Aqueous battery current collector, positive electrode, flexible battery and preparation and application thereof

A technology of battery collectors and current collectors, which is applied in the direction of battery electrodes, electrode carriers/current collectors, secondary batteries, etc., and can solve problems such as electrolyte corrosion and lack of advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

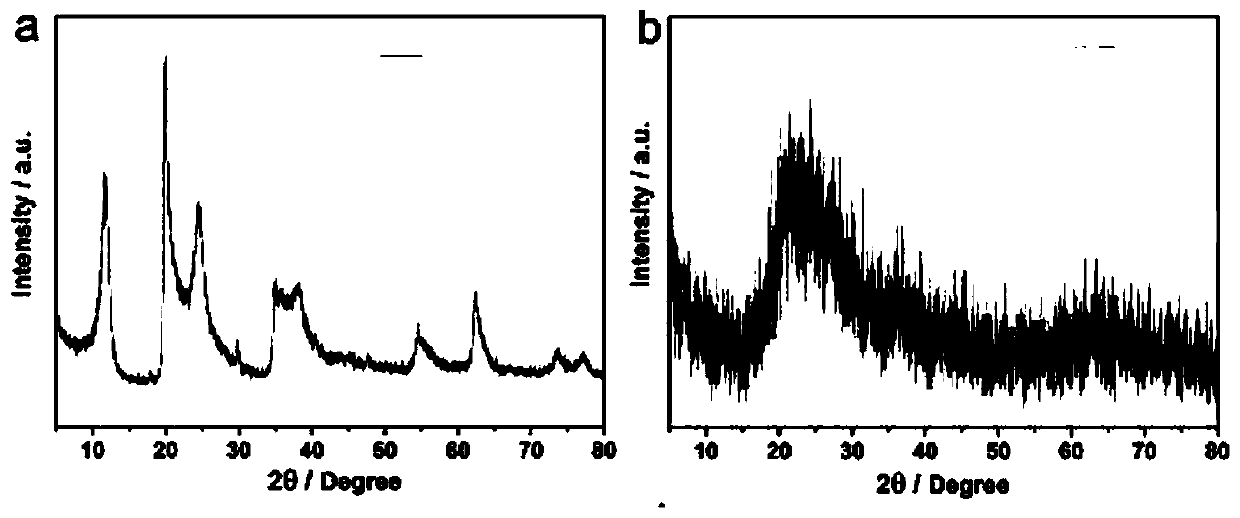

[0075] (1) Halloysite pretreatment: First, halloysite powder and deionized water are stirred and mixed according to the designed ratio, halloysite powder: deionized water=1g:50mL, the control stirring rate is 500r / min, the stirring time Next, let it stand for 10 minutes, and take the middle liquid; then, repeat the first two steps twice; finally, take the halloysite solution in the previous step, dry it for 10 hours at 40°C, and grind it for 30 minutes to obtain purified halloysite stone powder. The hydrochloric acid=1g:50mL ratio of 2mol / L is stirred and mixed, and the stirring rate is controlled to be 500r / min, and the stirring time is 4h, and then the solution is centrifugally cleaned to neutrality, the centrifugal rate is controlled to 3000r / min, and the number of centrifugation is 3 times, and the obtained The substance was dried at 40°C for 10 hours to obtain acidified halloysite (acidified halloysite). Its diffraction pattern is attached figure 1 shown.

[0076] (2) ...

Embodiment 2

[0083] (1) Halloysite pretreatment: first, halloysite powder and deionized water are stirred and mixed according to the designed ratio, halloysite powder: deionized water=1g:80mL, the control stirring rate is 700r / min, the stirring time Next, let it stand for 20 minutes, and take the middle liquid; then, repeat the first two steps 4 times; finally, take the halloysite solution in the previous step, dry it for 20 hours at 60°C, and grind it for 40 minutes to obtain the purified halloysite stone powder. The hydrochloric acid=1g:80mL ratio of 2mol / L stirs and mixes, and the control stirring speed is 700r / min, and the stirring time is 5h, and then the solution is centrifugally cleaned to neutrality, and the centrifugal speed is controlled at 4000r / min, and the number of centrifugation is 4 times, and the obtained The substance was dried at 60°C for 15 hours to obtain acidified halloysite (acidified halloysite).

[0084](2) Preparation of electrospinning solution: by mass percenta...

Embodiment 3

[0091] (1) Halloysite pretreatment: first, halloysite powder and deionized water are stirred and mixed according to the designed ratio, halloysite powder: deionized water=1g:100mL, the control stirring rate is 800r / min, the stirring time Next, let it stand for 20 minutes to take the middle layer liquid; then, repeat the first two steps 4 times; finally, take the halloysite solution in the previous step, dry it for 30 hours at 80°C, and grind it for 40 minutes to obtain the purified halloysite stone powder. The hydrochloric acid=1g:100mL ratio of 2mol / L is stirred and mixed, and the control stirring speed is 800r / min, and the stirring time is 6h, then the solution is centrifugally cleaned to neutrality, the centrifugal speed is controlled at 5000r / min, and the number of centrifugation is 5 times, the obtained The substance was dried at 80°C for 20 hours to obtain acidified halloysite (acidified halloysite).

[0092] (2) Preparation of electrospinning solution: by mass percenta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap