Stand-alone cutting apparatus

A cutting device, cutter technology, applied in the direction of printing device, packaging, transportation and packaging, etc., can solve the problem of unclear cutter rotation, printer cutting equipment blocking, supply roller edge printer or cutting equipment blocking and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

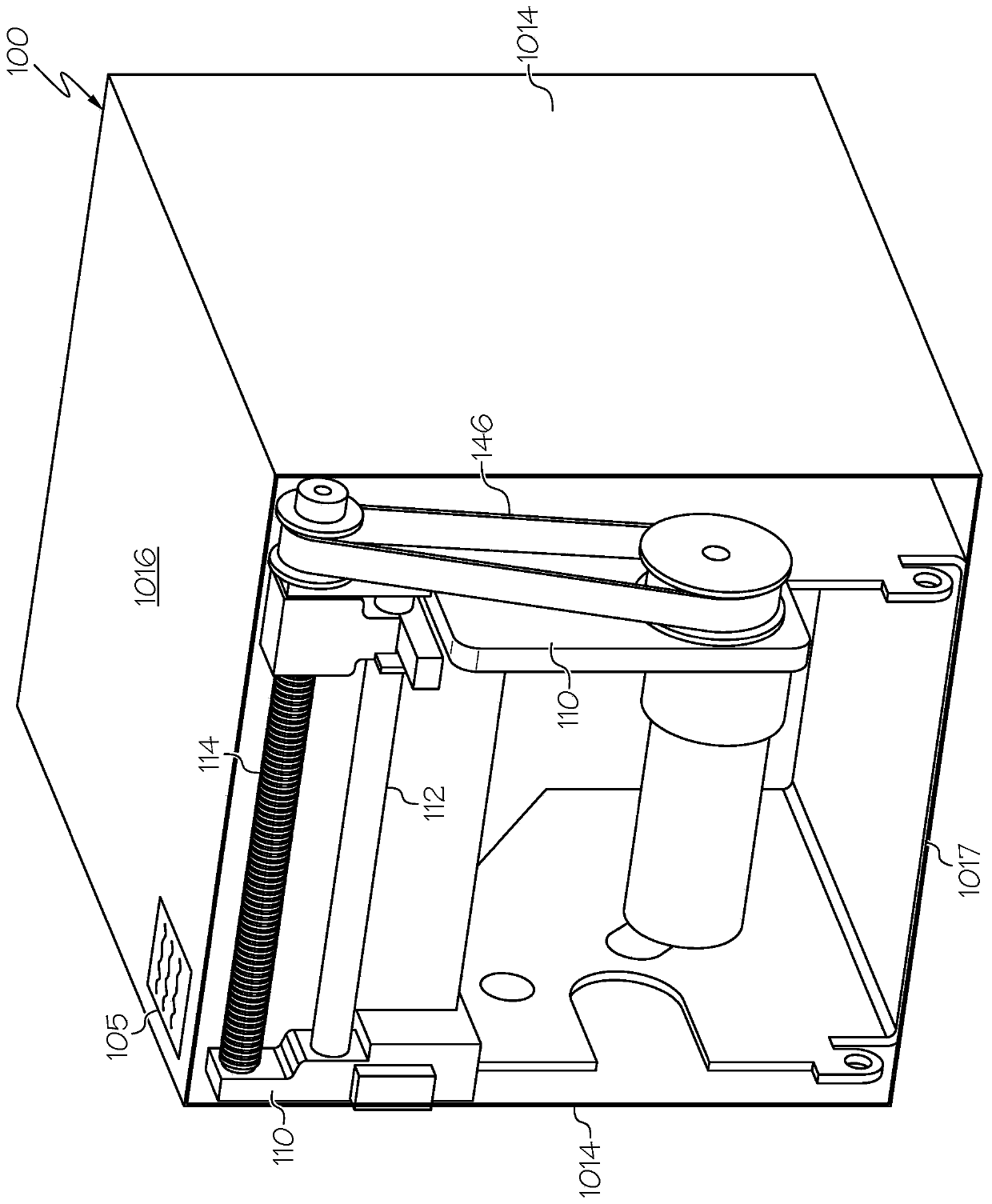

[0057] The present invention is now described with reference to the drawings, wherein like reference numerals are used to refer to like elements throughout. In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding. It is evident, however, that innovations can be practiced without these specific details. In other instances, well-known structures and devices are shown in block diagram form in order to facilitate their description.

