Feeding mechanism for intelligent power module connecting pieces and tapping device

A technology of module connection and intelligent power supply, which is applied in the field of tapping, can solve the problems of missed processing positions, repeated operation steps, and high labor intensity, and achieve the effects of improving processing efficiency, ensuring accuracy, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

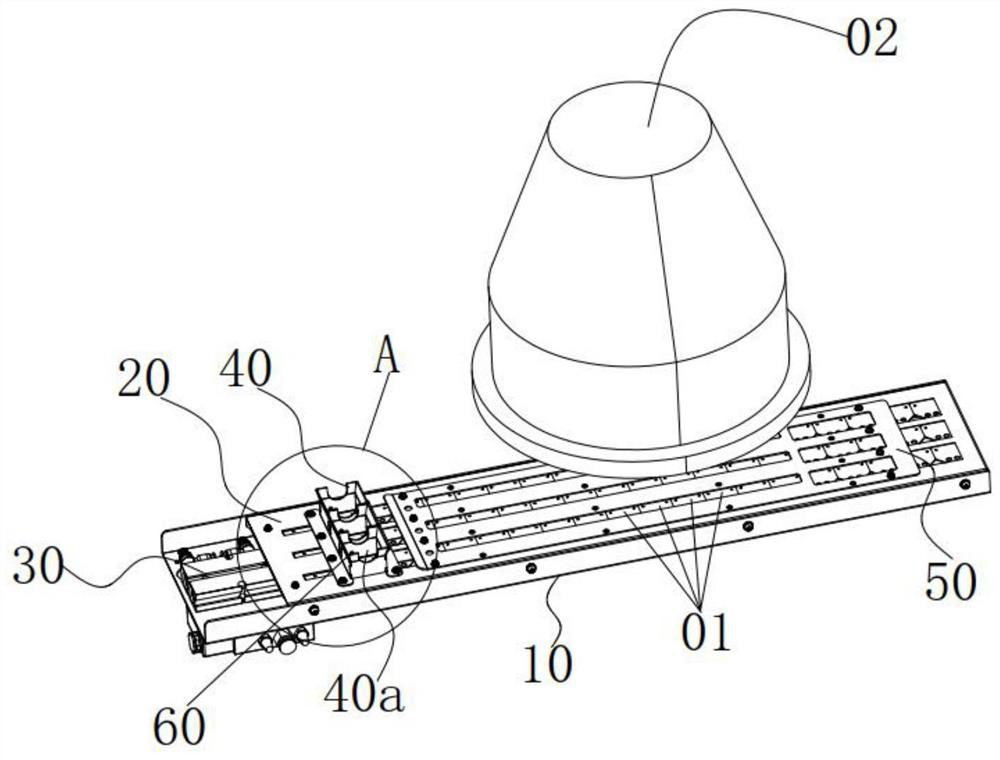

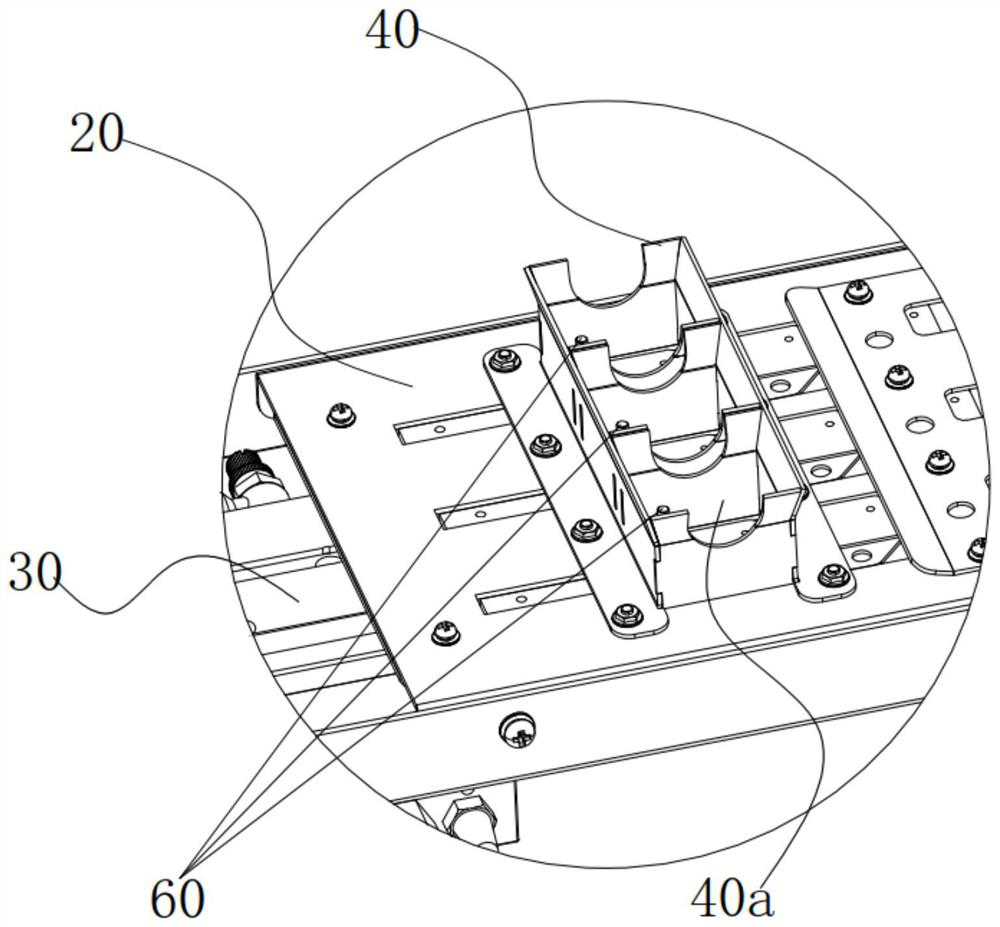

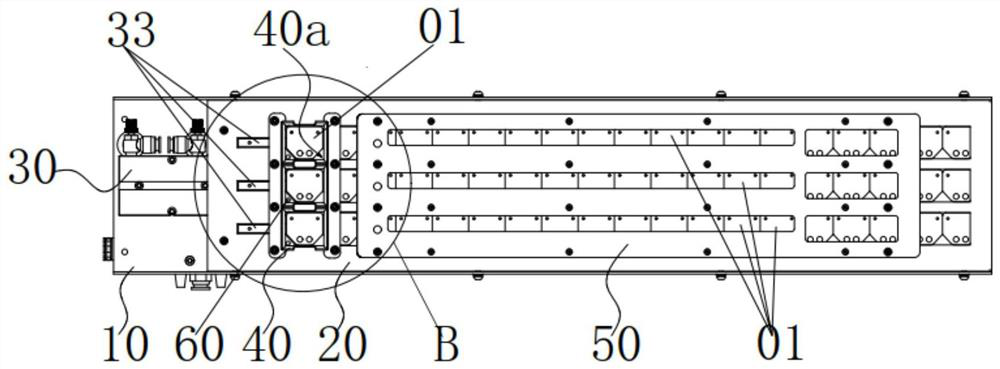

[0050] Such as figure 1 , Figure 5 , Figure 6 , Figure 12 As shown, the present invention provides a feeding mechanism for conveying the connecting piece of the intelligent power module in cooperation with the tapping head 02, which includes a base 10, a feeding plate 20 and a pushing device 30, and the feeding plate 20 is arranged on the base 10 On the feeding plate 20, there is a conveying chute 20a extending along the length direction of the feeding plate 20 (that is, the conveying chute 20a is arranged horizontally). At the tail end, the connecting piece processing position is located between the head end of the conveying chute and the tail end of the conveying chute; a plurality of connecting pieces 01 are arranged side by side on the conveying chute 20a between the head end of the conveying chute and the connecting piece processing position; The material device 30 includes a linear drive device 31, which has a pusher end 311 on the linear drive device 31, and the p...

no. 2 example

[0069] Such as figure 1 , Figure 5 , Figure 6 , Figure 12 As shown, the present invention provides a feeding mechanism for conveying the connecting piece of the intelligent power module in cooperation with the tapping head 02, which includes a base 10, a feeding plate 20, and a pushing device 30; wherein:

[0070] The feeding plate 20 is arranged on the base 10, and the feeding plate 20 is provided with a conveying chute 20a extending along the lengthwise direction of the feeding plate 20 (that is, the conveying chute 20a is horizontally arranged), and the conveying chute 20a has a conveying chute head end, The connecting piece processing position and the end of the conveying chute, the connecting piece processing position is located between the head end of the conveying chute and the end of the conveying chute;

[0071] The feeding plate 20 is provided with a feeding chute 40a that can stack a plurality of connecting pieces. The feeding chute 40a is located directly abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com