Improved welt bifurcated pipe calculation model

A technology for calculating models and welt bifurcated pipes is applied in the field of calculation models for welt bifurcated pipes, which can solve the problems of inaccurate calculation results, low calculation accuracy, and low calculation accuracy of shell elements, and achieve the effect of efficient structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

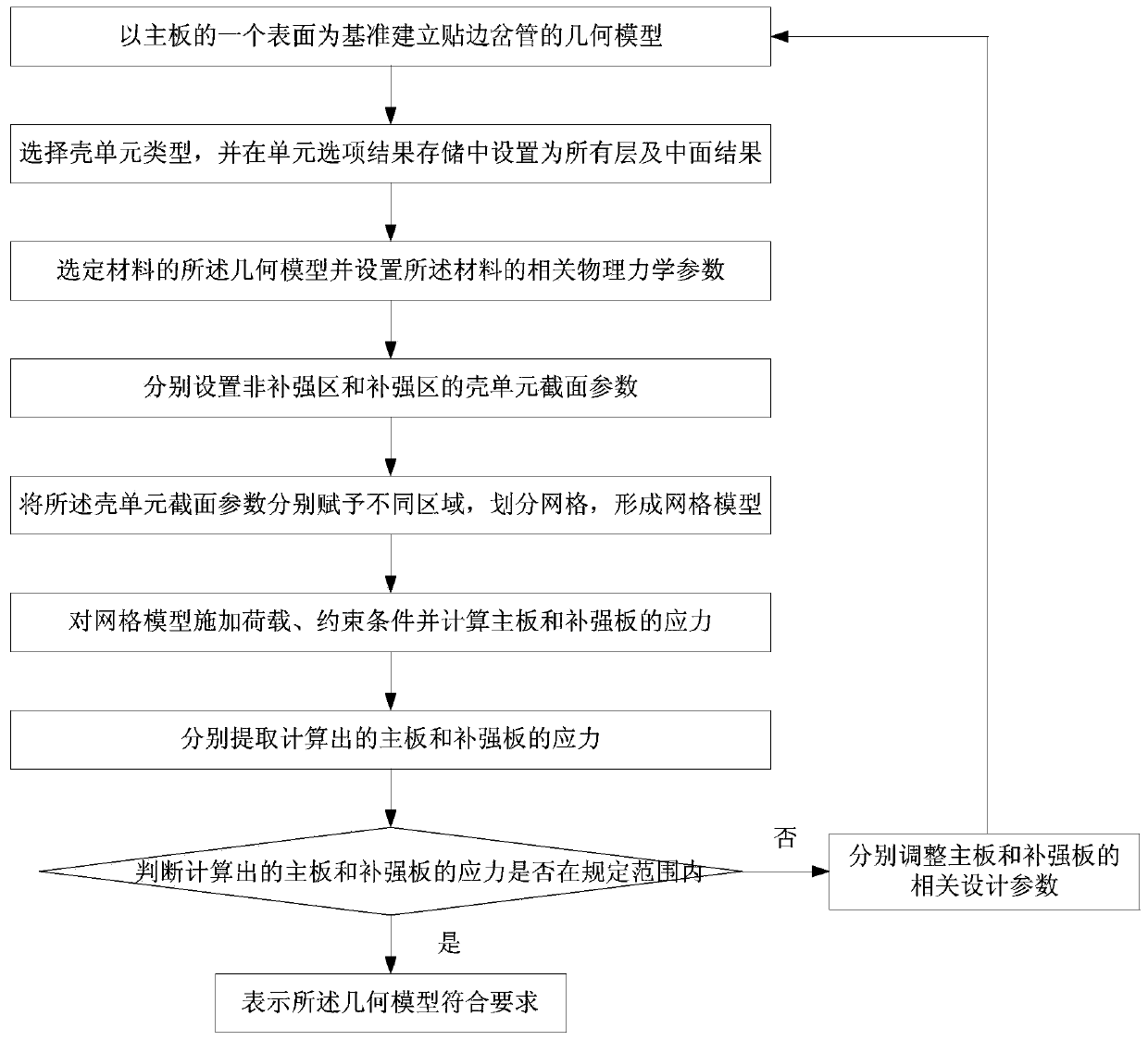

[0053] An improved calculation model for welted bifurcated pipes in the embodiment of the present invention is suitable for structural analysis of multilayer reinforced plate welted bifurcated pipes, and mainly includes the following steps:

