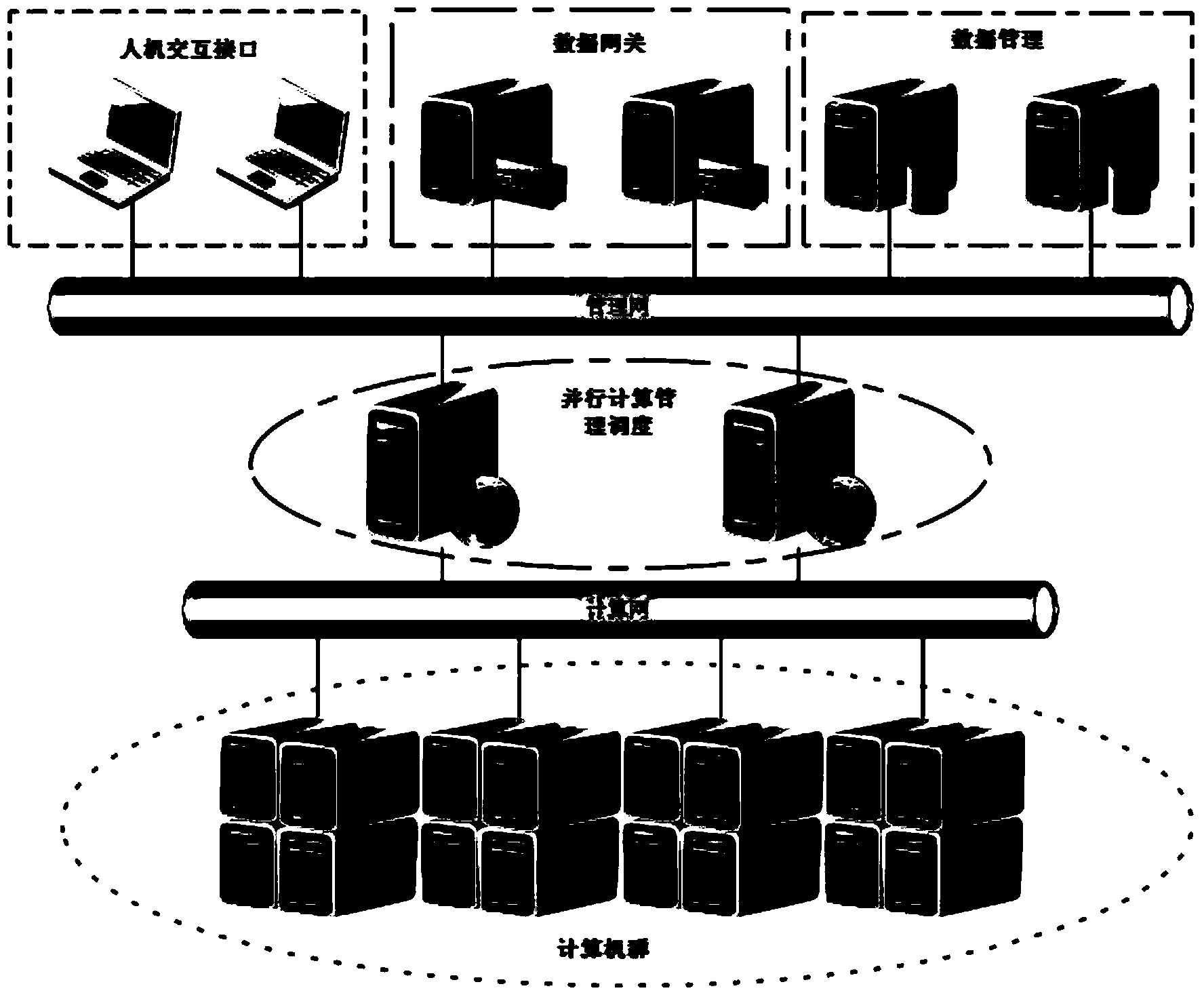

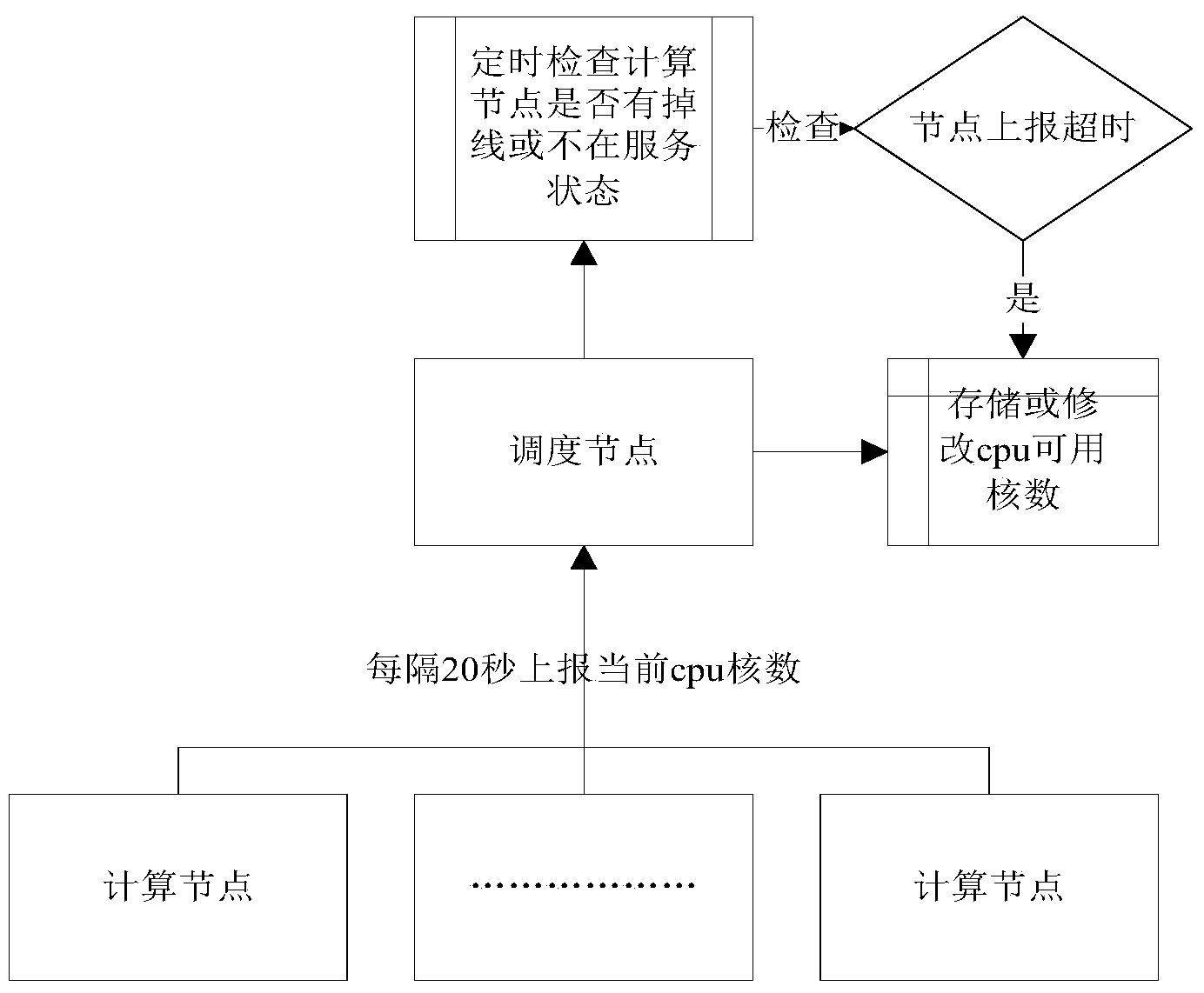

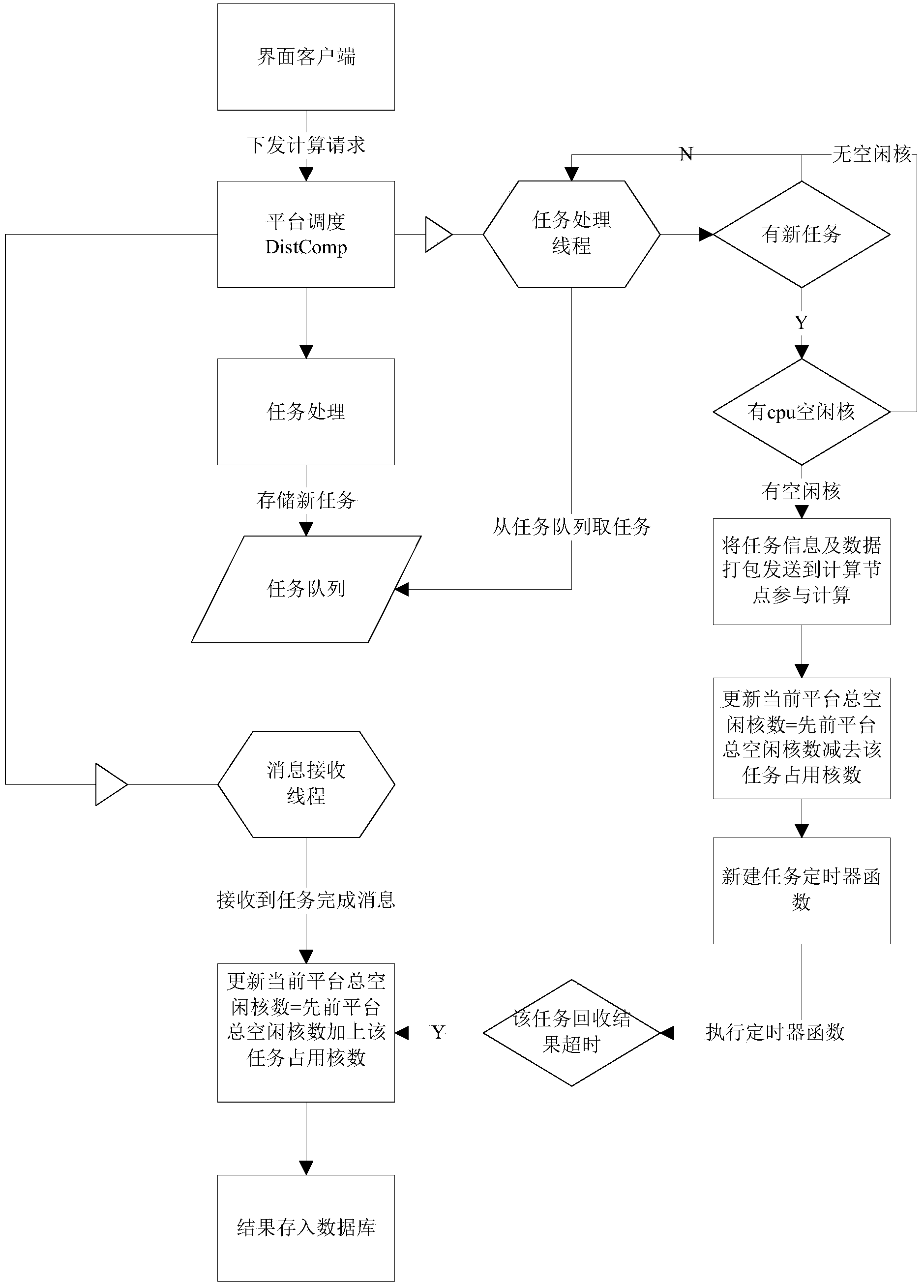

Distributive parallel computing platform and method based on CPU (central processing unit) core management

InactiveCN103870338ATake advantage ofImprove computing efficiencyResource allocationConcurrent instruction executionComputer resourcesThird party

The invention discloses a distributive parallel computing platform based on CPU (central processing unit) core management. The distributive parallel computing platform comprises a data node server, a dispatching node server and a computing node server, wherein the data node server comprises at least one computer with CPU multi-core capability, and is used for storing historical results and database service nodes, the dispatching node server comprises at least one computer with CPU multi-core capability, and is used for computing task dispatching and management, the computing node service comprises at least one computer with CPU multi-core capability and is used for processing data submitted by users and invoking third-party computing program to participate in the computing, and the third-party core computing program is deployed on the computing node. The distributive parallel computing platform based on CPU core management has the beneficial effects that the CPU multi-core technology is sufficiently utilized, the computing efficiency is greatly improved on the multi-task processing, computer resources are sufficiently utilized, a multi-core processing unit has better performance and efficiency advantages that a single-core processor, and the multi-core processing unit can become a widely adopted computing model.