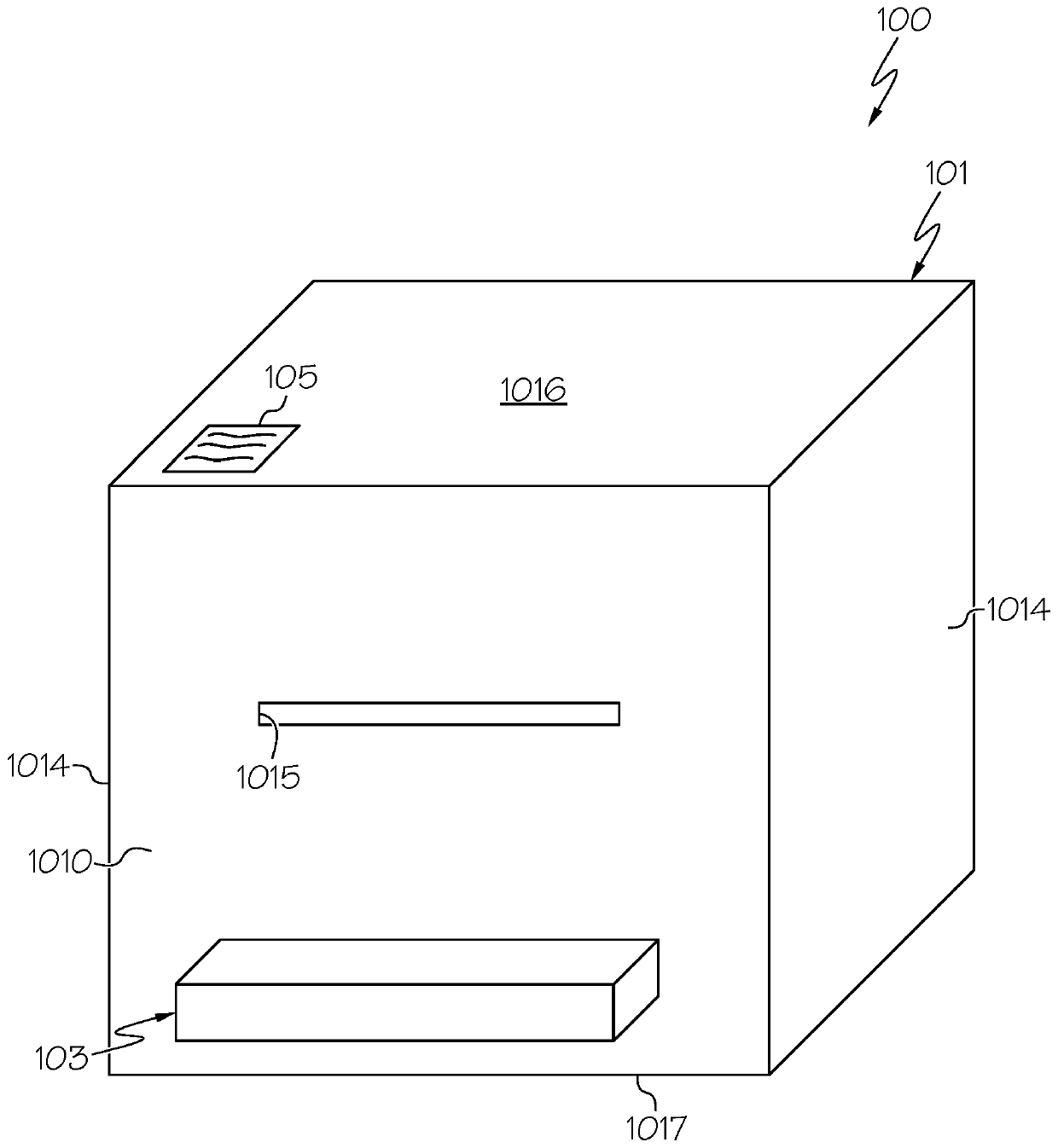

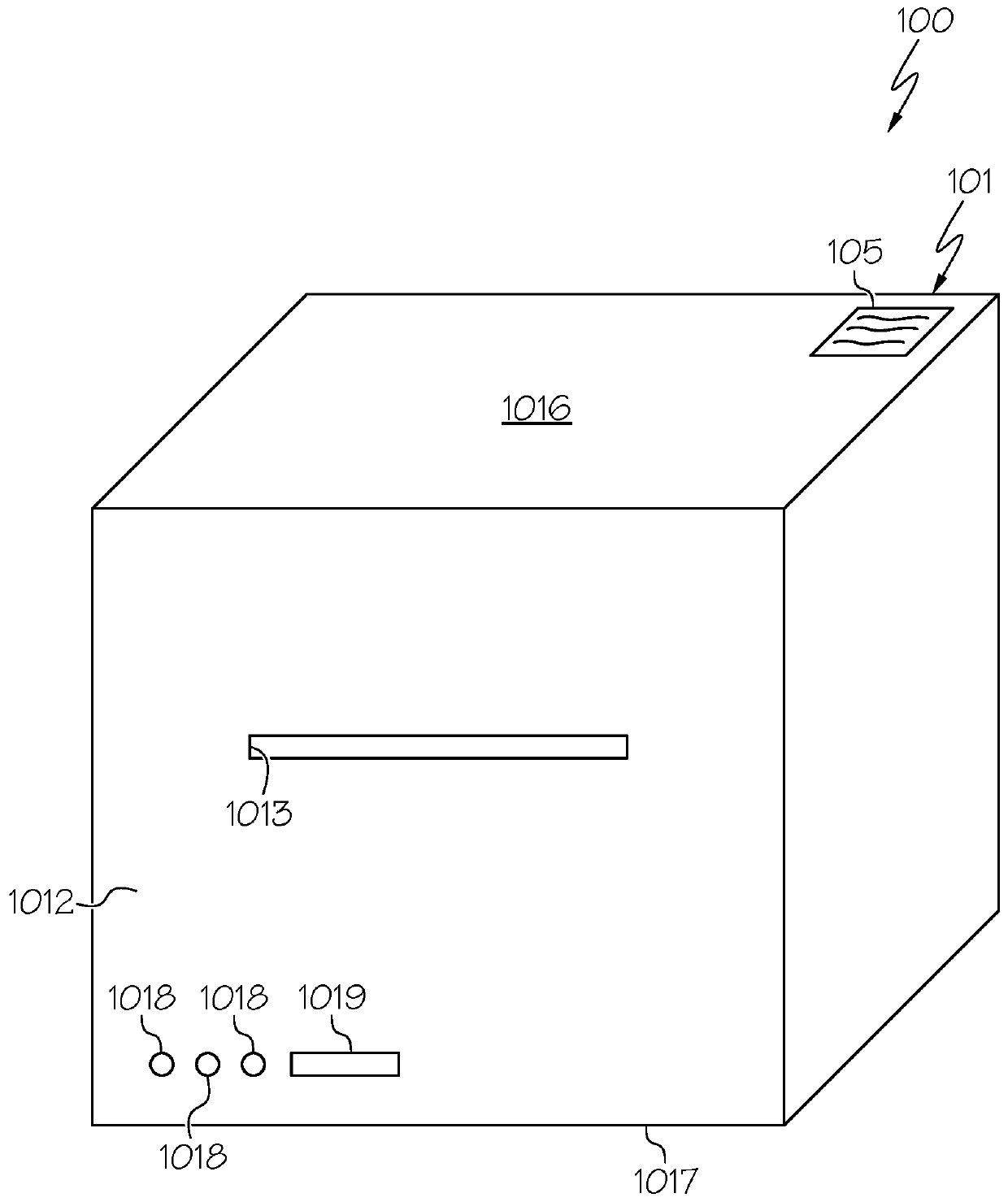

[0058] The present invention discloses a self-contained cutting device that can quickly and cleanly cut or "nip cut" a web of media stock 20 (such as a sheet of paper laminate, vinyl, or RFID stock) in a front-to-rear direction. material) without damaging the cutting blade or the material. Specifically, the cutting device of the present invention can perform "die-cutting"-like cutting on the stock material 20 without the same structural and operational limitation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com