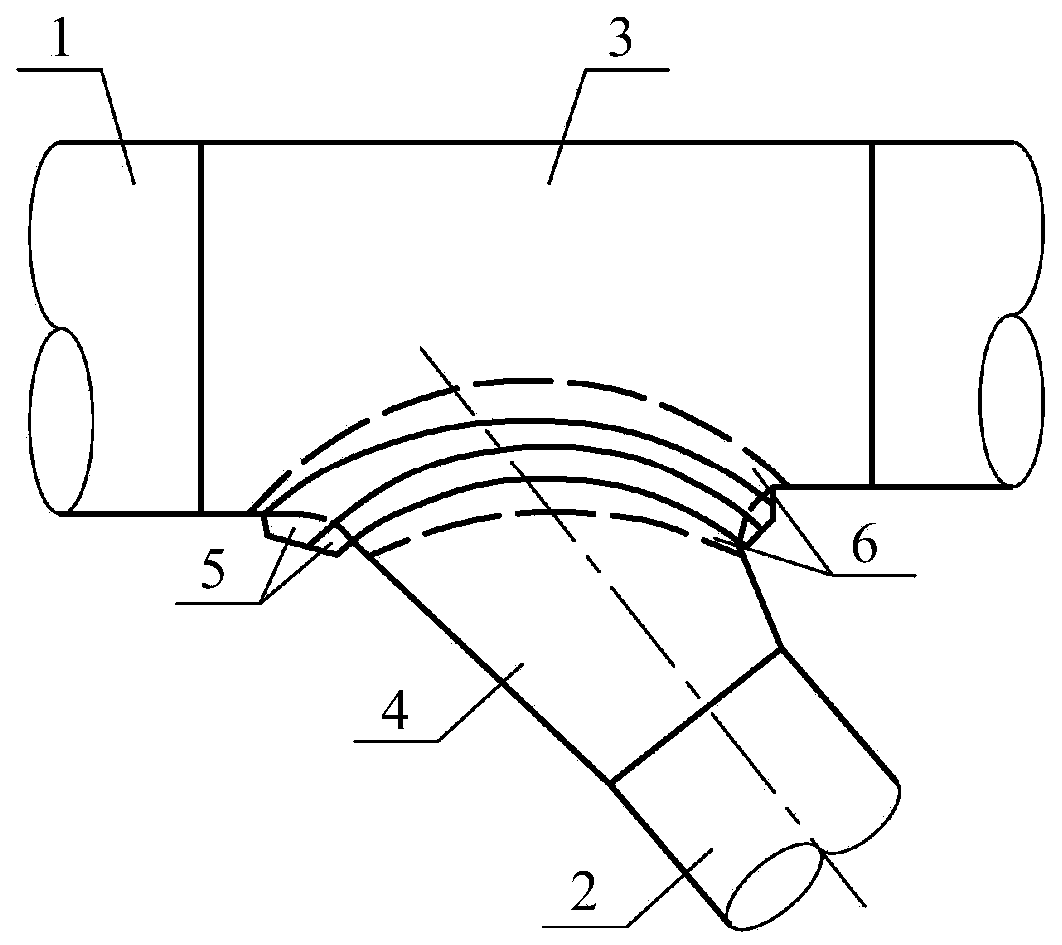

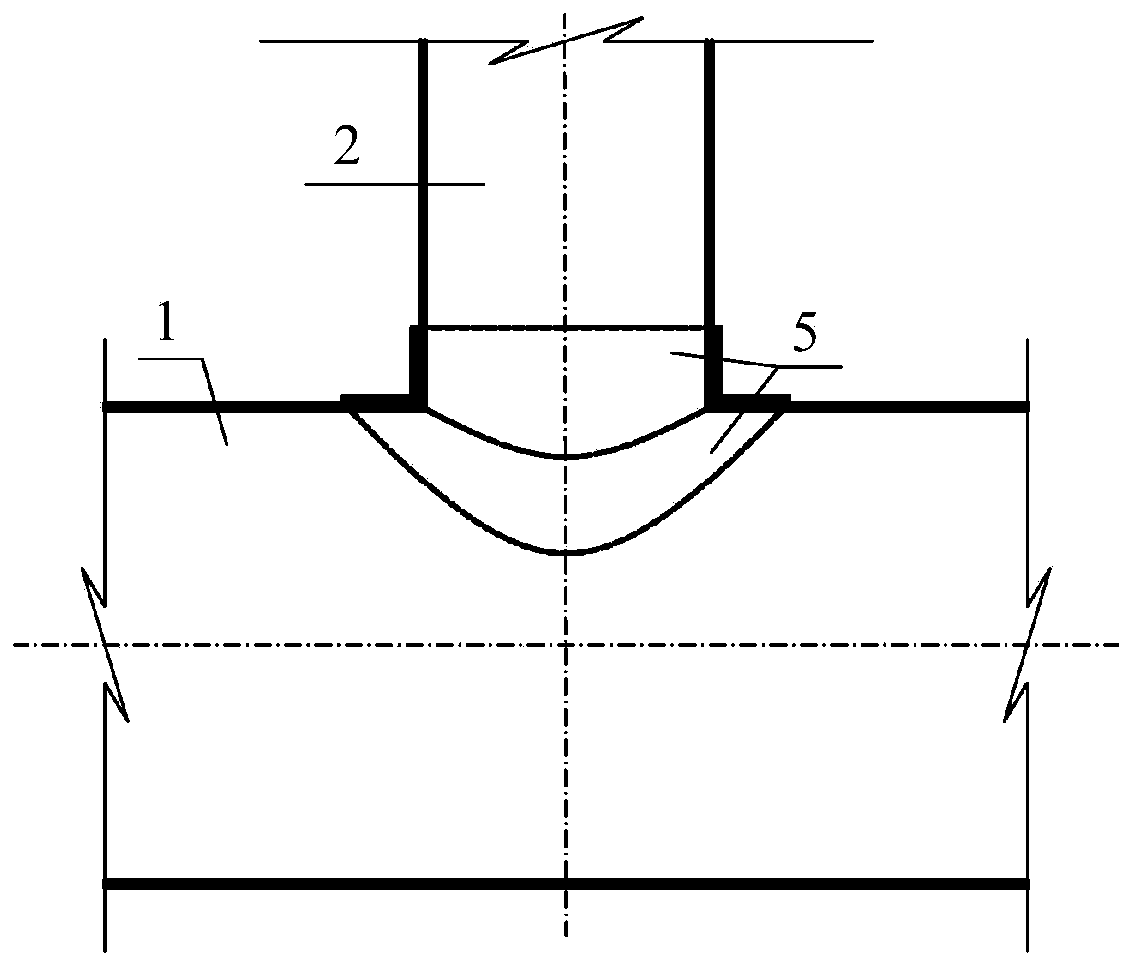

[0054] Build a geometric model: according to Figure 2 ~ Figure 6 The design drawing of the welted bifurcation, figure 2 is a schematic diagram of a typical welt bifurcation pipe, image 3 is the longitudinal section design drawing of the welt bifurcation pipe, Figure 4 It is the top view design drawing of the welted bifurcation pipe, Figure 5 It is a local large-scale sample diagram of the reinforcement area of the welted bifurcation pipe. For the local diagram of the geometric model of the welted bifurcation pipe in the ANSYS software, please refer to Figure 6 , including: supervisor 1, main board 11, branch pipe 2, main board 21 of branch pipe, main cone pipe 3, branch cone pipe 4, outer reinforcing plate 5, first layer outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com