Owner:STATE GRID CORP OF CHINA +2

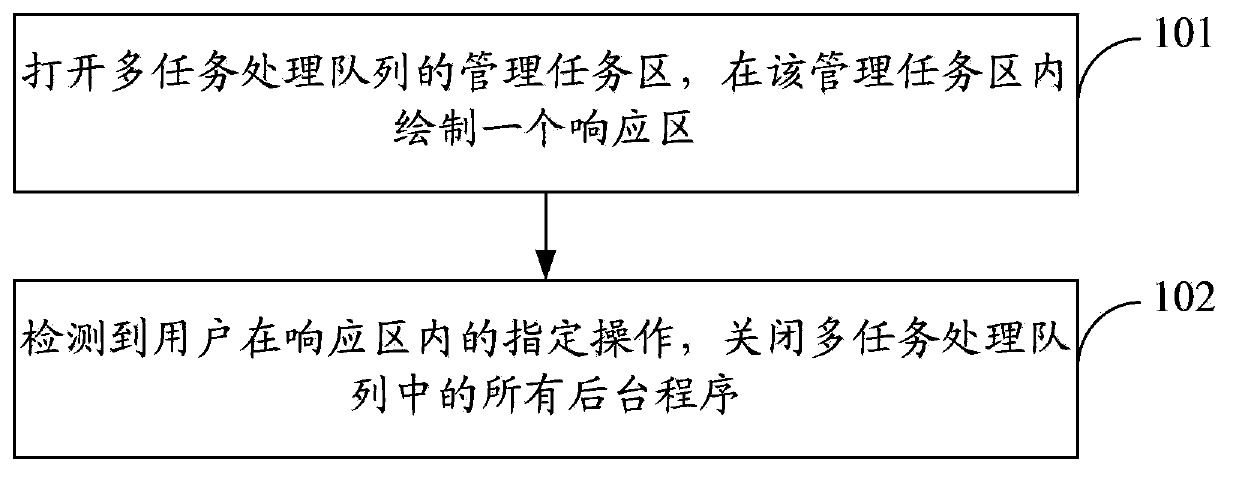

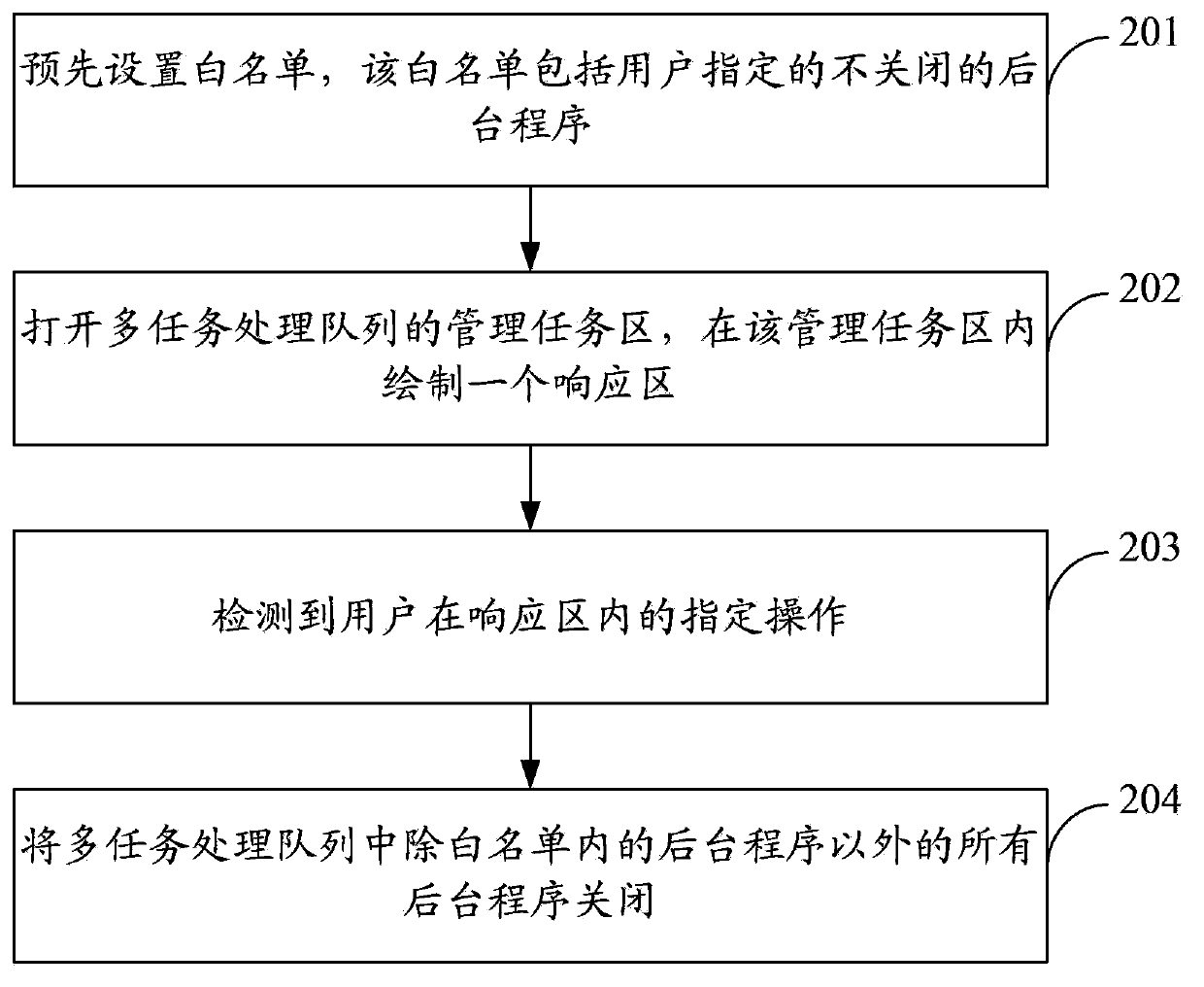

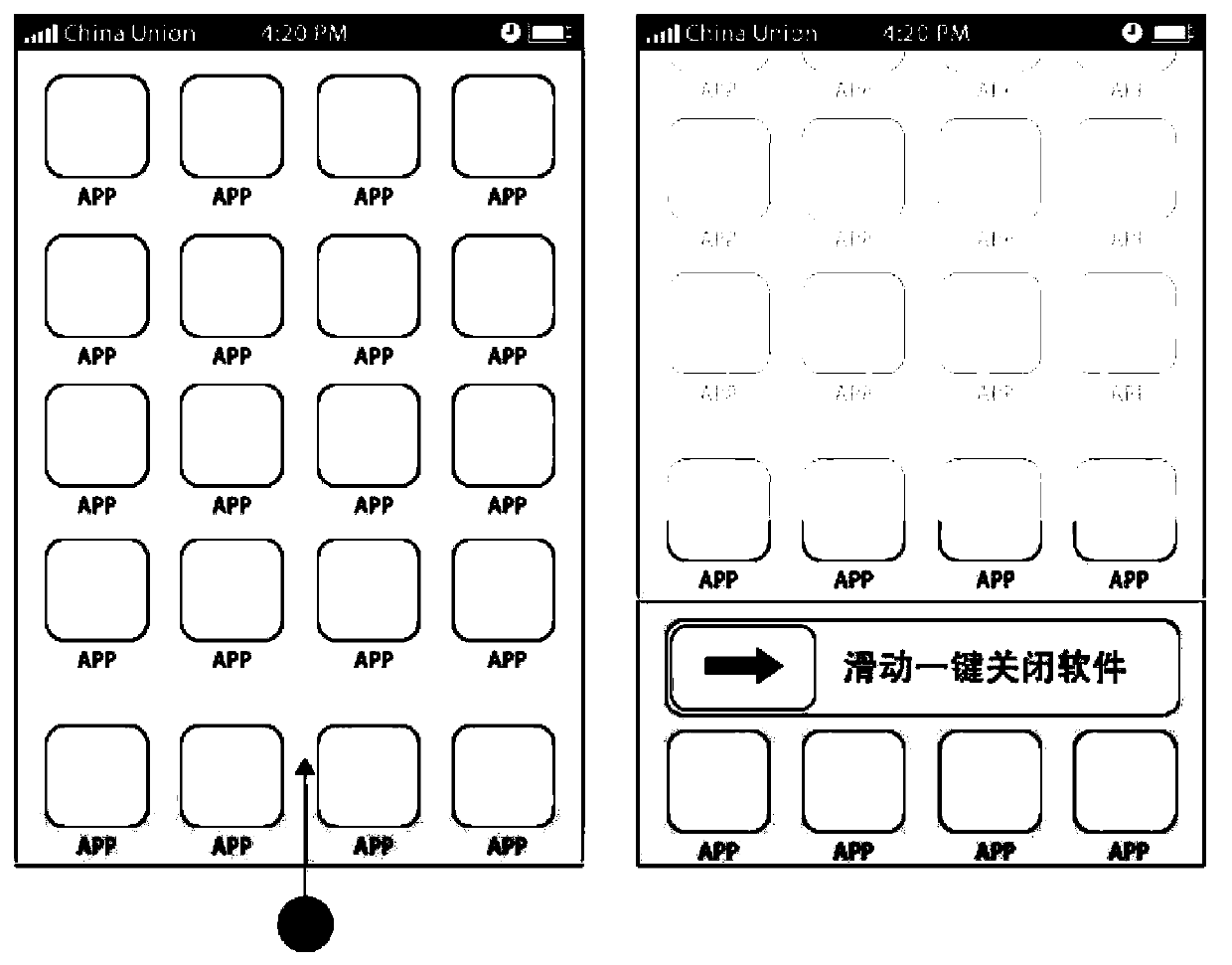

Method and device for stopping background programs

InactiveCN103970395AEasy to closeEasy to operateProgram loading/initiatingInput/output processes for data processingComputer multitaskingProgram treatment

The invention discloses a method and a device which are used for stopping background programs, and belongs to the field of background program processing. The method comprises the following steps: starting a management task region of a multi-task processing queue and drawing a response region in the management task region; detecting an appointed operation of a user in the response region and stopping all the background programs in the multi-task processing queue. The device comprises an initial processing module and a response module. According to the method and the device, the operation of stopping the background programs is simplified, the user can easily stop the background programs by executing the appointed operation in the response region only, and the operation is easy and convenient.

