Brake bottom plate machining production line

A technology of brake base plate and production line, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of large labor force consumption, high labor intensity, troublesome fixing process, etc., to achieve quick connection and improve utilization. High efficiency and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

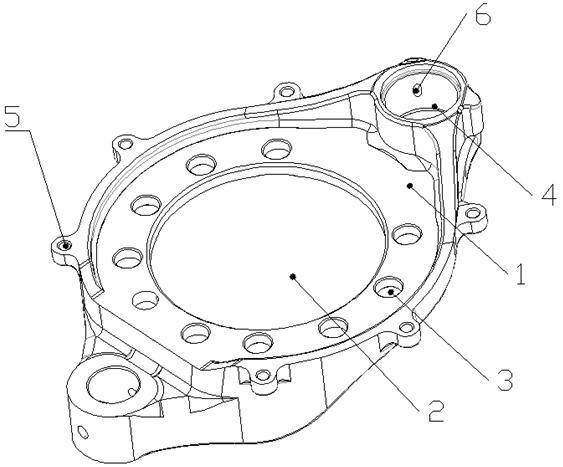

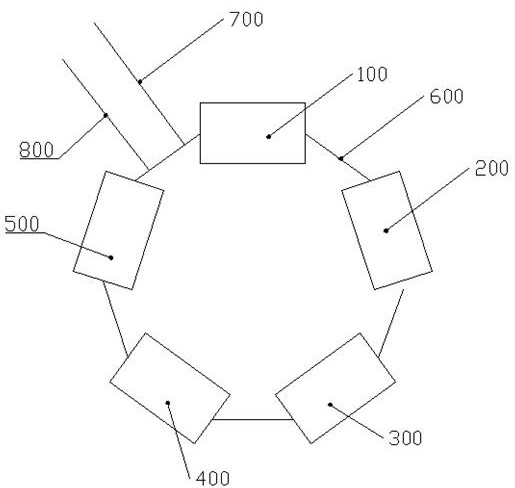

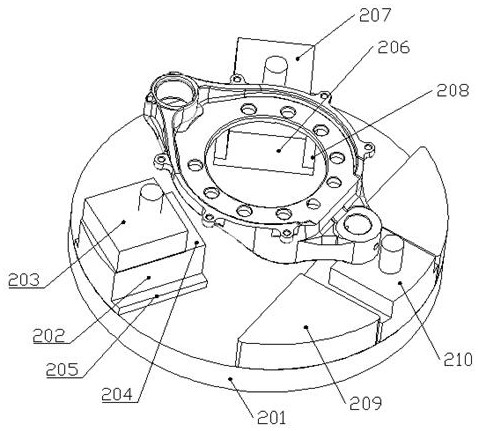

[0063] like Figure 2-Figure 13 The brake bottom plate processing production line shown in the figure includes a car plane unit, a milling plane unit, a mounting hole drilling unit, an assembly hole boring unit, and a dust-proof hole drilling unit distributed sequentially in a ring shape. The transition conveyor belt 600 is connected to form an endless cycle, and a feed conveyor belt 700 and a discharge conveyor belt 800 are also provided at the side end of the transition conveyor belt 600 for connecting the dust-proof hole drilling unit and the car plane unit, The feeding conveyor belt 700 is located on the side close to the car plane unit, and the discharging conveyor belt 800 is located on the side close to the dust-proof hole drilling unit.

[0064] Car plane unit comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com