Discharging device of automatic vending machine

A technology for vending machines and shipping devices, which is applied to instruments, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items, etc. and other problems, to achieve the effect of improving work reliability, convenient and reliable shipment, and saving delivery time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

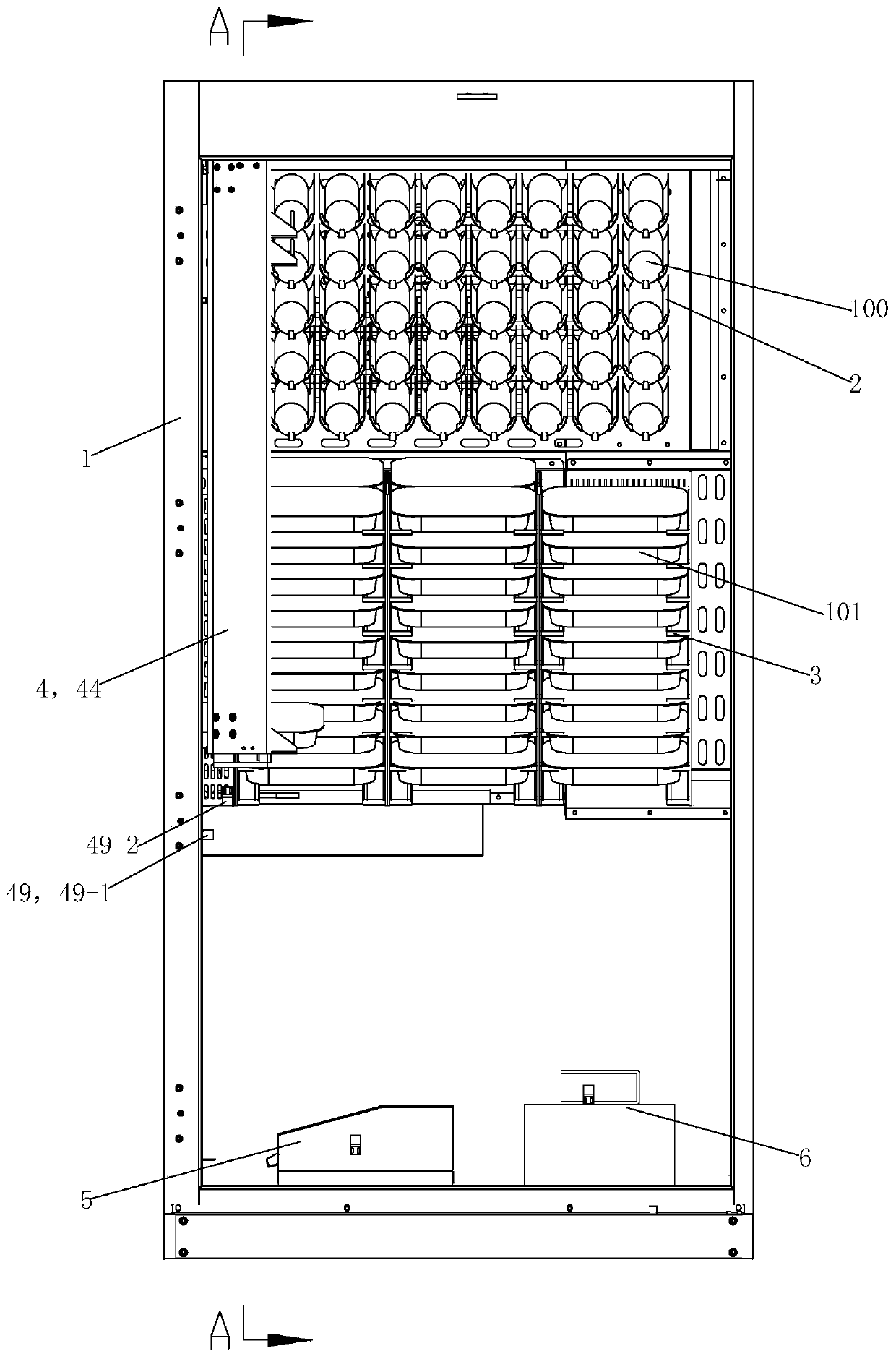

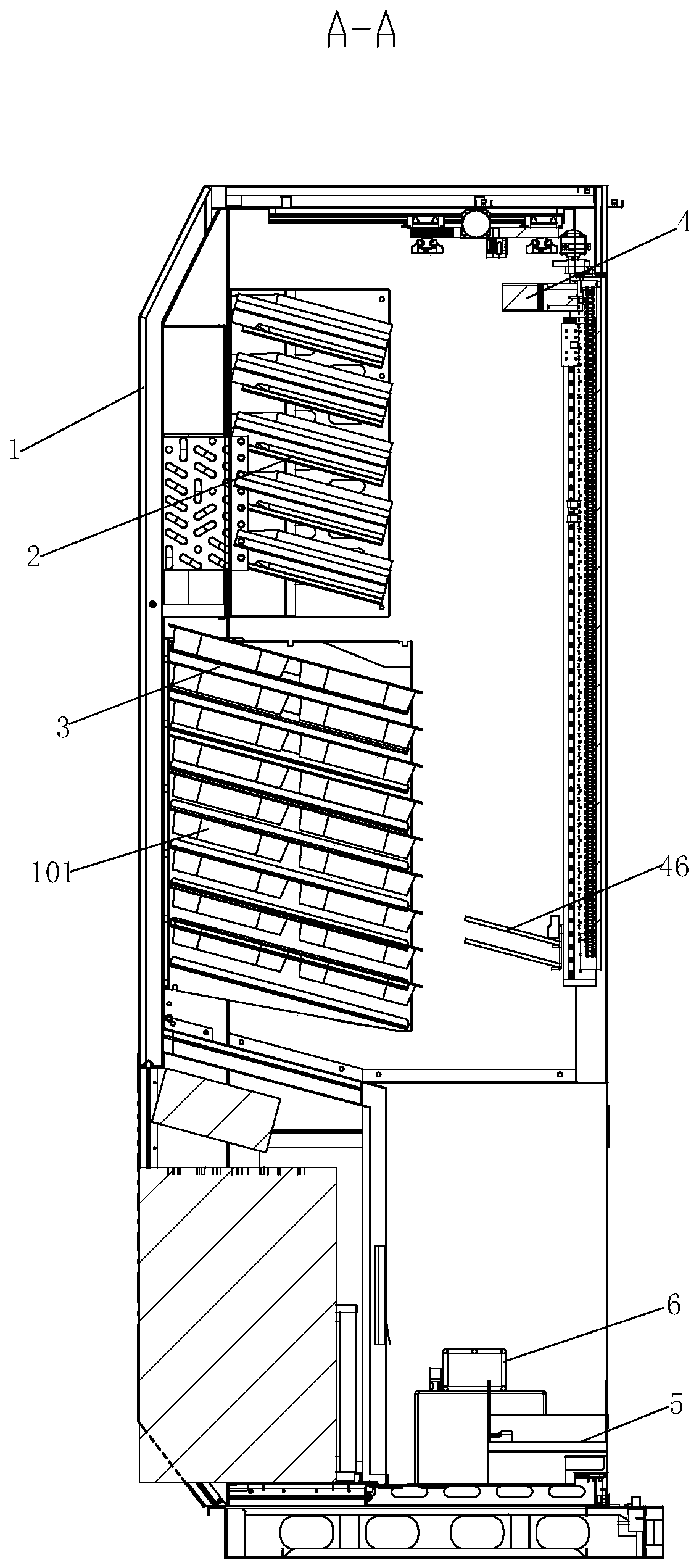

[0048] See figure 1 and figure 2 , the automatic vending machine shipping device of the present embodiment, it is mainly made up of body 1, beverage shelf 2, box-shaped goods shelf 3, automatic delivery mechanism 4, beverage delivery box 5 and box-shaped goods delivery shelf 6.