Owner:TENCENT TECH (SHENZHEN) CO LTD

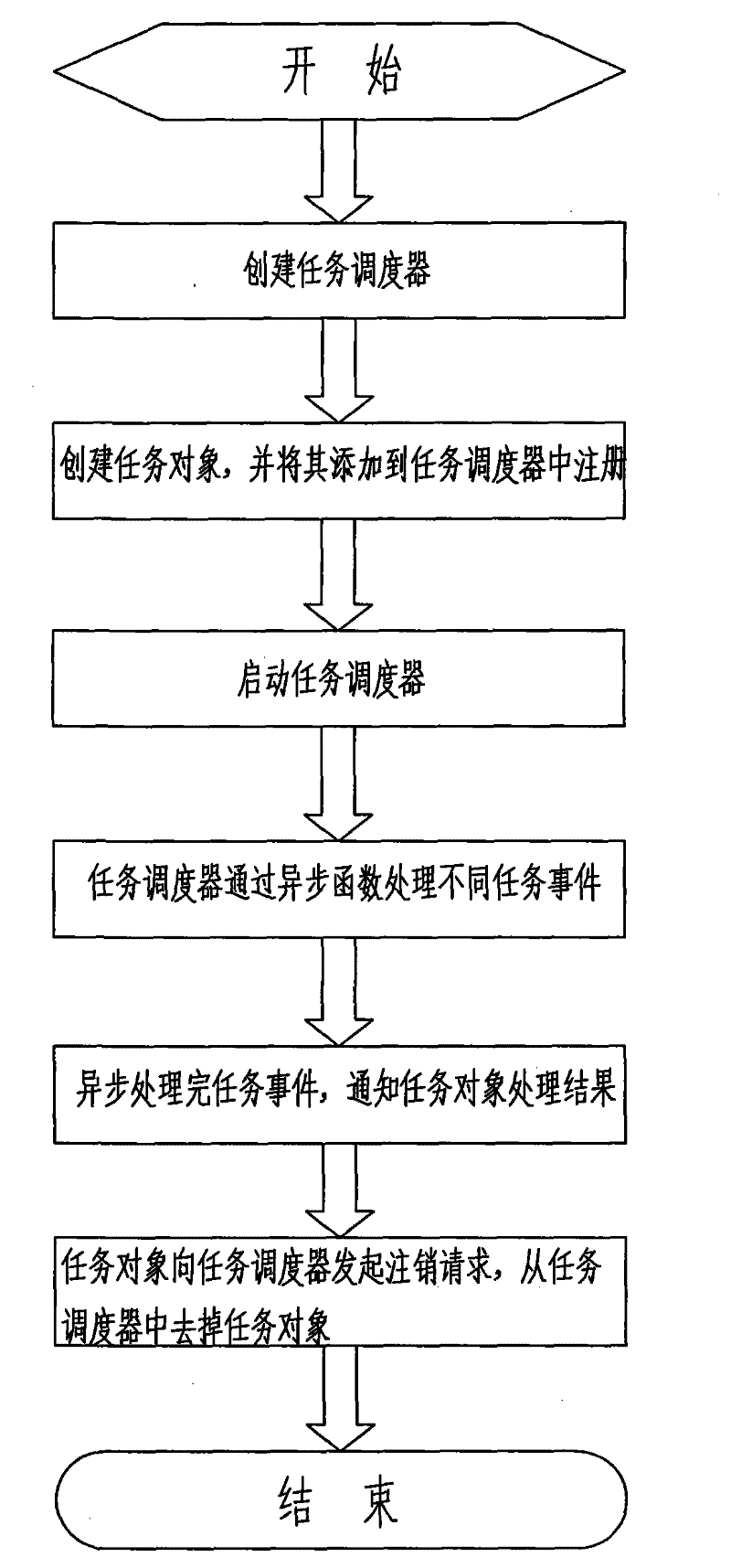

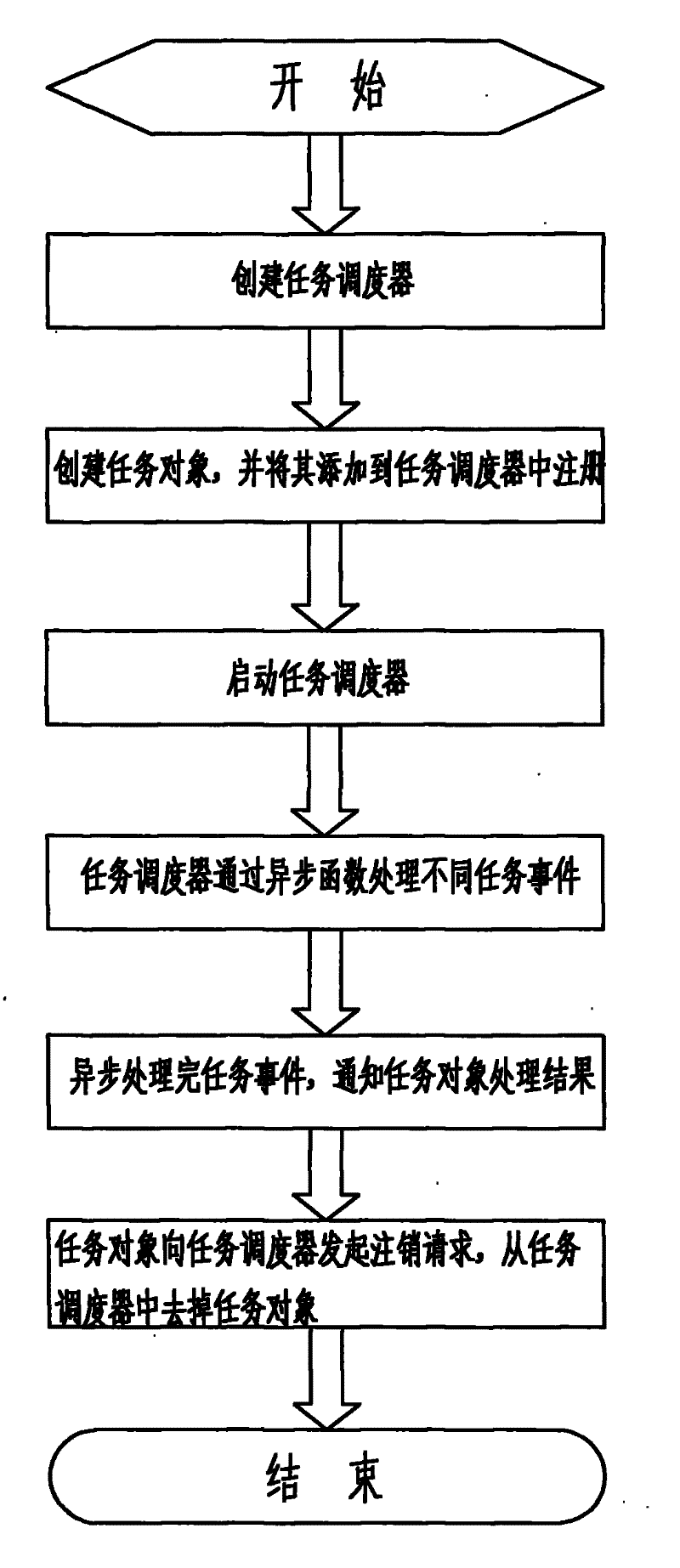

Method for increasing multi-tasking efficiency through thread management

ActiveCN102455933ALess development workCutting costsMultiprogramming arrangementsObject basedTask management

The invention is suitable for the field of multi-task management of a JAVA platform. Multi-thread operation is realized by using a task object in a single thread, and through inheriting a task object base class, carrying out different-priority and call-back interface configuration on each task object, registering in a task scheduler thread and configuring the task objects, the tasking speed is increased. The multi-task management mode comprises the steps of: S101, creating a task scheduler; S102, creating the task objects, adding into the task scheduler for registering; S103, starting the task scheduler; S104, processing different task events by the task scheduler through an asynchronous function; S105, asynchronously processing the task events, informing the task objects of the processing result; and 106, initiating a cancelling request to the task scheduler by the task objects, and cancelling the task objects from the task scheduler.

Owner:SHENZHEN CLOU ELECTRONICS

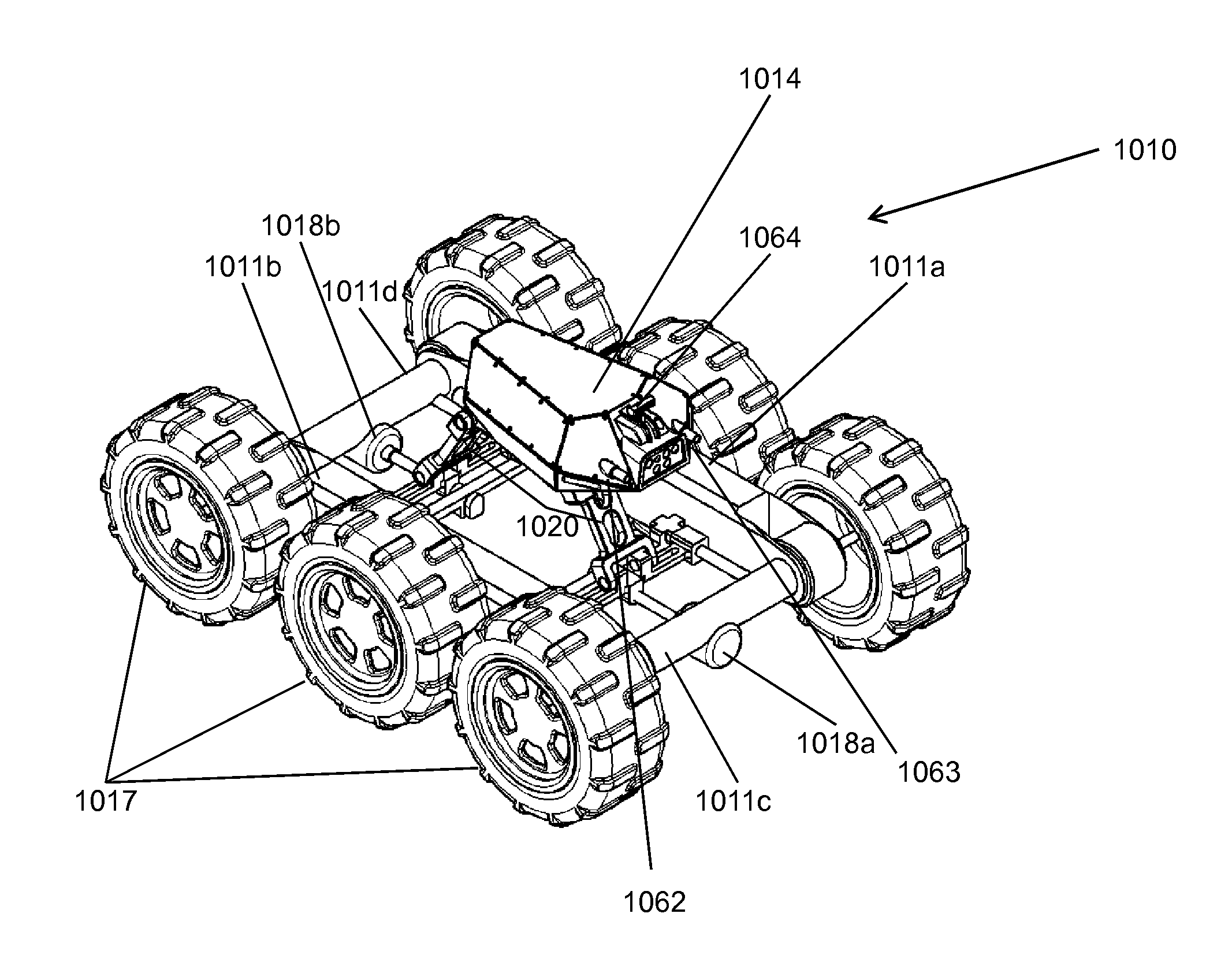

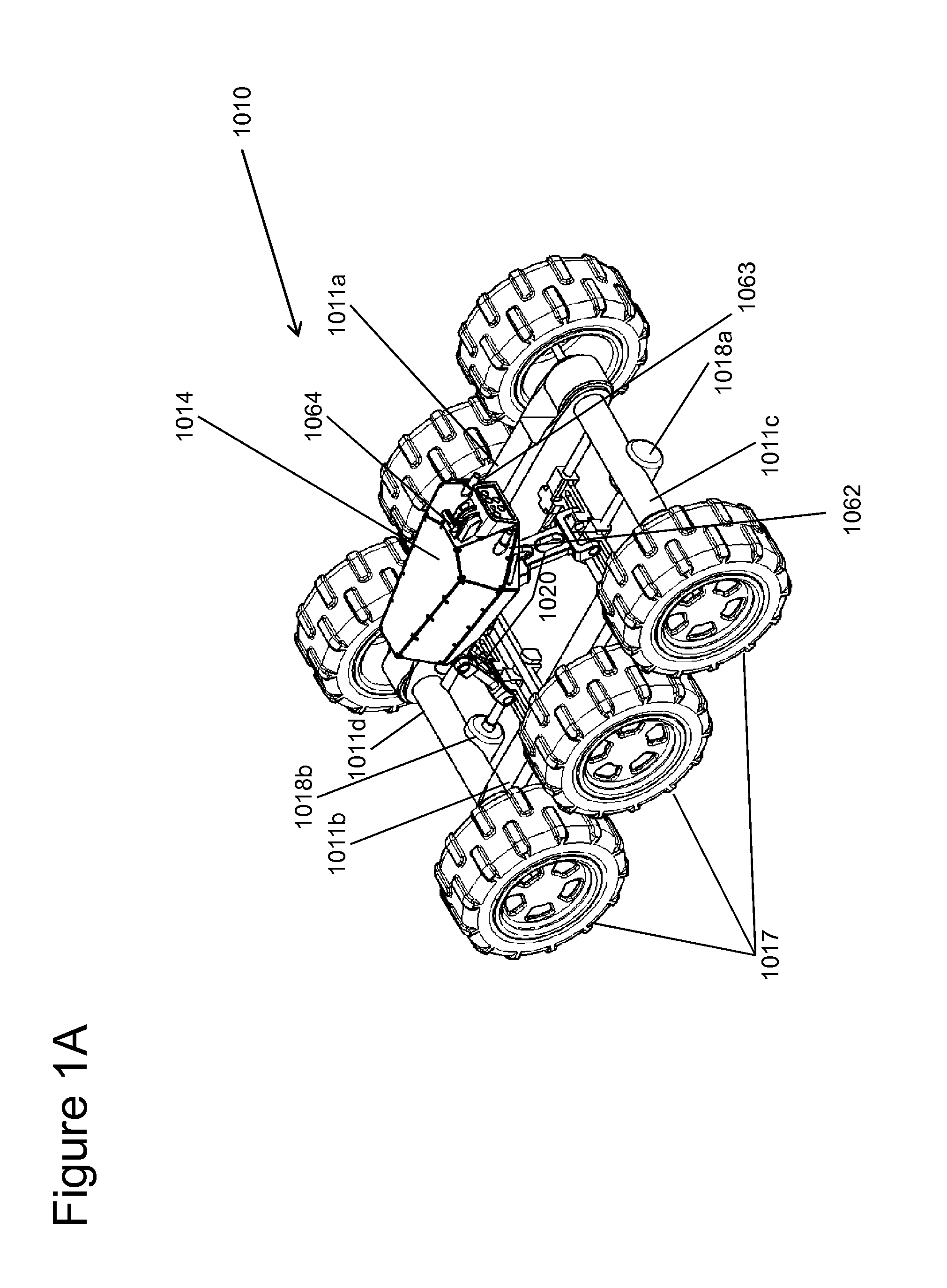

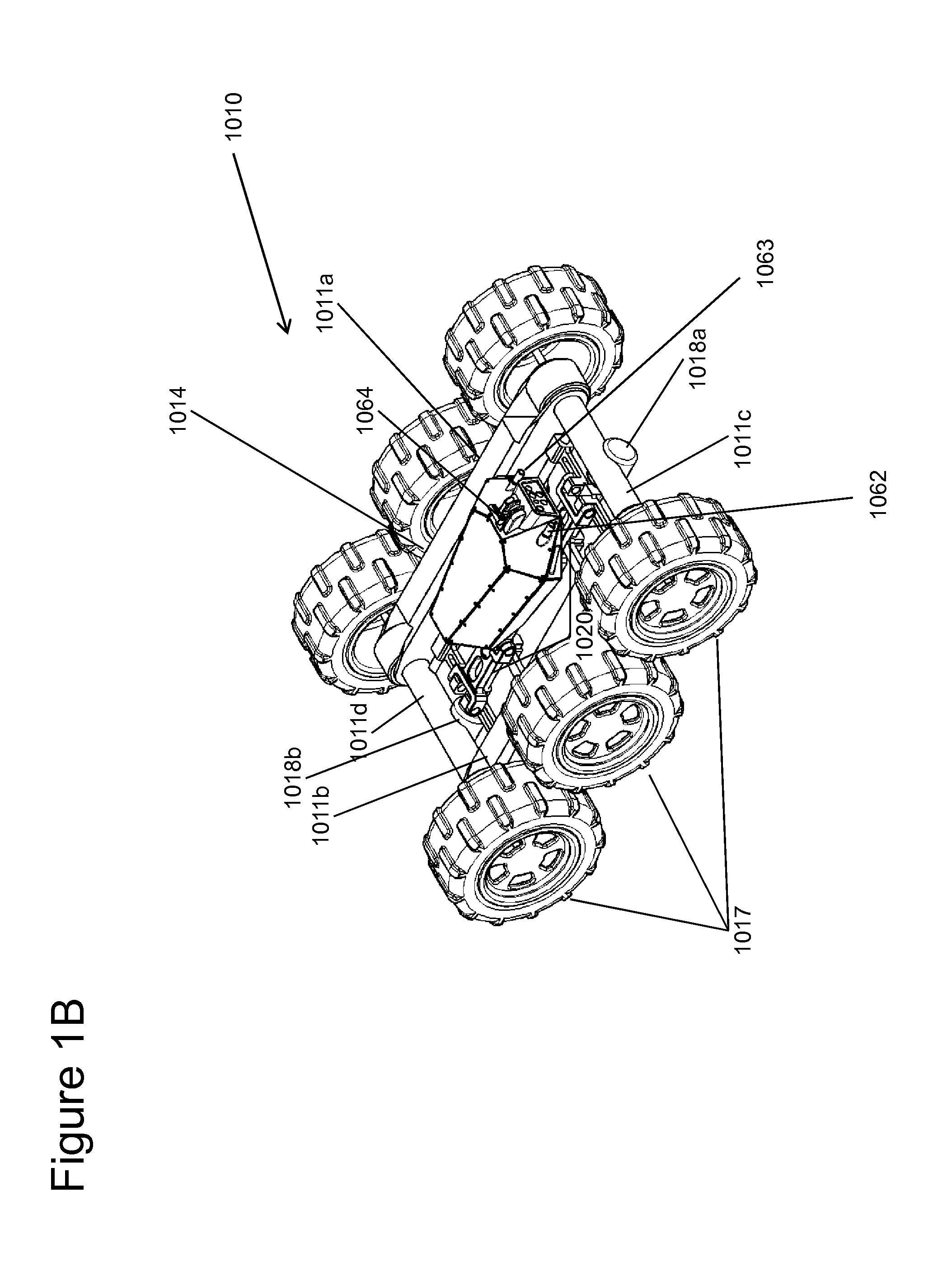

Single operator multitask robotic platform

InactiveUS8594844B1Simple powerAutomatically performComputer controlArmoured vehiclesRobotic armMarine engineering

A robotic platform is capable of multi-tasking under control of a single remote operator. The platform may include a turret mounted on a positioning mechanism. The turret may incorporate an imaging sensor, a target designator and a weapon in a synchronized manner. The robotic platform is capable of switching between different modes: (i) an engaged mode, in which the turret is aligned with the preferred direction of travel of the platform; in the engaged mode the turret is designated by maneuvering the entire robotic platform; (ii) a disengaged mode, in which the robotic platform faces in a first direction while the turret faces another direction to acquired targets. Various functions of driving the platform and operating the turret may be automated to facilitate control by a single operator.