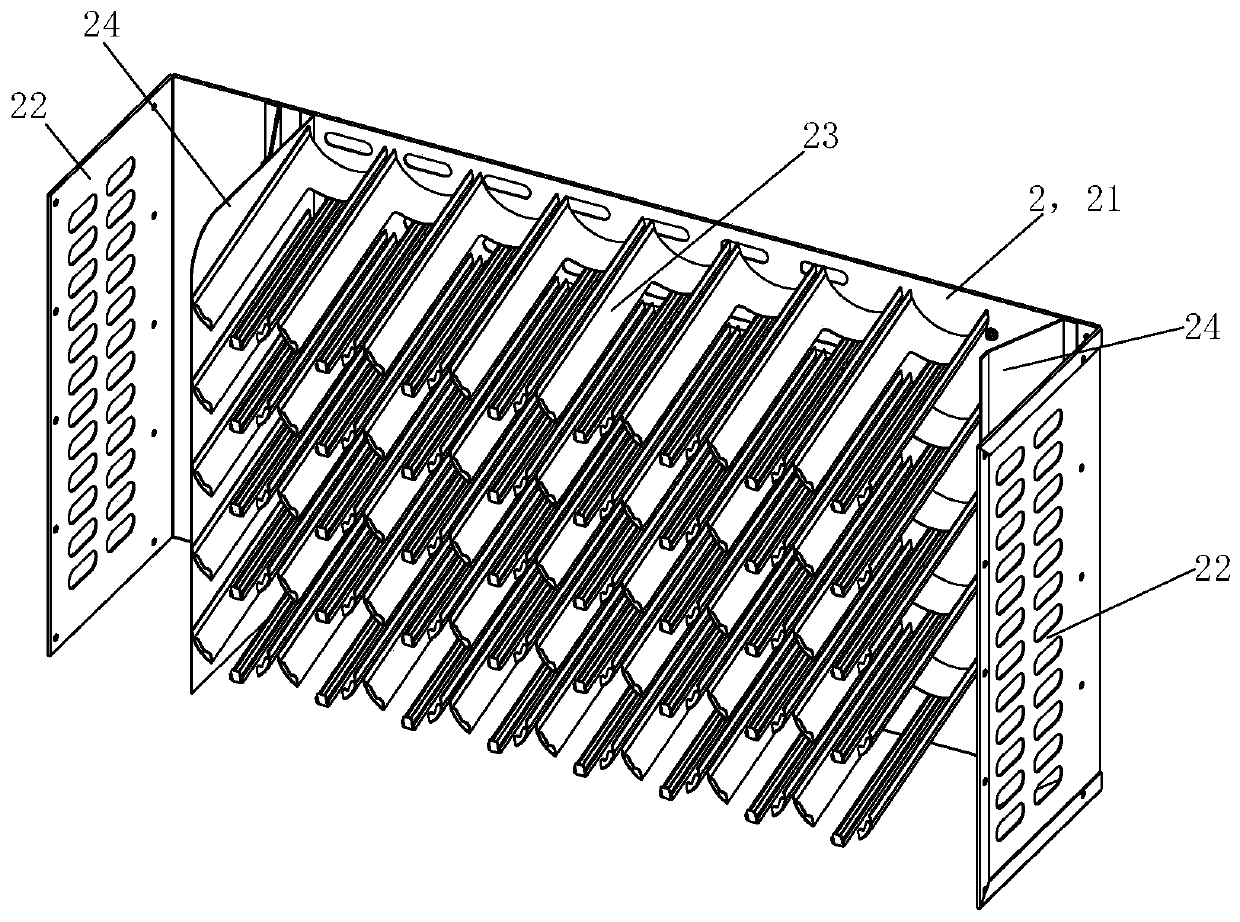

[0049] see image 3 , Beverage shelf 2 is mainly made up of rear panel 21, side panel 22 and beverage goods channel 23. Side plate 22 is provided with 2 pieces, and 2 pieces of side plates 22 are integrally or fixedly connected with the left and right sides of rear plate 21 and protrude forward, as preferred mode, rear plate 21 and 2 pieces of side plates 22 are all provided with some air-permeable hole. Beverage cargo lanes 23 are arranged in more than 2 rows parallel to the left and right and more than 2 rows are arranged in parallel up and down. Between the side plates 22, each beverage cargo channel 23 is fixedly arranged on the rear panel 21 in a way that the front end is lower than the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com