Owner:DEFENSE VISION

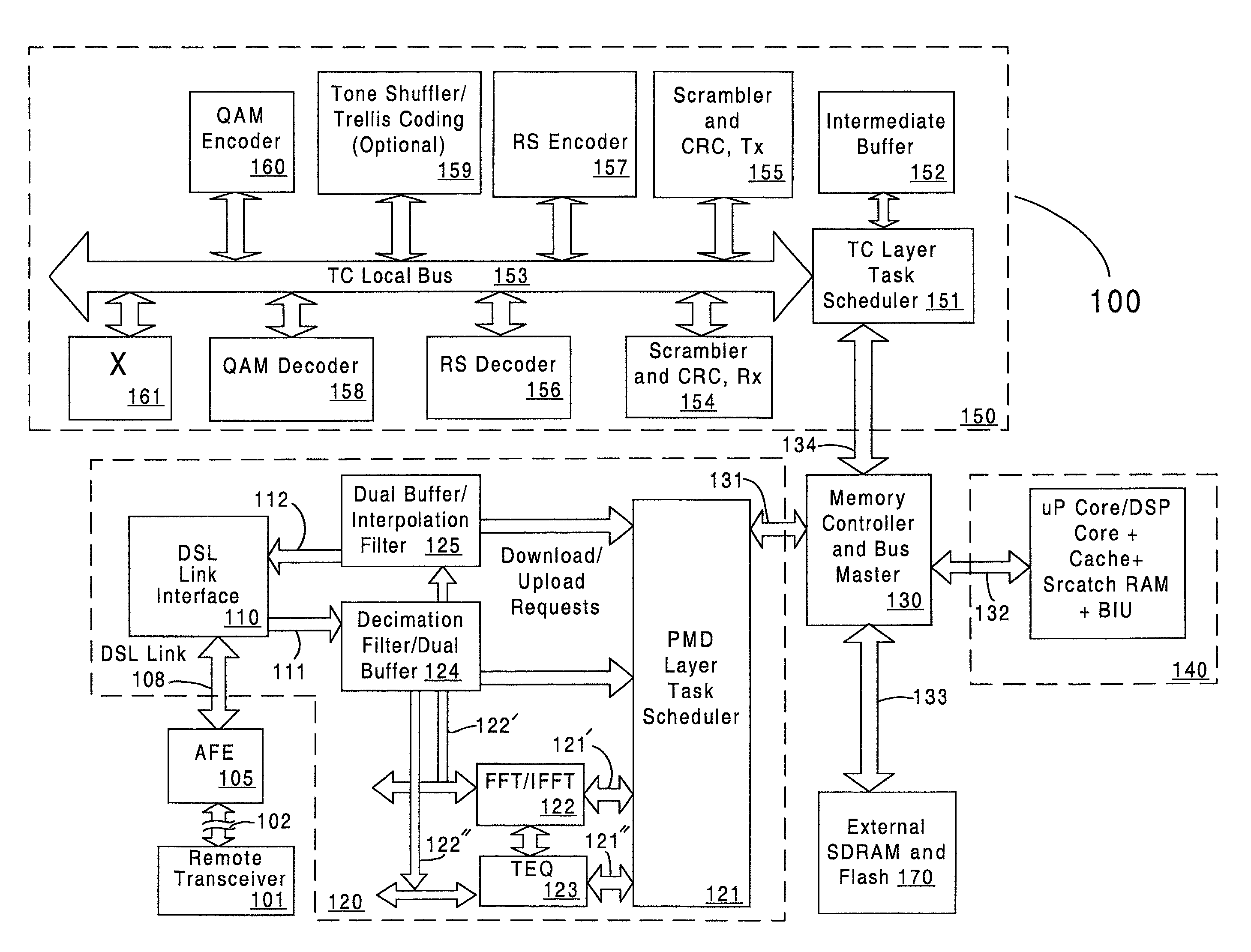

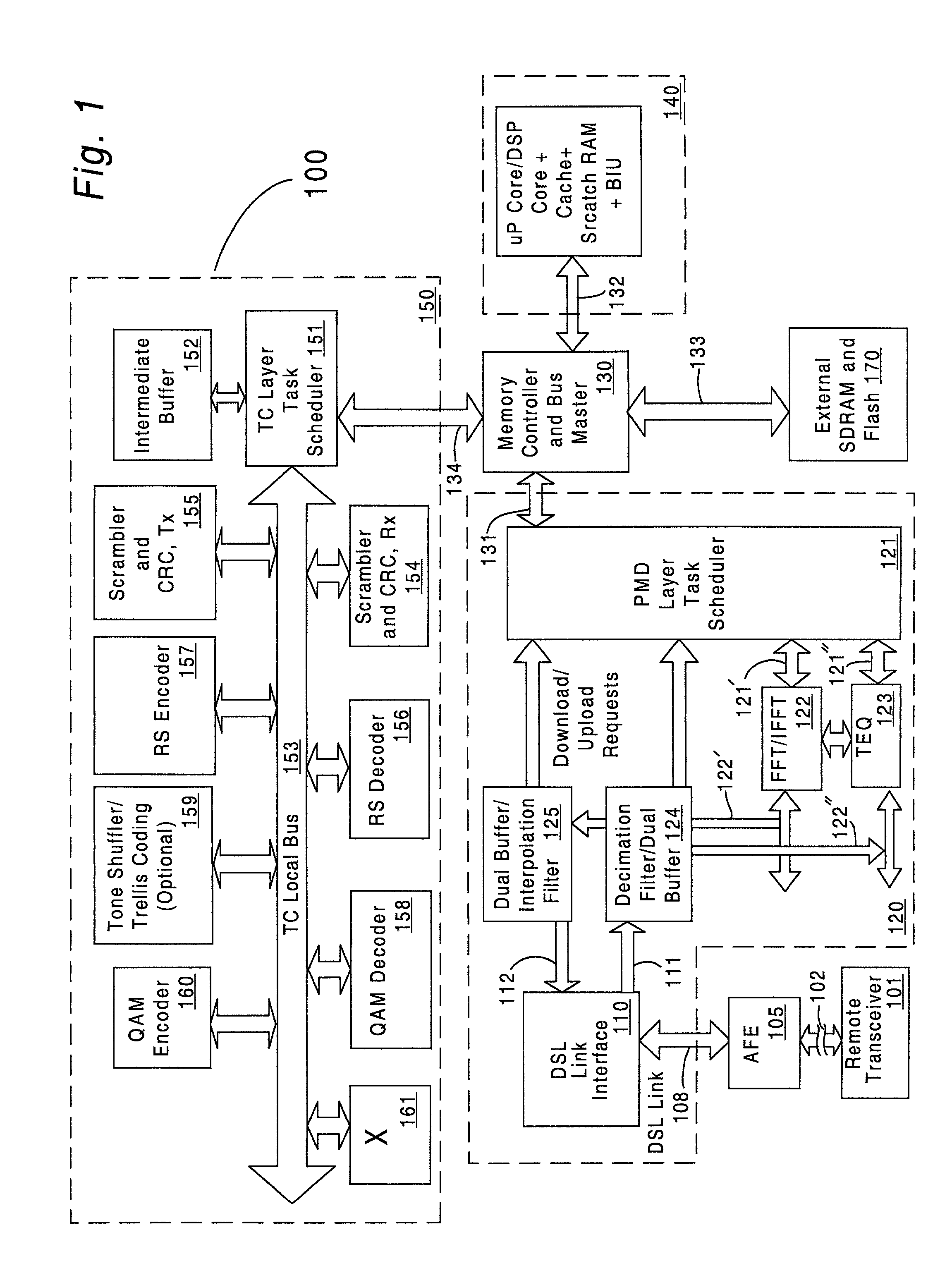

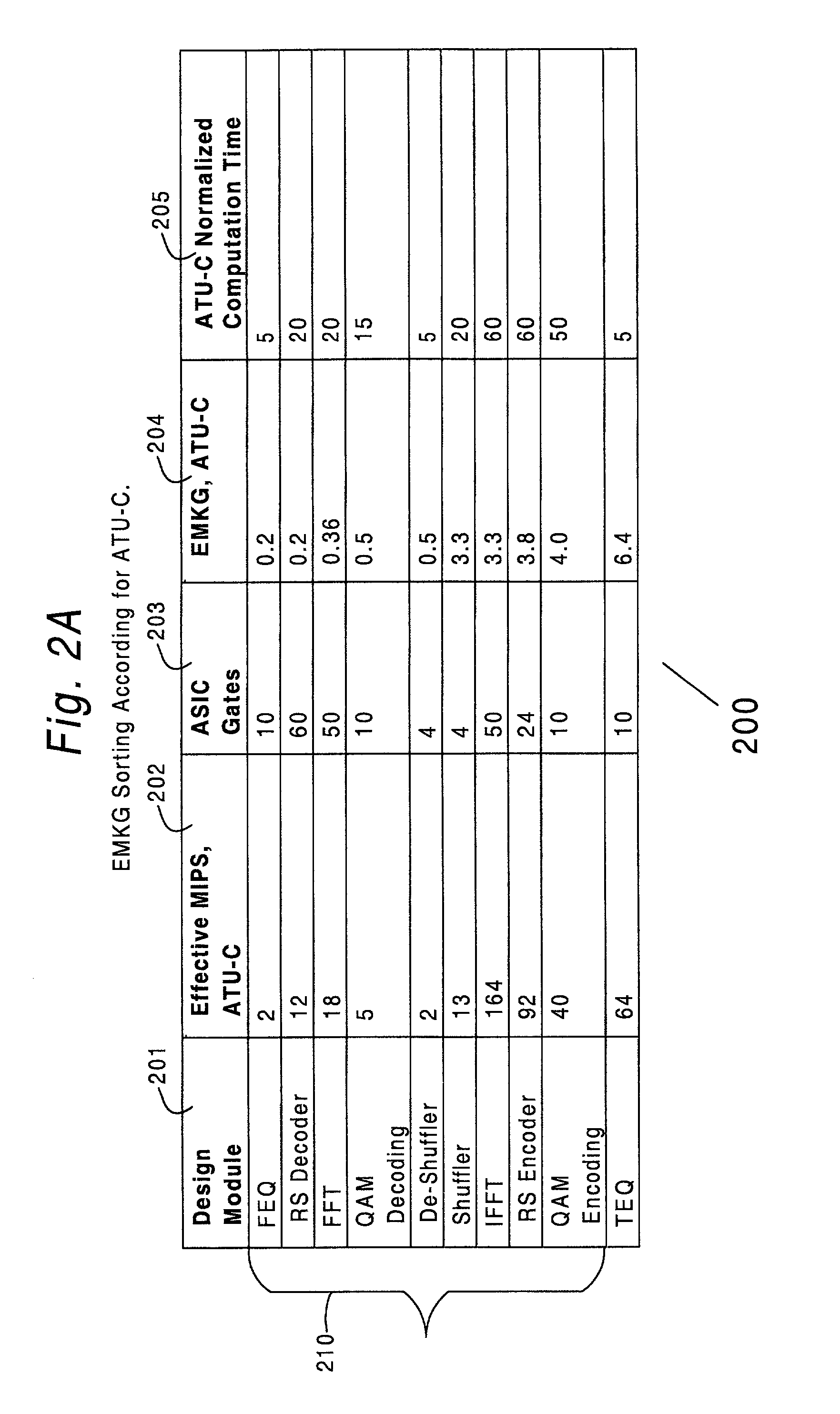

Physical medium dependent sub-system with shared resources for multiport xDSL system

Owner:REALTEK SEMICON CORP

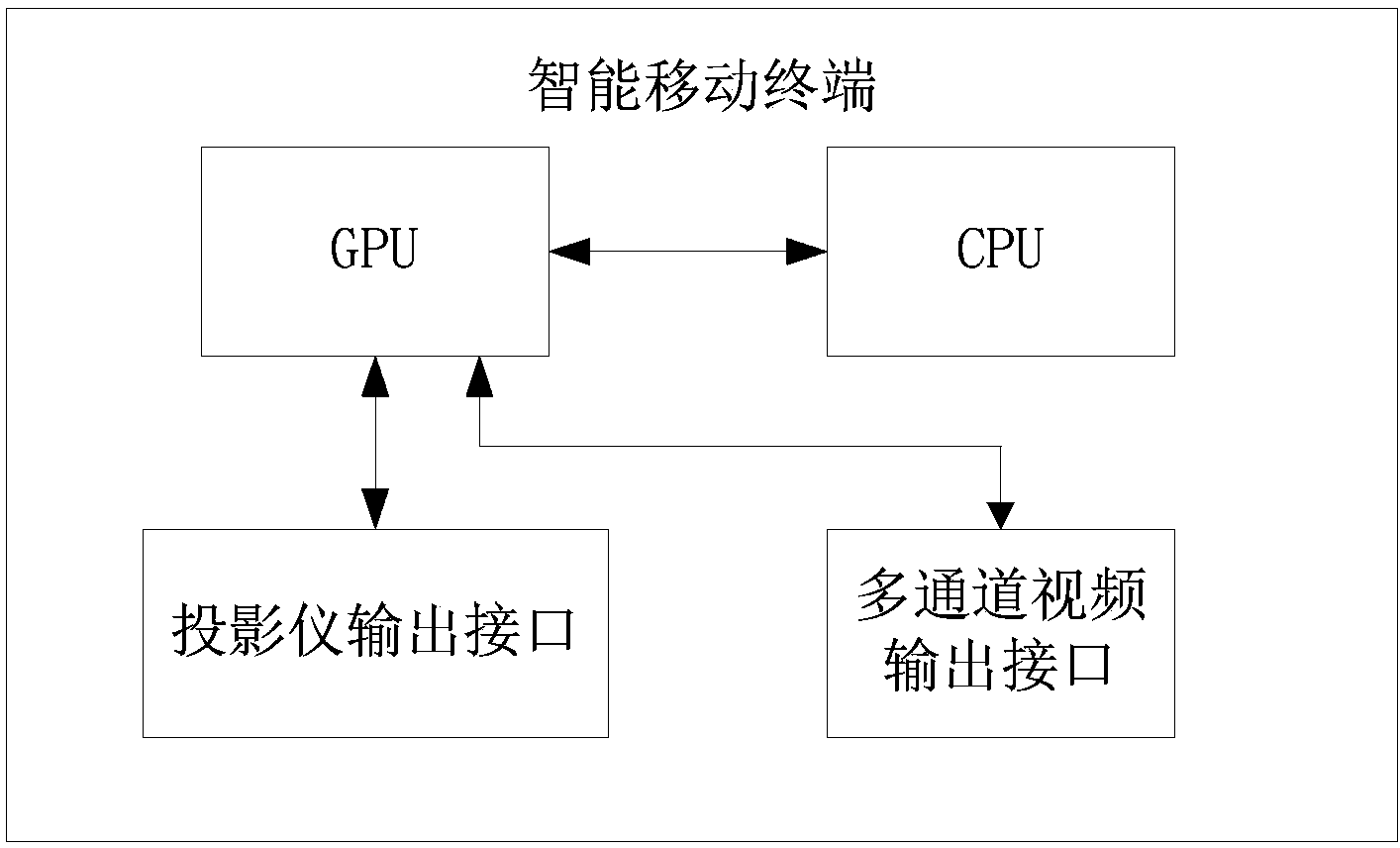

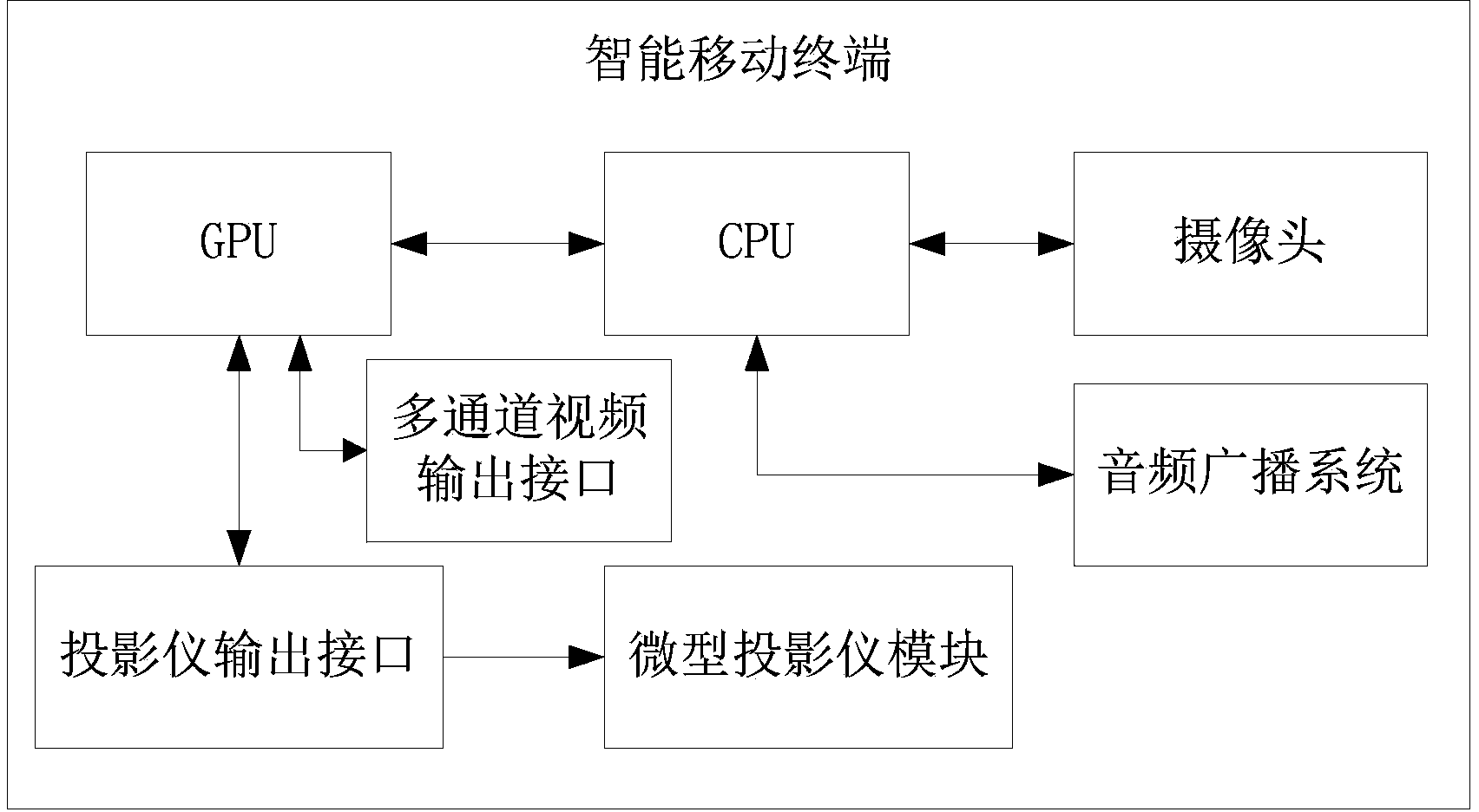

Intelligent split screen display available mobile terminal

InactiveCN103365620ADoes not compromise portabilityLift restrictionsDigital output to display deviceIntelligent lightingLarge screen

The invention discloses an intelligent split screen display available mobile terminal which comprises a CPU (Central Processing Unit) and a GPU (Graphic Processing Unit), wherein the CPU is a single-core or multi-core CPU supporting multithreading and multitasking; an inner core of the CPU supports a multi-domain display management function; the CPU is connected with the GPU; and the GPU is a single-core or multi-core GPU supporting split screen display and full high definition graphic processing, and is connected with a multi-channel video output interface and a projection output interface. The mobile terminal utilizes the CPU with the multi-domain display management function and the GPU with a split screen display function, so that the portability is kept, and display limitation of the mobile terminal is removed; a requirement of a large screen is met; intelligent multi-domain display management is available, so that the problem that display content can only be subjected to mirror image duplication in the prior projection is solved; and mobile equipment has powerful functions of equipment such as a PC (Personal Computer) and a palmtop, and has the potentiality of replacing the equipment such as the PC and the palmtop. The intelligent split screen display available mobile terminal can be widely applied to the field of the mobile terminals.

Owner:陈飞生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com